Fast Lokal 400 User manual

Lokal 400Operating Manual Page 1

Lokal 400

Operating Manual

Lokal 400Operating Manual Page 2

Contents

1. Safetyinstructions..................................................................................................................................3

2. Intendeduse...........................................................................................................................................3

3. Scopeofdeliveryandaccessories.......................................................................................................4

4. Controlelements....................................................................................................................................5

5. Poweringupandoperatingthedevice.................................................................................................6

5.1 Powering upforcorrelation...........................................................................................................6

5.2. Poweringupforelectroacousticlistening.....................................................................................7

6. Controlandmenustructure...................................................................................................................8

6.1. Control............................................................................................................................................8

6.2 Mainmenu.....................................................................................................................................8

6.3 Settings..........................................................................................................................................9

7.1 Automaticmeasurement.............................................................................................................12

7.2 Manualmeasurement.................................................................................................................13

7.3. Settingoptionsforcorrelation(correlationmainwindow)..........................................................14

7.4Receivingradiodata..........................................................................................................................17

7.5.Transautofunction............................................................................................................................17

8. Acousticleakagedetection..................................................................................................................19

8.1 Settingtheacousticparameters................................................................................................19

8.2 Measurementmodes..................................................................................................................21

8.3. Deletingthecurrentmeasurementseries..................................................................................23

8.4. Filtersetting..................................................................................................................................23

8.5. Savinganduploadingmeasurementseries..............................................................................24

9. ConnectiontheLOKAL400devicewithaPC...................................................................................25

10. Chargingthedevice.........................................................................................................................25

11. Troubleshooting...............................................................................................................................26

12. Cleaning,maintenance,andtransport............................................................................................28

Lokal 400Operating Manual Page 3

This measuring device has been designed in line with latest technological advancements and

meets all relevant requirements of the applicable European and national guidelines.

Conformity has been proved, and the corresponding declarations and documentation have

been filed with the manufacturer. In order to maintain full compliance with above stated

guidelines and to guarantee safe operation of the device, the operator is requested to follow

the below stated safety instructions.

1. Safety instructions

Please note that the manufacturer will not accept any liability for any damage which might occur due to

improper use or due to non-observance of the operating instructions stated in this Manual.

Improper use of the device or non-observance of the operating instructions automatically makes

productliabilityexpirewithimmediateeffect.

Pleasereadthese instructions in fullbefore theLOKAL400device isputinto operationfor thefirsttime.

For reasons of safety and CE compliance, you may not carry out any changes or modifications on the

device itself and/or on any other components which may be used in connection with this measuring

device!

•DO NOT carry out any measurement on live components;

•Please observe the measurement range of the particular measuring sensors

(microphones) before you start the measurement procedure;

•Please ensure proper storage and operating conditions;

•Any measurement data evaluations, any conclusions as well as any consequential

measures taken as a result thereof are subject to the operator’s sole responsibility. The

manufacturer can neither guarantee the validity of any measuring results nor does he

accept liability for any such results. The manufacturer does on no account accept

liability for any damage which may be caused as a consequence of the use of the

received measuring results.

2. Intended use

The Lokal 400 device is a multi-functional detector to be applied for the electroacoustic search

for leakages by means of correlation. It can also be used to listen to surfaces/fittings in an

electroacoustic way and to locate pipes acoustically.

The device may be used for the above-stated purposes only and within the technical data

parameters as specified.

Any other use is considered to be not intended for such purposes.

In accordance with the EU Directive 2002/96/EU on Waste Electrical and Electronic

Equipment (WEEE), issued by the European Parliament and by the European Council

on 27 January 2003, electronic equipment must not be treated as domestic waste but

must be disposed of professionally.

.

Please dispose of this device in a manner appropriate to the relevant legal requirements of

your country at the end of the product life of the device.

Lokal 400Operating Manual Page 4

3. Scope of delivery and accessories

1 Lokal400centralunit,withaerialsandcarrying

strap

2 BlueMB4with accelerometer

3 Red MB4withaccelerometer

4 Transport case for central unit, measurement

boxes, groundmicrophone, andtestrod

5 Groundmicrophonewithspiral cable

6 Testrod withextensions

7 Adapterfor headphonesto beconnectedto

centralunit

8 Tripod withmagnetsforgroundmicrophone

9 Headphones

10 AdaptercableforTest-rodoruniversal

accelerometer connectionto Lokal 400

11 AdapterpieceforconnectingsensorsfromMB3

orMB4directlytoLokal400

10 3-foldchargerforLokal400centralunitand

MB´s in the sametime

11 Hydrophone(optional),particularlyforplastics

Lokal 400Operating Manual Page 5

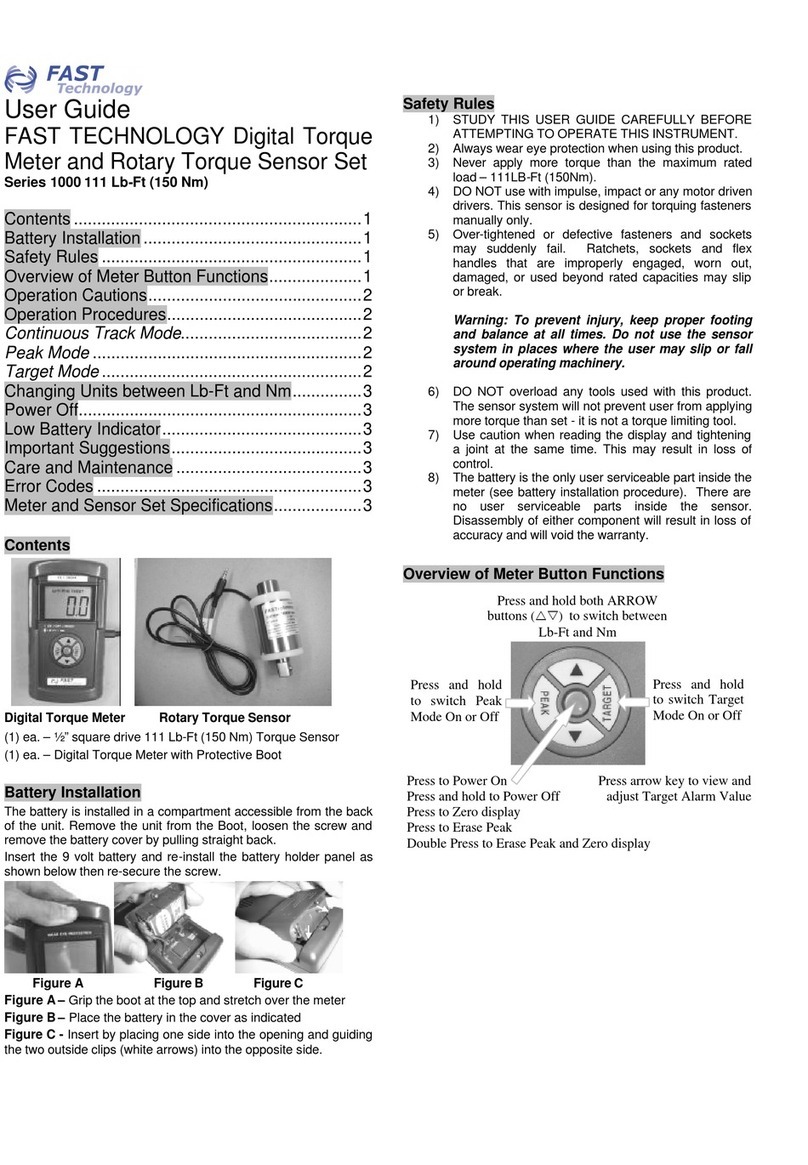

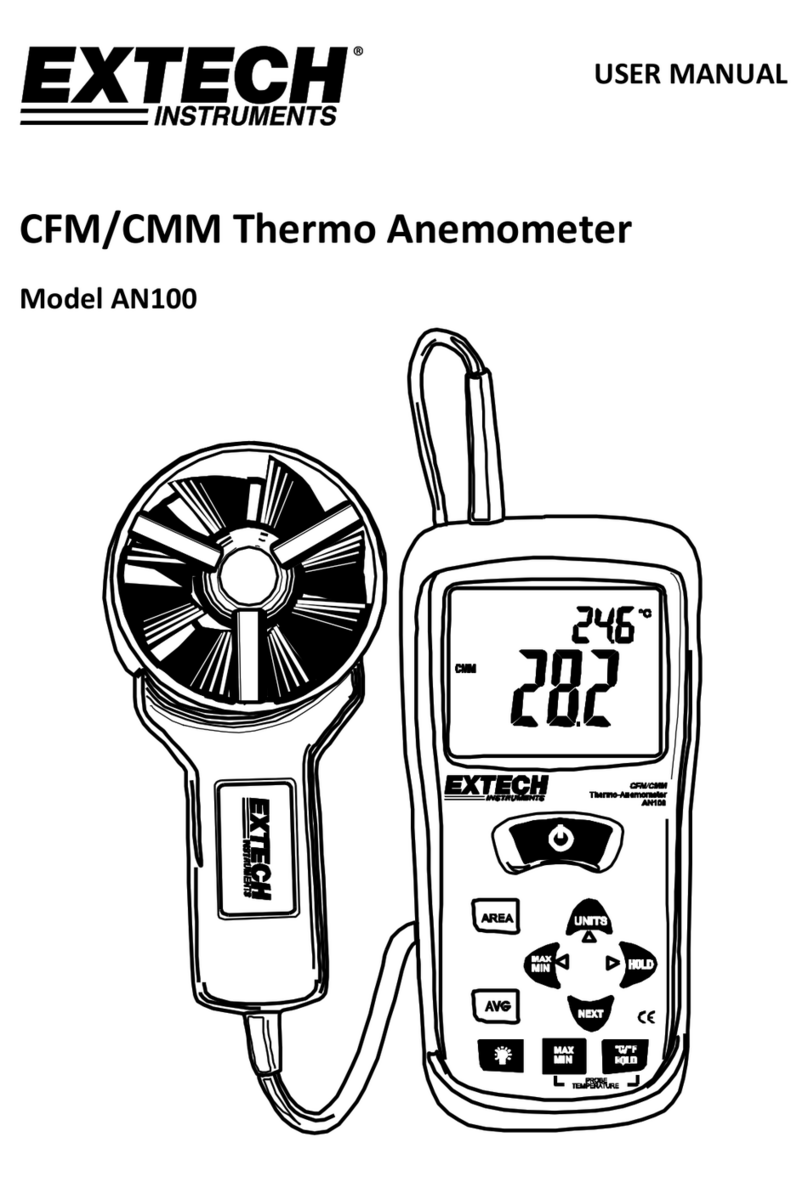

4. Control elements

1 Keyfordatareceptionprocess, auto-

adjustment,andcalibration

2 “Cancel”keytoreturntopreviousfunction,

todelete data,orto leavethe menu

3 On/Offkey[On = pressbriefly/ Off=

pressforafewseconds]

4 Touchdisplay

5 Thisdialhastwofunctions:youcaneither

press(5)A orturn(5)B thedual-function

dial.

Turnthedialtoaccessthemenuand

settingfunctionsandto specifyalready

selectedsettings.

Pressthedialtoconfirmanyselectionor

setting.

6 Aerial connection left

7 Jackfor headphonesconnection

8 Coverfor headphonesjack(IP65)

9 CoverforUSB cableconnection

10 USB cableconnection

11 ChargingstatusLED(fromtop)

blue: chargethedevice

green: chargingcompleted

orange: externalpowersupply,

mainsadapterpluggedin

12 Chargingjack

13 Coverforcharging jack(IP65)

14 Microphonejack

15 Aerialconnectionright

Lokal 400Operating Manual Page 6

5. Powering up and operating the device

The Lokal 400 leakage detector and its measurement boxes are equipped with internal nickel metal

hydridebatteries. Pleasemake surethatthe batteriesarefully chargedbeforethe deviceispoweredup.

The Lokal 400 multi-functional detector system is capable of carrying out both correlations and

electroacousticlisteningprocedures.Thesetwoseparatefunctionsaredescribedindetailbelow.

5.1 Powering up for correlation

Headphones:

Connect the headphones to the headphone jack of the LOKAL 400, if required [see Chapter 4, legend

itemno.(7)].Pleaseexclusivelyusetheoriginalheadphonesforyour measurements.Theheadphones

areappliedtolistentothenoisestransmittedbythetransmittersA/B/Corbythegroundmicrophone/other

microphones. This data isthenused tosetthefiltersandthe amplification levelofthe leakage detection

equipment.

Transmitter:

The measurement boxes (MB3 / MB4 / MB5) of the Lokal 400 leakage detection system are equipped

with sensors. The boxes have to be positioned on the leaking pipe for leakage search operation. It is

recommendedtokeepthedistancebetweenthetwotransmitters/sensorsasshortaspossible.Oncethe

sensors have been attached and the measurement boxes have been switched on, the noise level

indicatoronthemeasurementboxshouldindicateacertainnoiselevel.If this level is around “0” and there

is no noise to be heard, the distance to the leakage has to be reduced or another type of sensor has to

beselectedfortheleakagedetectionprocedure.

Basically,therearetwodifferent typesofsensoravailable:

- Accelerometer sensor[Chapter 3,(2)or(3)]

- Hydrophone sensor[Chapter3, (10)]

Theaccelerometershavebeendevelopedtomeettherequirementsofleakagedetectiononmetalpipes.

Theyareattachedtothepipewithamagnetataccessiblespotssuchashydrants,valvesorinmanholes

andpickupthesoundtravelling along theparticular pipe.

Hydrophonesensorshavebeendevelopedtomeettherequirementsof leakagedetectiononnon-metal

pipes(plastics)and have tobe indirect contact with the water columnat hydrantsor at other accessible

connections.Thesensorspick upthesoundtravelling inthemedium(water).

Therefore,thematerialoftheparticularpipetobecheckedhastobeidentifiedbeforehandinordertobe

abletoapplytheappropriatetype ofsensor.

For further information on the operation of the measurement boxes, please refer to the Measurement

BoxesOperatingInstructions.Ingeneral,thefollowing approachisrecommended:

1. Attachthesensorstothepipe

2. Switchon themeasurementboxes

3. Selectamplificationandappropriatefilters

Sensors:

TheLokal400systemiscapableofcorrelatinganoisethroughthetransmittersA/B/Candisalsocapable

of using another source of noise for its calculations through the direct sensor connection at the central

unit.If you wishtoconnectasensortotheLOKAL400 device,pleaseusethesensorjack [seeChapter

4, legend item no. (7)]. A more detailed description of the different sensors and their particular fields of

application isstatedbelow.

Lokal400centralunit:

Lokal 400Operating Manual Page 7

If you wish to power up the central unit, please briefly press the ON/OFF button [see Chapter 4, legend

itemno. (3)]. Oncethe startscreenhasfaded, thesystemoffersthechoice between“Correlationmode”

and ”Geophone mode“. For further information, please refer to [Chapter 7 Leakage detection:

Correlation] Executingacorrelation.

5.2. Powering up for electroacoustic listening

Headphones:

ConnecttheheadphonestotheheadphonesjackoftheLOKAL400device [seeChapter4,legenditem

no.(7)],ifrequired.Pleaseusetheoriginalheadphonesonlyastheyhavebeendesignedspecificallyfor

acousticleakagedetectionpurposes andfeaturecertainleakage-bornenoise identificationcapabilities.

Sensors:

Please make sure that one of the following microphones is used for an acoustic leakage detection

process(geophone) withthe Lokal 400 device:

- Groundmicrophone(seeChapter3,legenditem(5))

The ground microphone (5) is a wind-protected microphone to be applied for precise leakage

calibration.Itcanbepositioneddirectlyonpavedground.Ifthegroundisunsurfaced(e.g.grass

or gravel surface), the ground microphone can be attached to the tripod magnet (8).Therefore

itis perfectlysuitedfordouble-check orverifycorrelation results.

- Testrod(seeChapter3,legenditem(6))

Thetestrodis appliedtolistentofittingsinordertopre-locate anyleakage.The extensionsallow

the operator to reach even fittings which are located in deep manholes, and the operator does

notneedtotoclimbdownthemanhole.

- Universalmicrophone(accelerometer) / universalmicrophonewithhandle(notshown)

The universalmicrophonecan beappliedincombination withextensionsasatestrod,oritcanbe

usedincombinationwiththemagnetasacontactmicrophonetopre-locatealeakage.Thanks to

the tripod (8), the accelerometer can also be applied as a ground microphone to locate a leakage

preciselyortodouble-checkthecorrelationresults.

Lokal400centralunit:

If you wish to switch the central unit on, press the ON/OFF button [see Chapter 4, legend item (3)] just

briefly. As soon as the start screen has faded, the operator can select between “Correlation mode” and

”Geophone mode”. For further information, please refer to [Chapter 8 Leakage search: acoustic]

Carryingoutanacousticleakagedetectionprocedure.

Lokal 400Operating Manual Page 8

6. Control and menu structure

6.1. Control

TheLokal400devicefeaturesmenuitemsandselectionboxeswhichcanbeactivatedeitherdirectlythrough

thetouchscreenorwiththedial.Ifyouwishtooperatethedevicewiththetouchscreen,justpressyourfinger

ontherequestedmenuitemorselectionbox.

Asanalternative,youcanalsoturnthedialclockwiseorcounter-clockwisetoactivatetheavailablemenuitems

andselectionboxes.Activemenuitemsorselectionboxesarehighlightedinyellow.

Assoonastheoperatorhaspressed thedialtoconfirmhis/herselection,therequestedmenuitemandselection

boxrespectivelyisdisplayed.

Pressing on “Cancel“ makes the system leave the current menu item and selection box

respectively.Thecommandlineconfirmedlast will bedisplayed now.

6.2 Main menu

As soon as the central unit has been switched on, the main menu is displayed offering the following selection

options:

[1]Correlationmeasurement

[2]Geophonemeasurement (electroacousticlistening)

[3] Settings

[4]DataexchangewithaPC

Ifyouwishtoleavetheselectedmenuandtogobacktothemainmenu,press intheuppercontrol

menuor the“Cancel” key .

Lokal 400Operating Manual Page 9

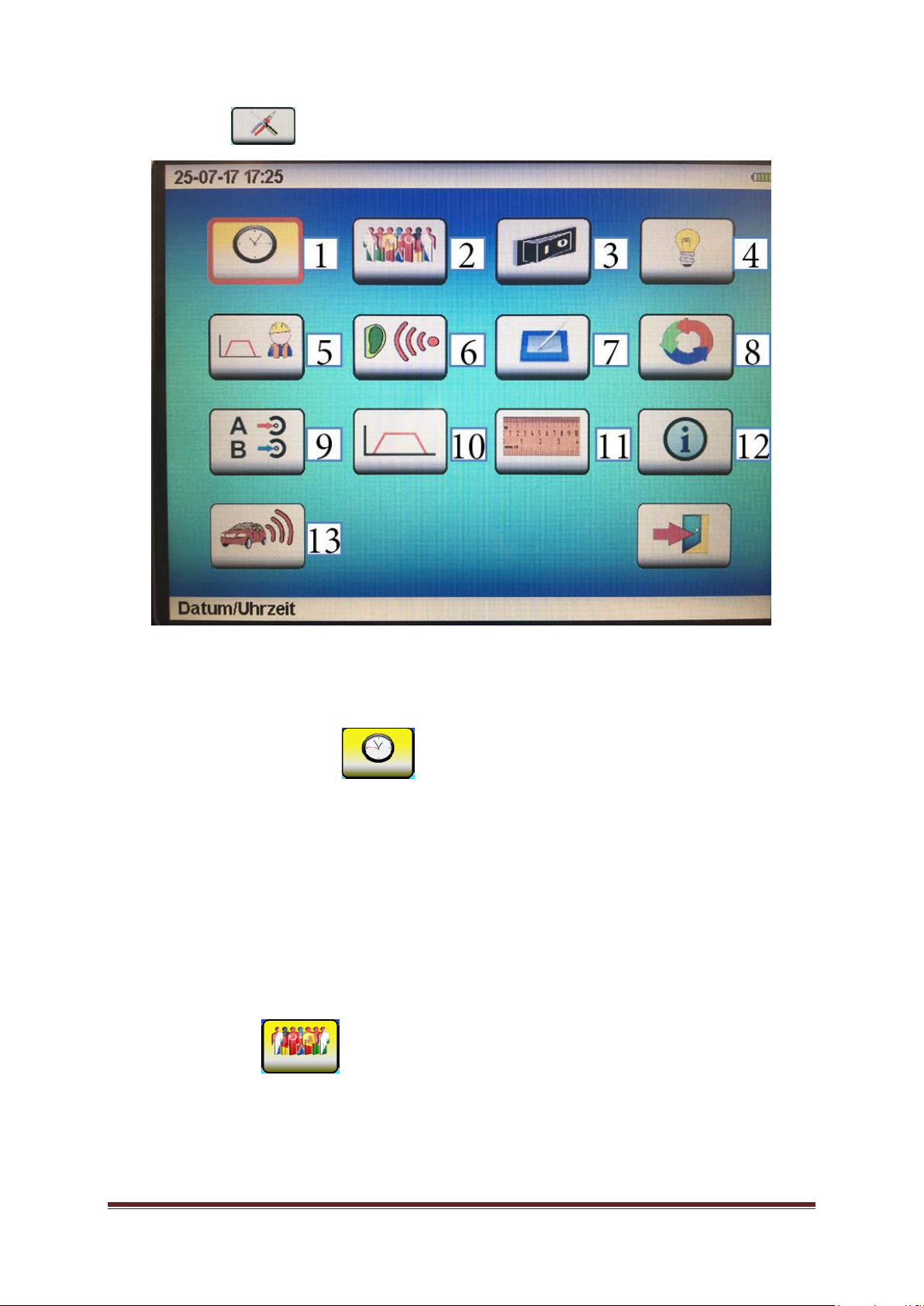

6.3 Settings

Themenusetting optionsarereachedthroughthesettingssymbolinthemainmenu.

Navigateto the requested setting option, select it, andsetyour requested configuration:

6.3.1. Date andtime of day [1]

Navigate to the “Date and time“ setting box with the dial. The selected setting box is now highlighted in

red.Confirmyourselectionbypressingonthedialtotheright.Theselectionisnowactivatedand willbe

highlighted in yellow. The settings can be changed by turning the dial (1-31 for the date; 1-12 for the

month,10-99 for theyear).Ifyouwishtoenterthedataon thetouchscreen,pleaseusethelowerfigure

box for the input. The input can be confirmed by tapping on the “OK” icon, and the input can be deleted

bytappingon “DEL”.

Please notethat you will have topressthe dialagainto confirmyour selection. Press the “Cancel” key if

you wishtocancelyourinput.

If you wish to confirm and leave the data you just entered, please press on the door icon. If you wish to

cancelall yoursettings andtoleavethesettingsmenu,pleasepressonthe”Cancel“ key.

6.3.2. Language [2]

The Lokal 400 system offers a number of display languages. Please scroll down until you reach the

languageyourequest andconfirmtheselectionofthislanguagebypressingtherightdial.

If you wish to leave the settings menu, please press on the “Cancel“ key or tap on the door icon on the

screen.

Lokal 400Operating Manual Page 10

6.3.3. Switch-off time [3]

Asthesystemisusuallyrunonbatterypower,itisreasonabletosavebatterycapacitywheneverpossible.

Therefore, the operator can set the time period when the device is switched off automatically unless in

use.Thisswitch-offtimerangesfrom1minuteupto60minutes. Thisfeaturesincreasesbatterylifeand

thustheoperating periodofthesystem.

Theconfigurationprocesscomplieswiththesettingprocessforthedateandthetimeofdayasdescribed

inChapter 6.3.1.

6.3.4. Lighting [4]

The brightness level for the display lighting can be adjusted individually on a scale ranging from

0% to 100%. The scale has two colored sections indicating the impact of the brightness level on the

energy consumption and thus on the battery’s operating period.

If the brightness level is chosen from within the green section, the operational period of the battery is

maximal.Theredsectionindicatesreducedoperatingtimeofthedevice.

The brightness can be changedby turning the right dial. The setting menu can be left either bypressing

thedial,orbypressingthe”Cancel“ key, or bytappingthedooricononthescreen.

6.3.5. Frequency range/Geophone [5]

Every acoustic leakage detection measurement mode offers two pre-selected filters (ground

microphone and testrod) and also a user-defined filter selection to be applied directly. These

settings can be determined in theFrequencyrangesetting menu.

High-pass filters (HP) and low-passfilter (TP) as well as the maximumrangeof the frequencyspectrum

can be adjusted. The maximum frequency range available for the geophone mode is 4,000Hz. The

configuration process complies with the setting process for the date and the timeof dayas described in

Chapter6.3.1.

6.3.6. Hearing protection [6]

The Lokal 400 leakage detection device features an automatic noise level absorber. This function

ensuresthattherequirementsforHearingProtection as perVBG121(VGB–GermanAssociation

of Institutions for Statutory Accident Insurance and Prevention) are fully met when operating the

original headphones (part of the delivery).Forindividualadjustmentofthenoiselevel,theLOKAL400

deviceoffersascalerangingfrom1(relativelylownoiselevel)to3(maximumnoiselevel),withanysetting

stillbeinginfullcompliancewithVGB121requirements.

Theconfigurationprocesscomplieswiththesettingprocessforthedateandthetimeofdayasdescribed

inChapter6.3.1.

6.3.7. Touch screen [7]

Withthis setting option, theoperator can de-activate thetouch screen, calibrate it,or runafunctionaltest

on the screen. Use the dial on the right to navigate to the requested selection field and confirm your

selectionby pressingthedial.

IfOn/Off hasbeen selected,thetouch screenfunctioncan be activatedandde-activated respectively by

pressing the dial. Please note that if the touch function has been de-activated any input can be made

throughthedialonly!

If the touch function of the LCD display does no longer work properly (e.g. a menu item can only be

selected by tapping beside the symbol), it may be necessarytocalibrate the touch function. If you need

todoso,pleasefollowtheinstructions as displayed andtaponthe spots as indicatedintheinstructions.

Afterthisreset,thetouchfunctionshouldworkproperlyagain.

Lokal 400Operating Manual Page 11

6.3.8.Clearingthememory[8]

Withthisfunction,theoperatorcandeletetwodifferentmemorystatesinthemeasurementdevice.

WithClearmemory, allmeasurementvaluessavedgloballyinameasurementdevicewillbe deleted.

WithResetparameters,alluser-specificsettingsforhigh-passfilters,low-passfilters,andthemaximum

rangeofthefrequencyspectrumassetintheFrequencyrangesettingmenu (seeChapter6.4.5) canbe

deleted.

Delete the memory directly by tapping on the touch screen or navigate with the right dial to the

selected setting menu and confirm your selection by pressing the dial. Successful deletion of the

memoryisindicatedwithatickbythesystem.

You can leave this setting menu either by pressing the “Cancel“ key or by tapping on the dooricononthe

screen.

6.3.9. Correlation entries [9]

Herethe signal entries canbeselectedtobeusedfor thecalculationof acorrelation.Thefollowing entry

combinationsareavailable:

- A-B

- A-C

- B-C

- A“Sensorentry“

- B “Sensorentry“

- C “Sensorentry“

A,B,andCarethechannelsofthemeasurementboxes(A=red;B=blue;C=yellow),and “Sensorentry“

indicates the direct connection of any microphone (see Chapter 5, Section ”Sensors“) to the Lokal 400

centralunit.

Thesesettingscanalsobemadethroughthecorrelationmainwindow.

6.3.10. Frequency settings/correlation [10]

Thismenuoffersthehigh-passfilterHP[Hz]andthelow-passfilterTP[Hz]aswellasthemaximumrange

of the frequency spectrum for the manual correlation measurement process. The maximum frequency

rangeavailableis5,000Hz.Theconfigurationprocesscomplieswiththesettingprocessforthedateand

thetimeofdayasdescribedinChapter6.3.1.

Thesesettingscanalsobemadeinthesub-menuformanualcorrelation.

6.3.11. Unit of measurement [11]

Twounitsofmeasurementareavailable:metric andimperial.

6.3.12. Information on the device [12]

Device-specificparameterssuchasfirmwareversionandserialnumberarelistedatInfo.

6.3.13.Transauto[13]

This function is to set the sensitivity limit for the interruption of a measurement process during the

correlation process. “0“ means off, “3“ means highly sensitive. For further information, please refer to

[Chapter7.5]

LOKAL 400OperatingManual Page12

7 Searching for a leakage by correlation

TheLOKAL400iscapableofcalculatingtheprecisepositionofa leakage(correlation).Inordertodoso,

please proceed as described in Chapter 5.1 “Powering-up for correlation“ and closely follow the hints

concerningthedifferenttypes ofsensor,themeasurementboxes,andthesignalentries.Ifyouintendto

start a correlation process, pleasetap on the correlation icon displayed or start the process with the dial

andthecorrespondingselections.

Basically,theLOKAL400deviceoffersa“manual“ correlation mode and an ”automatic“ correlation mode.

The “manual“ calculation requires analogue filters and signal amplification level to be defined by the

operator, whereas inthe ”automatic“ mode theLOKAL 400system selectssuchsettingsbyitself onthe

basis of certain algorithms. All settings concerning signal amplification and filter selection can also be

changed manually in any measurement mode in the correlation main window, i.e. there is the option to

readjusttheparametersmanuallyafter acertainmeasurementalsointheautomaticmode.

7.1 Automatic measurement

If you intend to carry out a measurement in the automatic mode, please tap on the automatic

measurement icon shown above. With this mode being selected, the correlation will always start in the

automaticmode[filtersandamplificationaresetbythesystem]inthecorrelationmainmask.

7.1.1 Entering pipe parameters

If the automatic measurement mode has been selected, the next window will display a table where the

pipe parameters such as pipe material [1], pipe length [2], and pipe diameter [3] need to be entered. As

soon as the relevant data has been entered in this line, the “Sound Velocity“ column [4] indicates the

assignedsoundvelocityforthispipesection.

The values are assigned in a table and saved in the device, but they can also be changed manually for

eachsectionsubsequently.This,however,isrecommendedforexperiencedoperatorsonly.Ifthesound

velocity was changed by mistake, it will be sufficient to change any parameter of the pipe and then to

resetit.Theassignedsound velocitywillthenbeindicatedinthecolumnagain.

LOKAL 400OperatingManual Page13

Up to 20 different pipe sections can be entered into the LOKAL 400 device. If a pipe consists of mixed

materials and/or features varying diameters, just enter the materials one by one into the table starting at

measurement box A (red). If you wish to delete any input, you can either press the button “line“ [6]

orselect ” ---“ as thepipematerial.

Whenallpipesectionmaterials havebeenenteredcorrectly,pressingthePLAYbutton[7] will

make the main mask of the correlation appear (see main illustration in Chapter 7.3 “Setting options for

correlation”). Pressing the door button [8] makes the system return to the main menu. If you press the

“Cancel”key(“X“),thesystem willgo backtothe windowwhere youcan choosebetweentheautomatic

and themanualmeasurementmodes.

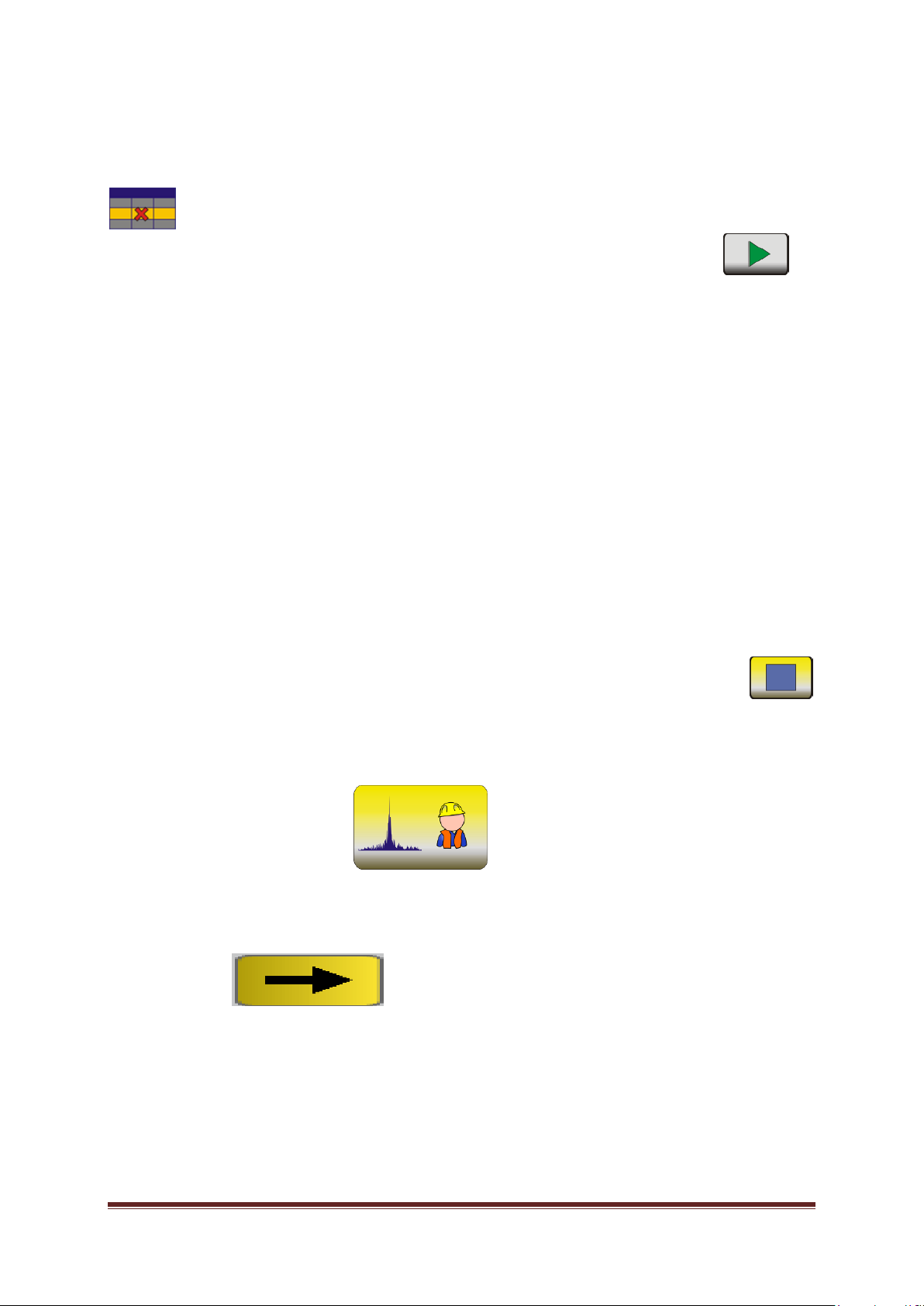

7.1.2. Starting the correlation

Once the “Play”button has been pressed, the LOKAL 400 device will start automatically to adjust the

noise level amplification for the two channels (A [8 and 8.1] and B [12 and 12.1]) so that the noise level

optimal for the measurement process is available to the system. This is also indicated through the

adaptation of the amplification level [8.1 and 12.1] displayed at the lower edge of the correlation main

window.

He LOKAL 400 system will then carry out some test measurements with different filter settings [10] to

determinetheoptimalnoisequalityofthetwosignals [9]and[10] andofthecoherence[10]respectively.

This is indicated by the number of average determinations [13] rising briefly, being canceled, and then

beingcountedupagainwiththenextfiltersetting[10]. Afterashortwhile,theLOKAL400devicewillthen

start on the proper measurement procedure and will determine the exact position of the source of the

noise. When the measurement has been completed, the number of average determinations stops

counting up [for the automatic mode, a total of 50 average determinations has been set ex works]. The

current measurement procedure can be interrupted anytime by tapping on the “Stop”icon

(displayedinfield[1]duringthemeasurementprocess).Thedetectedsourceofthenoise,whichisusually

theleakagespot,[seeChapter 14 “Troubleshooting“] willbedisplayedintheupperimage[6]asasymbol,

and the corresponding distance between the leakage spot and microphone A and microphone B

respectivelywill beindicated.

7.2 Manual measurement

If you wish to carry out a measurement manually, please tap on the “Manual measurement” icon (as

shownabove). Awindowwillappear whereyouneedtoentersomedatasuchasthepipematerial,pipe

length, and pipe diameter. Then proceed as described in Chapter 7.1.1 “Entering pipe parameters“ for

the automatic measurement mode. When all pipe parameters have been entered correctly, tap on the

“Continue“ button togettothemenuwherethefiltersneedtobeset(seeChapter

7.3.1 “Filter settings”). The main image will show the coherence of the last measurement. Now please

setthehigh-passfiltersandthelow-passfiltersinaccordancewiththefrequencydistribution.In addition,

the corresponding noises delivered through Channel A and Channel B can be listened to by activating

the headphones connection. So the operator can assess which filter setting provides the optimal noise

quality.

Clickon the “Continue“ button to reach the correlation main window (seeillustrationinChapter7.3“Setting

options for correlation”). In contrast to the automatic mode, the measurement procedure will not start

automatically in the manual mode. The system requests the noise level amplification for Channel A [8]

and Channel B [12] to be adjusted in the main window. The same applies to all other signal entries.

LOKAL 400OperatingManual Page14

Tappingonthelevelmakesanotherwindowopenwhereyoucanadaptamplificationtoalevelbetween

0 and100%. Pressing thedialortappingonthedeviceoutsidethewindowwillclosethissub-menu, and

the set amplificationlevel will be displayed belowthenoise level. Theappropriateamplification level has

been selected if the medium noise level fills about the half of the noise level indicator. The noise can be

listened to with the headphones and thus can be checked if the signal intensity is too low or if the signal

isoverdriven.

When all input has been entered, the correlation can be started by tapping on the “Play” button [1]

. The number of average determinations is counted up, and the correlation peak should start

forming. The measurement processcan be interrupted anytime by tapping on the “Stop”icon

locatedintheupperrightcorner. Themeasurementprocedurewillrunupto250averagedeterminations

in the manual mode unless the measurement is interrupted beforehand. Usually 40 to 50 average

determinations are sufficient to receive a proper result. If the result is not satisfactory, you may have to

checkandtoadjustthefiltersettings,amplification,orthemeasurementset-up.

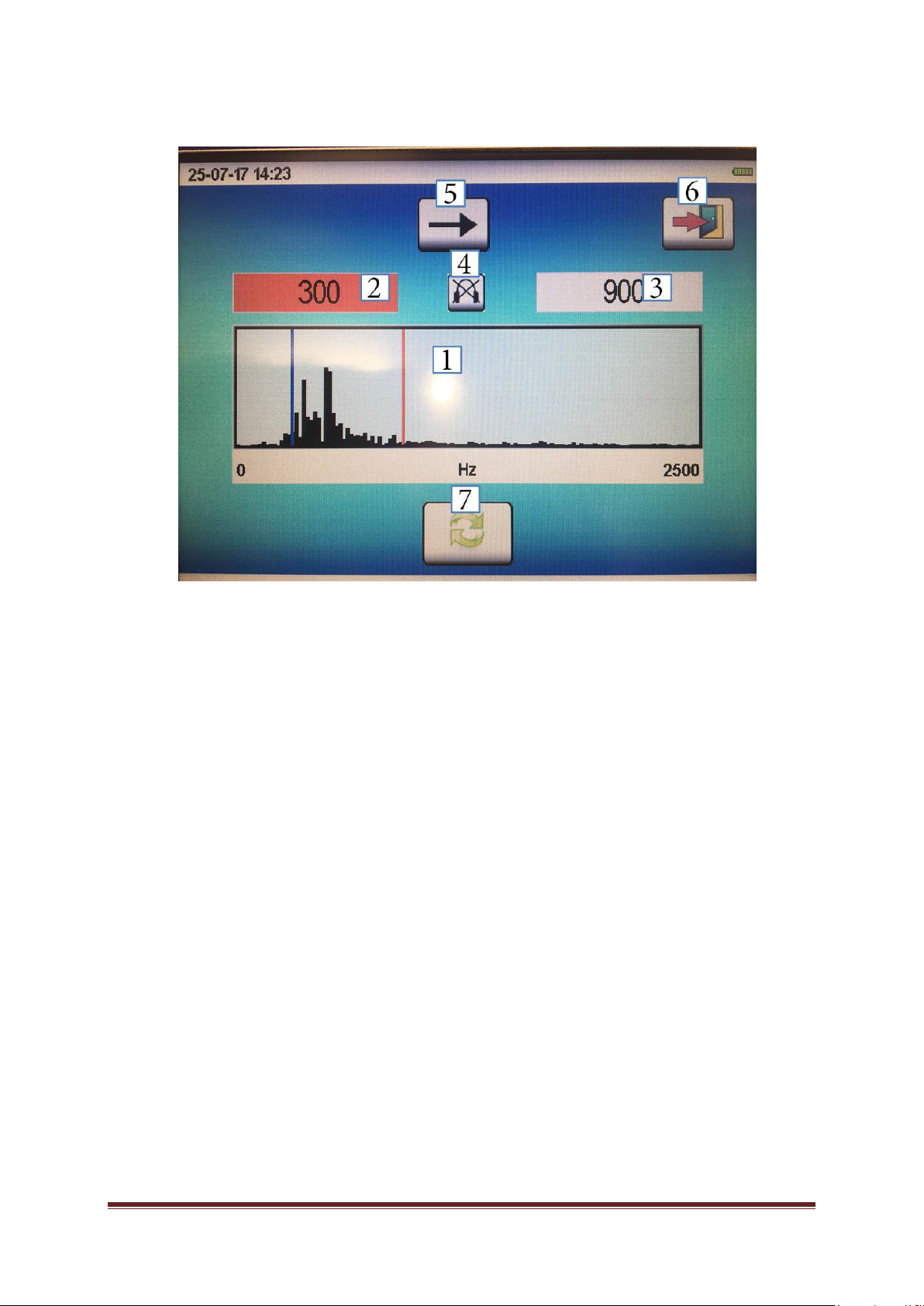

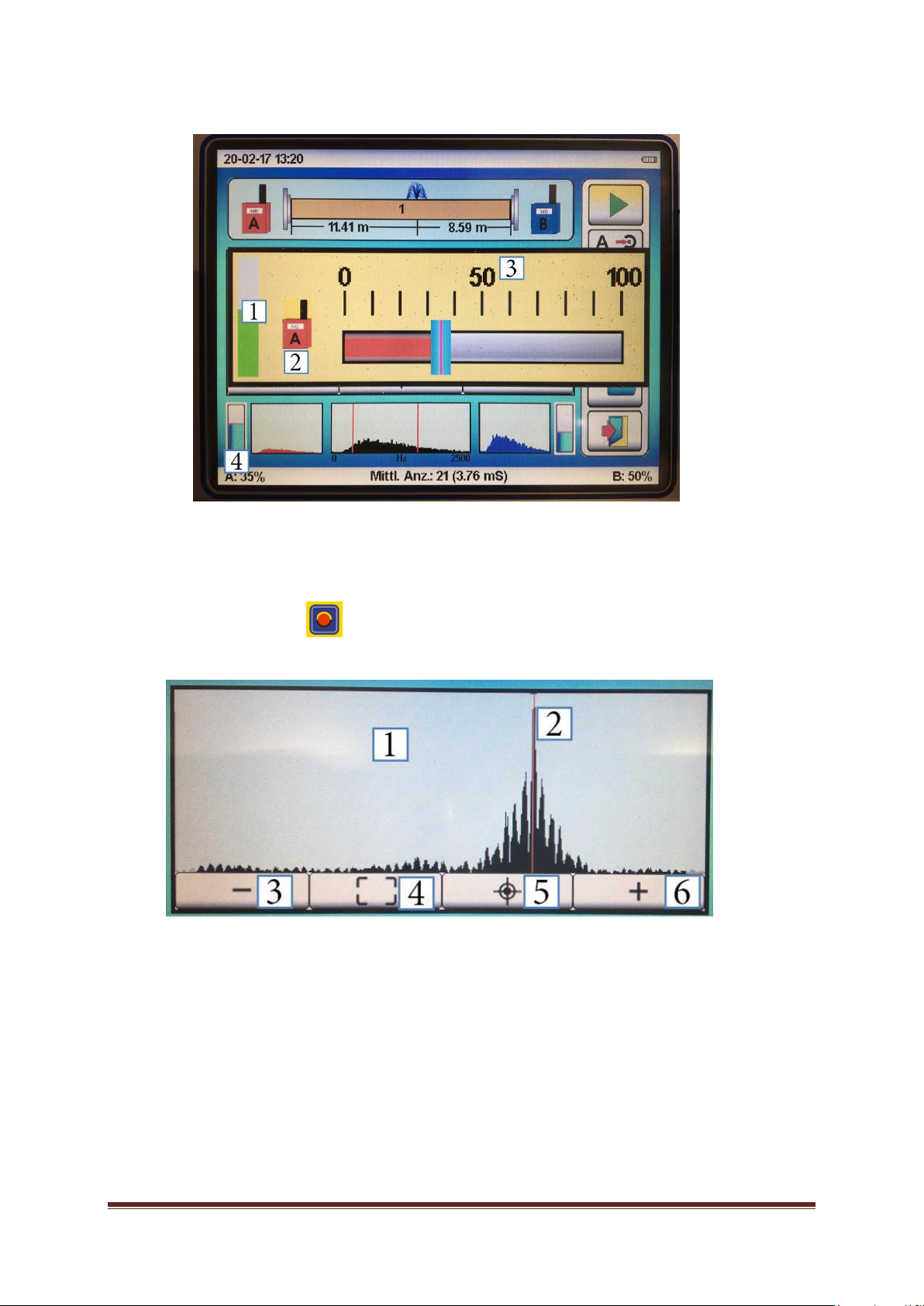

7.3. Setting options for correlation (correlation main window)

Thecorrelationmainwindowoffersthefollowingoperatingelements:

[1]Start/Stopofameasurement

[2]Switching betweendifferent signalentries

[3]Headphone jack for differentsignalentries

[4] Headphonevolume

[5]Savingthemeasurement

[6]Indicationofpipelinerupturesymbolicallyandnumerically&active buttonformaterialinput

[7]Correlationresults

[8]AmplificationChannelA [8.1]numericalvalue(0-100%)toamplifyChannel A

[9] Frequency illustration (FFT)for Channel A

[10]Coherence(FFT)forA and B

[11]Frequency illustration(FFT)forChannel B

[12]AmplificationChannelB [12.1]numericalvalue(0-100%)toamplifyChannelB

[13] Numberofcompleted averagedeterminations

[14]DELTA T inmilliseconds

LOKAL 400OperatingManual Page15

7.3.1. Filter settings

You will reach the filter setting mask either through the selection process of the manual measurement

mode in the second setting step or through the correlation main window by selecting the filter setting

options [10] by tapping on the touch screen or by applying the dial. A new window (as shown above) is

displayed,andthefollowingfunctionsareofferedtotheoperator:

[1]CoherenceimageofbothsignalsA and B

[2]Settingsforthehigh-passfilter(HP)

[3]Settingsforthelow-passfilter(TP)

[4]Activatingtheheadphonejack or Switching theheadphonejack betweenChannel Aand

ChannelB

[5] “Continue“ button

[6] “Back“ button

[7]Updating thecoherenceimage

In this filter selection menu, the coherence image [1] is always displayed as the result of the last

measurement procedure. Therefore, itisrecommendedtomakethesystemre-calculatethecoherence

image throughthe function [8] before the filters are set again to have the current coherence displayed. If

you press the “Update” button,itmaytakeseveralsecondsuntilthenewimagehas beencalculated.

The filter levels can be adjusted by selecting the appropriate high-pass filter [2] and low-pass filter [3]

fields.Thesetfiltersaredisplayedinthecoherenceimageasadditionalredlines.Ifthehigh-passfilteror

the low-pass filter has been selected, the line turns blue in the image and the box is highlighted in red.

Nowthefilterselectioncanbe changedbytappingonthe imageorbyapplyingthedial.

Press the “Continue“ button[6]ifyouwishtoreachthecorrelationmainwindow. If you tap on the “Back“

button [7], the subsequent window to be displayed depends on whether you reached the Filter settings

windowviathesecondsettingstepinthemanualmeasurementmodeorviathecorrelationmainwindow.

In the first case, the system will go back to the start screen; in the latter case, the system will goback to

thecorrelationmainwindow.

LOKAL 400OperatingManual Page16

7.3.2. Signal amplification

If you wish to set the amplification level of the corresponding entries, please tap on the ”Level“ button [4]

in the correlation main window. A new window is opened up where you can adjust the requested

amplification levelwiththedialorwiththetouchfunction.

NOTE:Amplifythenoiselevelsothatthebarofthenoiselevelindication[1]fillsabouthalfoftheindication

box.

TIPP: If you press on this button in the window or on the “Measurement box” button [2], the

LOKAL400system will automaticallyadjusttheamplificationlevel.

7.3.3. Correlation results

Ifameasurementisstoppedeitherafterthemaximumaveragedeterminationshavebeencompleted(50

determinationsintheautomaticmodeand250determinationsinthemanualmode)orbytappingon the

“Stop”buttonduringameasurement procedure,thesystemallows navigating inside thedisplayedresult

imageby selecting the correlationresultwiththedial or bytapping onthebutton. Insidethe window, the

followingselectionoptionsareoffered:

[1] Correlation imagebetween signal Aandsignal B

[2]Correlationpeak(red line)

[3]Zoomingout

[4] Displaying the entireimage

[5]Zoomingin

[6]Searchingforthemaximumvalue

LOKAL 400OperatingManual Page17

If the correlation image [1] is chosen with the touch function or by pressing the dial, the correlation peak

(red line)canbeadjustedwiththedialor withthetouchfunction.

Once a measurement procedure has been completed, the correlation peak is automatically set to the

maximum. If the operator wantstoknow if there is apossible second peak, the system offersa function

to find out about a second peak. If the line is moved with the dial, the position has to be confirmed by

pressing the dial again to make the system display the new distances in the “Pipe rupture” image (see

Chapter7.3.[6]).Withthetouchfunction,thenewdistance isdisplayeddirectly.

7.3.2 Saving/uploading a measurement

A measurement can be saved with the ”Filing“ button (as shown above) located in the correlation main

window.Asafirststep,youneedtodeterminethefolder wherethemeasurement hastobesaved. The

filewillbesavedbythesystemwiththecurrentdateandtimeofday. The device iscapableofsaving up

to 100 correlations. When the memory capacity is exhausted, it is recommended to save the data on a

PC. Old data can be overwritten, or you can delete the entire memory with the “Delete memory“ button

inthesettingsmenu[seeChapter6.3.8].

If youwishtouploadameasurement,gobacktothestartscreenand select ”Correlation“ .

Select the “Folder“ button in the next picture. Now a new window appears containing the list

withallsavedcorrelations.Ifyouchoosealineandconfirmyourselectionbypressingthedial,thesystem

willtakeyoudirectlytothecorrelationmainwindowwherethesavedresultwillbedisplayedandthepipe

parameters(length,material, diameter)canbechanged.

7.4 Receiving radio data

The system indicates throughthe two icons to the right and to the left of the pipe rupture indication [see

Chapter7.3[6]] whetherornot the dataissuedbyatransmitter(measurement box) isbeingreceivedby

theLOKAL400centralunit.Ifthedataisbeingreceived,theiconsaredisplayedasshownintheexample.

If datareceptionis interrupted[forpossiblereasonspleaseseeChapter11“Troubleshooting“],the icons

arecrossedwith ablackX.

NOTE: If data reception is interrupted during a measurement process, the measurement is stopped

automaticallyand will not becontinuedunless datareceptionhasbeen restored.

7.5. Transauto function

Transautofunctionsensitivity is adjustedasdescribedin”Settings“[see Chapter 6.3.13.Transauto].The

transauto function is always activated and can only be de-activated by setting the sensitivity to ”0“. The

function provides the operator withexcellentcorrelation resultseven ifthemeasurement is carriedout at

a noisy spot with changing disturbing noises such as a busy street. The system automatically interrupts

themeasurementprocessifadisturbingnoisedrownsouttheactualleakage-bornenoiseandcontinues

themeasurementassoonasthesourceofthedisturbingnoisehasdisappeared.

NOTE:Ifthetransautosensitivityhasbeensettoanexcessivelyhighlevel,itmayhappenthatthesystem

is not capableof carrying out any measurement procedure withtheactual settings attheparticular spot.

In such case, the sensitivity needs to be reduced or even set to “0” (de-activated), or the measurement

hastobecarriedoutatanotherpointoftimewhenthedisturbingnoiselevelislower.

LOKAL 400OperatingManual Page18

7.6 Calibration of sound velocity

In rare cases, it might happen that the sound velocity of the pipe-section is not the same than the one

storedintheLokal400.Thereasonfor thiscouldbetheageofpipelines(i.e.hardeningofthematerialin

plasticpipes)orincrustations(i.e.corrosiononductile orironpipes).Thesameproblemisfacedifrepairs

with different materials were not mapped or recorded (often not the same material gets used!!). A

difference in sound velocity is elaborate for the result of the correlation and could lead to miss digging in

the worst case. One option to check the sound velocity on the section of pipe you want to conduct the

measurementistocalibrateit.Pleaseapplyfollowing procedure:

1. Open outside of the measurement section a hydrant or wash out (or similar). Means, “behind” A

or B. Important: the sound needs to be greater than the leak noise itself. [Perhaps through new

positioningoftheMB´s,thenoisefromtheleakitselfcouldbeusedtocalibratethesoundvelocity

forthesection]

2. TypeinthepipeparametersforthesectionintotheLokal400[refertosection7.1.1]

3. Startacorrelationandwaituntilaresult(peak)isshown

4. Because the (main-) noise is now outside of the measurement section (between A and B) the

Lokal 400 will show a “leakage” directly on A or B (depending which one is nearest)

5. Nowyoucancalibratethesoundvelocityofthemeasurementsectionthroughpressinglongonto

this button . A multiple piep- tone will be audible. You will find the “calibrated” (new) sound

velocityinthepipeparametersettings[seesection7.1.1]

IMOPRTANT: Thisonlyworks, if onlyonesection is entered inthe pipe parametersettings. As soon as

moresections aretypedin,itdoesnotwork!

NOTE:Ifyouchange anything on the pipe parameters (i.e. dimension or material), the “calibrated” sound

velocitywillbedeletedandthestoredvelocitywillbetakenoverautomatically.Itmakessensetosafethe

calibrationfileforfuturemeasurementsonthissectioninthedevice.

LOKAL 400OperatingManual Page19

8. Acoustic leakage detection

Theacousticleakagedetectionmenuiscalledbytappingonthissymbol.

The following parameters can be set as per a uniform operating scheme in any of the two operating

measurement modes available for acoustic leakage detection irrespective of the actually set

measurementmode.

[1]Adjustingthesensitivityofthesensor

[2]Selectingthefiltersetting

[3]Adjustingthevolume(headphones)

[4]Selectingthesensors (filter pre-selections)

[5[ Selectingthemeasurementmode

[6]Saving ameasurement

[7]Uplopading ameasurement

8.1 Setting the acoustic parameters

8.1.1 Adjusting the sensitivity of the sensors

Ifyouwishtoadjustthesensitivityofthemicrophoneconnectedtothemeasurementdevice,pleasenavigate

in themeasurement indication windowto the symbol for sensor sensitivity setting (1). Activate the symbol

andconfirmyourselection.Thewindowwherethesensitivityof thesensorcanbeadjustedwillopenup,

and a scale ranging from 0 to 100% will be displayed where the currently set amplification of your

LOKAL 400OperatingManual Page20

microphone is displayed.Amplificationcanbeadjustedbyturningthedialorbydrawingthescalebarwitha

fingeronthetouchscreentotherequestedsensitivitylevel.

Youhavesettheoptimalsensitivitylevelassoonasthecontrolbar(2)displayedintheleftpartofthewindow

levelsoutatabout50%.

PressingthedialorpressingtheAmplificationiconagainactivatesthesetamplificationlevel.

TIP:Iftheamplificationmenuiscalledand ifthis buttonispressedforalittlewhile,theLOKAL400system

willchoosetheoptimalamplificationlevelautomatically.Assoonastheoperatorhearsseveralbeepswhilethe

buttonispressed, the buttoncanbereleasedand thesystemwillchoosethemostsuitableamplificationlevel.

ATTENTION: thesensorhastobepositionedatthespotwherethenoiseistobepickedup.

NOTE: Assoonasthesensitivitylevelischanged,thecurrent measurementseries will bedeleted!

8.1.2 Setting the sensor selection (filter pre-settings)

The system offers three pre-defined filter settings for acoustic leakage detection. In addition, every filter

rangecanbechangedindividuallyduring ameasurementprocedure:

If you wish to select any of the three pre-defined filter settings, please navigate in the measurement

indication window to the filter mode symbol (1), activate the symbol, and confirm your selection. The

windowwherethefilterpre-settingscanbeselectedwillopenupnow.

Threepre-settingsareavailable:

Fittings(2)

A frequency range of 0to2,000 Hz is pre-defined, witha high-pass filterof 200 Hzand a low-pass

filterof 800Hz.Thissetting isoptimalforlisteningtofittingsandhydrants.

Ground(3)

A frequency range of 0 to 1,000 Hz is pre-defined, with a high-pass filter of 50 Hz and a low-pass

filterof 400 Hz.Thissetting isoptimalforlisteningtosurfaces.

Operator(4)

Thispre-setting usesthefilter range youhavepre-setaccording toyourpersonalfilter preferences inthe

settings menu at Frequency range Geophone (see Chapter 6.3.5). The system comes with a standard

pre-setfrequencyrangeof0to1,250Hz,withahigh-passfilterof100Hzandalow-passfilterof800Hz.

The pre-set filter frequencies can be adjusted individually anytime and in any measurement mode

betweenthesingleacousticleakagedetectionmeasurements.Forfurtherinformation,pleaserefertothe

instructionsasstatedinChapter8.4.

NOTE: Assoonasthefiltersetting ischanged,thecurrentmeasurementserieswillbedeleted!

8.1.3 Adjusting the volume

You can adjust the volume for the headphones subject to the pre-set hearing protection level (see

Chapter6.4.6.).

Thecurrentlysetvolumeisindicatednumericallyandalsoasabarchartinthesymbolfortheheadphone

volumesetting (1) located inthe measurement indication window.

Table of contents

Other Fast Measuring Instrument manuals