4534

Drwg. No.

In case of failure of operation:

- Verify that the power supply to the electronic unit is 230V ±10

- Verify that the power supply to the Electric motor is 230V ±10

- For distances over 50 meters increase the wire section.

- Verify the fuses

- Verify that the Photocells are in closed contact setting

- Verify all the closed contacts NC: Stop and Safety Edges

- Verify that there is no voltage drop between control panel and electric motor

- Verify to have connected the earth ground terminals 19 and 23

- Verify that the Motor and its terminal board are connected to work at 230V

- Verify that low speed and operator torque settings are adapted to the weight of the gate.

Description: The electronic control panel Elpro 220 is an electronic unit with microprocessor for motors up to 3,0 HP (2,2KW) three-phase, installed on big sliding gates.

Power supply is of 230V 50Hz±10 single-phase. Elpro 220 controls three-phase motors 220V delta connection, or single-phase motors without condenser. A display allows

programming of the main function as required and real time visualising: braking with motor slowdown, motor gradual starting, gate limit travel learning, torque control on

lower speed setting on braking and starting phases, operator torque control adjustment. It is built in full compliance with the Low Voltage Safety Norms 2006/95 CE and

Electro-Magnetic Compatibility 2004/108/EEC - 92/31/EEC. Fitting operations are recommended to be carried out by a qualified technician in conformity to the existing safety

standards. The manufacturing company declines any responsability for incorrect handling and applications; also, it reserves the right to change these instructions or update

the control panel any time. Failure to observe the installation instructions may cause serious damages to properties and persons.

IMPORTANT:

- The control unit is to be fitted in a sheltered place inside a suitable enclosure

- Fit the mains to the control panel with a 0.03A high performance magnetic-thermal circuit breaker

- Verify that the power supply to the electronic control panel is 230V ±10% 50Hz

- For power supply to the electric motor 230V ±10% 50Hz use 2.5 mm² section wires to 50 m distances and set the motor terminal board for 230V power supply

-

Power supply, Flashing lamp use cables with 1,5 mm² section wires up to 50m of distance; for limit switches and accessories use cables with 1mm² section wires

- If photocells are not used bridge terminals 1 and 2, 25 and 26, 27 and 28 with 26

- If no key or button-operated switch is used bridge terminals 3 and 6

- To use shielded cables for the motor connection and to earth system by using terminal 19.

ATTENTION:

- Once power to the control panel is interrupted, wait until the condensers are discharged: D2 led must go off

- The control panel is factory pre-set on AUTOMATIC mode

- For the 24V direct current low voltage connections, respect strictly + and - symbols

- The system can work only if the ground terminals 19 and 23 are properly connected

- When power is set back after a power failure, the automation carries out motions at slow down speed until a limit switch is reached.

But all the previously selected modes stay in the memory.

Fault Ditection Led:

D2 = Normally on, card under voltage

D3 = Normally on green, 24V supplied

24V OUTPUT. Max Load:

n°2 Pairs Photocells

n°1 Radio receiver

INDICATION LIGHT 24V max 3W

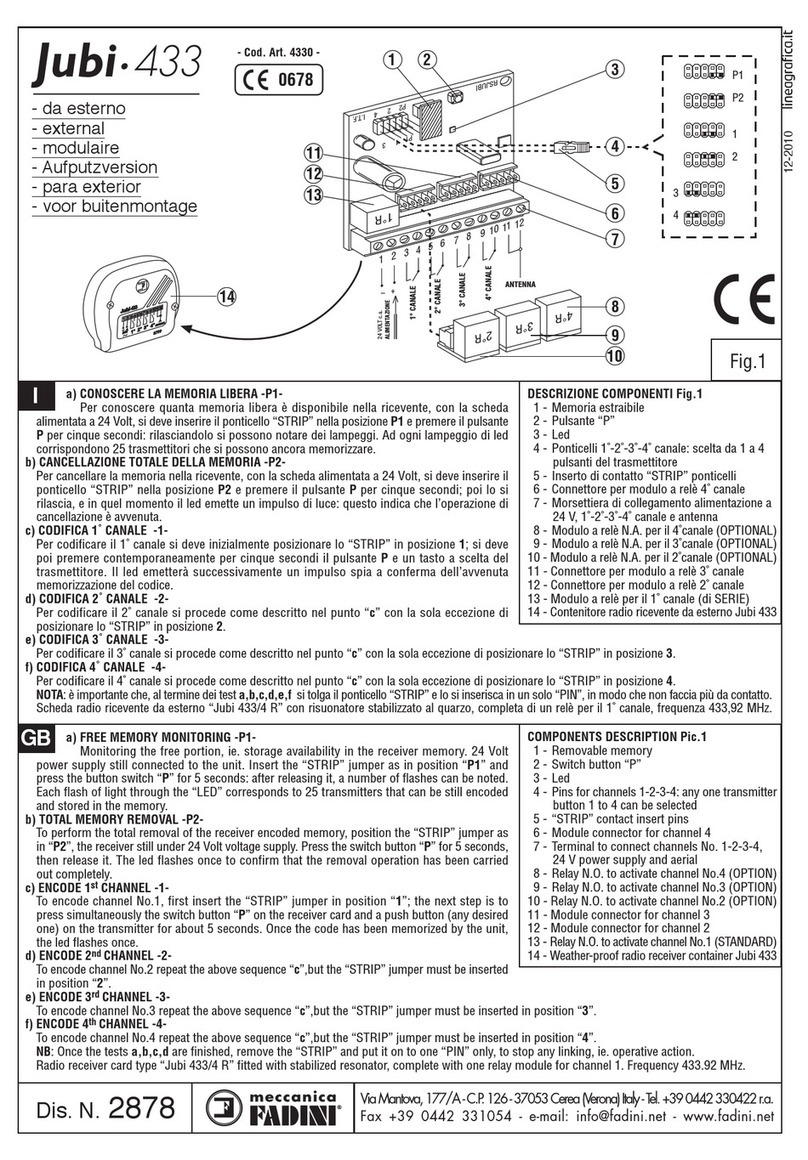

174 10 11 12 13 20

285

396

FLASHING LAMP

230V 25W max

F1=10A Mains

F2=10A Mains

PLUG-ON

RECEIVER CARD

CONNECTOR

ELPRO

220

1816 17

COMMON

M

MOTOR

connection:

230V

U

WV

21 2322

+

GND

-

19 24

14 15 25 26 27 28

GROUND

TRANSFORMER

RESET ENTER

Display

NEUTRAL

S

PHASE

Terminal N°23

- ground -

IMPORTANT

230V ±10 50Hz

SINGLE-PHASE

VOLTAGE SUPPLY

N

R

S

T

Neutral

Electric network

PHOTOCELL 2

nd

PAIR

PHOTOCELL 1

st

PAIR

SAFETY EDGE 1

SAFETY EDGE 2

COMMON

STOP

COMMON

CLOSE

RADIO

LIMIT SWITCH CLOSE

LIMIT SWITCH OPEN

LIMIT SWITCH COMMON

COMMON

9

D3 GREEN

220 THREE-PHASE THREE-PHASE FOR AUTOMATIONS WITH

HEAVY SLIDING GATES - DIGITAL PROGRAMMING

GB

®

Fan

FUN1

temperature sensor

FUN1A

fan

OPEN / PEDESTRIAN OPENING

D2 RED