4

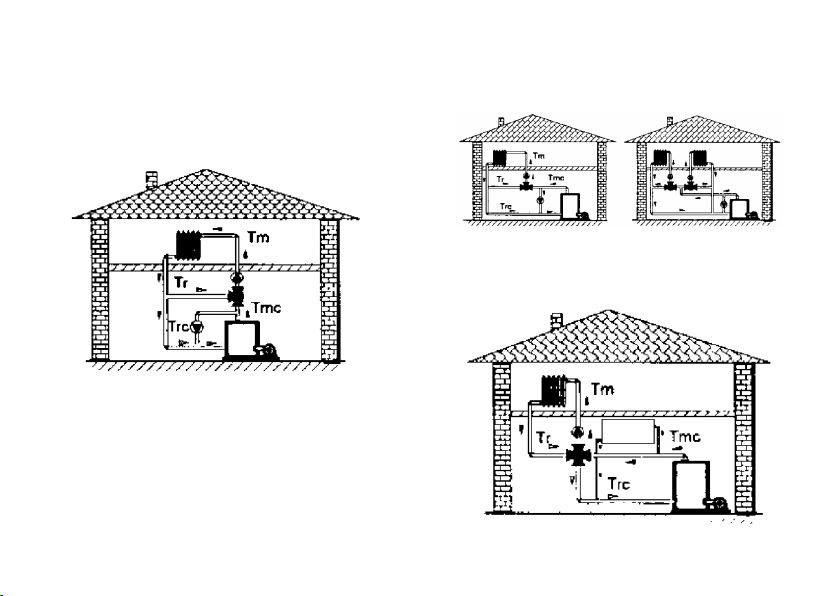

Avoid to make probe connections close to distribution

cables with high current loads.

Connect the different devices according to shown

diagrams.

Make sure that coupling connections are clean and

not oxidised.

Connect the control unit Fastons to the proper cou-

plings on the terminal base, pressing them down to

full bedding.

Then tighten the fastening bolt.

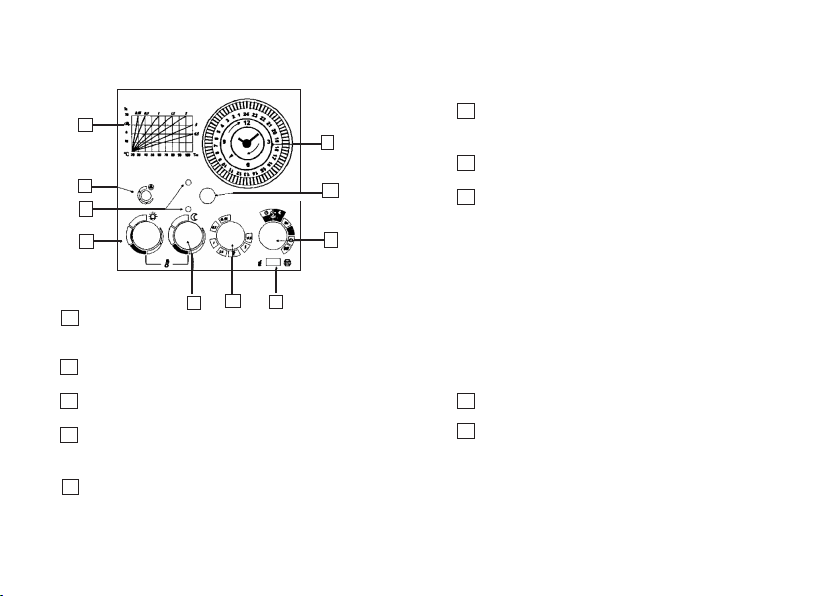

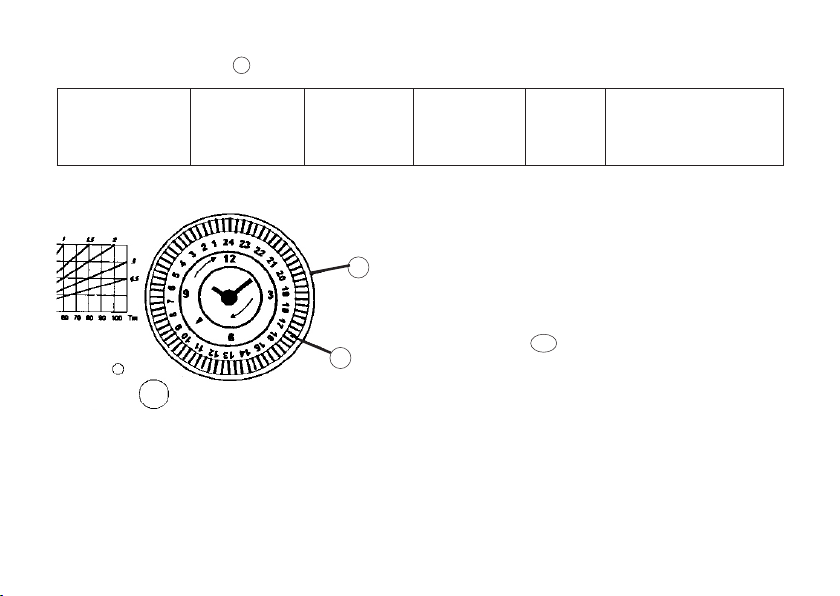

OPERATION TYPE SELECT SWITCH

Switch G (pg 6) shall be used for immediate selec-

tion between proportional-time control of motor-op-

erated mixing valves (wiring diagrams 1 and 2) and

burner ON/OFF control (wiring diagram 3).

CIRCULATION PUMP CONTROL

EV02F control unit is preset for automatic circulation

pump control.

If connections are carried out according to shown dia-

grams, the circulation pump will be working during the

following operating modes: AUTOMATIC 1, always

ON, always economy; and it will be off when in OFF

mode. It will also be off (with the exception of the an-

tifreeze protection) in the antifreeze operating mode

and at night in the AUTOMATIC 2 operating mode.

To make the most of the remaining heat accumulated

during the daytime mode, the pump will shutdown

(with 60-minute adjustable delay) after turning the

system off.

SERVO CONTROL OPERATION TEST

Turn control unit selector H (pg 6) to ON and OFF

positions, check for proper valve movement and com-

pare it with plate data.

When the selector is at OFF, the valve control lever

pointer shall move to COLD; when the selector is at

ON, the lever pointer shall move to HOT.

Otherwise exchange servo control connections 2 - 3

or connections 6 - 8 on the control unit base.

IN THE EVENT OF SYSTEM UNSUCCESSFUL

OPERATION CHECK THE FOLLOWING:

Supply voltage, that shall be: 230V 50Hz.

Probe circuit, by means of the tester provided for

measuring the resistance value.

Connections and settings of burner thermostats,

safety thermostats, etc.

Turn the daytime ambient temperature regulation

knob fully clockwise and counterclockwise for several

consecutive times: if the two pilot lamps turn on and