TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................................................................6

PRODUCT WARRANTY..............................................................................................................................................................................7

GENERAL SAFETY INSTRUCTIONS.............................................................................................................................................................8

STARTING .................................................................................................................................................................................................8

TRANSPORT..............................................................................................................................................................................................9

OPERATION ..............................................................................................................................................................................................9

MAINTENANCE.......................................................................................................................................................................................10

SAFETY INSTRUCTIONS FOR THE WINCHES ...........................................................................................................................................11

STICKERS AND PLATES............................................................................................................................................................................12

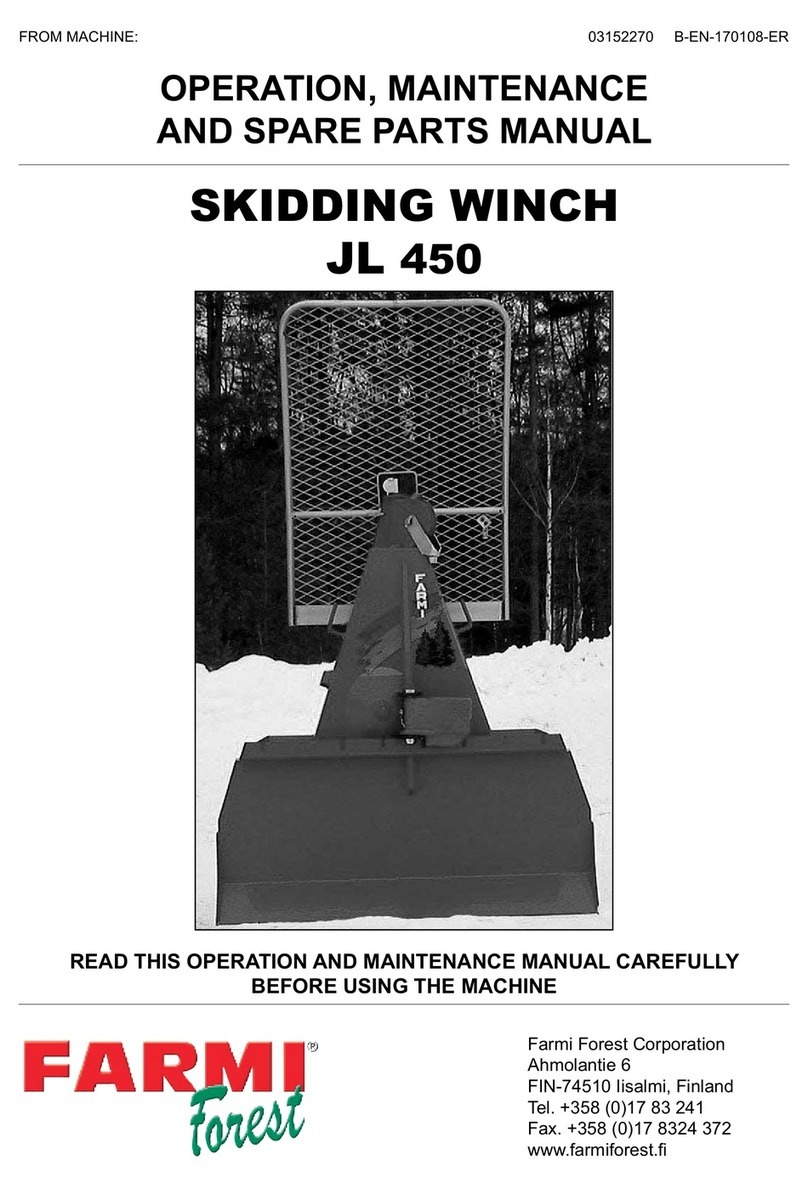

MAIN PARTS AND ACCESSORIES ............................................................................................................................................................15

TECHNICAL SPECIFICATION....................................................................................................................................................................16

MOUNTING ............................................................................................................................................................................................17

FASTENING THE CABLE TO THE DRUM ..................................................................................................................................................18

PRE-OPERATION CHECKS .......................................................................................................................................................................19

DISCONNECTING THE SKIDDING WINCH FROM THE TRACTOR .............................................................................................................20

STORAGE................................................................................................................................................................................................20

OPERATION ............................................................................................................................................................................................20

WINCHING .............................................................................................................................................................................................23

SKIDDING ...............................................................................................................................................................................................24

MAINTENANCE.......................................................................................................................................................................................26

TROUBLE SHOOTING..............................................................................................................................................................................31

SPARE PARTS..........................................................................................................................................................................................32

WARRANTY ............................................................................................................................................................................................41

FARMI FOREST REPRESENTATIVES.........................................................................................................................................................41

When ordering spare parts, please indicate the serialnumberofyourmachine canbefoundonthe machine plate, spare parts

order number, description and quantity required. Example. W35R, 94624046, torsion spring, 2 pcs