3

SECTION 2

SAFETY CONSIDERATIONS

Safe operation of the Differential Sticking Tester requires that the operator understand and practice the

correct assembly and operation of the equipment. Improper assembly, operation, or the use of defective

parts poses the possibility of cell leakage or failure which could result in serious injury and damage.

Following is a list of suggestions that should be observed to assure safe operation and maintenance of

the Differential Sticking Tester.

A. Safe Pressurization

1. Always use either Carbon Dioxide or Nitrogen. Never connect the Differential Sticking Tester

to Compressed Air, Oxygen or other non-recommended gas. If Nitrogen is used it must be

supplied in an approved Nitrogen gas cylinder or the nitrogen supply system must be built into

the laboratory. Nitrogen Cylinders must be secured to meet safety standards. Carbon

Dioxide is normally supplied in small cartridges which contain about 900 psi (6206 kPa)

pressure. They are primarily used for field operations. Do not allow these cartridges to be

heated or exposed to fire. They can explode if overheated.

2. Maintain pressure regulators in good condition. Never use oil on pressure regulators. Leaking

pressurization systems should be repaired or replaced. Gauges, fittings and hoses should be

kept in good condition and leaks should be found and corrected. If Nitrogen is being used,

periodically test the safety relief valve to verify they will relieve if excessive pressure should

occur. Never plug or bypass the safety valve.

3. Before pressurizing the Differential Sticking Tester always check to be sure the regulator tee

screw is backed out until free turning thereby putting the regulator in the closed position.

Insert and puncture the CO2cartridge or open the nitrogen gas supply valve, then adjust the

regulator. Do not attempt to pressurize higher than the equipment is rated. When de-

pressurizing, shut off the supply pressure, bleed the system of pressure, and then back out

the regulator Tee screw.

B. Safe Test Cell Maintenance

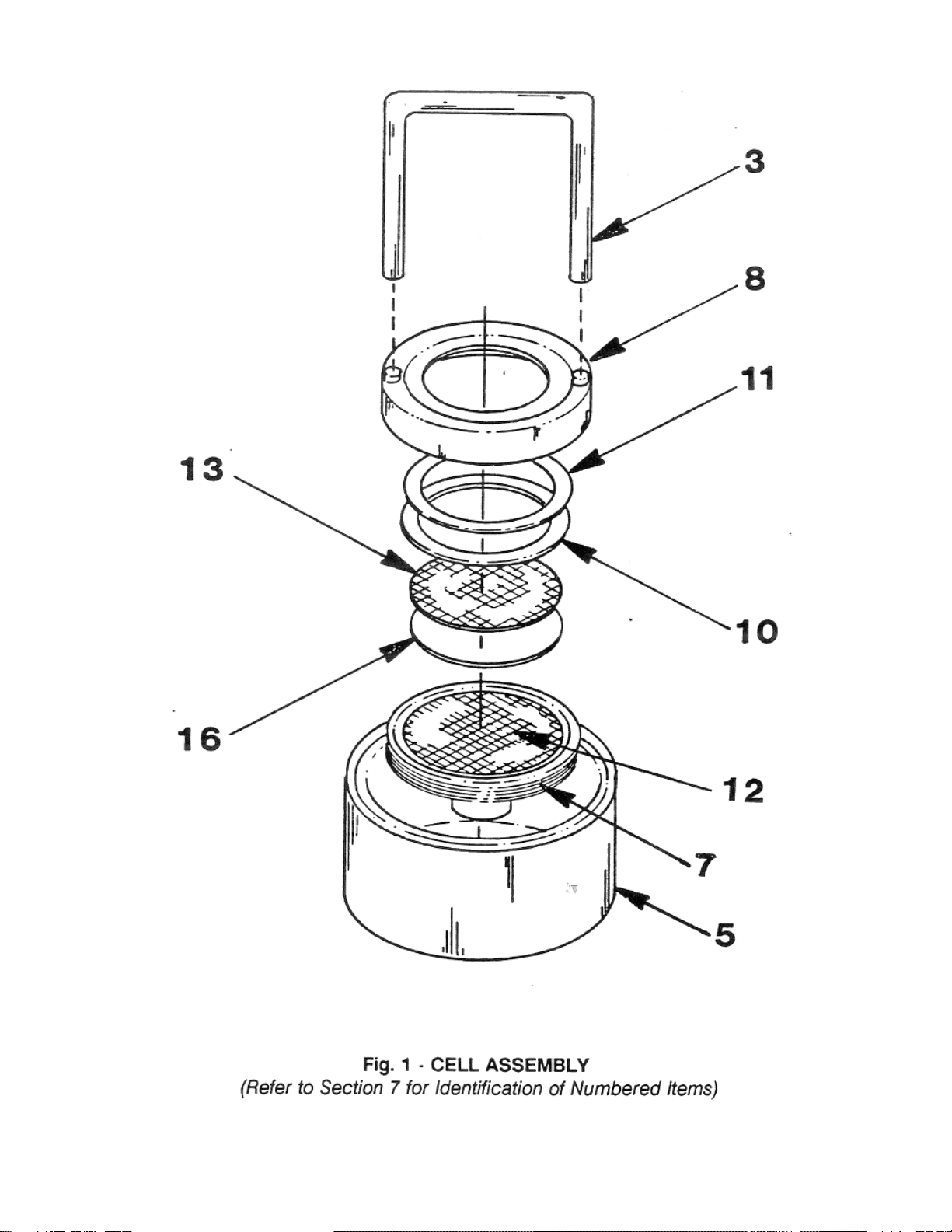

The Differential Sticking Tester Cell Assembly constitutes a PRESSURE VESSEL.

The Safety Precautions listed should be followed to assure safe operation.

1. Cell material should be compatible with the test sample.

2. Cells that show signs of stress cracking, severe pitting, or have damaged threads must not be

used.

C. Safe Operation

The Differential Sticking Tester is a relatively small and light weight instrument. Observe the following

cautions in its operation to prevent injury and damage due to the instrument slipping on the work

bench or accidentally being knocked off the bench.

1. Before attempting to tighten Cell Cap onto Cell Body, Refer to Fig. 3, make sure Bolt [26], Fig. 2 is

installed and tightened. This will insure the Cell does not slip off the Stage.