TABLE OF CONTENTS

Contents

TO THE PURCHASER ..................................................................................................... 4

1. ABOUT THIS MANUAL ........................................................................................... 1

2. INTRODUCTION ....................................................................................................... 1

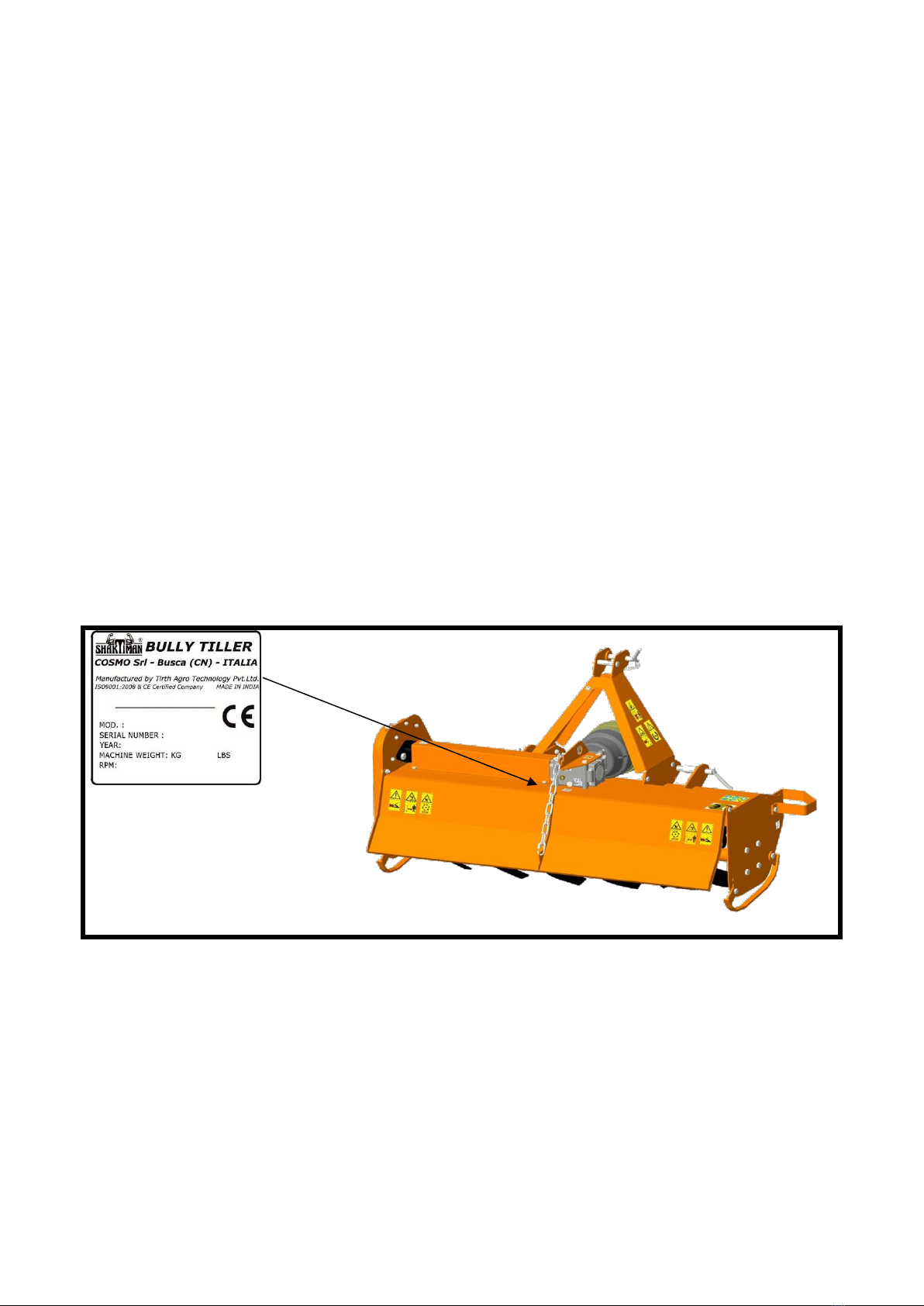

2.1. TILLER IDENTIFICATION ................................................................................................................. 1

2.2. INTENDED USE............................................................................................................................... 1

2.3. MAIN PARTSDESCRIPTION............................................................................................................. 2

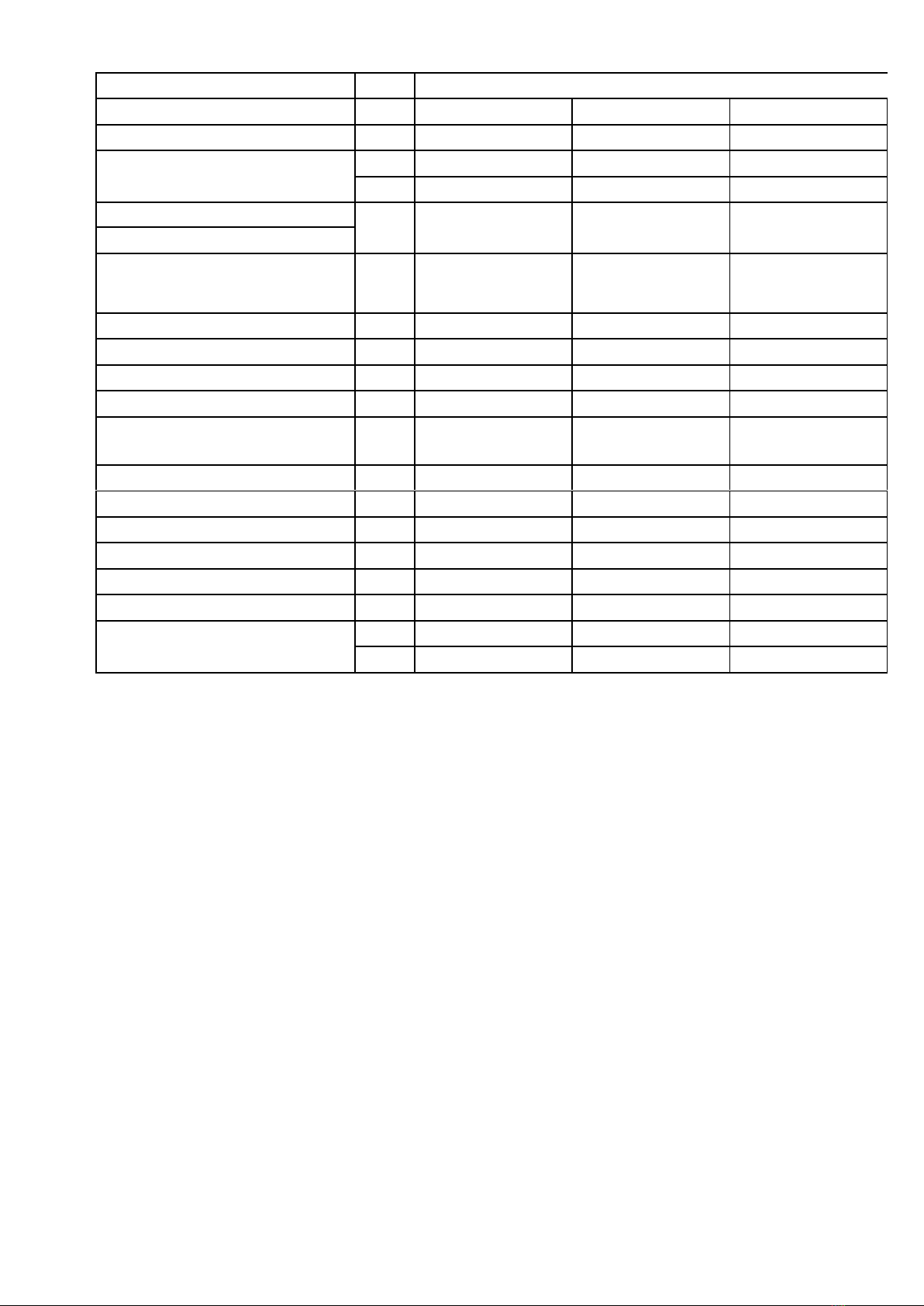

2.4. TILLER SPECIFICATIONS.................................................................................................................. 2

3. SAFETY........................................................................................................................ 3

3.1. GENERAL SAFETY INSTRUCTION .................................................................................................... 4

3.2. EQUIPMENT SAFETY INSTRUCTIONS ............................................................................................. 5

3.3. OPERATING SAFETY INSTRUCTIONS .............................................................................................. 6

3.4. TRANSPORTING SAFETY INSTRUCTIONS........................................................................................ 7

3.5. MAINTENANCE SAFETY INSTRUCTIONS......................................................................................... 8

3.6. STORAGE SAFETY INSTRUCTIONS.................................................................................................. 8

3.7. SAFETY LABELS............................................................................................................................... 8

4. SET UP...................................................................................................................... 13

4.1. CONNECTING TO THE TRACTOR .................................................................................................. 13

4.2. DRIVELINE INSTALLATION............................................................................................................ 13

4.3. TRACTOR-TILLER STABILITY ......................................................................................................... 15

5. OPERATING ............................................................................................................ 16

5.1. START UP ..................................................................................................................................... 16

5.2. OPERATING INSTRUCTIONS......................................................................................................... 18

5.3. ADJUSTMENTS ............................................................................................................................. 18

REAR BOARDADJUSTMENT...................................................................................................................... 20

5.4. STOPPING AND DISCONNECTION................................................................................................ 21

5.5. TRASPORTING.............................................................................................................................. 22

6. MAINTENANCE...................................................................................................... 22

6.1. BLADES REPLACEMENT................................................................................................................ 22

6.2. GEARBOX LUBRICATION .............................................................................................................. 23

6.3. SIDE CASE LUBRICATION.............................................................................................................. 24

6.4. BEARING HOUSING LUBRICATION............................................................................................... 25

6.5. DRIVESHAFT MAINTENANCE ....................................................................................................... 26