Fast Master Products Swivelwheel-58DW Assembly instructions

1

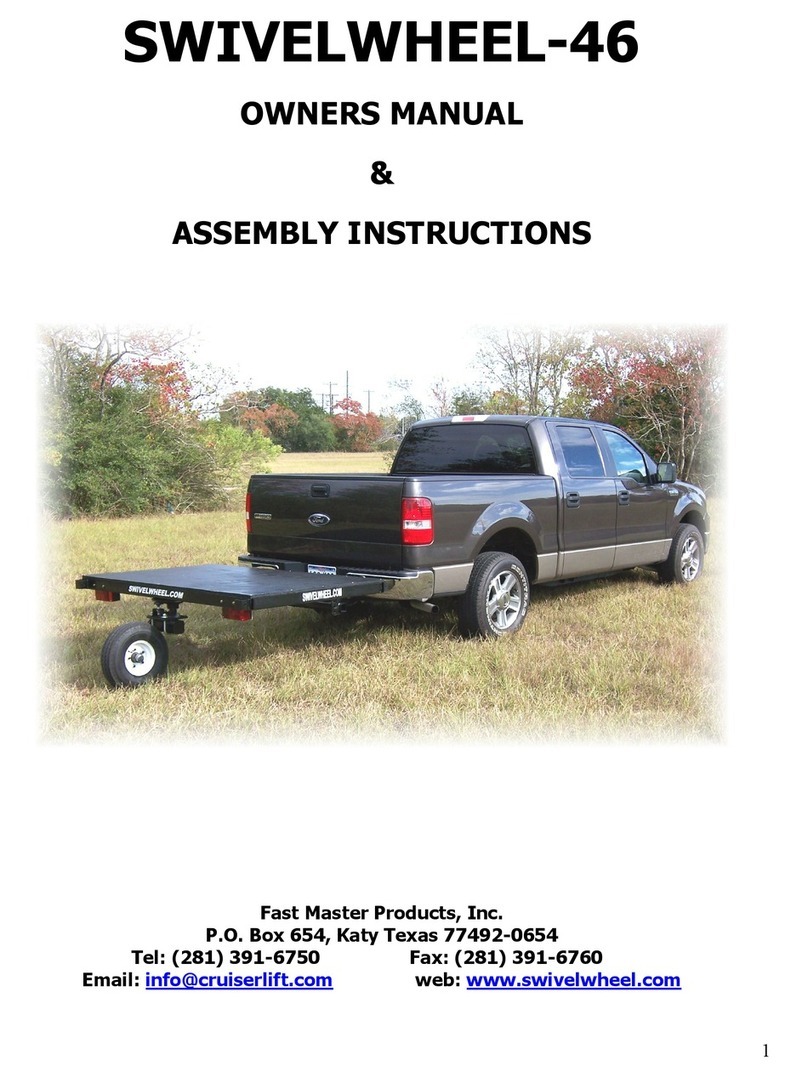

SWIVELWHEEL-58DW

OWNERS MANUAL /ASSEMBLY INSTRUCTIONS

Fast Master Products, Inc.

P.O. Box 654, Katy Texas 77492-0654

Tel: (281) 391-6750 Fax: (281) 391-6760

Email: info@cruiserlift.com

2

SWIVELWHEEL-58DW COMPONENTS

Jack Stands with

wheels for easy

movement while

disconnected from

vehicle

¾” Treated / Painted

Plywood Decking

Torsion Suspension

with Friction

Dampener

Highway

Speed

Trailer Tires

DOT required

lighting w/ 4-wire

flat plug

2” x 2” Stake Bed

Receivers

Welded

Tubular Steel

Frame

Safety Chains

3

CAUTIONS & DISCLAIMERS

1. SYSTEM MUST BE UNLOADED AT THE TIME OF

CONNECTING TO AND DISCONNECTING FROM

THE TOW VEHICLE.

2. THE SWIVELWHEEL-58DW SYSTEM IS NOT

INTENDED FOR SHORT-NARROW WHEEL

BASE VEHICLES. USE ONLY WITH FULL SIZE

PICK-UPS, MID TO FULL SIZE SUV’S

(EXPIDITION, TAHOE, ETC), CLASS-A AND

CLASS-C MOTOR COACHES, AND FIFTH WHEEL

TRAVEL TRAILERS.

3. WHEN LOADED, THE DECK SHOULD BE LEVEL

OR SLIGHTLY LOWER IN THE FRONT. NEVER

PULL THE SWIVELWHEEL-58DW SYSTEM WITH

THE REAR DECK LOWER THAN THE FRONT, OR

MORE WEIGHT TO THE REAR THAN THE FRONT.

ALWAYS LOAD AND UNLOAD THE SYSTEM

WITH THE SWIVELWHEEL SYSTEM ON

LEVEL GROUND.

4. IF ATTACHING TO A FIFTH WHEEL TRAILER,

YOU MUST INSTALL THE TWO SUPPLIED

RECEIVERS TO THE REAR OF THE TRAILER. THE

SWIVELWHEEL-58DW SYSTEM UTILIZES A DUAL

RECEIVER CONNECTION

5. PAYLOAD MUST BE CONFINED TO WITHIN THE

FRAME PERIMETER OF THE SYSTEM.

6. WHEN BACKING THE SYSTEM UP, BE AWARE OF

CURBS, PARKING STOPS AND POT HOLES.

7. DO NOT BACK UP AT A HIGH RATE OF

SPEED.DAMAGE MAY OCCURE TO THE SYSTEM.

8. WHEN BACKING, SYSTEM DECK HEIGHT MAY

LOWER SLIGHTLY.THIS IS NORMAL.

9. SYSTEM NOT INTENDED FOR PASSENGER USE.

10. MAKE SURE THAT LOADING RAMPS ARE

LOCKED INTO POSITION AND SECURE PRIOR

TO USE.

11. IF USING LOADING RAMPS, REMOVE PRIOR TO

MOVING THE SYSTEM.

12. IF USING THE FAST MASTER LOADING RAMPS

AS SIDE GUARDS, BE SURE THAT THE RAMPS

ARE SECURELY LOCKED INTO PLACE PRIOR

TO MOVING.

13. REPLACEMENT TIRES MUST BE A SIZE 5.70-

8” 6 PLY “C” RATED, 910 LB, HIGHWAY SPEED

TRAILER TIRE. CHECK TIRE PRESSURE

FREQUENTLY. MOST TIRE FAILURES ARE DUE

TO OVER OR UNDER INFLATION. (75 PSI

COLD). CARLISLE SPECIFIES 75 PSI COLD FOR

THIS TIRE. NEVER REDUCE THE TIRE

PRESSURE WITHIN A HOT TIRE. ALWAYS

ALLOW THE TIRE TO COOL FULLY

BEFORE REDUCING ANY TIRE PRESSURE.

14. NEVER REPLACE THE SYSTEM TIRE (“C”) WITH

A LOWER RATED TIRE.

15. COMPLY WITH ALL STATE AND LOCAL

LICENSING AND REGISTRATION LAWS WHERE

APPLICABLE.

16. WHEN USING THE JACK STANDS, THE SYSTEM

MUST BE UNLOADED. DO NOT LEAVE SYSTEM

DETACHED FROM TOW VEHICLE IN THE

LOADED CONFIGURATION.

17. DO NOT EXCEED 65 MPH. THE

MANUFACTURER OF THE TIRE (TOWMASTER)

STATES THAT THE MAXIMUM SPEED FOR A

5.70 X 8”, C-RATED, 6-PLY TIRE IS 65 MPH.

HIGHER SPEEDS COULD INCREASE THE HEAT

GENERATED WITHIN THE TIRE AND COULD

CAUSE TIRE FAILURE.

18. CHECK THE BEARING ASSEMBLY TO THE

SWIVEL WHEEL ASSEMBLY ONCE A YEAR.

CHECK AND TIGHTEN THE WHEEL LUG NUTS

ON A ROUTINE BASIS. SERVICE THE WHEEL

BEARINGS ONCE A YEAR OR EVERY 10,000

MILES.DO NOT DRIVE WITH THE SYSTEM IN

THE FLIPPED UP POSITION.

19. MODIFICATIONS TO THE SWIVELWHEEL

SYSTEM WITHOUT WRITTEN APPROVAL FROM

FAST MASTER PRODUCTS WILL RELEASE FAST

MASTER PRODUCTS FROM ALL LIABILITIES,

AND WILL VOID ALL WARRANTIES.

20. IF PURCHASING THE DW-58 TANDEM TOW OR

THE DW-58 TO CONVERT IT TO THE TANDEM

TOW, IT CAN NOT BE USED BEHIND A

FIFTHWHEEL. SINCE THE TOW BAR WOULD

BE FOR TOWING IT WOULD MAKE IT TRIPPLE

TOWING AT THAT POINT. THE DW-58

TANDEM TOW IS FOR MORTORHOME USE

ONLY.

4

SYSTEM SPECIFICATIONS

TOW VEHICLE:

CLASS “A” DIESEL MOTOR COACH

CLASS “A” GAS MOTOR COACH

CLASS “C” MOTOR COACH

FIFTH WHEEL TRAVEL TRAILER

FULL SIZE PICK-UP

MID TO FULL SIZE SUV’S (EXPIDITION,

TAHOE, SUBURBAN, ETC)

HITCH REQUIREMENTS:

THE SWIVELWHEEL-58DW SYSTEM

REQUIRES THE USE OF DUAL POINT

RECEIVERS FOR OPTIMUM STABILITY.

RECEIVERS ARE SPACED 30” APART

CENTER TO CENTER.

SYSTEM LOAD / WEIGHT LIMITS:

1200 POUNDS

FRAME:

RECTANGULAR TUBULAR STEEL FRAME

DECK DIMENSIONS:

DECK WIDTH = 8’

DECK LENGTH = 5’

DECK HEIGHT:

25¾” TRAILING POSITION (EMPTY / LEVEL

DECK) with 8” wheel assy.

DECK CONSTRUCTION:

¾” TREATED & PAINTED PLYWOOD

AXLE:

TWO TORSION, SWIVEL AXLE

WHEEL / TIRE:

5-SPOKE, WHITE MAG WHEEL (STANDARD)

5.70-8” “C” RATED, 6-PLY, HIGH SPEED

HIGHWAY TRAILER TIRE @ 910 POUNDS

RATING.

LIGHTING:

RUNNING LIGHTS, RT & LT TURN, STOP

LIGHTS, & LICENSE PLATE LIGHTING.

4-WIRE FLAT TRAILER PLUG (STANDARD)

6-WAY ROUND to 4-WIRE FLAT ADAPTER

(OPTIONAL)

7-WAY ROUND to 4-WIRE FLAT ADAPTER

(OPTIONAL)

TIE DOWN POINTS:

VERTICAL POWDER COATED E-TRACK ON

RIGHT AND LEFT DECK SURFACE

A-TRACK TIE-OFF ADAPTERS. (OPTIONAL)

MOTORCYCLE / ATV LOADING RAMPS:

7’-6” LONG x 45” WIDE THREE PIECE.

LATCHES TO THE REAR OF THE SYSTEM.

TOW-VEHICLE MOUNTING:

ONE PERSON, ADJUSTABLE HEIGHT,

PIVOTING MOUNTING HARDWARE.

SYSTEM INCLUDES A DUAL RECEIVER /

ROTATIONAL HITCH ASSEMBLY.

TWO ADDITIONAL RECEIVERS INCLUDED

FOR TOW VEHICLE MOUNTING.

JACK STANDS:

REMOVABLE, JACK STAND PEDESTALS

WITH WHEELS

MAY BE USED TO ROLL SYSTEM TO

STORAGE LOCATION.

MISC. OPTIONAL ACCESSORIES:

MOTORCYCLE FRONT WHEEL CHOCK (NON-

LOCKING) (OPTIONAL)

MOTORCYCLE FRONT WHEEL LOCKING

WHEEL CHOCK (OPTIONAL)

COMPLETE MOTORCYCLE TRAY

POWER WINCH MOUNT W/ 3000 LB

ELECTRIC WINCH FOR PULLING

MOTORCYCLES, ATV’S, AND GOLF CARTS

ONTO THE DECK.

CRUISERRAMP MOTORCYCLE LOADER

SYSTEM

5

ASSEMBLY

Remove the Swivelwheel-58DW system from the

packaging and make sure that all components are

present.

a) 1ea Frame & Deck

b) 2ea Torsion Suspension w/ Lug Nuts at

top spindle and wheel hub

(Make sure that all lug bolts (10ea) have a nut

attached)

c) 2ea Tire & Wheel Assembly

d) 2ea Jack Stand w/ Wheels & Lock Pins

e) 1ea Driver Side Light w/ quick connects

f) 1ea Passenger Side Light w/ quick

connects

g) 2ea Safety Chains w/mounting bolts

h) 1ea Dual Receiver Rotating Hitch

Assembly

i) 2ea Receiver Tubes (To be welded to

tow vehicle)

j) 4ea 5/8” x 3” Hitch Pins w/ Hair Pin

Cotter

k) 1ea Owner’s Manual/Installation

Instructions

Note: The Manufacturers Certificate of Origin

along with your receipt will be mailed to you

the day the system leaves the factory. It is not

sent in the packaging for security reasons.

If you have ordered any options, please make sure

that the options such as Loading Ramps, Wheel

Chocks, etc, are included in the packaging.

1. If available, set the deck on top of saw

horses for ease of system assembly.

2. Remove the right and left rear corners of

the decking from the system to access the

right and left swivel boxes for Torsion

Suspension mounting. An electric drill works

well for this.

3. Remove the lug nuts from the upper swivel

mount on the torsion suspension.

4. With another person helping. insert the

swivel mount lug bolts from the bottom

upward through the swivel box, and install

the lug nuts.

Note: Make sure that the Torsion Tube is

facing toward the center of the trailer as

shown above.

5. Once one lug nut has been installed, the

torsion will stay in position. Insert all

remaining lug nuts and tighten. Torque 90-

110 lbs.

Torsion

Suspension

Tube

Wheel Hub

Lug Nuts

Table of contents

Other Fast Master Products Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction