CAUTIONS & DISCLAIMERS

1. SYSTEM MUST BE UNLOADED AT THE TIME OF

CONNECTING TO AND DISCONNECTING FROM THE

TOW VEHICLE.

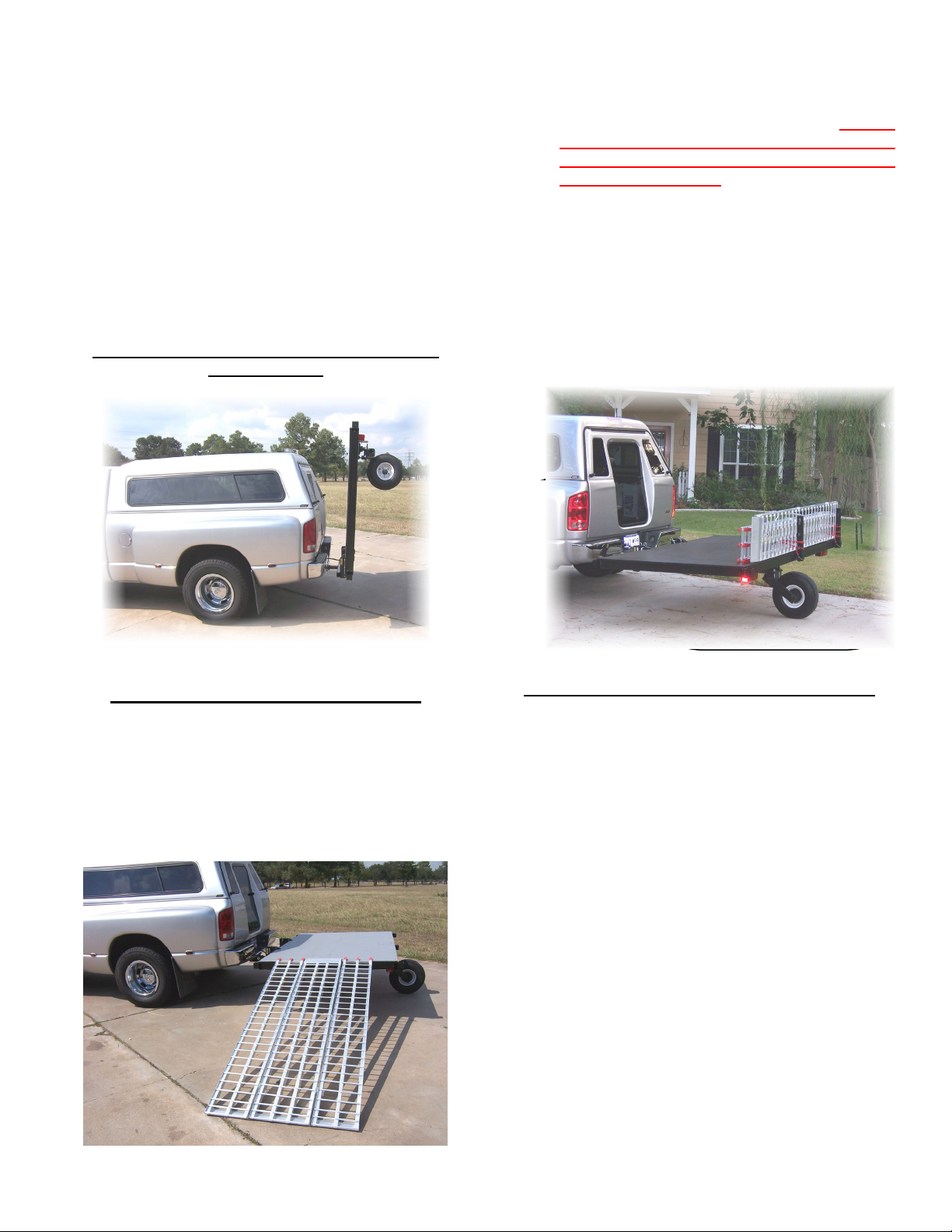

2. THE SWIVELWHEEL-58 SYSTEM IS NOT

INTENDED FOR SHORT-NARROW WHEEL BASE

VEHICLES. USE ONLY WITH FULL SIZE PICK-UPS,

MID TO FULL SIZE SUV’S (EXPIDITION, TAHOE,

ETC), CLASS-A AND CLASS-C MOTOR COACHES, AND

FIFTH WHEEL TRAVEL TRAILERS.

3. WHEN LOADED, THE DECK SHOULD BE LEVEL OR

SLIGHTLY LOWER IN THE FRONT. NEVER PULL THE

SWIVELWHEEL-58 SYSTEM WITH THE REAR DECK

LOWER THAN THE FRONT, OR MORE WEIGHT TO

THE REAR THAN THE FRONT. NEVER LOAD OR

UNLOAD THE SWIVELWHEEL PLATFORM ON AN

INCLINE. ONLY LOAD OR UNLOAD ON LEVEL

GROUND.

4. NEVER DISCONNECT THE SWIVELWHEEL

SYSTEM WHILE PARKED ON AN INCLINE.

ALWAYS CONNECT AND DISCONNECT THE

SYSTEM ON LEVEL GROUND.

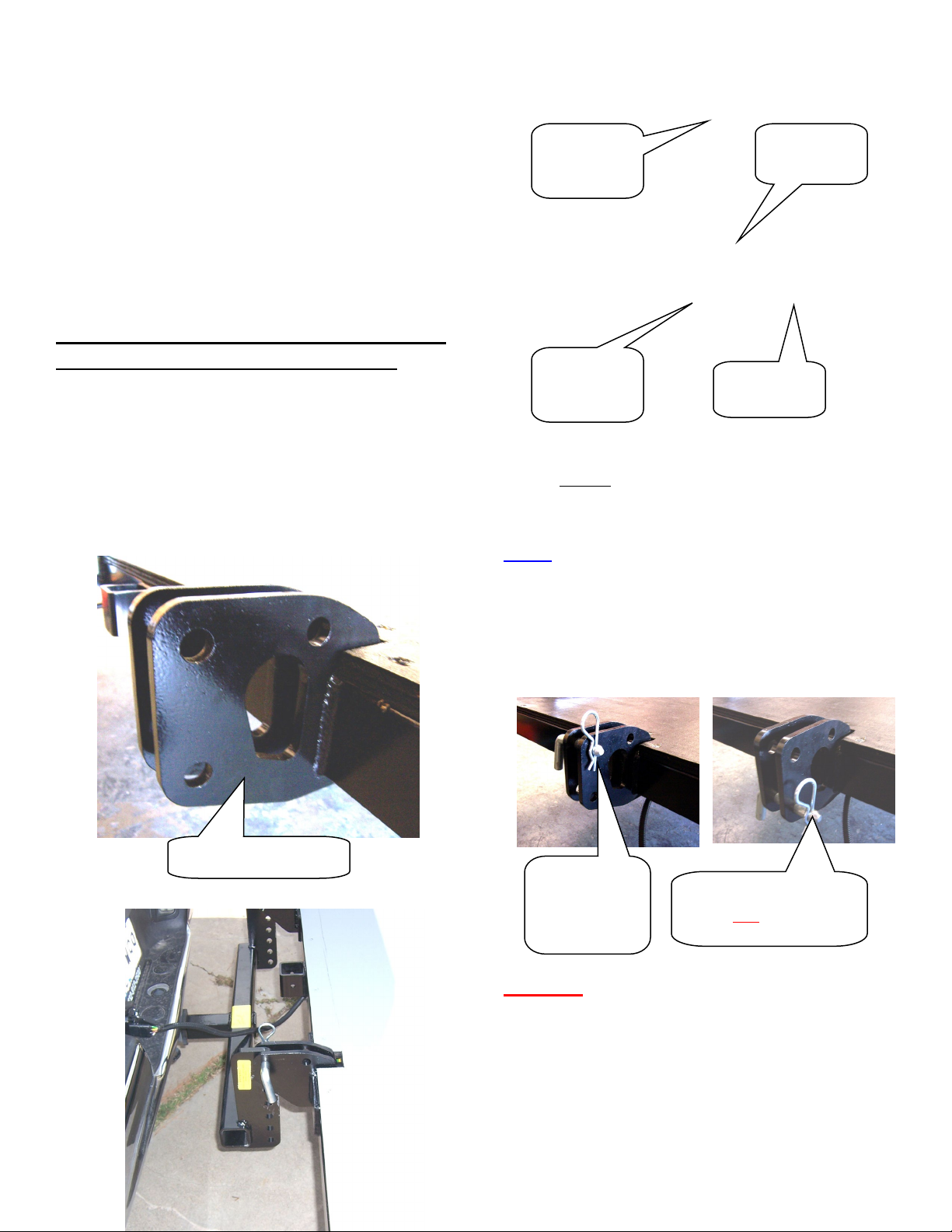

5. BEFORE DISCONNECTING THE SWIVELWHEEL FROM

THE VEHICLE MAKE SURE SUSPENSIONS ARE IN THE

DRIVE POSITION. TO PREVENT THE DECK FROM

FLIPPING.

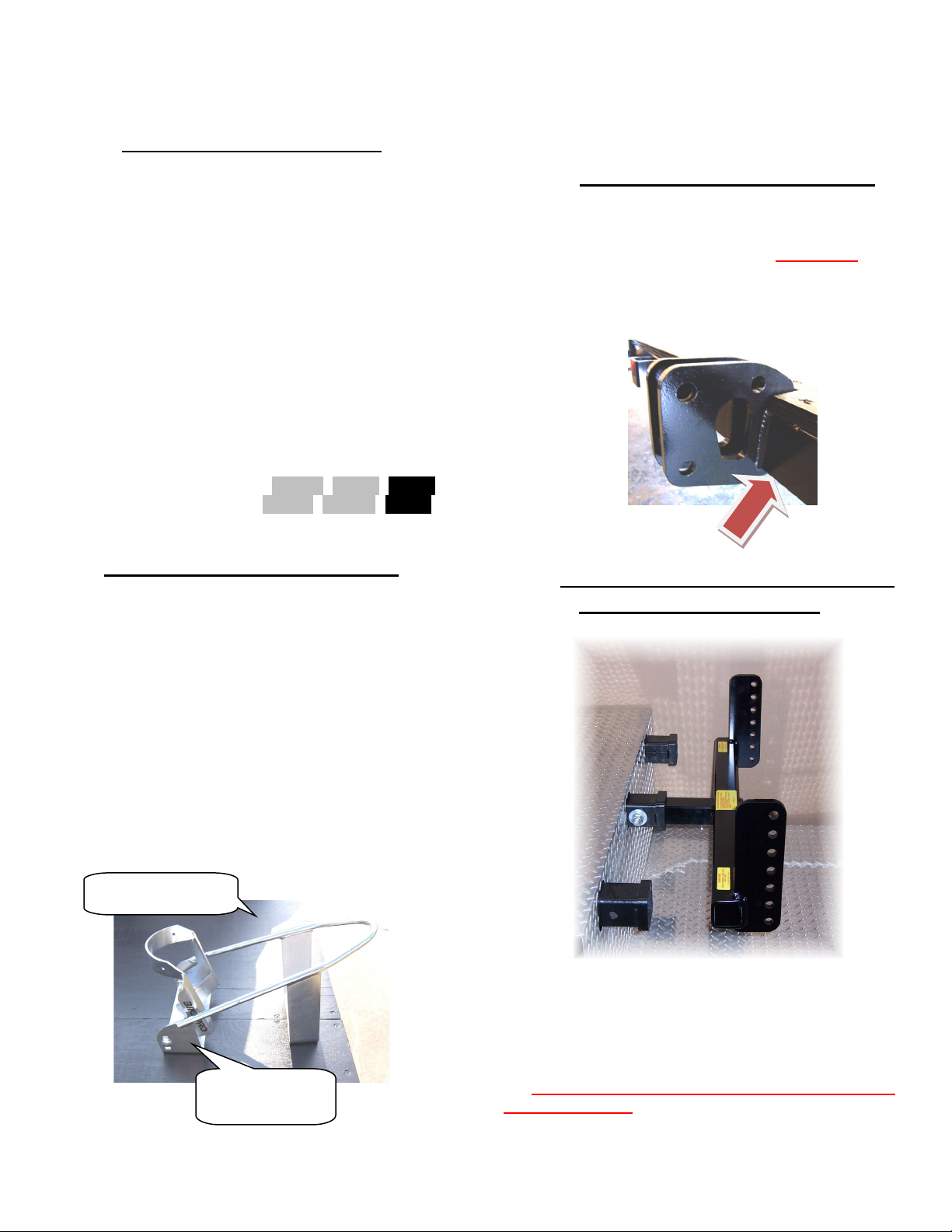

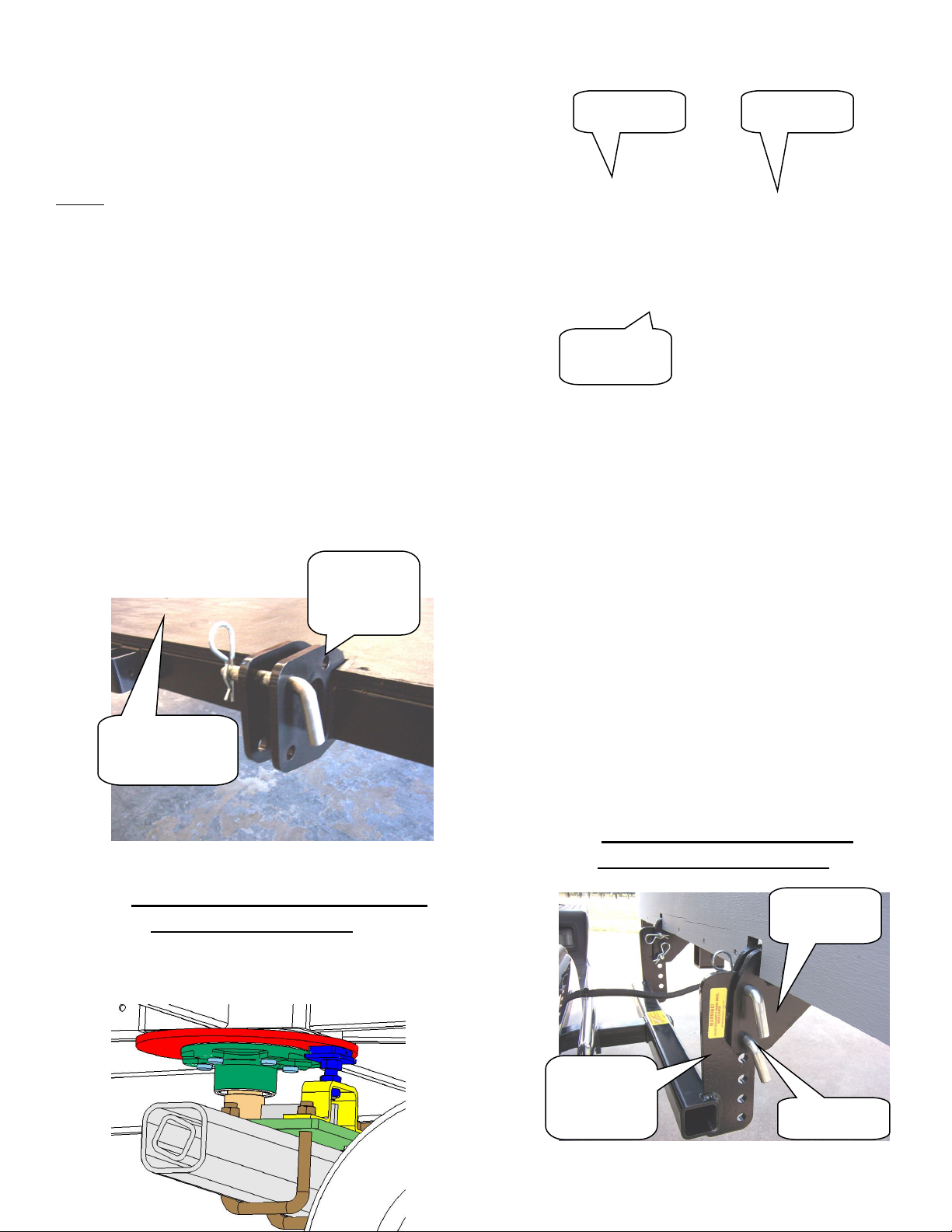

6. BE SURE THAT THE HITCH MOUNTING BOLT HAS

BEEN FULLY TIGHTENED PRIOR TO USE. CHECK THE

MOUNTING BOLT FROM TIME TO TIME FOR

TIGHTNESS

7. IF ATTACHING TO A FIFTH WHEEL TRAILER, DO

NOT EXCEED THE INSTALLED HITCH LOAD RATING.

DO NOT EXCEED THE WEIGHT CAPACITY OF THE

SYSTEM

8. PAYLOAD MUST BE CONFINED TO WITHIN THE

FRAME PERIMETER OF THE SYSTEM.

9. WHEN BACKING THE SYSTEM UP, BE AWARE OF

CURBS, PARKING STOPS AND POT HOLES.

10. DO NOT BACK UP AT A HIGH RATE OF

SPEED.DAMAGE MAY OCCURE TO THE SYSTEM.

11. WHEN BACKING, SYSTEM DECK HEIGHT MAY LOWER

SLIGHTLY.THIS IS NORMAL.

12. SYSTEM NOT INTENDED FOR PASSENGER USE.

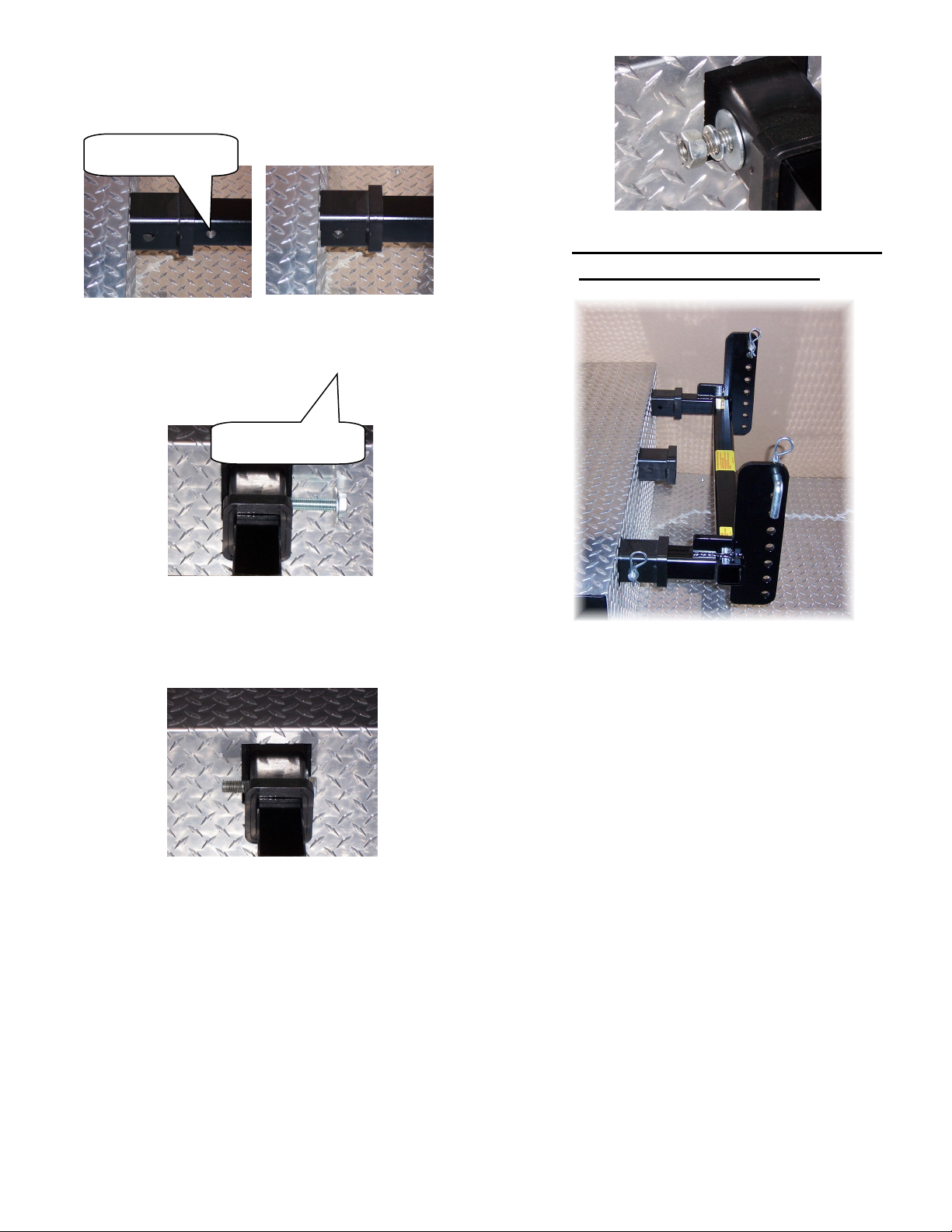

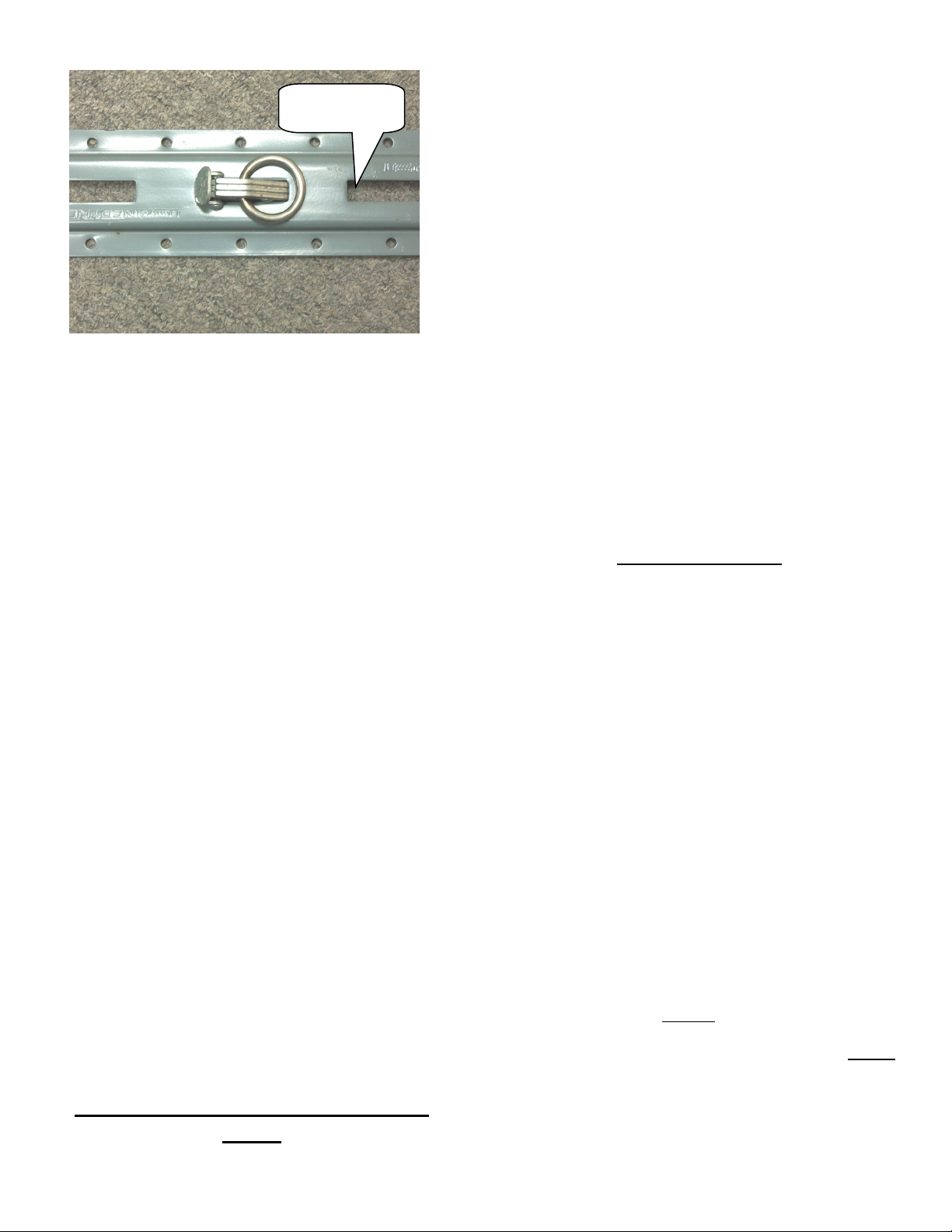

13. MAKE SURE THAT LOADING RAMPS ARE LOCKED

INTO POSITION AND SECURE PRIOR TO USE.

14. IF USING LOADING RAMPS, REMOVE PRIOR TO

MOVING THE SYSTEM.

15. IF USING THE FAST MASTER LOADING RAMPS AS

SIDE GUARDS, BE SURE THAT THE RAMPS ARE

SECURELY LOCKED INTO PLACE PRIOR TO

MOVING.

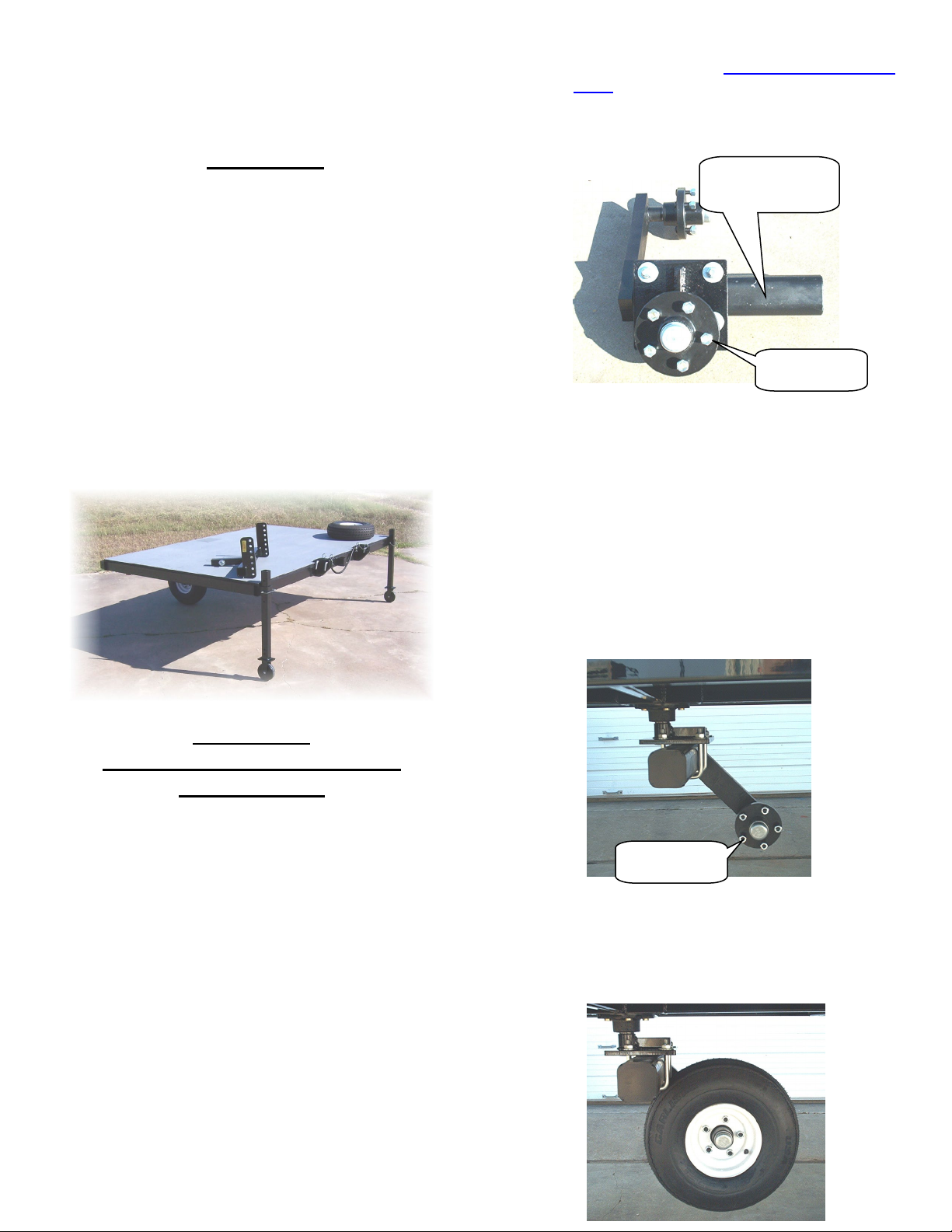

16. REPLACEMENT TIRES MUST BE A SIZE 5.70-8, “D”

RATED, 1075 LB, HIGHWAY SPEED TRAILER TIRE.

CHECK TIRE PRESSURE FREQUENTLY. MOST TIRE

FAILURES ARE DUE TO OVER OR UNDER

INFLATION. (100 PSI COLD). CARLISLE SPECIFIES

100 PSI COLD FOR THIS TIRE. NEVER REDUCE

THE TIRE PRESSURE WITHIN A HOT TIRE.

ALWAYS ALLOW THE TIRE TO COOL FULLY

BEFORE REDUCING ANY TIRE PRESSURE.

17. NEVER REPLACE THE SYSTEM TIRE WITH A

LOWER RATED TIRE.

18. COMPLY WITH ALL STATE AND LOCAL LICENSING

AND REGISTRATION LAWS WHERE APPLICABLE.

19. IF DIAMOND PLATE ORDERED WITH SYSTEM, BE

AWARE THAT THE DIAMOND PLATE MAY BE

SLIPPERY WHEN WET.

20. WHEN USING THE JACK STANDS, THE SYSTEM

MUST BE UNLOADED. DO NOT LEAVE SYSTEM

DETACHED FROM TOW VEHICLE IN THE LOADED

CONFIGURATION.

21. DO NOT EXCEED 65 MPH. THE MANUFACTURER

OF THE TIRE (CARLISLE) STATES THAT THE

MAXIMUM SPEED FOR A 5.70 X 8”, D-RATED, 8-

PLY TIRE IS 65 MPH. HIGHER SPEEDS COULD

INCREASE THE HEAT GENERATED WITHIN THE

TIRE AND COULD CAUSE TIRE FAILURE.

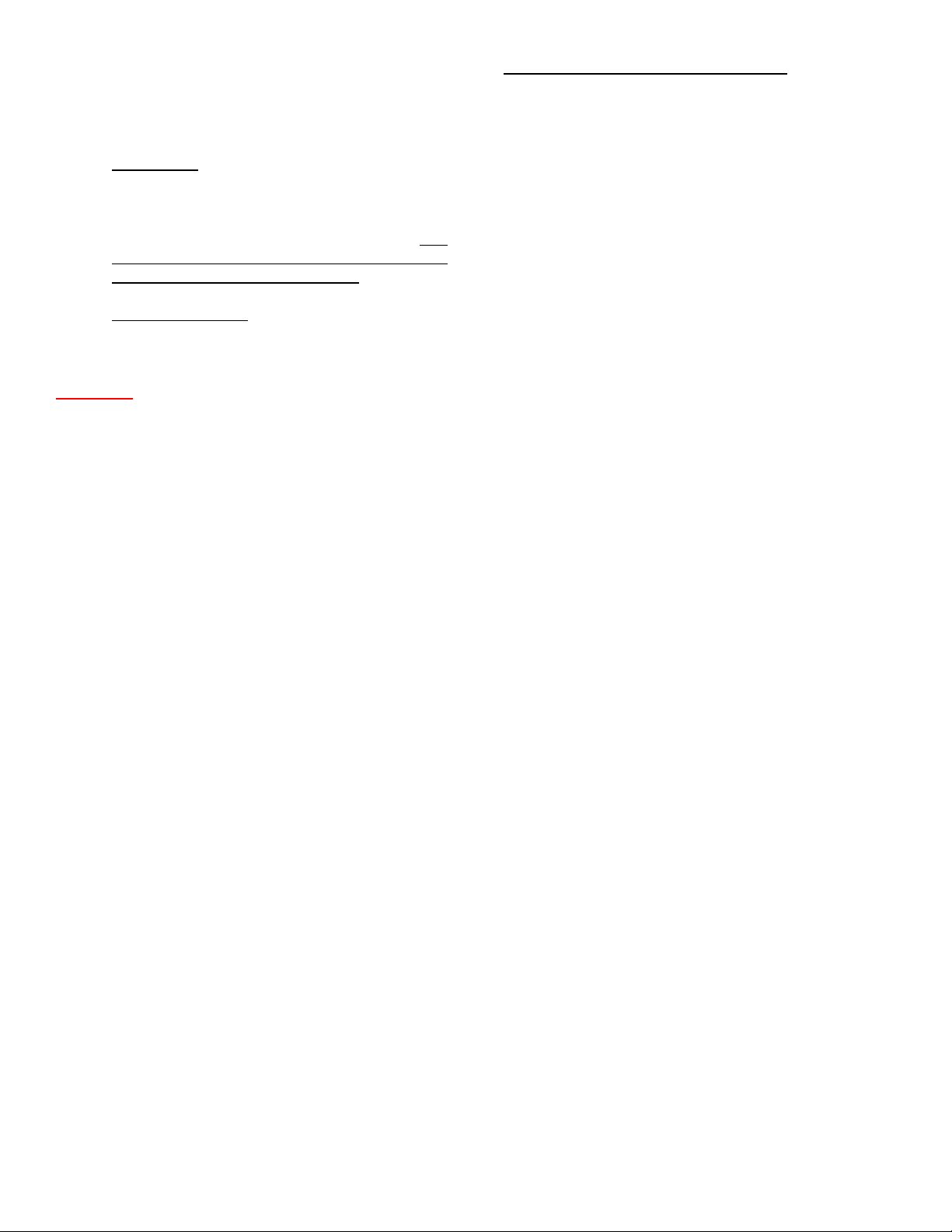

22. CHECK THE BEARING ASSEMBLY TO THE SWIVEL

WHEEL ASSEMBLY ONCE A YEAR. CHECK AND

TIGHTEN THE WHEEL LUG NUTS ON A ROUTINE

BASIS. SERVICE THE WHEEL BEARINGS ONCE A

YEAR OR EVERY 10,000 MILES.DO NOT DRIVE

WITH THE SYSTEM IN THE FLIPPED UP POSITION.

23. MODIFICATIONS TO THE SWIVELWHEEL SYSTEM

WITHOUT WRITTEN APPROVAL FROM FAST

MASTER PRODUCTS WILL RELEASE FAST MASTER

PRODUCTS FROM ALL LIABILITIES, AND WILL

VOID ALL WARRANTIES.

24. THE SWIVELWHEEL-58 SYSTEM WAS NOT

DESIGNED FOR TOWING BEHIND “LITE”

CONFIGURATION TRAILERS SUCH AS BELOW 30

FEET IN LENGTH AND UNDER 10,000 POUNDS

GVWR.