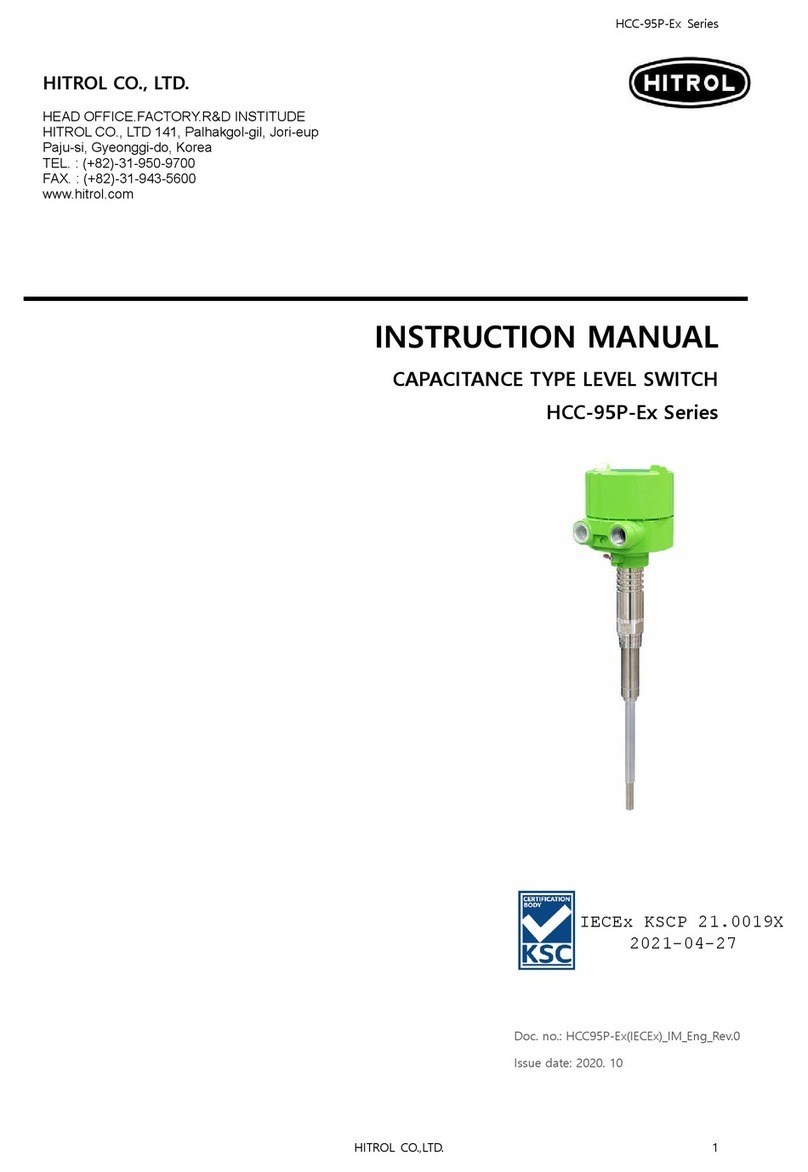

HITROL HR-10L User manual

HITROL CO., LTD.

HEAD OFFICE.FACTORY.R&D INSTITUDE

HITROL CO.,LTD 141, Palhakgol-

road, Jori

Paju-si, Gyeonggi-do, Korea

TEL. : (00)-82-31-950-9700

FAX. : (00)-82-31-943-5600

www.hitrol.com

HITROL CO.,

LTD.

HEAD OFFICE.FACTORY.R&D INSTITUDE

road, Jori

-eup

INSTRUCTION

Level Switch

for Magnet Float Type Level Gauge

Doc. no.

: H

Issue

date : 20

HR-10L Series

LTD.

1

INSTRUCTION

MANUAL

for Magnet Float Type Level Gauge

HR-10L Series

: H

R10L_IM_Eng_Rev.0

date : 20

20. 06

HR-10L Series

HITROL CO., LTD. 2

Table of contents

Overview and Features · · · · · · · · · · · · · · · · · · · · 3

Operating and Composition · · · · · · · · · · · · · · · · 3

Specification · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

Wiring · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 5

Dimension · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · 6

Maintenance · · · · · · · · · · · · · · · · · · · · · · · · · · · · 6

Precaution for Transportation, Assembly and

Installation· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Safety and Environment · · · · · · · · · · · · · · · · · · · 7

Marking · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

User Training · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 8

Warranty and Contact· · · · · · · · · · · · · · · · · · · · · · · 8

Overview

and Feature

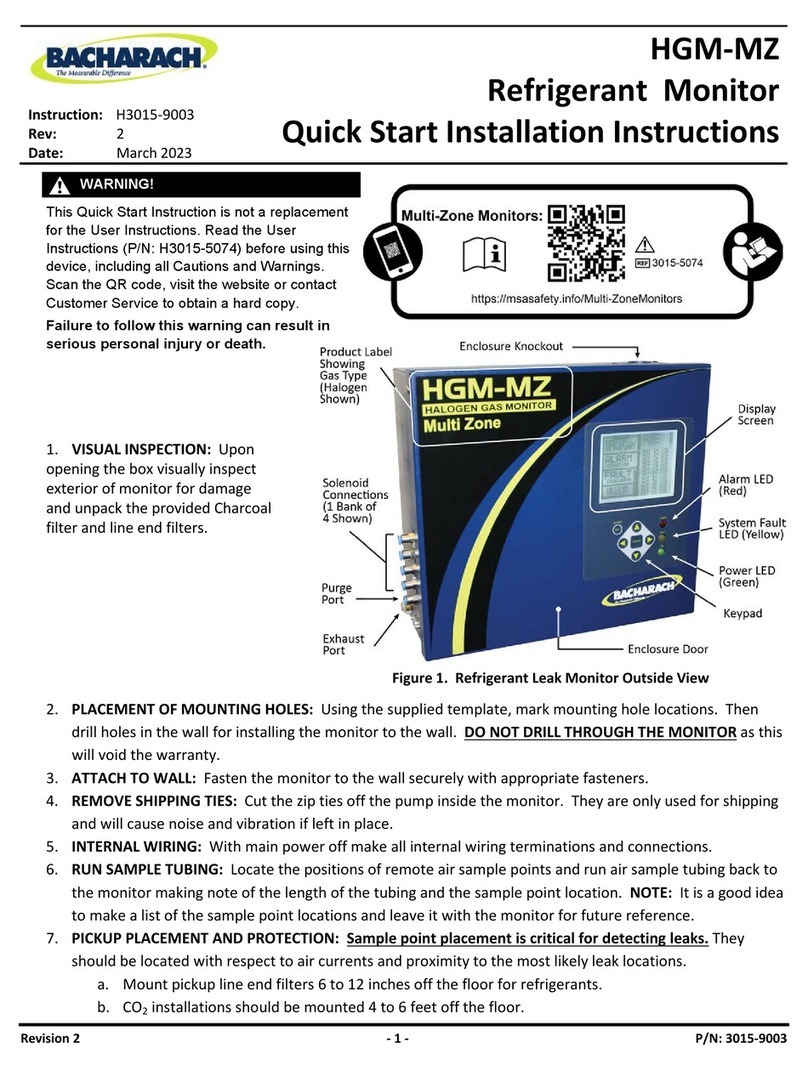

The HR-

10L (Ex) Series attaches to its Level Gauge (HLG

inside the various containers (tank).

alarms and controls in water

Operating

and

Composition

The F

loat rises or falls wh

If a magnet in the

Chamber

within the Level Gauge, the contact point becomes On/Off.

Using this principle,

automatic supply pump of liquid,

supply the liquid

TANK

HITROL CO.,

LTD.

10L (Ex) Series attaches to its Level Gauge (HLG

-

100F) to detect the

inside the various containers (tank).

It is used for processes that perform the function of

alarms and controls in water

supply or drainage.

loat rises or falls wh

en the liquid level inside the Level G

auge rises or falls.

If a magnet in the

Float passes the contact point of the Re

ed Switch inserted into the

within the Level Gauge, the contact point becomes On/Off.

Using this principle,

the wiring with the Control Unit can be used to prevent idle of the

automatic supply pump of liquid,

to alarm

the upper and lower level

supply the liquid

automatically, and to drain the liquid automatically

.

TANK

HR-10L Series

LTD.

3

100F) to detect the

liquid level

It is used for processes that perform the function of

auge rises or falls.

ed Switch inserted into the

within the Level Gauge, the contact point becomes On/Off.

the wiring with the Control Unit can be used to prevent idle of the

the upper and lower level

of the liquid, to

.

LEVEL GAUGE

HLG-100F

LEVEL SWITCH

HR-10L

MAGNET FLOAT

HR-10L Series

HITROL CO., LTD. 4

Specification Weather-Proof

Model HR-10L

Type Level Switch

Mounting With HLG-100F Band Fasten

Ambient Temperature -20°C ~ +60°C

Enclosure Weather-Proof (IP65)

Material

Head PA66 AL.C

Body Duralumin

Switch Type Reed Switch

Max. Switching Voltage 24 VDC

Switch Form SPDT

Cable Entry PG 7 PF 1/2”(F)

Ex-Proof

Model HR-10L-Ex

Type Level Switch

Mounting With HLG-100F Band Fasten

Ambient Temperature -20°C ~ +60°C

Enclosure Ex-Proof (Ex d IIC T6,IP65)

Material

Head AL.C

Body Duralumin

Switch Type Reed Switch

Max. Switching Voltage 24 VDC

Switch Form SPDT

Cable Entry PF 3/4” (F)

Contact Rating

Max. Switching voltage Max. Switching current Contact rating

Capacity(VA)

220VAC/24VDC 0.5A / 0.5A 40W / 10W

Wiring The

terminals of the products are

connected

as follo

<Weather-

Proof>

1 : High

2 : Low

3 : C

om

G : Ground

<Ex-Proof>

*

Grounding of

HITROL CO.,

LTD.

terminals of the products are

composed according to contact points and shall be

as follo

w.

Proof>

1 : High

A : High

B : Low

om

C : Com

Red : High

Black : Low

White : Com

: Ground

Grounding of

Ex-proof products is in external and internal.

HR-10L Series

LTD.

5

composed according to contact points and shall be

HR-10L Series

HITROL CO., LTD. 6

Dimension <Weather-Proof>

PA66 HEAD Aluminum HEAD

<Ex-Proof>

Maintenance ■ Inspection of products

The main inspection part of the HR-10L (Ex) series is Reed S/W.

The life span of the main components depends on the environment and can be used in

optimal condition through periodic checks. Therefore, users should perform maintenance

through regular inspections at least once a year. Using a Digital Multimeter, the inspection can

be carried out simply as follows.

- Select the buzzer of the Digital Multimeter and connect it to the N.O. and Com

terminals of the product.

- It is normal when the buzzer sounds at the point of contact by moving the magnet

up and down at the body of HR-10L.

HR-10L Series

HITROL CO., LTD. 7

- If checking contact status with resistance, the Digital Multimeter represents 0 ohms

when it represents a normal close (NC) and displays infinite when it is normal open

(NO).

■ Precautions for Installation

- If there is explosive gas atmosphere, do not open the cover.

- Unlock the lock key (Set screw) before removing the cover. (Ex-proof)

Precaution for

Transportation,

Assembly

and

Installation

■ Precaution for Installation

- As it is assembled and shipped to a level gauge (HLG-100F), no special

precautions are required for installation.

- Do not shock the product when transporting or dismantling it.

■ Precaution for Inserted External Wire (IP65)

- Use the cable gland connection or metal pipe line lead-in in the wire inlet.

- Use a product with equivalent Ex-proof certificate to connect it with the

external line lead-in method.

- For Non-use external wire inlet, use a close plug that passes safety certificate

above equivalent performance with the product.

■ Precaution for Grounding

- The grounding has an external and an internal grounding. When connection to

an external ground, the ground wire shall be 4mm2 (4mmSQ).

- The internal grounding wire shall be the same size as the power line, and the

size of the internal grounding terminal lug shall be 3.1mm2 (3.1mmSQ). If the

power line is larger than 3.1mm2, connect the ground wire without terminal lug.

<Warning> Make sure to insert a washer if the terminal lug is removed from

ground terminal and then re-connected.

Safety and

Environment

■ Caution for Use

- Make sure to connect the product and the container using the required tools.

- Keep the lock key safe and make sure that it is locked.

- Do not cause high impact to the product.

■ Cautions for Wiring

- Make sure to wire contacts correctly (Refer to Wiring)

- Internal ground (inside product housing) and external ground shall be

connected.

■ Disposal

- M

ake sure to separate the AMP and main unit from the housing before

disposing the product. No part has an influence

attention is not required (e.g., mercury switch).

Marking

The label stating the model, serial

output is attached on the housing. The serial number is a unique manufacturing

number.

<

Weather

User Training

T

emperature of the medium in the tank should not exceed the maximum temperature

described at

the specification

be over -

20 ~ +60

Ex-

proof type of product is certified as pressure

the cover of product if explosive gas atmosphere exists.

Do not apply the Non Ex

The Ex-

proof product can be used where the envir

containers

are of Zone 1 and Zone 2.

Warranty

and Contact

Warranty

of the

malfunction occurred under use in normal condition, but it can be charged regardless

of warranty period in case that after sales service is requested not for malfunction of

product.

T

he After sales ser

Headquarter

Address :

141,

Tel.

: 031

Fax.

: 031

Website

: http://www.hitrol.c

HITROL CO.,

LTD.

ake sure to separate the AMP and main unit from the housing before

disposing the product. No part has an influence

on the

environment

attention is not required (e.g., mercury switch).

The label stating the model, serial

number

working temperature, working pressure, and

output is attached on the housing. The serial number is a unique manufacturing

Weather

-proof> <Explosion-

p

emperature of the medium in the tank should not exceed the maximum temperature

the specification

. And also, ambient temperature around product

20 ~ +60

℃.

proof type of product is certified as pressure

-

resistant. So, it is not allowed to open

the cover of product if explosive gas atmosphere exists.

Do not apply the Non Ex

-proof product in an Ex-proof zone.

proof product can be used where the envir

onment and liquid inside the

are of Zone 1 and Zone 2.

of the

product

is 2 years after shipment and it can be warranted for

malfunction occurred under use in normal condition, but it can be charged regardless

of warranty period in case that after sales service is requested not for malfunction of

he After sales ser

vice can be requested through our website or headquarter.

Headquarter

· Factory · R&D Contact Number

141,

Palhakgol-gil-road, Jori-eup, Paju-si, Gyeonggi-

do, Korea

: 031

-950-9700

: 031

-943-5600

: http://www.hitrol.c

om

HR-10L Series

LTD.

8

ake sure to separate the AMP and main unit from the housing before

environment

, so special

working temperature, working pressure, and

output is attached on the housing. The serial number is a unique manufacturing

p

roof>

emperature of the medium in the tank should not exceed the maximum temperature

. And also, ambient temperature around product

should not

resistant. So, it is not allowed to open

onment and liquid inside the

is 2 years after shipment and it can be warranted for

malfunction occurred under use in normal condition, but it can be charged regardless

of warranty period in case that after sales service is requested not for malfunction of

vice can be requested through our website or headquarter.

do, Korea

This manual suits for next models

1

Table of contents

Other HITROL Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics J353B33 Installation and operating manual

Extech Instruments

Extech Instruments MA610 user manual

Alpha

Alpha Dickson KT8P0 quick start

evertz

evertz HD9010TM instruction manual

Bacharach

Bacharach HGM-MZ Quickstart installation instructions

Banner

Banner A-GAGE EZ-ARRAY instruction manual

Pepperl+Fuchs

Pepperl+Fuchs PMI360DV-F130-IU2E2-V15 manual

Merck

Merck Spectroquant Prove 100 quick guide

Sedanamedical

Sedanamedical AMG-06 user manual

Campbell

Campbell CNR4 instruction manual

Delta Electronics

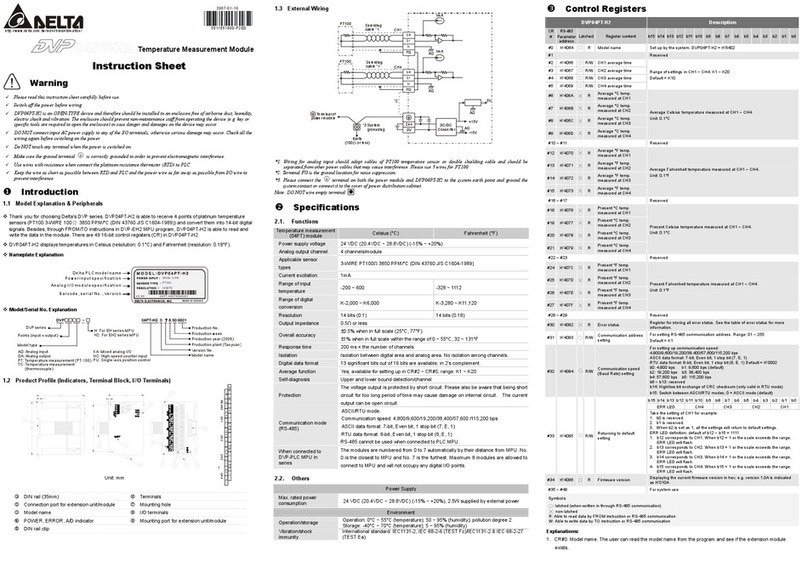

Delta Electronics Temperature Measurement Module DVP04PT-H2 instruction sheet

KMC Controls

KMC Controls 2000-2 Operation guide