Installation

Clean all pipelines to remove dirt and scale efore

installation.

Apply a minimum amount of pipe compound to the male

threads of the fitting only. Start with the third thread

ack and work away from the end of the fitting to avoid

the possi ility of contaminating the regulator. Install the

regulator in the air line.

The inlet and outlet connections are la eled on the un-

derside of the regulator with the arrows pointing in the

direction of the flow. Tighten connections securely.

Avoid undersized fittings that will limit the flow through

the regulator and cause a pressure drop downstream.

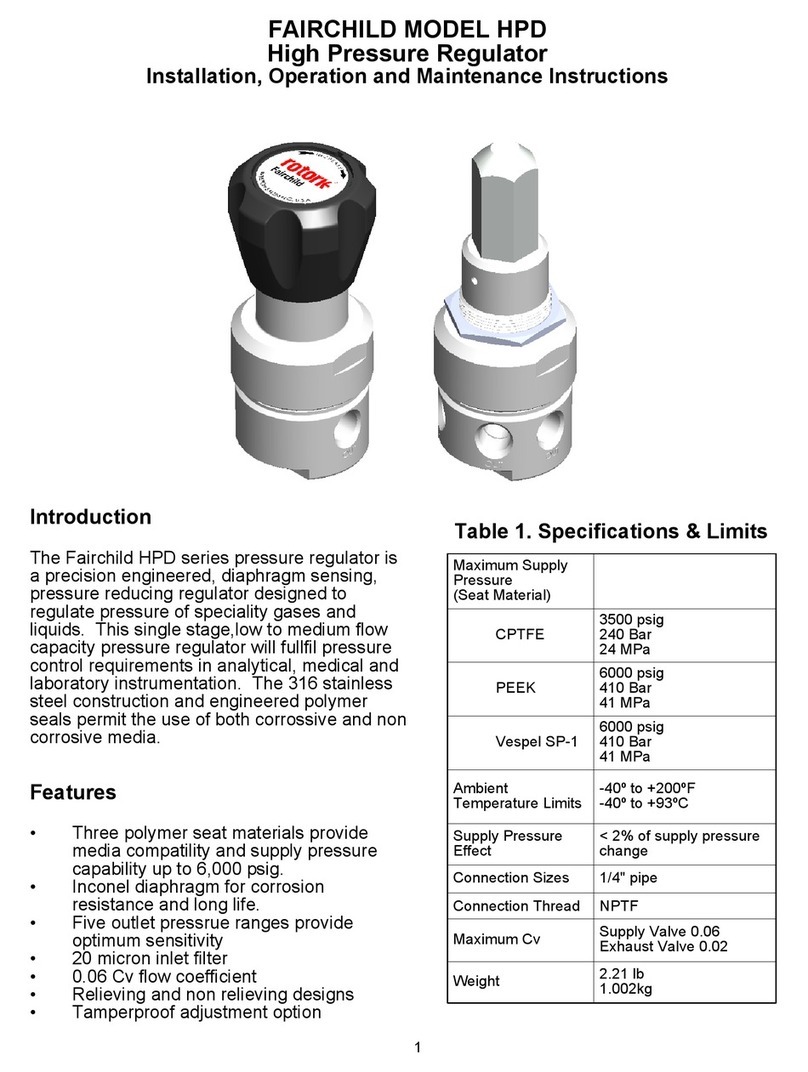

For more information, see Figure 1. “Outline Dimen-

sions”.

N TE: Oil free air must e applied to the

regulator. Use a filter to remove dirt and

entrained liquid in the air line ahead of the

regulator. If an air line lu ricator is used, it

MUST e located downstream of the

regulator, to avoid interference with

regulator performance.

Flow

Process

Vacuum Pump

OUT

IN

IS-1000017

Litho in USA

Rev 0108

Maintenance

To clean the Model 10V, use the following

procedures:

1. Before assem ly, shut off the valve that is

supplying air to the regulator. This is to prevent

air from escaping. It is not necessary to

remove the regulator from the air line.

2. Remove the two Screws from the ottom of the

unit.

3. Pull out the Inner Valve Assem ly. Wash the

Seat on the Inner Valve Assem ly carefully.

4. Wipe off any particles that may e attached to

ru er Seat Ring in Body.

5. Replace the assem ly carefully.

6. Keep the vent hole in the Bonnet clear for proper

regulator operation. Lu ricate the adjusting

screw with Molycote “G”.

Figure 2. Model 17 Installation Diagram

N TE: Avoid such solvents as acetone,

carbon tetrachloride and

trichorethylene.

Trouble-Shooting

Problem Solution

Leakage Body Screws

Tightness.

Diaphragms.

Valve Seal Ring

Chatter lu rication.

LEGAL N TICE

The information set forth in the foregoing Installation, Operation and Maintenance Instructions shall not e modified or amended in any respect without prior

written consent of Fairchild Industrial Products Company. In addition, the information set forth herein shall e furnished with each product sold incorporating

Fairchild's unit as a component thereof.