COMPANY PROFILE MAATSKAPPYPROFIEL

Falcon Agricultural Equipment (Pty) Ltd is an owner-

managed business and the largest manufacturer of rotary

cutters in Africa. he company opened its doors in 1985, at

its current premises in Howick, Kwazulu-Natal, South

Africa. his is the ideal location as it is an agricultural area

with a leading agricultural college nearby. Falcon is a

recognised BBBEE contributor and our skilled labour force

is a dedicated team of whom we are proud.

Falcon Agricultural Equipment (Edms.) Bpk. is ’n eienaar-

bestuurde besigheid en die grootste vervaardiger van

wentelsnyers in Afrika. Die maatskappy het sy deure in 1985

by sy huidige perseel in Howick, KwaZulu-Natal, Suid-Afrika,

geopen. Die ligging is ideaal: in ’n boerderygebied met ’n

vooraanstaande landboukollege naby. Falcon is 'n erkende

BBBEE-bydraer en ons geskoolde arbeidsmag is ’n toegewyde

span op wie ons trots is.

Our primary market is the agricultural sector, with niche

efforts into the industrial and turf implement market. We

distribute our products through more than 350 authorised

dealers countrywide, as well as across our borders into

other African countries.

Ons hoofmark is die landbousektor, met nisverkope in die

nywerheids- en grasbaanimplement-markte. Ons versprei

ons produkte deur meer as 350 gemagtigde handelaars

landwyd, asook buite ons grense in ander Afrika-lande.

We manufacture the Falcon and Locust ranges of

implements and our on-going programme of innovation

and improvement ensures that we consistently launch

implements to satisfy our customers’ ever-changing needs.

Ons vervaardig die Falcon- en Locust-implementreekse, en

ons voortgesette program van vernuwing en verbetering

verseker dat ons konstant implemente bekendstel wat ons

kliënte se immer veranderende behoeftes bevredig.

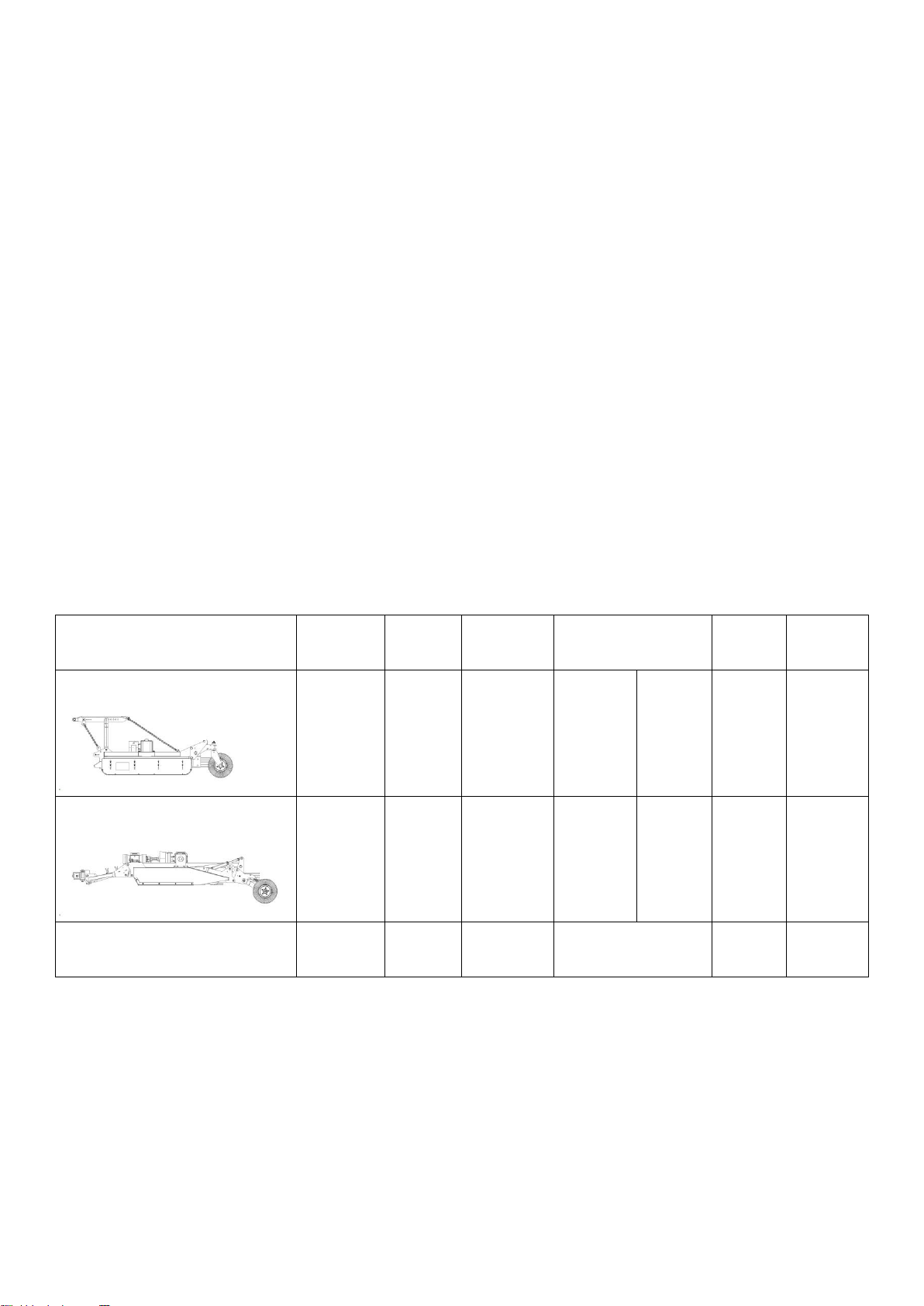

he Falcon range includes slashers, Haymakers

, material

handling implements, mulchers, mowers, spreaders,

rotavators and flail cutters. Each is designed to be simple,

safe and serviceable, while offering excellent value for

money. hey are built to last and are capable of coping

with the tough South African conditions.

Die Falcon-reeks sluit wentelsnyers, Hooimakers

,

materiaalhanteringsimplemente, mulchers, grassnyers,

strooiers, kapploeë en vleëlsnyers in. Almal is ontwerp om

eenvoudig, veilig en diensbaar te wees terwyl hulle

uitstekende waarde vir geld bied. Hulle is gebou om te hou

en ons strawwe Suid-Afrikaanse toestande die hoof te bied.

In many parts of South Africa "Falcon" is the generic term

for grass-cutting implements, making us the undisputed

leader in our field. Delivery on a marketing promise is the

foundation of any successful marketing drive and farmers

buying the Falcon brand buy more than just a product -

they buy the heritage and expertise of a company that has

been around for a long time!

In baie dele van Suid-Afrika is “Falcon” die generiese term vir

grassny-implemente, wat ons die onbetwiste leier op ons

gebied maak. Die nakom van ’n bemarkingsbelofte is die

grondslag van enige geslaagde bemarkingsveldtog, en boere

wat die Falcon-handelsmerk koop, koop meer as net ’n

produk – hulle koop die erfenis en deskundigheid van ’n

maatskappy wat al lank in die land is!

he Locust range of economy implements is particularly

suited to smallholders, more price-sensitive buyers and

emerging farmers. hese implements, which include

slashers and roller mowers, work well with older or lower-

powered tractors.

Die Locust-reeks ekonomiese implemente is veral geskik vir

kleinhoeweboere, meer prysgevoelige kopers en ontluikende

boere. Hierdie implemente, wat wentelsnyers en rollersnyers

insluit, werk goed saam met ouer of minder kragtige

trekkers.

We also import a range of implements that complement

the locally manufactured ones. hese include the Amazone

spreaders, sprayers, mowers and soil tillage implements

(from Germany), the Votex shredders and mowers,

including reach mowers (from the Netherlands), and the

heavy-duty Woods Batwing rotary cutters (from USA).

Ons voer ook ’n reeks implemente in wat die plaaslik-

vervaardigdes komplementeer. Dit sluit in die Amazone-

strooiers, -spuite, -grassnyers en -grondbewerkings-

implemente (uit Duitsland), die Votex-stokkiekappers en

-grassnyers, insluitend reiksnyers (uit Nederland), en die

swaardiens Woods Batwing-wentelsnyers (uit die VSA).

Falcon Agricultural Equipment (Pty) Ltd is committed to

supporting our local communities in many different ways.

Our main focus is the well-being of children and we

provide a safe and suitable school environment for them,

as well as school-related necessities.

Falcon Agricultural Equipment (Edms.) Bpk. is verbonde tot

die ondersteuning van ons plaaslike gemeenskappe op baie

verskillende maniere. Ons hooffokus is die welsyn van

kinders, en ons verskaf vir hulle 'n veilige en geskikte

skoolomgewing, sowel as skoolverwante benodigdhede.

Our team prides itself on its professional approach to

business. We have built long-standing relationships with

our dealers and their customers based on honesty, trust,

respect and integrity. Excellent customer service is an

important part of the Falcon promise.

Ons span is trots op sy professionele benadering tot

besigheid. Ons het langdurige verhoudings met ons

handelaars en hul klante opgebou wat op eerlikheid,

vertroue, respek en integriteit gebaseer is. Voortreflike

klantediens is ’n belangrike deel van die Falcon-belofte.

2