General Safety Rules

■ When using garden pesticides, herbicides,

insecticides, fungicides or any other form

of garden chemical always obey the

manufacturer’s instructions fully.

■ Do not use petroleum based products in

this sprayer.

■ Do not spray toxic or harmful liquids on

persons, animals or foodstuffs.

■ For certain weed killers and pesticides,

trace elements may always remain.

Consult the product manufacturer’s

instructions, but in such cases, it is

recommended that once such products are

introduced, then the sprayer should only be

used for that specic application thereafter.

■ Consult the products manufacturer’s

instructions about safe and lawful disposal

of excess product when emptying unused

product from the tank and during the

cleaning process. (Many products cannot be

disposed of in drains and sewers).

■ Strain any mixtures that contain sediments

before introducing product to the tank. Strain

through a ne sieve or cloth.

■ Wear the appropriate protective equipment

coverall, gloves, goggles and suitable

respiratory mask. For details of a complete

range of protective equipment, visit the

SCAN Safety Website at www.scan-safety.com

■ Avoid contact with the skin and eyes, do not

eat, drink or smoke when using the sprayer.

■ Wash hands and face after use.

■ Do not leave the sprayer within the reach of

children.

■ Keep bystanders away whilst using the sprayer.

■ Always direct the spray downwind as

spraying into the wind will result in operator

contamination.

■ Do not leave the sprayer exposed to heat

sources or intense cold.

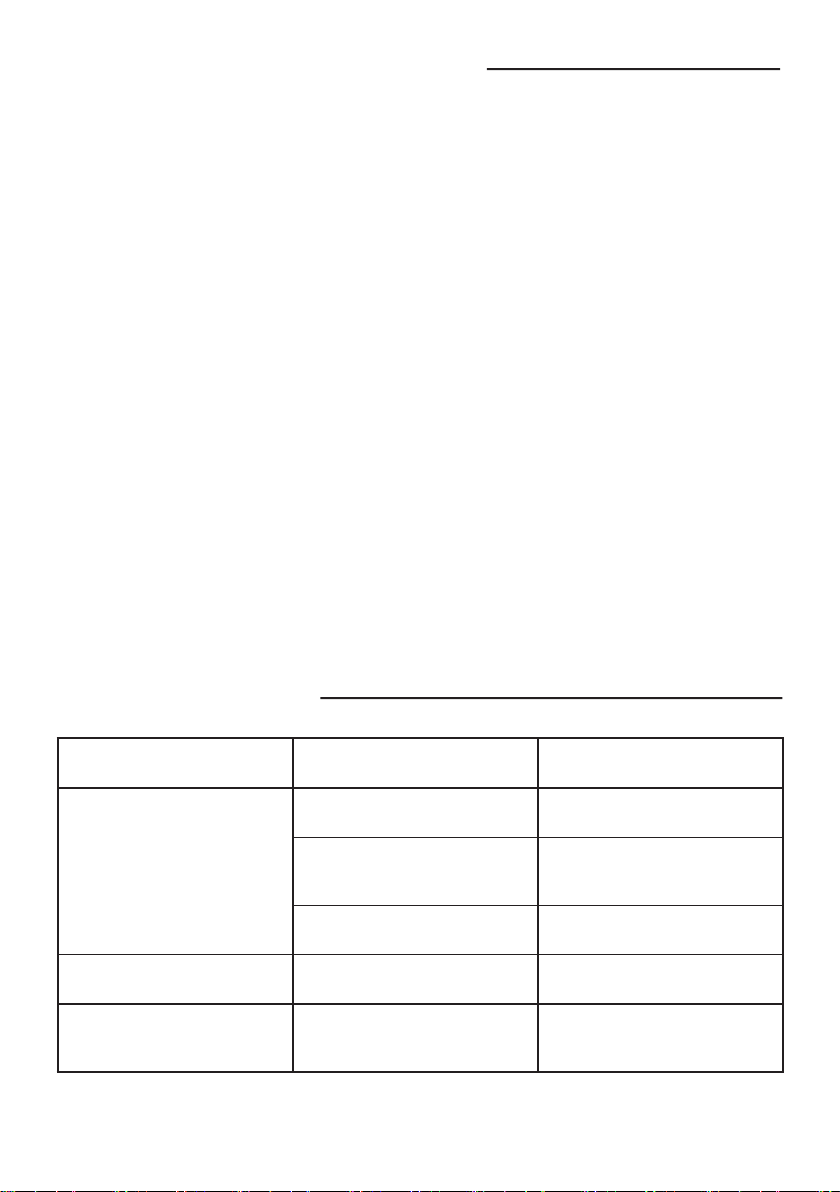

■ Release pressure after each use, even if you

are going to recommence spraying in a few

minutes.

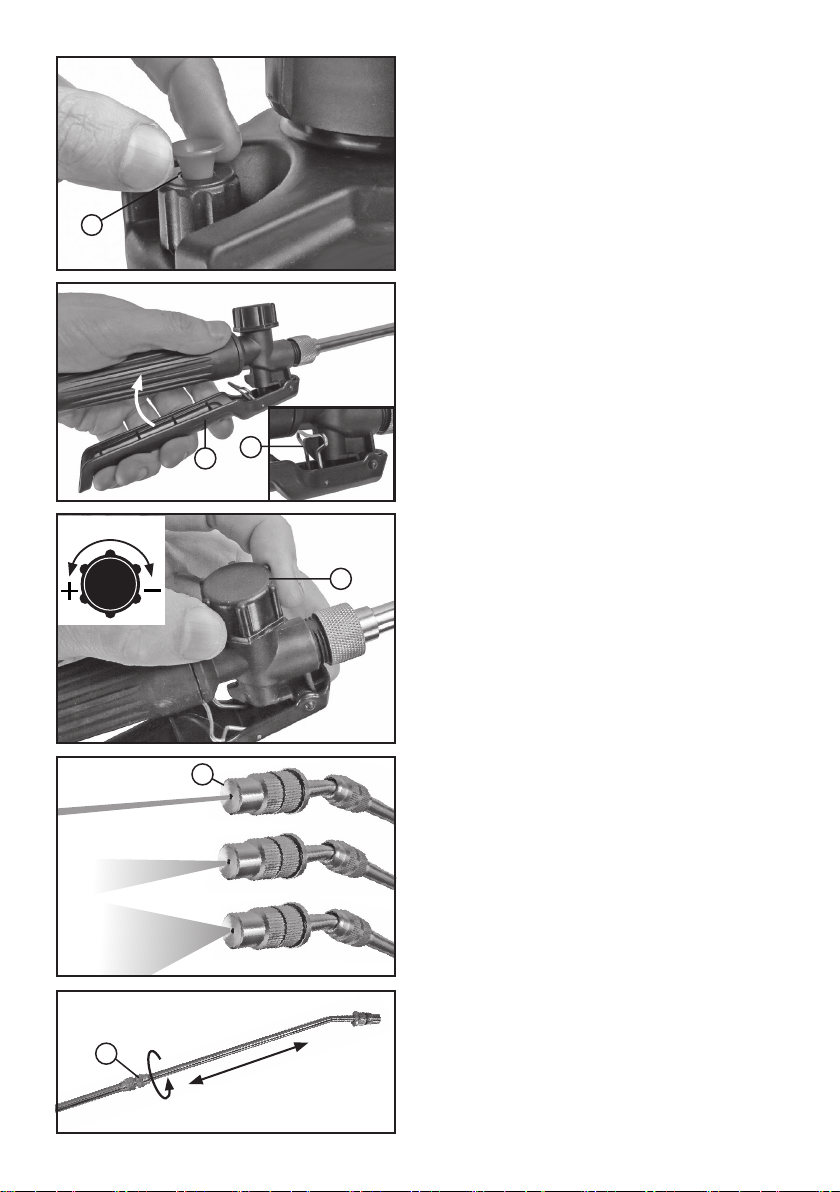

■ Ensure pressure is released before attempting

to remove the pump assembly mechanism.

■ Do not pressurize by any means other than

pumping.

ALWAYS WEAR

SUITABLE PROTECTION

Introduction

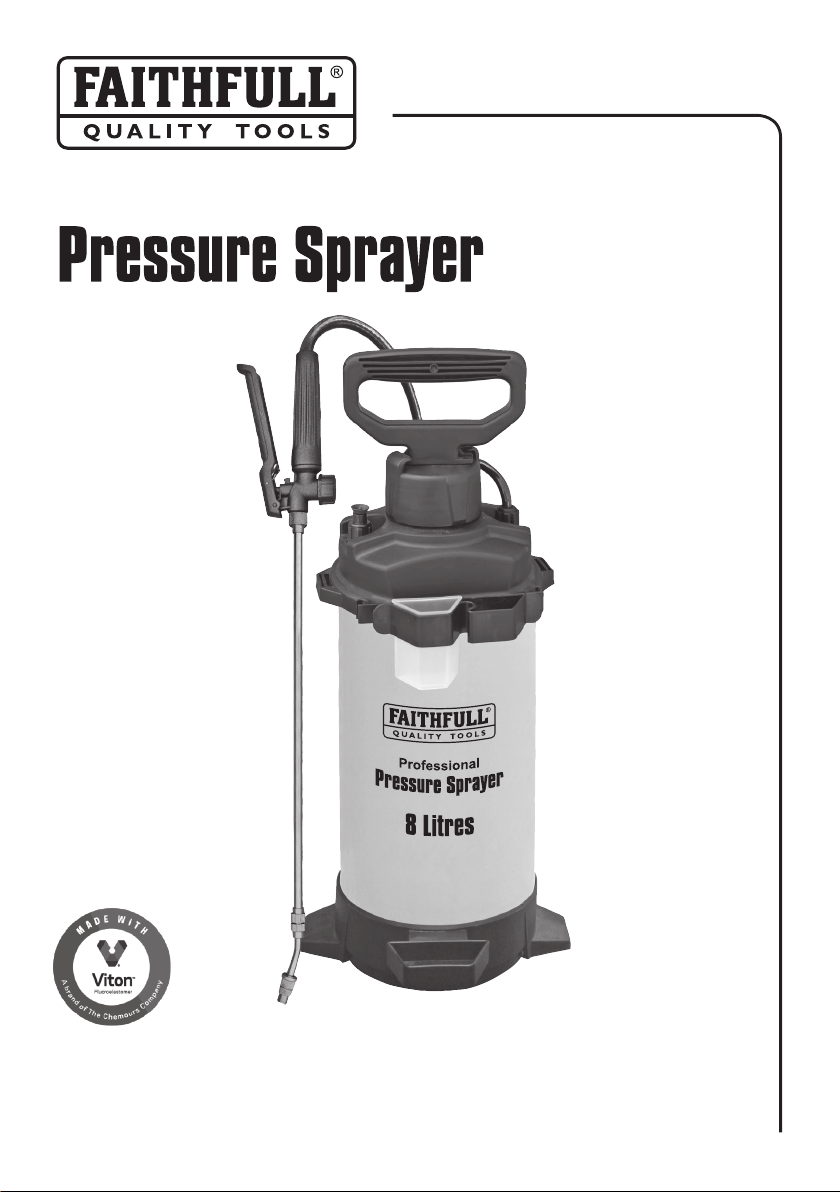

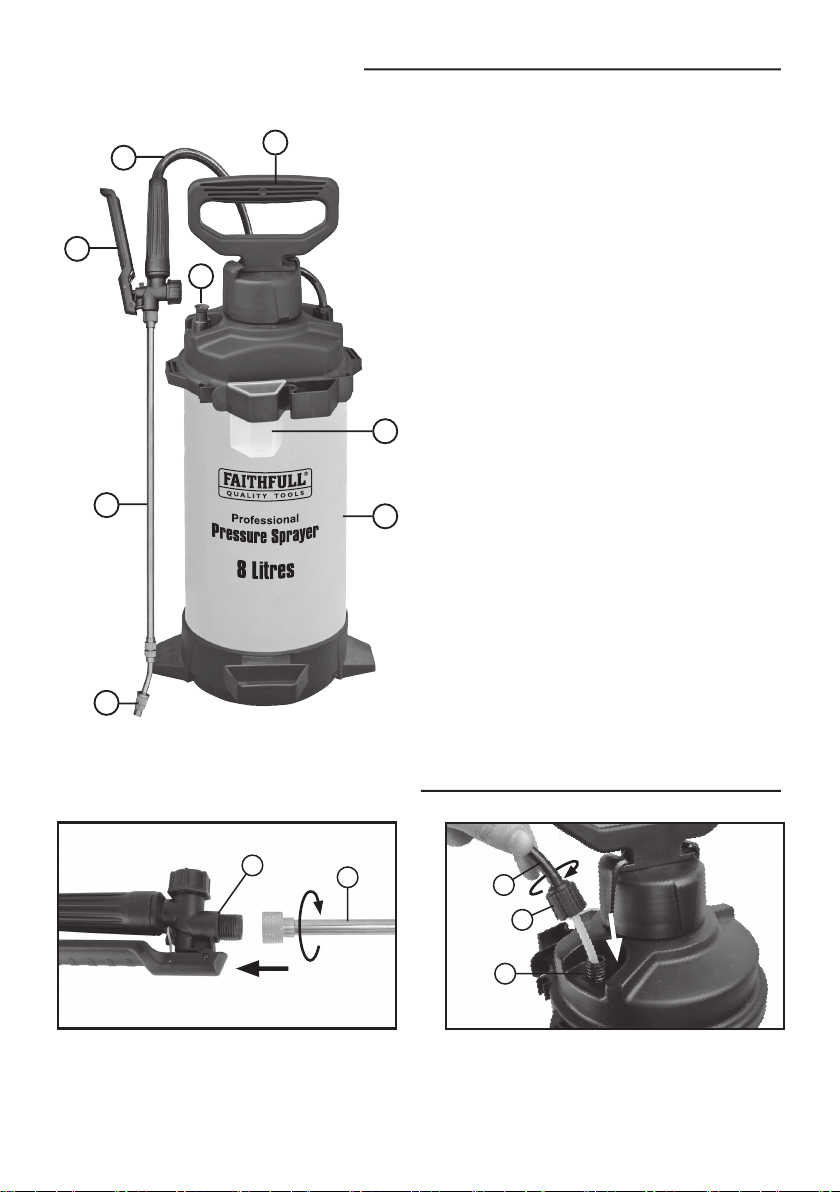

The FAISPRAY8HD Professional Sprayer

is tted with VITON™ seals which are

resistant to most acids and solvents,

enabling this sprayer to be used with

more aggressive chemicals widely used in

automotive and professional cleaning and

some agricultural applications.

It is always advisable where possible to

use water-based product as these are less

damaging to the environment.

Use of aggressive chemicals will inevitably

shorten the working life of these seals.

Working capacity: 8 Litres

Working pressure: 2.5 bar

Net weight: 1.760kg

Area coverage: 40M2 - 100M2

Specications