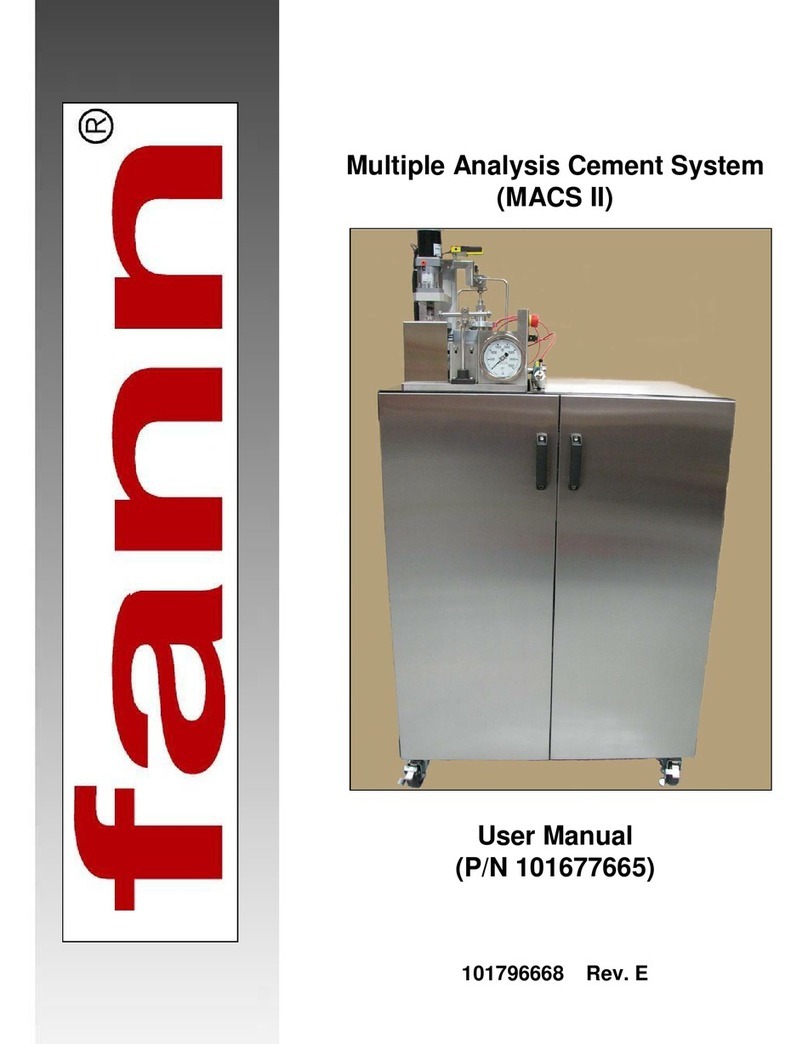

Cement Curing Autoclave User Manual

100072577 Revision H ii

Contents

1Introduction.............................................................................................................1

1.1 Cement Curing Autoclave ................................................................................... 1

1.2 Function............................................................................................................... 1

1.3 Features................................................................................................................ 2

2Safety.......................................................................................................................4

2.1 Machine Hazards ................................................................................................. 4

2.2 Ergonomic Considerations................................................................................... 5

3Features and Specifications ..................................................................................6

3.1 Cement Curing Autoclave Mechanical................................................................ 6

3.2 Cement Curing Molds.......................................................................................... 7

3.3 Cement Curing Autoclave Controls and Indicators............................................. 9

3.4 Temperature Controller Configuration.............................................................. 10

3.5 Pressurizing the Cement Curing Autoclave....................................................... 24

4Installation.............................................................................................................26

4.1 Parts of the Cement Curing Autoclave.............................................................. 26

4.2 Other Parts ......................................................................................................... 26

4.3 Locating the Cement Curing Autoclave ............................................................ 26

4.4 Electric Power Supply ....................................................................................... 26

5Operation...............................................................................................................28

5.1 Sample Preparation............................................................................................ 28

5.2 Prepare the Cube Mold ...................................................................................... 28

5.3 Prepare the Cement Slurry................................................................................. 32

5.4 Fill the Molds..................................................................................................... 32

5.5 Place molds into chamber.................................................................................. 35

5.6 Place chamber in heating jacket......................................................................... 39

5.7 Pressurize the chamber ...................................................................................... 41

5.8 Running a test .................................................................................................... 41

5.9 Ending the test ................................................................................................... 43

5.10 Remove the chamber ......................................................................................... 43

5.11 Cleaning the molds, pressure chamber, and autoclave...................................... 44

6Analyzing Results.................................................................................................45

7Troubleshooting and Maintenance......................................................................46