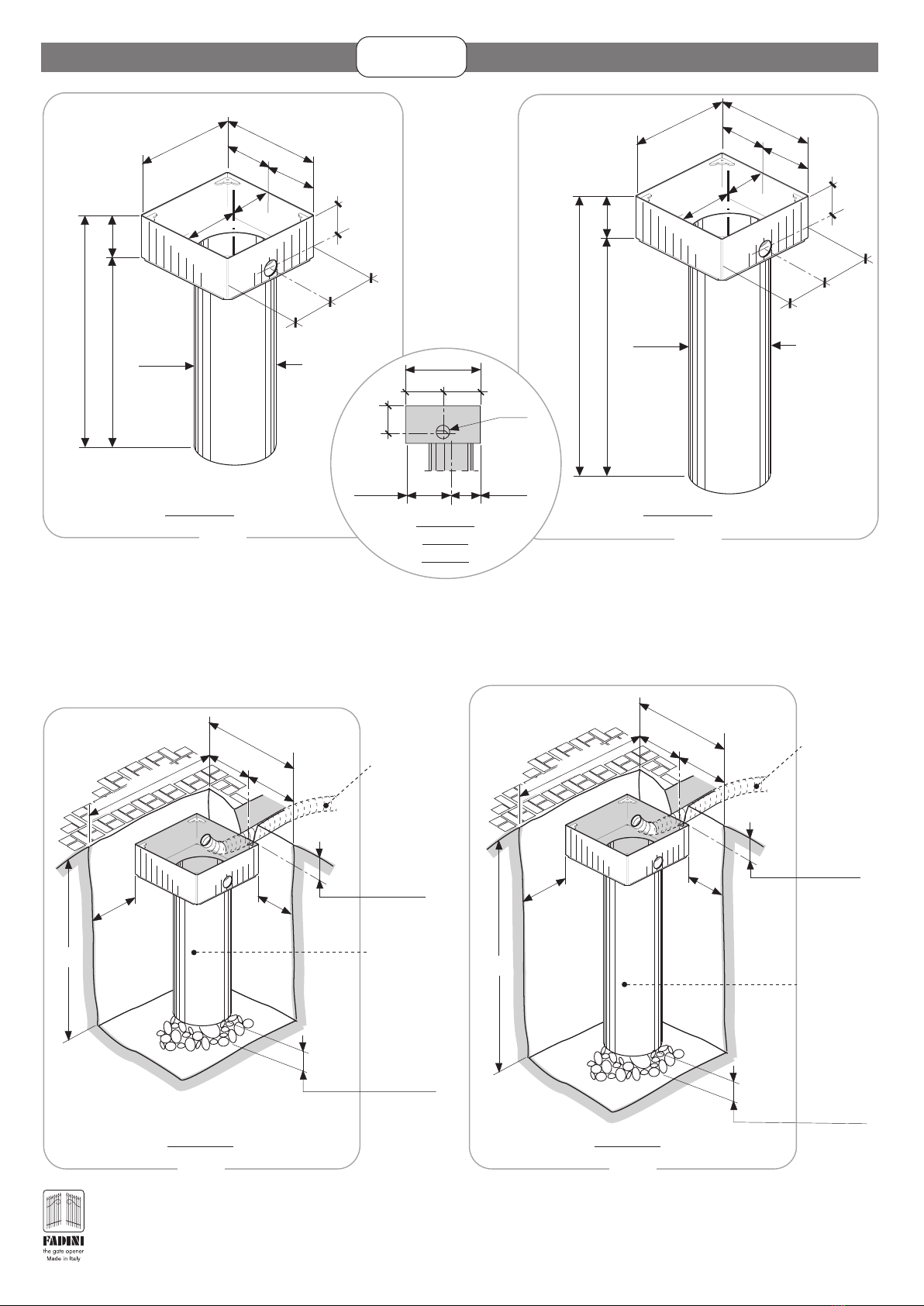

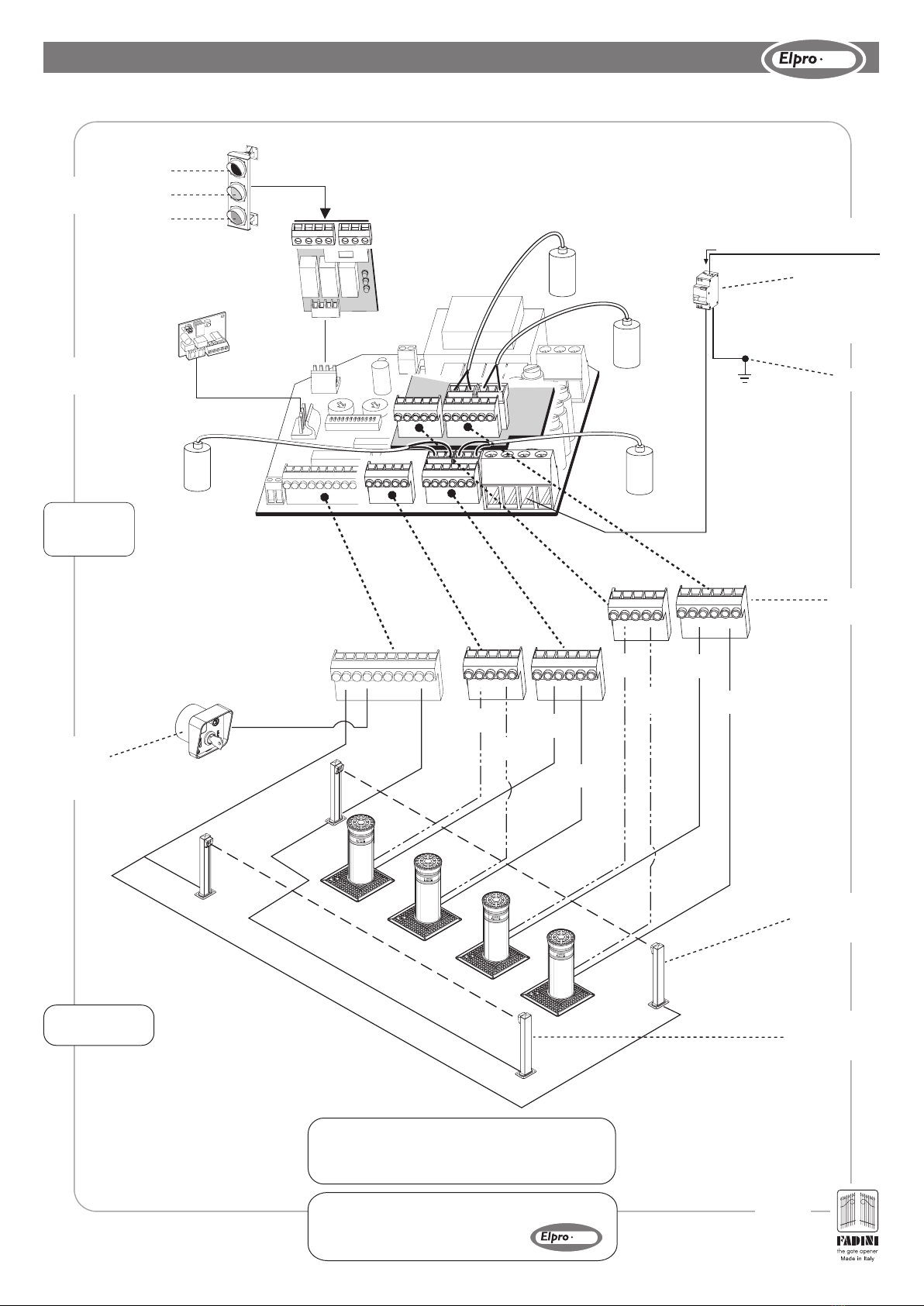

S40

VIGILO 2250

VIGILO 2280

8

VIGILO 2250

VIGILO 2280

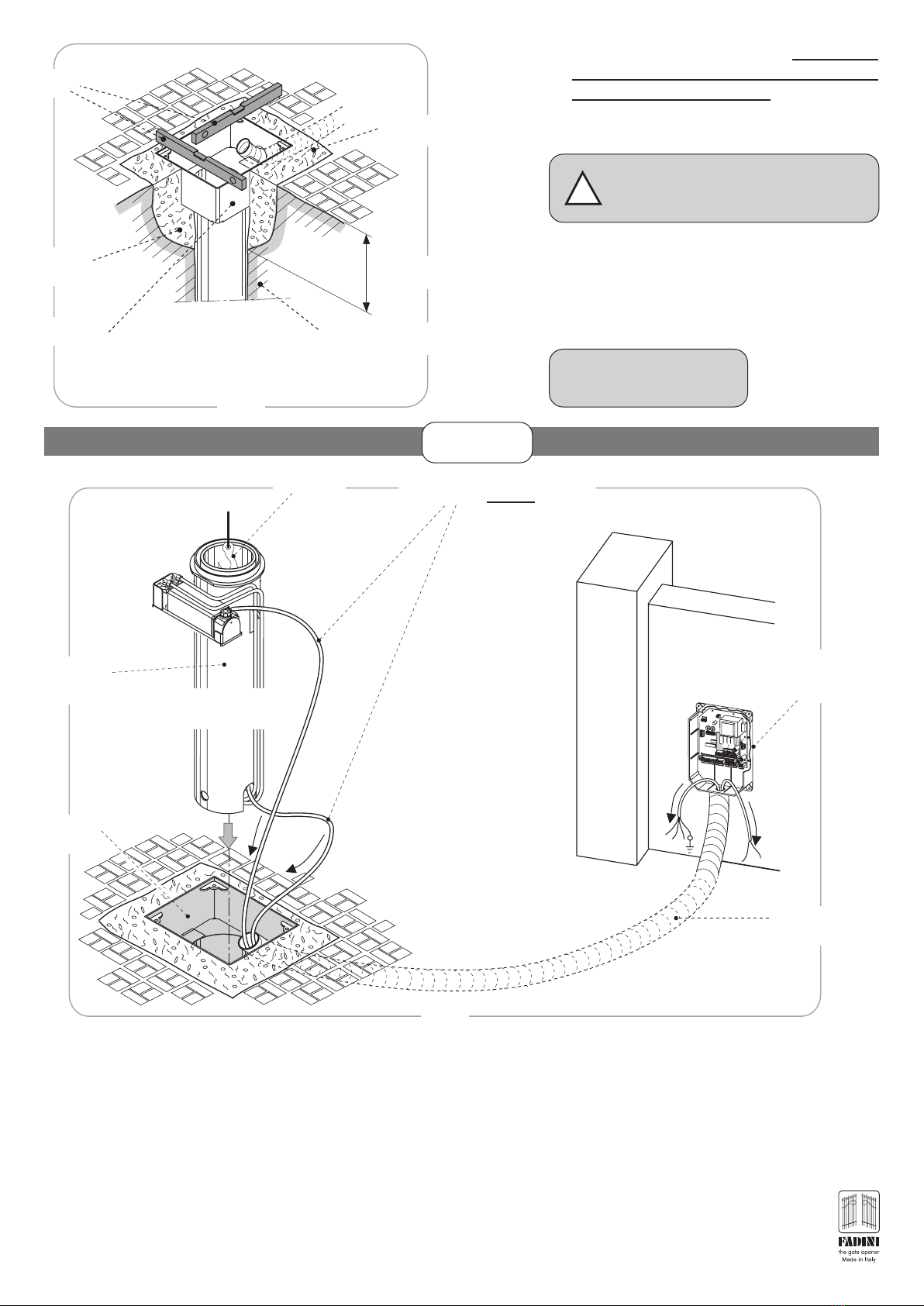

PIC. 15

4x1mm

2

2x1mm

2

4x1mm

2

4x1,5mm

2

8

9

7

10

6

11

1

2

3

4

5

6

7

4x1mm

2

4x1mm

2

2x1mm

2

PIC. 14

®

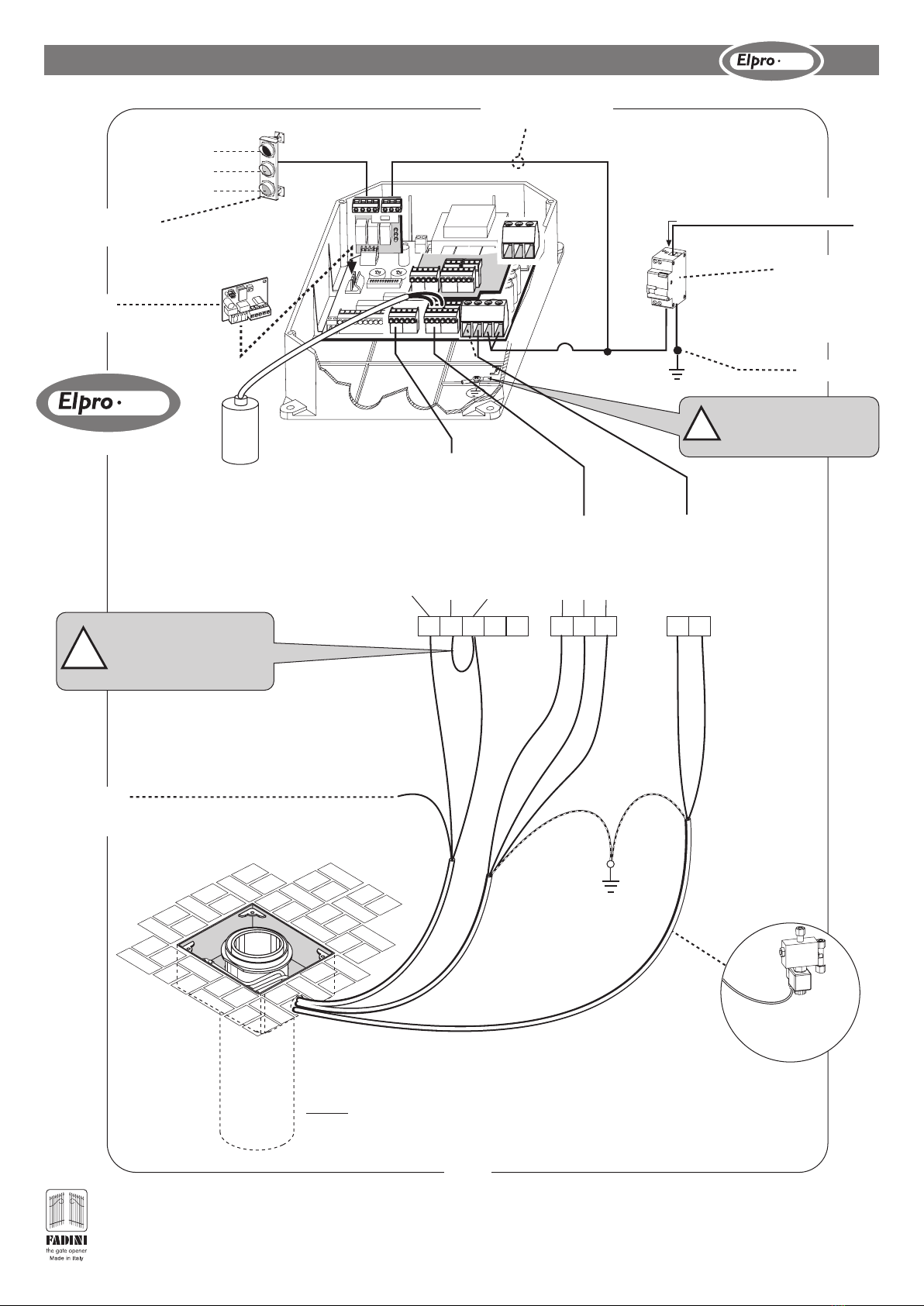

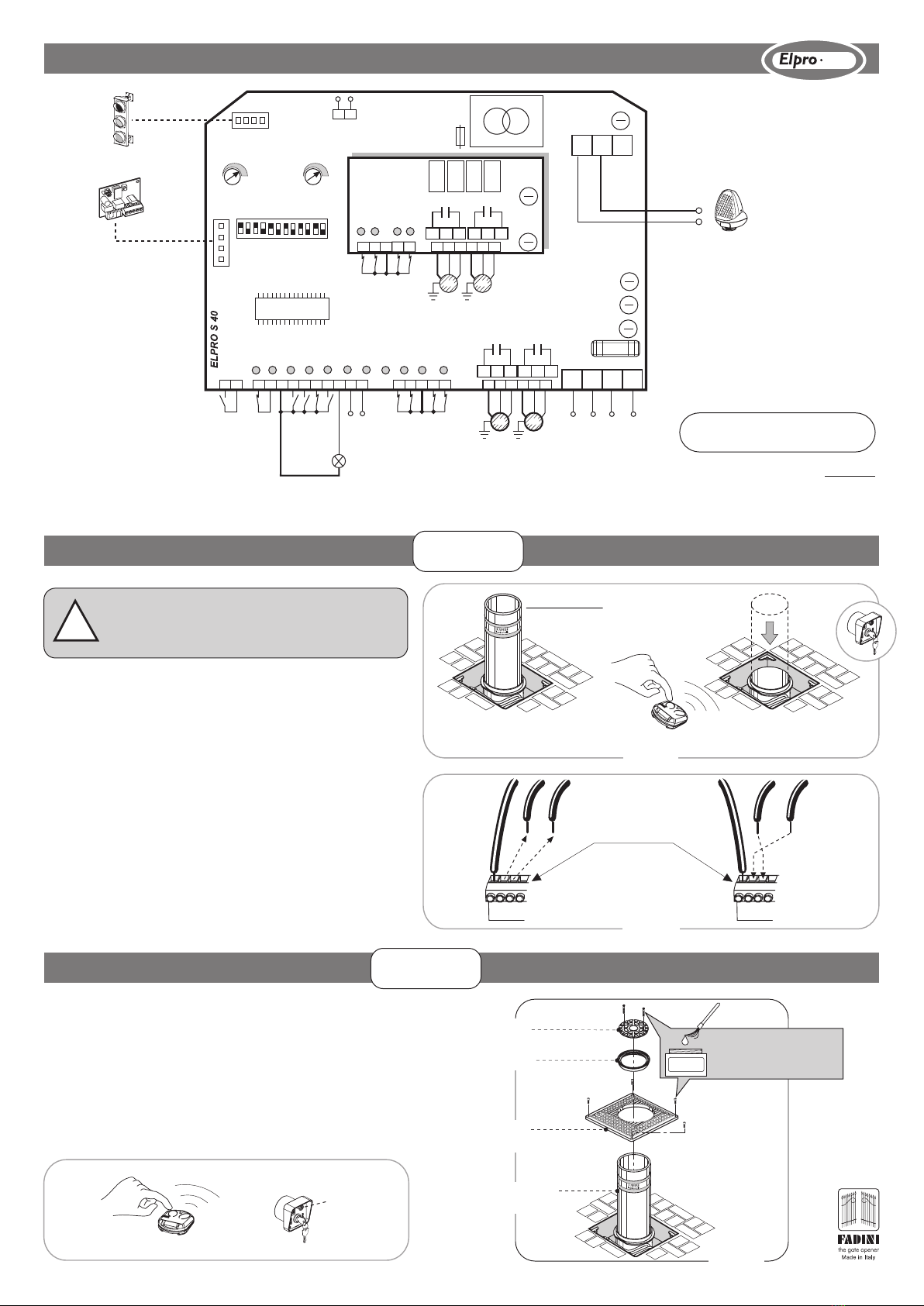

ARRANGING THE SAFETY AND SIGNALLING ACCESSORIES

All safety and control accessories must be installed at certain

distances from the operator in order to obtain effective

installation. Connect to earth.

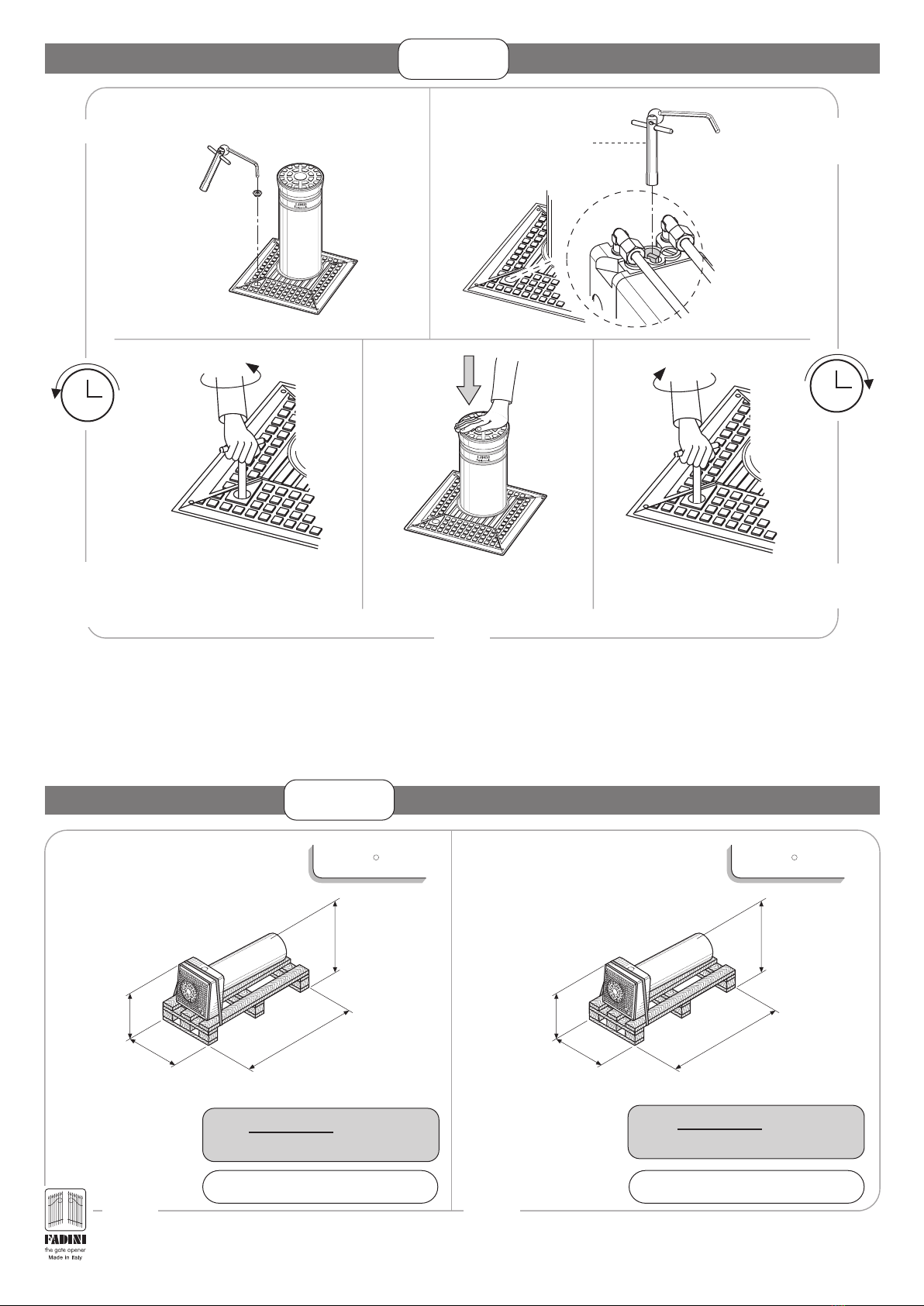

ARRANGEMENT OF THE PHOTOELECTRIC CELLS

The photoelectric cells must be installed at a minimum

working distance as indicated in Pic. 15.

ARRANGING VISUAL 344

The 2 or 3-module Visual 344 cabinet is a metal accessory

used to house the Elpro S40 in exposed positions, in those

installation situations in which the programmer cannot be

wall- or recess-mounted. It has also been designed for the

installation of possible control accessories such as intercom

systems or key switches, in the immediate vicinity of the

Vigilo 2250 or Vigilo 2280 (pic. 15).

Before making electric connections, carefully read the wiring diagrams attached: Elpro S40 electronic programmer instruction booklet

- Drwg. 4555.

- Power supply, electric motor and flashing light wiring must be made using cables with 1.5 mm2sections, for a maximum distance of

50 m. For distances of over 50 metres, we recommend using electric wires with sections of 2 mm2.

- For the Photoelectric cells, button switches and accessories, electric wires with 1 mm2sections may be used.

- The whole electrics system must be earthed.

INSTALLATION WIRING

Components

1 - MIRI 4 flashing light with built-in aerial

2 - Wall-mounted Astro 43 radio receiver

3 - Elpro S40 Electronic programmer

4 - Differential circuit breaker switch

(sensitivity 30mA, protection 6-10A)

5 - Junction box, electric wires

6 - Polo 44 photoelectric cell projector

7 - Polo 44 photoelectric cell receiver

8-Prit 19 key switch

9-Two-light 230V traffic light

10 - Vigilo 2250 or Vigilo 2280 retractable traffic control post

11 - Astro 43/2 Piccolo transmitter

IMPORTANT:

The whole electric system must be earthed (Pic. 15).

230V ±10%

50 Hz

2x1mm

2

RGB cable

min 1

.

0 m

Prit 19

Earthing

4x1mm

2

- Motor

2x1mm

2

- Limit switch