目录二

CONTENTS

..........................................................................................................................................1

1Safety instructions ...........................................................................................................1

1.1Environmental conditions.......................................................................................1

1.2Description of warning signs..................................................................................1

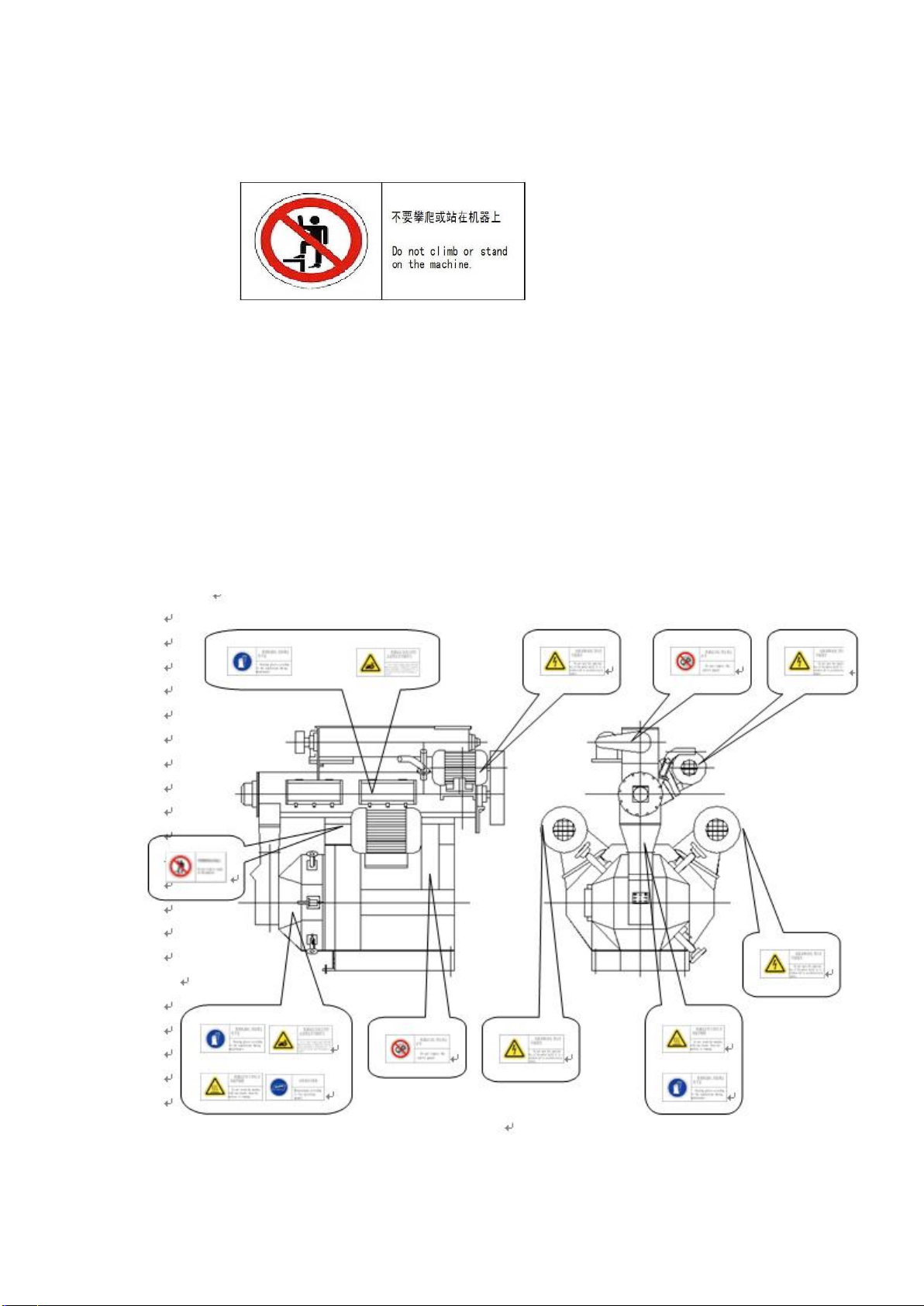

1.3Description of safety signs.....................................................................................2

1.4 Safety instructions.................................................................................................5

1.5Safety instructions in transport, storage and installation.........................................6

1.6 Safety instructions in operation, inspection and maintenance...............................6

1.7Personal protection................................................................................................9

1.8 Explosion Protection: Countermeasures against dust explosion and fire hazard.11

1.9 Other safety precautions (environmental protection measurements)...................13

2 General Description........................................................................................................1

2.1Application and adaptability ...................................................................................1

2.2Main features and functions...................................................................................1

2.3Main structureand working principle.......................................................................2

3 Specification of the pellet mill..........................................................................................1

3.1 Working condition .................................................................................................1

3.2Meanings of the model...........................................................................................2

3.3Accessory equipments...........................................................................................2

3.3.1Feeder.........................................................................................................2

3.3.2Conditioner ..................................................................................................3

3.3.3 Steam system.............................................................................................3

4Transportation, installation and adjustment......................................................................6

4.1Transportation........................................................................................................6

4.2 Installation ............................................................................................................8

4.2.1Installation of the principal machine .............................................................8

4.2.2 Connection of compressed air pipeline .......................................................9

4.2.3Installation of steam pipeline........................................................................9