Fast SINGLE SENSOR KIT User manual

1

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

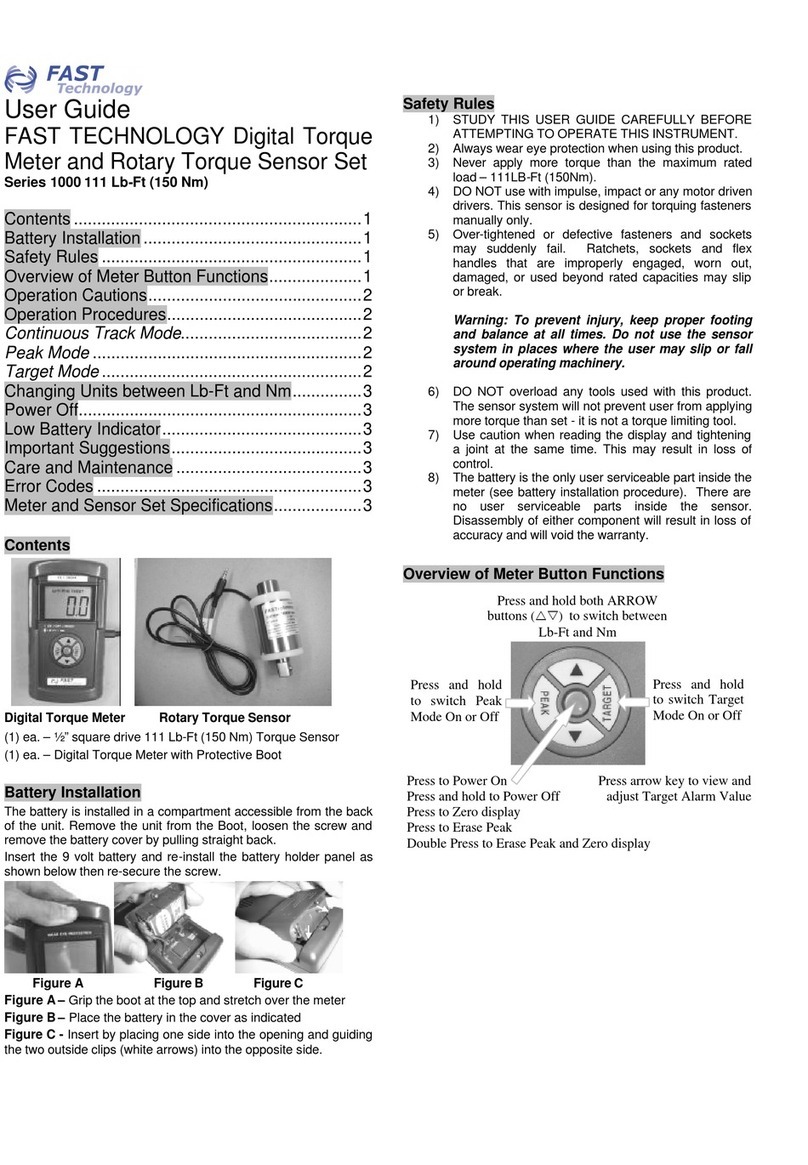

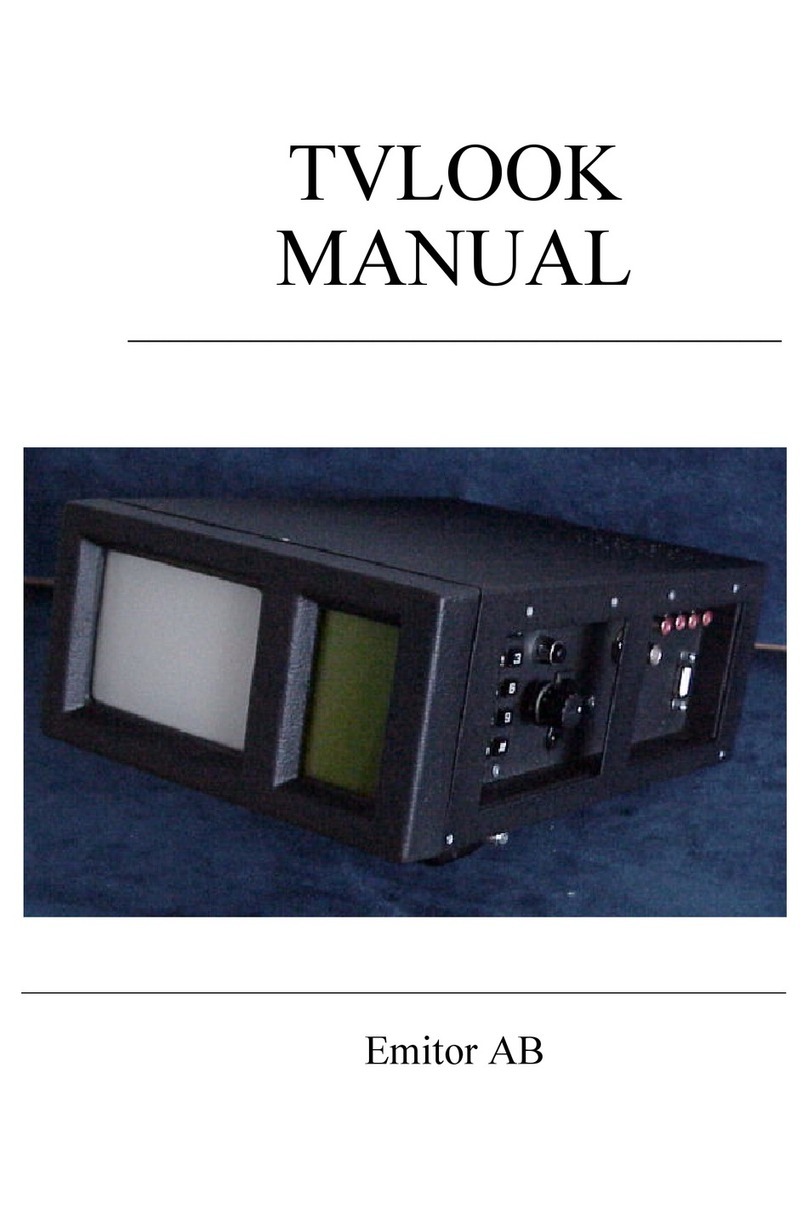

FAST™ Air/Fuel Meter

Thank you for choosing FAST™ products; we are proud to be your manufacturer of choice. Please

read this instruction sheet carefully before beginning installation, and also take a moment to review the

included limited warranty information.

Warning: Read these instructions completely before attempting to tune with your FAST™

Air/Fuel Meter. Failure to do so may result in damage to your engine and/or vehicle. FAST™ is

not responsible for damage or injuries caused by improper use of this unit.

Kit Parts List

INSTRUCTIONS

SINGLE SENSOR KIT QTY.

Air/fuel meter 1

12 ft. sensor/power cable 1

6 ft. plug-in power cable 1

O2sensor 1

Weld-in threaded sensor bushing 1

Sensor bushin

g

p

lu

g

1

DUAL SENSOR KIT QTY.

Air/fuel meter 1

12 ft. sensor/power cable 1

12 ft. sensor only cable 1

6 ft. plug-in power cable 1

O2sensor 2

Weld-in threaded sensor bushing 2

Sensor bushing plug 2

2

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

What makes the FAST™ Air/Fuel Meter work so well:

•Our single or dual oxygen sensor kits give you accurate air/fuel ratios for tuning your engine to

perfection.

•Single sensor version that can be upgraded later to the two sensor technology. Simply purchase

an additional cable and sensor, plug it in, and the air/fuel meter is ready to go!

•With the FAST™ Air/Fuel Meter, you can read two sensors individually or have them averaged

together for super accurate readings of the engine’s true air/fuel ratio.

•Simple, built-in data-logger doesn’t require you to download to a laptop/computer.

•Advanced features include outputs for external data-loggers, digital gauges, as well as a

narrow-band simulator function that allows you to feed your engine’s computer a factory signal

while using the wide-band sensor for air/fuel measurement.

Quick Start Reference Guide:

O2sensor location: For maximum accuracy, install the oxygen sensor just upstream of the catalytic

converter. You can install the sensor after the converter, but the readings will register slightly leaner

than if measured before the converter. Do not install the oxygen sensor in the 6 o’clock position in the

exhaust pipe. If this is done, condensation may puddle in the sensor, causing corrosion and damage to

the sensor. Do not install the O2sensor closer than 20 inches from the cylinder head flange, the excess

heat can cause damage to the sensor. It is preferred that the sensor be installed in or after the collector

area.

Use of leaded fuel: The use of leaded fuel will significantly reduce the lifespan of the oxygen sensor.

Depending on the leaded fuel that is used, the sensor will provide 50-500 hours of accurate reading.

When the sensor begins to read inaccurately, simply replacing the sensor with a new one will return the

air/fuel meter to perfect operating condition.

Un-powered sensor: When an engine is running and the sensor or sensors are installed in exhaust

pipe, for maximum sensor life, it is advisable to be in the active air/fuel display mode. When in the

active air/fuel display mode, power is applied to the heating element of the oxygen sensor, and this

helps to reduce the build-up of exhaust deposits on it. If the sensor is not powered-up, exhaust deposits

may build-up on the sensor element and reduce its accurate life expectancy.

Stand-by power consumption: When the FAST™ Air/Fuel Meter is powered down, a small amount

of current is required to maintain its standby. If the unit is in a vehicle that will not be run in the next

15 days, it is recommended to simply unplug the unit from the cigarette lighter.

Installation Instructions:

1. Install threaded sensor bushing. For maximum accuracy, install the oxygen sensor just

upstream of the catalytic converter. You can install the sensor after the converter, but the

readings will register slightly leaner than if measured before the converter. Do not install the

oxygen sensor in the 6 o’clock position in the exhaust pipe. If this is done, condensation may

puddle in the sensor, causing corrosion and damage to the sensor. Mark the spot where you

would like to install the threaded sensor bushing, drill a .750 diameter hole, and weld the

bushing centered on the hole. If you do not have access to a welder, any competent exhaust

3

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

shop can install the threaded bushing for you. It is still advisable to locate where you would like

the sensor mounted, mark it, then let the shop drill the hole and weld the bushing in place.

2. Run sensor cable to interior of vehicle. Attach the cable’s sensor connector to the oxygen

sensor and then route the cable to the interior of the vehicle.

3. Connect cable to power and display. Plug in the cigarette lighter power adaptor and connect

it to the sensor cable. Plug in the sensor cable to the side of the display housing. The unit

should automatically power-up at this point.

4. Follow the on-screen menu options. Select the sensor options, wait for the unit to warm-up,

and then read your air/fuel ratio. There are several sensor options to choose from. Single sensor

mode will measure only one sensor. Dual sensor mode will measure two sensors. In dual sensor

mode you can read these sensors individually (Fig. A) or as a combined average.

Operational Features & Descriptions

Data Logging:

1. In any live air/fuel display screen, you may press the up-arrow button (the button next to the L

on the display screen) to begin recording your air/fuel ratio (Fig. A). When pressed, the L will

begin to flash, indicating that you are now recording. The FAST™ Air/Fuel Meter contains

enough memory to record up to 50 minutes of data in single sensor mode and up to 25 minutes

in the dual sensor mode. When you are finished recording, simply press the up-arrow button

(L) again. The L will stop flashing and your data log is saved. If you press the up-arrow button

(L) again, the old log is erased and a new log will be created.

Fig. B

Analog Signal Output

Wire (GREY)

Signal Ground Wire

(BLACK)

Fig. A

The “up-arrow” button next to the “L” starts

the data logger recording the air/fuel data

The “down-arrow” button next to the “P”

starts the data logger playback mode

4

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

2. To review the data log in real-time play back, simply press the down-arrow button (the button

next to the P on the display screen) (Fig. A). The log will load, the P will begin flashing, and

the data log will immediately begin its play back. At any time you can pause the playback by

pressing the down arrow (P) button. By pressing it again, you will resume playback from the

point you originally paused it at. When the log is finished playing, it will prompt you to decide

if you want to replay again. If you select no, you will be put back into the live air/fuel screen.

If you select yes, it will reload the log and begin playback again.

Advanced Options:

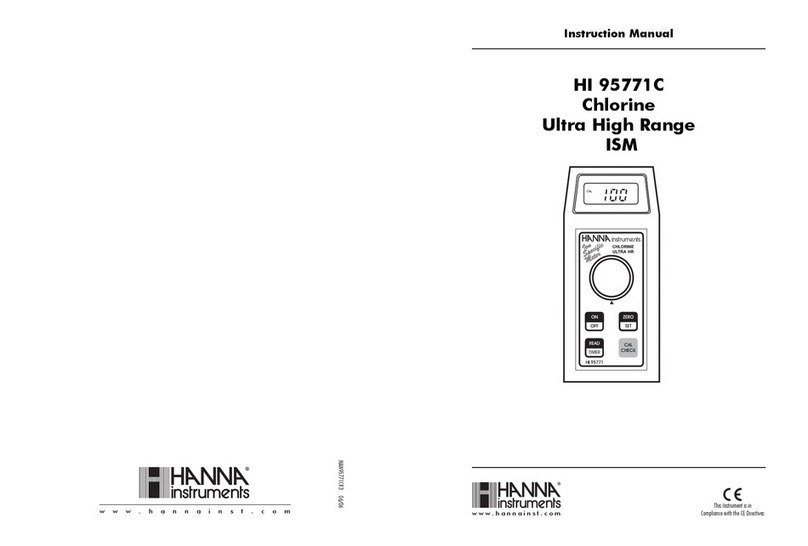

•Fuel Type: Gasoline and alcohol (i.e. methanol) fuel calibrations can be selected, depending

on the type of fuel you chose to run. Once this is selected, it will become the default value

when the unit is powered up. You can go back later and change the fuel type at any time.

•Analog Output Mode: When reading air/fuel in this mode, an additional analog signal output

is provided that will run most external, electronic air/fuel gauges and/or feed an external data

logger (Fig. B). This signal is sent via two wires that are factory contained under the connector

heat-shrink wrap at the display housing end of the wiring harness (Fig. B). Simply cut the

shrink wrap back and pull out the black and grey wires. The black wire is the signal ground

wire and the grey wire is the analog signal output wire.

•Simple Mode: This takes the output voltage and multiplies it by 10 to calculate the actual

air/fuel ratio. Many external electronic air/fuel gauges use this signal type.

•High Res Mode: This provides a 0 - 4.096 volt output signal. Certain digital gauges and data

acquisition systems use this type of signal.

•Narrow Band Simulator Mode: This provides a narrow band output signal that simulates

many OEM style air/fuel sensors. This will allow you to use the wide-band style sensor the

FAST™ Air/Fuel Meter uses not only to serve the air/fuel meter, but to also run the engine’s

computer. This mode is compatible only with pre-OBDII vehicles.

Tuning Advice

Air/fuel ratio requirements vary greatly from application to application, but some generalities can be

found to get a tuner “in-the-ballpark” when tuning an engine. Below is a graphical chart that represents

the normal operating environment for most engines using gasoline for fuel. The left side vertical

column reads boost pressure or vacuum in the engine’s manifold. The horizontal bottom row is the

engine’s rpm. For those running methanol, the proper air fuel ratio changes dramatically. At part

throttle cruising and idle, the proper air/fuel ratio is around 6.4 to 1. At wide open throttle, an air/fuel

ratio of 5.5 to 1 is a good starting point for maximum power production.

5

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

GASOLINE Tuning Chart

RPM

RPM

6

Part #170450

Revised 3/08/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

Limited Warranty

FAST, Inc. warrants that all of its products are free from defects in material and workmanship for a

period of 1 year from the date of purchase. This limited warranty shall cover the original purchaser.

FAST, Inc.’s obligation under this warranty is limited to the repair or replacement of its product. To

make a warranty claim, the part must be returned within 1 year of purchase to the address listed below,

freight prepaid. Items covered under warranty will be returned to you freight collect. It is the

responsibility of the installer to ensure that all of the components are correct before installation. We

assume no liability for any errors made in tolerances, component selection, or installation.

There is absolutely no warranty on the following:

•Any parts used in racing applications.

•Any product that has been physically altered, improperly installed or maintained.

•Any product used in improper applications, abused, or not used in conjunction with the proper

parts.

•Damage due to excessive manifold pressure, i.e. nitrous backfires, engine misfire, etc.

There are no implied warranties of merchantability or fitness for a particular purpose. There are

no warranties, which extend beyond the description of the face hereof. FAST, Inc. will not be

responsible for incidental and consequential damages, property damage or personal injury damages to

the extent permitted by law. Where required by law, implied warranties or merchantability and fitness

are limited to a term of 1 year from the date of original purchase.

This warranty gives you specific legal rights and you may also have other legal rights, which vary from

state to state.

This manual suits for next models

1

Other Fast Measuring Instrument manuals