FAIRCHILD

®

precision pneumatic & motion control

FAIRCHILD INDUSTRIAL PRODUCTS CO.

REGISTERED TO ISO 9001:2008

10002346 QM08

1

KEY

2

3

4

5

6

Fairchild Products Company

3920 West Point Blvd. • Winston-Salem, NC 27103

phone: (336) 659-3400 • fax: (336) 659-9323

II-500T9000

Litho in USA

Rev _ 4/11

3

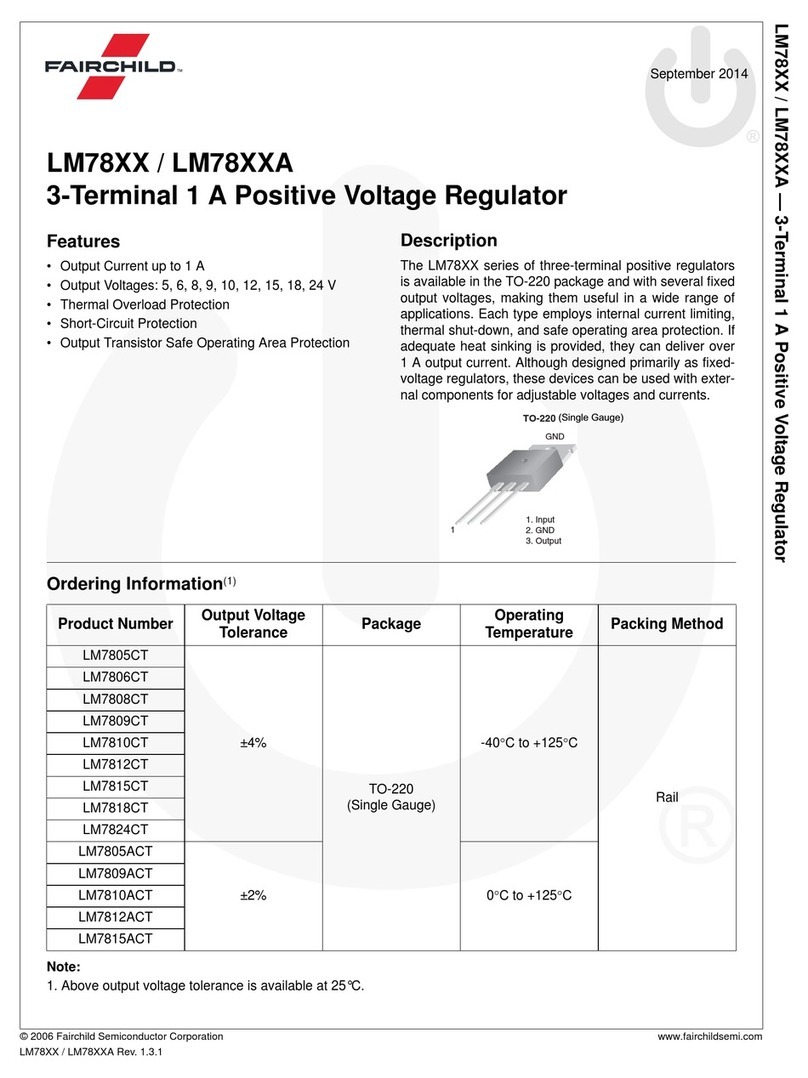

PNEUMATIC CONNECTIONS

Clean all pipelines to remove dirt and scale before

installation.

Apply a minimum amount of pipe compound to the male

threads of the air line only.

Do Not use teflon tape as a

sealant.

Start with the third thread back and work away

from the end of the pipeline to avoid the possibility of

getting pipe compound into the air lines.

The inlet and outlet ports are labeled on the bottom of the

Pressure Controller. Tighten connections securely. Avoid

undersized fittings that will limit the flow through the

transducer. For more information, see Figure 1. "T9000

Outline Dimensions" on page 1.

CAUTION:

Oil free air is required. Use a filter to remove dirt and liquid

in the air line ahead of the pressure controller. If an air line

lubricator is used, it MUST be located downstream to avoid

interference with pressure controller performance.

Supply pressure must be no less than 5 psig, [0.35 BAR],

(35 kPa), above maximum output.

ELECTRIC CONNECTION

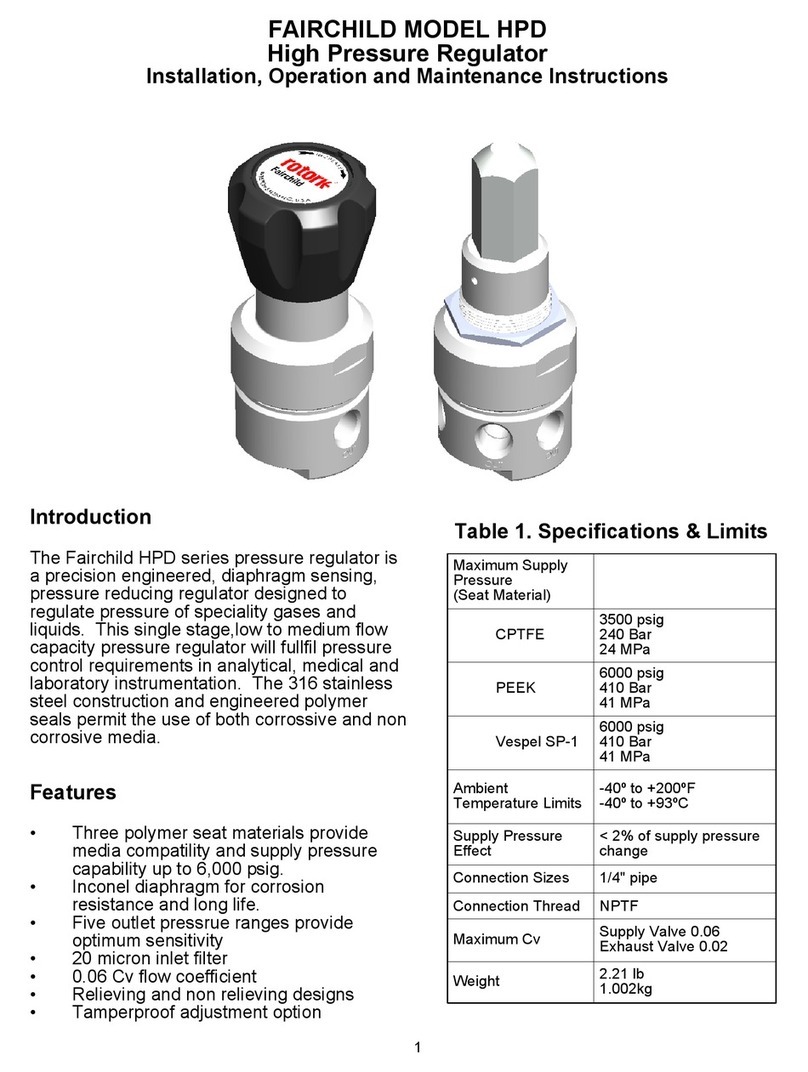

For the T9000 Pressure Controller, make connections as

shown below in Figure 2. "Electrical Connections". For

compatible cord sets and connections refer to Table 1.

below.

For signal lines of six feet or less, 22 gage wire may be used.

For longer signal lines, use 18 gage wire. Shielded cable

must be used for the signal lines for noise immunity.

¹ Colors apply only to FIPC DeviceNet compatible cables.

Figure 2.

Electrical Connections.

Model T9000 Series

Table 1. T9000 Cables

(Sold Separately)

Part number

Description

032-IPI-018-2

Cable w/one straight connector (2

meter)

032-IPI-019-2 Cable w/one right angle connector (2

meter) shown

Pressure Controller Electrical Connections

PIN #

Wire Color

Function

1

Brown

(+) 4-20mA or 0-10vdc FEEDBACK

2

White

(-) FEEDBACK RETURN

3

Blue

(+) 4-20mA or 0-10vdc CONTROL SIGNAL

4

Black

(-) CONTROL SIGNAL RETURN

5

Gray

(-) SUPPLY RETURN

6

Pink

(+) 18-32VDC SUPPLY