Fast Master Products SWIVELWHEEL-46 User manual

2

SWIVELWHEEL-46

COMPONENTS

Torsion

Suspension and

Tire

Front Jack Stand Legs

with Wheels

3” x 1” Rectangular

Steel Tubing Frame

Optional

Spare Tire

Two Point Hook-Up Hitch

Assembly

¾” Treated/Painted

Plywood Decking

Front Support

Mounts

DOT Lighting Wiring

Harness with 4-Wire

Flat Trailer Plug

DOT Regulated

Lighting

2” x 2” ID

Stake Bed

Receivers

3

CAUTIONS &

DISCLAIMERS

1. SYSTEM MUST BE UNLOADED AT THE TIME OF

CONNECTING TO AND DISCONNECTING FROM

THE TOW VEHICLE.

2. WHEN LOADED, THE DECK SHOULD BE LEVEL

OR SLIGHTLY LOWER IN THE FRONT. NEVER

PULL THE SWIVELWHEEL-46 SYSTEM WITH THE

REAR DECK LOWER THAN THE FRONT, OR

MORE WEIGHT TO THE REAR THAN THE FRONT.

ALWAYS LOAD AND UNLOAD THE

SWIVELWHEEL DECK WHILE ON LEVEL

GROUND.

3. ALWAYS CONNECT AND DISCONNECT THE

SWIVELWHEEL SYSTEM WHILE ON LEVEL

GROUND.

4. BE SURE THAT THE HITCH MOUNTING BOLT

HAS BEEN FULLY TIGHTENED PRIOR TO USE.

CHECK THE MOUNTING BOLT FROM TIME TO

TIME FOR TIGHTNESS

5. IF ATTACHING TO A FIFTH WHEEL TRAILER, DO

NOT EXCEED THE INSTALLED HITCH LOAD

RATING. DO NOT EXCEED THE WEIGHT

CAPACITY OF THE SYSTEM.

6. PAYLOAD MUST BE CONFINED TO WITHIN THE

FRAME PERIMETER OF THE SYSTEM.

7. WHEN BACKING THE SYSTEM UP, BE AWARE OF

CURBS, PARKING STOPS AND POT HOLES.

8. DO NOT BACK UP AT A HIGH RATE OF

SPEED.DAMAGE MAY OCCURE TO THE SYSTEM.

9. WHEN BACKING, SYSTEM DECK HEIGHT MAY

LOWER SLIGHTLY.THIS IS NORMAL.

10. SYSTEM NOT INTENDED FOR PASSENGER USE.

11. MAKE SURE THAT LOADING RAMPS ARE

LOCKED INTO POSITION AND SECURE PRIOR

TO USE.

12. IF USING LOADING RAMPS, REMOVE PRIOR

TO MOVING THE SYSTEM.

13. IF USING THE FAST MASTER LOADING RAMPS

AS SIDE GUARDS, BE SURE THAT THE RAMPS

ARE SECURELY LOCKED INTO PLACE PRIOR

TO MOVING.

14. REPLACEMENT TIRES MUST BE A SIZE 5.70-

8”, “C”RATED, 6-PLY 910 LB, HIGHWAY SPEED

TRAILER TIRE. CHECK TIRE PRESSURE

FREQUENTLY. MOST TIRE FAILURES ARE DUE

TO OVER OR UNDER INFLATION. (75 PSI

COLD). THE TIRE MANUFACTURER SPECIFIES

75 PSI COLD FOR THIS TIRE. NEVER

REDUCE THE TIRE PRESSURE WITHIN A

HOT TIRE. ALWAYS ALLOW THE TIRE TO

COOL FULLY BEFORE REDUCING ANY

TIRE PRESSURE.

15. NEVER REPLACE THE SYSTEM TIRE WITH A

LOWER RATED TIRE.

16. COMPLY WITH ALL STATE AND LOCAL

LICENSING AND REGISTRATION LAWS WHERE

APPLICABLE.

17. WHEN USING THE JACK STANDS, THE SYSTEM

MUST BE UNLOADED. DO NOT LEAVE SYSTEM

DETACHED FROM TOW VEHICLE IN THE

LOADED CONFIGURATION.

18. DO NOT EXCEED 65 MPH. THE

MANUFACTURER OF THE TIRE (CARLISLE)

STATES THAT THE MAXIMUM SPEED FOR A

5.70 X 6 C-RATED, 6-PLY TIRE IS 65 MPH.

HIGHER SPEEDS COULD INCREASE THE HEAT

GENERATED WITHIN THE TIRE AND COULD

CAUSE TIRE FAILURE.

19. CHECK THE BEARING ASSEMBLY TO THE

SWIVEL WHEEL ASSEMBLY ONCE A YEAR.

CHECK AND TIGHTEN THE WHEEL LUG NUTS

ON A ROUTINE BASIS. SERVICE THE WHEEL

BEARINGS ONCE A YEAR OR EVERY 10,000

MILES.

20. MODIFICATIONS TO THE SWIVELWHEEL

SYSTEM WITHOUT WRITTEN APPROVAL

FROM FAST MASTER PRODUCTS WILL

RELEASE FAST MASTER PRODUCTS FROM

ALL LIABILITIES, AND WILL VOID ALL

WARRANTIES.

4

SYSTEM

SPECIFICATIONS

TOW VEHICLE:

CLASS “A” DIESEL MOTOR COACH

CLASS “A” GAS MOTOR COACH

CLASS “C” MOTOR COACH

CLASS-“B” MOTOR HOME

FIFTH WHEEL TRAVEL TRAILER

PICKUPS

SUV’s

AUTOMOBILES

HITCH REQUIREMENTS:

CLASS-III 5000 POUND LOAD @ 500 LB

TONGUE WEIGHT

CLASS-IV 10,000 POUND LOAD @ 1000

LB TONGUE WEIGHT

WEIGHT LIMIT:

600 POUNDS

FRAME:

3” X 1” RECTANGULAR TUBULAR STEEL FRAME.

NOT ANGLE IRON.

DECK DIMENSIONS:

DECK WIDTH = 6’

DECK LENGTH = 4’

DECK HEIGHT:

25¾” TRAILING POSITION (EMPTY/LEVEL DECK)

WITH 8” WHEEL ASSEMBLY.

DECK CONSTRUCTION:

¾” TREATED & PAINTED PLYWOOD

AXLE:

TORSION, 360 DEGREE SWIVEL AXLE

WHEEL/TIRE:

5-SPOKE, WHITE MAG WHEEL (STANDARD)

5.70-8” “C”-RATED, 6-PLY, HIGH SPEED

HIGHWAY TRAILER TIRE @ A COLD INFLATION

PRESSURE OF 75 PSI, AND MAXIMUM 910

POUND LOAD RATING.

LIGHTING:

RUNNING LIGHTS, RT & LT TURN, STOP

LIGHTS, & LICENSE PLATE LIGHTING.

4-WIRE FLAT TRAILER PLUG (STANDARD)

6-WAY ROUND to 4-WIRE FLAT ADAPTER

(OPTIONAL)

7-WAY ROUND to 4-WIRE FLAT ADAPTER

(OPTIONAL)

TIE DOWN POINTS:

OPTIONAL VERTICAL POWDER COATED E-

TRACK ON RIGHT AND LEFT DECK SURFACE

E-TRACK TIE-OFF ADAPTERS. (OPTIONAL)

LOADING RAMPS:

7’-6” LONG x 45” WIDE THREE PIECE. LATCHES

TO THE REAR OF THE SYSTEM.

TOW-VEHICLE MOUNTING:

ONE PERSON, ADJUSTABLE HEIGHT, PIVOTING

MOUNTING HARDWARE.

JACK STANDS:

REMOVABLE, JACK STAND LEGS WITH WHEELS

MAY BE USED TO ROLL SYSTEM AROUND WHILE

DISCONNECTED FROM THE TOW VEHICLE.

SYSTEM WEIGHT LIMITS:

600 POUNDS

5

ASSEMBLY

INSTALLING THE TORSION

SUSPENSION

The Swivelwheel-46 system is shipped to you

unassembled to reduce the freight costs. These

instructions will guide you through the assembly

process. Once you receive the system, remove the

components from the boxes.

1. Place the Swivelwheel-46 frame with the

plywood decking facing upward on a pair

of sawhorses.

2. Remove the plywood hatch from the

frame. At the rear of the frame, in the

center, you will find the swivel box for

mounting the torsion suspension.

3. Remove the lug nuts from the studs on

the swivel mount on the torsion

suspension. There should be a round

silver rotor plate slid over the swivel

mount. Do not remove this plate

4. With another persons help, lift the torsion

suspension up into the swivel mount plate

on the Swivelwheel-46 frame. Start a

couple of lug nuts on the studs. You may

now release the torsion suspension and it

will stay in place. Install the remaining lug

nuts and tighten. When attached to the

base frame, the assembly should look like

the next drawing. Torque 90-110 lbs.

5. Remove the lug nuts from the wheel

assembly spindle if not already done so.

Install the wheel and tire to the assembly.

Replace the lug nuts and tighten. Torque

90-110 lbs.

Lug Nuts

Torsion

Suspension Tube

Lug Nuts

6

TAIL LIGHT MOUNTING

1. Install the lights to the rear of the

trailer. The lights should be marked

“Passenger” and “Driver” side. If

not, the light with the clear bottom

lens is always mounted on the

driver side.

2. Connect the light wires to the trailer

wiring harness with the installed

quick disconnects. These wires are

all color coded so match them up

and plug them into each other.

Passenger Side = Brown,

Green, White

Driver Side = Brown,

Yellow, White

3. Install the right and left side jack

stand legs to the front outside 2” x

2” stake bed receivers and lock into

place with the supplied lock pins.

ADJUSTING THE FRICTION

ROTOR ASSEMBLY

ALL SWIVELWHEEL SYSTEMS ARE

SHIPPED WITH A FRICTION ROTOR AND PAD

ASSEMBLY

1. Adjust the friction pad so that it touches the

friction plate (Red Disk) at there is slight

tension between the friction plate and

friction pad.

2. Once the correct amount of friction is

applied, tighten the mounting jam nuts to

hold the friction pad (Blue) in place.

3. You will notice that some pressure at the

rear of the Swivelwheel system is needed in

order to turn the wheel while moving the

system around. This is normal. When the

system is being towed, the wheel assembly

will turn as designed. If you notice that you

cannot move the system around without

really having to push hard, the friction pad

may be too tight.

4. You may hear a slight squeaking noise when

the wheel turns. This is normal due to the

friction pad turning on the rotor plate.

2” x 2” ID

Receiver

Friction

Plate

FRICTION PAD

(Blue)

7

SINGLE RECEIVER

MOUNTING TO THE TOW

VEHICLE

The Single Receiver Hitch will slide into a standard

Class-III or Class-IV receiver on the tow vehicle. If

you do not have this class of receiver, one must be

installed in order to use the system. Check the

vehicles Owners Manual for towing specifications.

Do not exceed the receiver weight rating on

your tow vehicle.

1. Slide the hitch solid 2” x 2” OD insert into

the tow vehicles Class-III or Class-IV

receiver. Line up the mounting hole on the

hitch with the hole on the receiver.

2. Insert the 5/8” x 4” Gr-8 mounting

bolt with 5/8” lock washer from the

passenger side, through the receiver

and into the hitch insert. The insert

is threaded about half way through.

3. Screw the bolt into the insert. Do not

cross thread the bolt. Once the bolt is

inserted all of the way in, tighten the bolt

head fully. This takes out any play within

the hitch assembly.

4. Install the 5/8” lock washer and 5/8” nut

to the bolt. Tighten just enough to

compress the lock washer and then a

slight amount more. Do not over

tighten this nut.

(15/16” Socket or Wrench)

You should now be able to attempt to move the

hitch without any play in the mount. Inspect the

bolt tightness from time to time. If there is play

in the hitch assembly, re-tighten the mounting bolt.

JAM NUT

FRICTION

ROTOR

FRICTION PAD

FRICTION PAD

ADJUSTMENT

BOLT

8

ATTACHING THE

SWIVELWHEEL-46 SYSTEM TO

THE HITCH MOUNT

1. Roll the swivelwheel-46 system up to the

hitch mount on the tow vehicle.

2. Line up the two Adjustable Mounting

Plates (Upper Right Photo) with the center

of the Support Brackets on the front of the

Swivelwheel-46 system.

3. Slide the uprights between the mounting

brackets.

4.Raise one corner of the system to the

closest upward hole position and insert

the supplied 5/8” x 3” bent hitch pin

through the mounting holes.

5. Repeat this procedure for the other side of

the system.

6. Continue raising the deck sides until you

achieve a deck position of slightly lower in

the front than the back. In this position,

when loading the deck, the platform will

lower slightly to a level position for travel.

NOTE:

You may have to adjust the deck a couple of

times to get the correct position. Never have

the rear deck lower than the front while

traveling. If you cannot achieve a level

position, it is better to have a slightly lower

front deck. Once you get the deck

positioned properly for the load, you will

know where to set it each time you haul

that specific item.

7. You may raise the jack stand legs and pin

them in the up position by utilizing the

lower mounting holes.

8. If you wish to remove the jack stand legs

for travel - as you are making the deck

height adjustment, raise the deck slightly

higher at the corner and slide the leg out

of the stake bed receiver.

The photo above left shows the

Jack Stand Legs in the down

position for moving the system

around while disconnected from

the tow vehicle.

The photo above right shows the

Jack Stand Legs raised and pinned

for travel.

Adjustable

Support Plate

Swivelwheel-46

Support Brackets

9

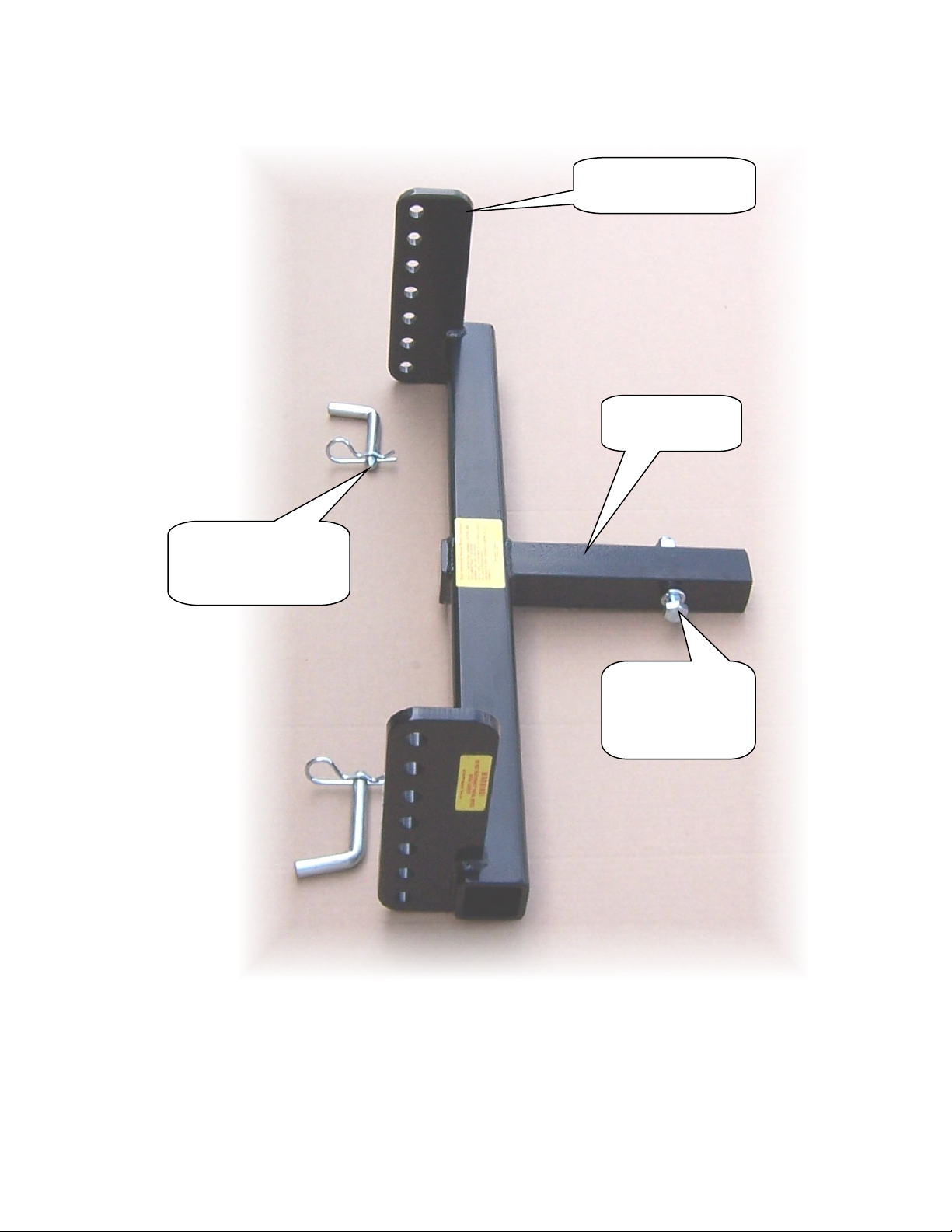

Adjustable Support

Plate

5/8” x 4” Grade-8

Hex Bolt with

Lock Washers

and Nut

2” x 2” Solid

Steel Insert

5/8” x 3”

Bent Hitch Pin with

Hair Pin Cotter

10

OPTIONAL LOADING RAMPS

1. Lay the Loading Ramps out to the side or

rear of the Swivelwheel-46 system as shown

below. The two side ramps have red fingers

that extend over the deck edge. The center

ramp has an aluminum plate that extends

over the deck edge.

2. All ramp sets come with safety straps.

Follow the inserted instructions with the

straps to keep the ramps from moving while

in use.

3. The two outside ramps have a load rating of

750 pounds. The center ramp has a load

rating of 1500 pounds. This is sufficient for

any full size motorcycle.

If so desired, you could transport two ATV’s with

the system. By dropping the tailgate, one ATV may

be loaded into the pickup bed. Close the tailgate and

load the second unit onto the Swivelwheel-46.

LOADING THE PLATFORM

1. Always load and unload on level ground. A

good starting point is to level the deck on

the hitch bar, then drop it down one hole so

that the deck is slightly lower in the front

than the rear. As the deck is loaded, the

deck will lower slightly. You want the deck

as level as possible when fully loaded. If you

cannot achieve a level deck, it is better to

have the deck slightly lower in the front

than the rear.

2. Make sure that the systems suspension and

wheel are in the trailing position. This will

reduce the amount of drop in the rear of the

deck while loading. If the tire is turned

around to the front of the system the deck

will lower more due to the leverage applied

to the rear of the system.

3. When using loading ramps, make sure that

the ramps are secure to the Swivelwheel

platform before loading. Do not use

unneeded power when loading to keep the

loading ramps from shooting out from under

the wheels.

4. Ride onto the platform slowly in order to

keep your balance especially with a

motorcycle. Be aware of the opposite end of

the platform. Do not ride off of the opposite

11

end of the platform. If using a wheel chock

for motorcycles, be sure that motorcycles

front tire is lined up with the chock. Ride

into the chock slowly.

MAINTENANCE

BEARINGS: The Swivelwheel-46 systems wheel

hub assembly should be inspected from time to time

to assure there is sufficient grease. These hubs have

quality bearings installed. There should be no reason

for the bearings to fail as long as the grease level is

maintained. The Bearings should be repacked yearly

or every 10,000 miles as most trailer hubs.

The upper swivel hub has a access hatch cut out of

the deck material. This allows for the swivel hub

inspection. This hub turns very little. The only time

the wheel spins 360 degrees is when you back up.

Otherwise the wheel turns about 15 degrees during

travel and at a full turn. The photo right shows a

Dodge 3500 one ton, four door, with 8-foot bed in a

360 degree turn. This shows the maximum wheel

turn on the Swivelwheel during normal travel.

FRAME: From time to time scratches will

develop on the frame. These scratches may be

touched up with a good Rust-Oleum Black Semi-

Gloss spray paint. Most of these are fast drying

paints. If you get the enamel paints, expect to wait

24 hours to fully dry.

DECK: The top deck is painted with Black

Premium Outdoor Gloss paint. The plywood used on

the deck of the Swivelwheel-46 system is pressure

treated. The bottom of the deck is not painted

because it does not need to be. If you want to paint

the bottom of the plywood you may do so.

TIRE: The tire is a 5.70 x 8”, C-Rated, 6-

Ply, Highway Speed Trailer Tire. The load rating with

this tire is 910 pounds @ 75 psi cold inflation. This

tire will never see 910 pounds with a 600 pound

deck load. Never replace this tire with a lower

rated tire. This tire was chosen to fit the torsion

suspension being utilized. A larger tire will not fit

this system. Always check tire pressures prior

to using, and always when the tire is cold.

Maintain a 75 psi “cold” inflation pressure in this

tire. The tire left in the photo is the 5.70 x 8” tire

that is used with the Swivelwheel system. The tire to

the right of it is a 4.80 x 8” tire that is usually sold at

Wal-Mart, etc.

This tire is highway speed rated for 65 mph.

I know what you’re thinking! I drive at 70 and 75

mph when I travel. I know that some highways have

speed limits of 75 mph, but the trailer tire

manufacturers have told us that the majority of the

trailer tires on the market today have a speed rating

of 65 mph. Some fifth wheel trailers use a light truck

tire (LT235/75R16) that will withstand higher speeds

and have an 80 psi cold inflation pressure.

The fact is …… tire ratings are specified by the tire

manufacturers. All I can say is that what you choose

to do with that information is up to you.

The tire indicated by the arrow is the tire used with

all Swivelwheel systems.

TORSION SUSPENSION:

There is no maintenance required for this

suspension other than occasionally inspecting the U-

Bolts for tightness.

12

POLICY / RETURNS

IT IS THE POLICY OF FAST MASTER

PRODUCTS TO OFFER THE HIGHEST QUALITY

PRODUCT AT THE BEST POSSIBLE PRICE.

ALL FAST MASTER PRODUCTS ARE FULLY

ASSEMBLED AND TESTED PRIOR TO

SHIPPING. THIS REDUCES THE POSSIBILITY

OF THE UNFORTUNATE SURPRISE FACTOR OF

NOT RECEIVING A PART, OR OF HAVING A

MALFUNCTION OUT OF THE BOX.

UNFORTUNATELY, MURPHY COULD STILL

RAISE HIS UGLY HEAD.

WE ARE PROUD OF OUR QUALITY

CONTROLS AND CUSTOMER SERVICE. IF AN

ISSUE DOES ARISE WITH ONE OF OUR

PRODUCTS, SUCH AS FREIGHT DAMAGE,

MISSING PARTS, ETC, PLEASE CONTACT US

AS SOON AS POSSIBLE TOLL FREE AT (866)

794-8357.

FREIGHT DAMAGES MUST BE REPORTED

WITHIN 24-48 HOURS IN ORDER FOR US TO

FILE FREIGHT CLAIMS WITH THE CARRIER.

(SEE RETURNS BELOW)

ALL OF THE PRODUCTS MANUFACTURED BY

FAST MASTER PRODUCTS, INC. HAVE BEEN

TESTED UNDER ADVERSE CONDITIONS. USE

OF THESE PRODUCTS BEYOND THE RELM OF

THEIR TESTING MAY CAUSE DAMAGE TO THE

SYSTEM, OR PERSONAL INJURY. PLEASE

READ AND FOLLOW THE GUIDELINES WITHIN

THE CAUTIONS AND DISCLAIMERS SECTION

WITHIN THE SUPPLIED OWNERS MANUAL.

•Modifications or changes made in any

product manufactured by Fast Master

Products, Inc, without written consent

from Fast Master Products, Inc. will void the

warranty and product liability insurance

associated with that product.

•The Swivelwheel system was not designed

or tested for towing from another towed

vehicle behind a motor coach (Triple Towing

behind a motor coach).

The weight and mass of the Swivelwheel trailer

in conjunction with a towed vehicle behind a

motor coach may cause the combination to

become unstable and uncontrollable. Fast

Master Products, Inc. will not be held

responsible for damage or injury from such

a combination use.

•The swivel wheel and suspension

components are not a sellable component

off of the system. These components are a

proprietary component of the Swivelwheel

product. Replacement suspension parts are

available to customers with Swivelwheel

products only. When ordering, please

provide the name of the owner and the VIN

number associated with the system.

DEALERS:

All dealer sells are final and nonrefundable.

•If a customer has any questions or concerns

about installation please call Fast Master

Products, Inc. at 1-866-794-8357

RETURNS:

Fast Master Products, Inc. sells all Swivelwheel

products as a titled product. Since it is a titled

product there is no return or refund once the title

has been issued to the customer. With that being

said:

•Please Note: If there is any freight damage

noted upon delivery, note the damage on

the freight bill and contact Fast Master

Products, Inc. right away with the

information. Fax a copy of the freight bill to

us at (281) 391-6760. This must be done

within 24-48 hours to allow us to file a

freight claim with the carrier. If available,

take pictures and email them to

info@cruiserlift.com. If this procedure is not

followed, we must assume that the damage

occurred after the delivery date.

13

WARRANTY POLICY: All systems

(Swivelwheel, Cruiserlift, CruiserRamp) have

a one year warranty from the date of the

original invoice. NOTE: Removing the VIN

sticker from our systems will void all warranty

and return possibilities. In addition, Warranty

is not transferable from the original owner of

the system.

•Modifications or changes made in any

product manufactured by Fast Master

Products, Inc, without written consent

from Fast Master Products, Inc. will

void the warranty and product liability

insurance associated with that

product.

WARRANTY REPLACEMENT

PARTS:

In the event of warranty replacement parts, we will

bill you for the part being sent to you unless

otherwise directed by Fast Master Products, Inc.

management. Once the defective part has been

returned to Fast Master Products, Inc, and found

that it was a warranty issue, you will be credited for

the charge.

The defective component must be returned

within 15 days, or credit cannot be issued. This

policy has had to be implemented due to the

following reason.

•As other manufacturers, some of our

components are purchased from outside

vendors. These vendors also have a

warranty return policy. When we send a part

out under warranty, and do not receive the

defective component, we cannot file a

warranty claim with that specific vendor for

repair or replacement under their policy

deadlines.

MODEL No: SWIVELWHEEL-46

VIN No:

Table of contents

Other Fast Master Products Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction