Fastbind Pureva XT User manual

1. INTRODUCTION...............................................................3

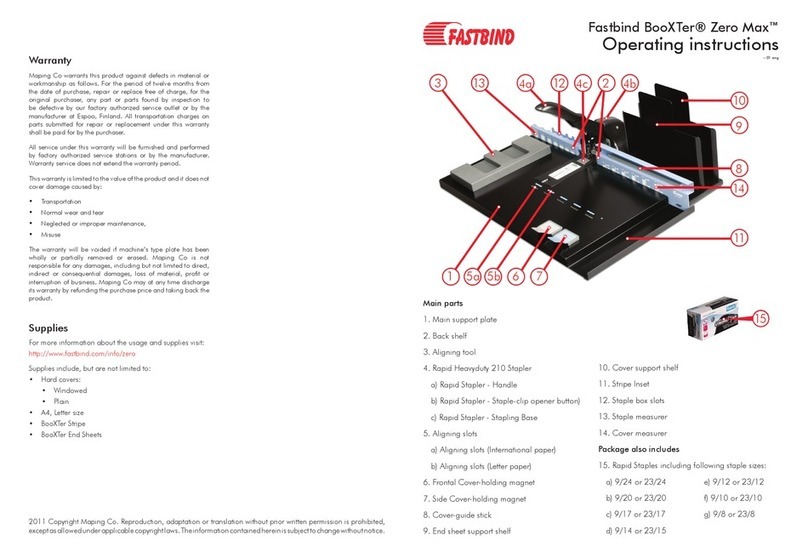

2. MAIN PARTS AND CONTROLS.......................................4

3. HOW TO USE: MAIN STEPS.............................................5

4. HOW TO USE: STEP BY STEP............................................6

Step 1: Mounting the book block.....................................6

Step 2: Trimming.............................................................14

Step 3: Mounting the cover............................................15

5. COPYRIGHT, TRADEMARKS AND WARRANTY.............18

Table of conTenTs

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

3

DRAFT

1. INTRODUCTION

1. InTroducTIon

FASTBIND PUREVA XT is a professional perfect binder with a

small footprint that uses a pioneering system allowing for both PUR

or EVA glues to be used (patents pending). Take advantage of this

new technology to produce the strongest bound highest quality books

faster and easier than ever before!

Main features:

• Interchangeable and reusable PUR and EVA glue cartridges

• Hard Cover, Soft Cover, Tape and padding bind books produced

with one machine

• With EVA glue, no cleaning necessary

• Using PUR glue, the strongest binding can be achieved, and its

simple and quick to clean the glue cartridge which can be reused

or replaced.

• Precise electronic temperature control

Overview

Specications

Europe U.S.A.

Machine cycles/hour Up to 450 Up to 450

Capacity books/minute* 1 - 3 1 - 3

Min/max binding thickness 0.1–45 mm 0.004–1.7˝

Max. binding length Up to 455 mm Upto17.9˝

Min/Max. binding height 140 mm / 320 mm 5.5/12.6˝

Max cover thickness** Up to 400 g/m2Up to 225 index

Voltage (V) / Frequency (Hz) 220–240 / 50-60 110–120 /50-60

Max. current 1,5 A 3 A

Machine dimensions (W x L x H) 107 x 60 x 64 cm 42.2x23.6x25.2˝

Weight 90 kg 198.4 lbs

Standard tools

Hard & Soft cover tool set Hard & Soft cover tool set

Approvals CE

* output rate depends on operator, selected cover and glue type

** depending on material properties.

Product information as of July 2014 and is subject to change without prior notice.

1

14

15

1716

13

18

19

21

20

22

6

5

7

4

8

2

3

10 12 11

9

23

23

3

x2

x2

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

4

DRAFT

2. PacKaGe conTenTs

2. PACKAGE CONTENTS

1. PUREVA XT perfect binder

2. storage locker

3. 2 storage locker ring magnets

4. 2 glue cartridge grippers

5. 2 glue cartridge caps

6. cap hook (tool for glue cartridge cap)

7. EVA glue cartridge

8. PUR glue cartridge

9. soft cover nipping tool front

10. soft cover nipping tool back

11. hard cover nipping tool front

12. hard cover nipping tool back

13. thermal casing

14. front heat shield

15. storage tray

16. drop cards

17. llingfunnels

18. fume extraction adapter 50 mm

19. fume extraction adapter 100 mm

20. 4 fastenin screws for fume extraction adapter

+ 4 washers

21. Hex key 4 mm

22. Hex key 2,5 mm (for nipping bar adjustment)

23. Power cord

Figure 2-1 Package Contents

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

5

DRAFT

5

8

12

13

12

7

6

4a

1b

1c/ 1d

1e/ 1f

3a

1a

2

3

1

3b

3c

3e

3d

4b

4

9b

9a

10

11

9

8b

14

1 Positioning deck

1a Positioning deck

1b Nipping cams

1c/1d

Nipping tool back (soft cover/ hard cover)

1e/ 1f

Nipping tool front (soft cover/ hard cover)

2 Turn table handle

3 Press clamp turn table

3a Clamp handle

3b Support rod

3c Paper guide for soft and hard covers

3d Turn table front plate

3e Fastening holes for paper guide

4 Temperature control panel

4a Indicator lights

4b Temperature selection button

5 Front heat shield

3. maIn ParTs and conTrols

6 Storage tray

7 Cap hook

8 Thermal casing

8b handling lid

9 Fume extraction hood

9a Light switch

9b Bypass valve

10 Applicator handle

11 Roughening handle

12 Glue cartridge gripper

13 Storage locker

Figure3-1Mainpartsandcontrolsidentied

3. MAIN PARTS AND CONTROLS

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

6

DRAFT

3. macHIne InsTallaTIon

3. MACHINE INSTALLATION

Opening the package

handling the Machine

• Remove the ”brackets” on the bottom of the shipping container

withaatheadscrewdriver.

• Remove the top parts (cover and mantle).

• Take out the inner carton box.

• Remove all packaging material around the machine

installing the stOrage lOcker

• Lift the machine from the pallet and place it on a solid work

surface. The recommended table height is 90 cm (36 inches) and

the minimum loading capacity is 200 kg (440 lbs.).

o WARNING!

▪The machine weights 90 kg (198 lbs.).

▪Please follow proper lifting guidelines

▪It is strongly suggested that three people are available to

lift and move the machine safely. Safe lifting positions are

highlighted on the picture in green on both sides of the

machine.

o WARNING!

▪Do not lift from the areas marked in red highlight in the

picture.

▪Lifting from the wrong locations can result in personal

injury and damage to the machine

▪Use caution when lifting the machine

• The machine is delivered with a separate storage locker.

• The storage locker is packages separately and its purpose is for

storing the glue cartridge gripper tool.

• Remove the packaging material around the locker.

• Attach two ring magnets (included in the delivery) to the right side

of the storage locker around the top screw heads, position marked

highlighted in green in the image.

o WARNING!

▪The storage locker is connected with the ring magnets,

and will not stay in position if the magnets are not installed

correctly installed.

▪Ensure that the magnets are properly attached before

locker installation.

• Install the storage locker on the left side of the machine so that

the ring magnets are against the machine’s left side panel and the

rear edge is against the left end panel.

• The storage locker has two compartments and it is intended only

for storing glue head grippers.

o WARNING!

▪Thestoragelockerisnotpermanentlyxedtothe

machine.

▪Remove the locker before moving the machine.

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

7

DRAFT

installing stOrage tray • ThemachineisdeliveredwithaseparateTeoncoatedplatform.

• The storage tray is placed on top of the machine, on the upper

right corner.

• The storage tray is intended for storing hot parts when the glue

tankisre-lled.

• The platform has enough space for the thermal casing, the glue

tank cap and the cap hook.

eva -glue

4. Glue, Glue carTrIdGe

pur -glue

• Recommended glue: Fastbind hot melt type 5.1, for normal

binding operations

• Generic glue for normal papers

• The EVA glue can be left in the cartridge at all times (no need for

draining or cleaning).

• Select the EVA -temperature setting on the control panel.

• PURglueisusedforpaperthatisdifculttobindwithEVAglue

• Sold in granules (Contact Fastbind for more information)

• Fume extraction recommended, unit should not be operated

without positive ventilation.

• Once cleaned of PUR glue, the glue cartridge can be used

multiple times.

• If the glue head is not cleaned immediately after use, the PUR glue

solidiesandthecartridgehastobereplaced.Thecartridgesare

inexpensive and can easily be replaced, contact Fastbind for more

information.

• Select the PUR -temperature setting on the control panel.

glue cartridge • One PUR and one Eva glue cartridge are included in the delivery.

• Both cartridge types are also available as accessories. They are

delivered without the tank cap (the main tank cap is included with

the machine and should be retained when replacing the cartridge.

If a cap is needed, it can be ordered separately.

cleaning the pur glue cartridge • APURgluecartridgehastobedrainedandushedtwicewithEVA

after use. Leave a small amount of EVA glue in the tank to protect

the glue cartridge during the storage.

• Drain the glue cartridge by applying glue using a chip board (gray

board) or other thick paper substrate.

3. MACHINE INSTALLATION & 4. GLUE AND GLUE CARTRIDGE

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

8

DRAFT

selecting the teMperature

5. conTrol Panel and TemPeraTure conTrol

standby/ autO-Off

• The control panel indicates the selected temperature (PUR or EVA).

• SelectPURwhentheglueheadislledwithPUR-glueandEVA

whentheglueheadislledEVA–glue.

• When the indicator light is blinking, the glue head has not yet

reached the selected temperature.

• The machine is equipped with timer and auto-off feature.

• The timer starts when the machine is switched on.

• Pressing the temperature selection button resets the timer to zero.

• Auto-off turns the heaters off after 10 hours.

• When the auto-off has turned the heaters off, the red standby –

light is lit.

• When the temperature selection button is pressed, the machine

starts heating again.

5. CONTROL PANEL AND TEMPERATURE CONTROL

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

9

DRAFT

extractOr hOOd and readiness

fOr fuMe extractiOn

6. fume eXTracTor

cOnnectiOn tO the extratOr hOOd

• The machine is equipped with a fume extraction hood which

directs the fumes away from the operator towards the fume

extraction port.

• Either a connection to your existing external/outside ventilation

or a fume extraction unit is recommended for all PUR glue

operations. No fume extraction device is included in the delivery.

• The extractor hood has a work light which can be turned on/off

from the switch located on the upper edge of the hood.

• The hood is equipped with fume exit connector port, and

the machine is equipped with 50mm (2”) and 100 mm (4”)

connectors.

o WARNING!

▪Hot PUR glue emits fume containing isocyanate. Glue

fumes can be harmful. Read the material safety data

sheet for the PUR –glue before using the glue. Do not use

PURgluewithoutsufcientfumeextractionandproper

ventilation. Follow all local and federal guidelines for

proper ventilation.

o RECOMMENDATION!

▪Itisrecommendedtoconnectasufcientlypowerfulfume

extraction device to the extractor hood to collect fume

emissions. Always follow local rules and regulations.

bypass valve On the fuMe extractOrs

• The extractor hood has a bypass vent on right side.

• Open the vent by bending and pulling the blue handle. The vent

is locked to the open position with magnets marked with green

highlight in the image.

• Make sure that the bypass vent is closed when applying glue on

the book spine.

• The bypass vent is opened to improve fume extraction from the

glue cartridge when adding PUR glue or checking glue level. For

details, please, please see

Glue Cartridge Handling

-section

6. FUME EXTRACTOR

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

10

DRAFT

7.1 installing a new glue

cartridge tO the gripper

7. HandlInG Glue carTrIdGe

• Remove the packaging on the glue cartridge and the gripper.

• The gripper has a locking latch which is opened by pressing the

blue trigger on top.

• Press to open the locking latch. Position the gripper by guiding the

screws marked in green highlight in the image, by guiding slots

marked with red highlight in the image.

• Secure the glue head by releasing the latch

• Make sure that locking lid marked with green highlight in the

image is securely attached to the glue cartridge

o WARNING!

▪When the glue head is heating up in the heating dock, all

related parts and surfaces become very hot. This includes

the glue cartridge, the heating dock, the glue tank cap

and any drops of glue dripping from the glue cartridge.

The parts can remain hot for a long time after the heating

or the machine is switched off even when the glue

cartridge is removed from the machine.

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪While the machine is turned on, assume all parts in the

glue cartridge area to be HOT!

▪Use the gripper when handling the hot glue head & use

the cap hook only when taking off or putting on the glue

tank cap

7. HANDLING GLUE CARTRIDGE

7.2 stOring the gripper and glue

catridge head in the stOrage lOcker

• Store the glue cartridge only in the gripper storage area.

o WARNING!

▪Always assume the glue cartridge and the tank cap can be

hot!

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪Never touch the cartridge with your hands if the machine

has been turned on, always use the gripper

o WARNING!

▪When moving the glue cartridge, do not tilt or turn it over.

The cap can come off and hot glue may spill from the tank.

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪Always keep the gripper in upright position.

▪Store the gripper in the locker. The locker must be properly

installed (see the locker installation instructions)

lIsÄÄ KuVaT:

1. KaKsI KorKKIa

2. KorKIn aVausTyöKalu

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

11

DRAFT

7.4 handling the glue tank cap • The machine is delivered with two glue cartridge caps and a

cap hook for handling them. The cartridge cap is placed on the

glue cartridge to close the tank and keep the glue fumes inside

the tank. Use one cap for the glue cartridge with PUR glue and

another for EVA glue.

• Keep the cap on the glue cartridge while storing it in the gripper to

prevent the cap from getting lost and keeping any hot glue fumes

inside the glue cartridge.

• Open the cap only for adding glue or checking the glue level.

Otherwise, keep the cap on to prevent glue fumes from escaping.

o WARNING!

▪The tank cap is hot! DO NOT TOUCH ANY HOT

SURFACE AT ANY TIME OR YOU RISK INJURY

▪Always use the cap hook to handle the cap.

o WARNING!

▪Hot PUR glue emits fumes which can be harmful if

inhaled. Before removing the cap, ensure that

- the externally connected fume extractor is on and

operating

- and the glue cartridge is securely connected in the

heating dock, positioned under the bypass vent, which

must be in the open position.

7.3 installing the glue cartridge

tO the heating dOck

• Always Turn the table down before installing or removing the glue

cartridge

• Install the glue cartridge to the heating dock jaw by sliding it in

aprox 3/4 of the way in.

• The correct position to attach it is shown in the image with green

highlight.

• Before pushing the glue cartridge all the way in, check that the slot

onthetorquewheeltstothecorrespondingwedgeoftheheating

dock.

• The torque wheel can be rotated to the correct position by moving

the heating dock left or right using the applicator handle.

• Push the glue cartridge all the way in to the locked position.

7. GLUE CARTRIDGE HANDLING

• To remove the gripper press the blue trigger with your thumb.

• Pull towards you about 2 cm in order to release the lock.

• Remove the gripper from the machine and store it into the gripper

locker

• Check that safety latch is down, (marked with green highlight)

• Check that the machine is set for the correct glue type temperature

(PUR or EVA)

• Place the thermal protection (covers) back in the correct place.

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

12

DRAFT

7.5 chanching the glue catridge

7. Glue carTrIdGe HandlInG

• Table needs to be in down position

• Remove thermal casing and heat shield

o WARNING!

▪When glue cartridge is heating up , all related parts

and surfaces become hot. This includes glue cartridge,

heating dock, glue tank cap and possible glue drops from

glue cartridge. They can be hot for a long time even if

the machine is switched off - or glue cartridge has been

removed

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪Do not touch

▪Use the gripper when handling the hot glue cartridge and

cap hook only for glue tank cap.

• Place the gripper on glue cartridge by pressing blue locking lid

and push the gripper to its place using the guiding screws marked

in green highlight in the image.

• Release the blue locking lid trigger once the cartridge is placed

correctly

• Securely hold the gripper with both hands with the blue handle.

• Pull the gripper towards you gently until safety latch (highlighted in

red) touches the safety stop

• Press the safety latch down, pull the gripper out and store it in the

storage are on the left side of the machine

o WARNING!

▪If glue cartridge is tilted, the cap can come off and hot

glue can spill out

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪Keep the gripper always in upright position.

▪Store the gripper in the locker, making sure it is properly

installed (see locker installation instructions).

7. GLUE CARTRIDGE HANDLING

lIsÄÄ KuVaT:

1. KaKsI KorKKIa

2. KorKIn aVausTyöKalu

• Install new cartridge as in section 7.3

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

13

DRAFT

adding glue

8. addInG Glue and usInG THe byPass ValVe

• !! IMPORTANT!! Ensure that the fume extraction device is

connected and switched on

• Lift the thermal case cover and place it in the designated area.

o WARNING!

▪DO NOT TOUCH ANY HOT SURFACE AT ANY TIME OR

YOU RISK INJURY

▪Use only the glue cap handle to move the glue cap.

• Move the heating dock sideways under the fume extractor bypass

vent using the applicator handle , and open the vent

• Remove the cap from the cartridge with the cartridge cap hook

and place the cap on storage tray.

o WARNING!

▪The glue cartridge cap is hot! DO NOT TOUCH ANY

HOT SURFACE AT ANY TIME OR YOU RISK INJURY

o WARNING!

▪Hot PUR glue emits fumes which can be harmful if

inhaled. Before removing the cap, ensure that

- the externally connected fume extractor is on and

operating

- and the glue cartridge is securely connected in the

heating dock, positioned under the bypass vent, which

must be in the open position.

• Installthellingfunnelontopofthegluecartridge.

o WARNING!

▪The glue cartridge is hot! DO NOT TOUCH ANY HOT

SURFACE AT ANY TIME OR YOU RISK INJURY

• Addmoreglue,maximumllinglevel2/3ofthecartridgeheight,

see the picture.

o WARNING! DO NOT OVERFILL

▪Risk of injury !

▪Risk of machine failure!

• Removethellingtunnel

• Replace the cap on the glue cartridge, using the cap tool.

• Move the heating dock back to home position

• Replace thermal casing covers

• Close the vent

• Wait a minimum 10 minutes before resuming normal operations

8. ADDING GLUE AND USING BYPASS VALVE

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

14

DRAFT

9. THermal ProTecTIons

THERMAL CASING

• The machine is delivered with a separate

thermal casing cover for the glue cartridge.

• Only touch or move the thermal casing covers

by the handles. All other surfaces are very hot.

• The casing cover is designed to protect the user

from the hot surfaces inside the glue cartridge/

heating dock

• The thermal casing must be removed to open

the glue tank cap or when installing or removing

the glue cartridge

HEAT SHIELD

• The machine is delivered with a separate front

heat shield.

• The purpose of the front heat shield is to protect

the user from hot parts and hot glue drops.

• The front heat shield should always be installed

with the following exceptions:

o When the heat shield needs to be removed

temporarily to install or remove the glue

cartridge or to remove or add drop trays

9. THERMAL PROTECTIONS

Figure 9-1 Thermal casing and heat shield

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

15

DRAFT

10. funcTIons

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

16

DRAFT

TURN TABLE HANDLE

• When in the neutral position, the nipping

plate is open and the turn table is in the down

position.

• By turning the handle up, the turn table rotates

to up or ”gluing” position.

• By turning the handle down, the nip plate moves

to press the book spine.

o Warning!

▪Always use the handle to rotate the turn

table or it may, suddenly drop back

to the down position. Risk of personal

injury and machine failure.

10. funcTIon descrIPTIon

10. FUNCTION DESCRIPTION

NIPPING TOOLS

• The machine is delivered with two pairs of

nipping tools for spine pressing. A pair includes

a moving tool (in front) and a back support.

• Soft cover tools are marked with letter S and

hard cover tools with letter H.

• Install the back support to the rear part of the

positioning deck against the back limiter. The

back support is held tight with magnets.

• The moving tool is placed to the front of the

positioning deck on top of the nipping cams.

CLAMP

• The clamp handle is spring loaded. Pull the

clamp up and release the handle to lock it to

the UP -position.

• The clamp stays in the up position when the

locking pin rests in the slot on the support rod.

• Press the handle down against the U-shaped

groove to move the clamp. Slide the clamp so

that it touches the book block.

• Turn the handle all the way up to lock the

clamp.

• When putting a book cover in the binder, lift

the table slightly up with the cclamp handle and

slide the cover in from above.

• When closing the clamp, press the support rod

down to hold the table in position when locking.

Figure 10-x X

Figure 10-x X

Figure 10-x X

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

17

DRAFT

HARD COVER PAPER GUIDE

• It can be used with both soft and hard covers

• When binding a soft cover book, align the cover

horizontally against the paper guide.

• When binding a hard cover book, pull the

spring loaded outer rim up and align the hard

cover against the inner rim. Release the outer

rim to lock the hard cover down.

Figure 10-x X

ROUGHENING

• For roughening the roughener back and forth

over the book spine when the table is in the

glueing position.

• The book spine must be roughened before

glueing.

• Compress the spine back to shape after

roughening to form a square shaped book

spine.

o CAUTION!

▪Do not use roughening after glue has

been applied to the book spine as glue

destroys the roughening parts!

APPLYING GLUE

• Glue is applied by moving heated hot glue

cartridge back and forth over the book spine

using applicator handle. The glue roller located

on bottom of the glue cartridge spreads the glue

on the book spine.

• Repeat to apply more glue to the spine. Avoid

applying too much glue.

o WARNING!

▪The applied glue is hot! DO NOT

TOUCH ANY HOT SURFACE AT ANY

TIME OR YOU RISK INJURY

▪Do not touch the glue!

• Side gluing for soft cover books

o Pull 3 to 4 times from the cover after

gluing to put more glue between the cover

andtherstpage.

• Side gluing for hard cover books

▪Aftergluing,ipthespinestickonthe

glued book spine to get a professional

nish.

Figure 10-x X

Figure 10-x X

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

18

DRAFT

BEFORE DRAINING

• Place a gray board (chip board)on the

positioning deck, the rear edge against the back

support.

• Put a stack of papers (approximately 4 cm/ 1.5”

thick) on the position deck in portrait position

(the short edge against the deck). Close the

clamp and turn the table to gluing position.

• The glue has to be melted before the glue

cartridge can be drained. Use the PUR

temperature setting for PUR -glue and the EVA

setting for EVA -glue.

11. draInInG THe Glue carTrIdGe

11. DRAINING THE GLUE CARTRIDGE

Figure 10-x X

DRAINING THE PUR GLUE CARTRIDGE

• Cover the book block spine with gray board

so that the long edge of the board is towards

you (the long edge is parallel with the glue

applicator rail).

• Move the heating dock sideways close to the

book block by using the applicator handle.

Move the gray board against the back wall

of the glue cartridge docking station. Apply a

sufcientamountofglueonthegrayboardby

moving the unit back and forth from applicator

handle.

• Stop the heating dock in the middle of the paper

block. Remove the gray board by pulling it

towards yourself, throw out the greyboard. Move

the heating dock right over the edge of the

paper block.

• Repeat the steps until the glue roller stops

applying glue on the gray board and it is empty,

add a small amount of EVA glue and repeat

twice.

• Leave a small amount of EVA glue in the

cartridge.

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

19

DRAFT

HoW To use VIdeos

maInTenance

declaraTIon of conformITy

Address:

Telephone:

Fax:

E-mail:

Internet:

Nordea Bank Finland Plc,

ID No.:

DECLARATION OF CONFORMITY

We, Maping Company, hereby declare that following product:

Machine name:

Model number:

Type:

Fastbind ELITE XT

17

Hot melt book binding machine

is in conformity with essential requirements of the following standard:

98/37/EEC (MC).

Manufacturer:

Maping Co

Atomitie 5 F, FIN-00370 Helsinki, Finland

Tel. +358 9 562 6022 Fax: +358 9 562 6215

Helsinki, 2006-01-05

_______________________

Lauri Huotari, Managing Director

Espoo, 25.6.2014

DECLARATION OF CONFORMITY

We, Maping Company, hereby declare that following product:

Machine name:

Model Number:

Type:

Pureva XT

7502

Hot melt book binding machine

The product fullls the essential safety requirements for CE conformity

marking according to the Low Voltage Directive (2006/95/EC) and EMC

Directive 2004/108/EC.

Manufacturer: Maping Co

Kuusiniemi 10, FIN-02710 Espoo, FINLAND

Tel. +358 9 562 6022 Fax: +358 9 562 6215

Applied standards: EN 60950 - 1:2001 (safety)

EN 61000 - 6-3:2001 (EMC emission)

EN 61000 - 6-1:2001 (EMC immunity)

o TÄNNE TARVITTAISIIN

UUSIN VERSIO

60950 ja EMC

DIREKTIIVEISTÄ

FASTBIND PUREVA XT USER MANUAL | v 1.0 | © Maping Co 2014

20

DRAFT

5. coPyrIGHT, TrademarKs and WarranTy

5. COPYRIGHT, TRADEMARKS AND WARRANTY

cOpyright infOrMatiOn © 2014 Copyright Maping Co. Reproduction, adaptation or translation

without prior written permission is prohibited, except as allowed under

the copyright laws. The information contained herein is subject to

change without notice.

tradeMarks and patents

One year liMited warranty

cOntact infOrMatiOn

X, Y, Z are trademarks of Maping Co. Fastbind Pureva XT is invention

of the Maping Co (patent pending).

Maping Co warrants this product against defects in material or

workmanship as follows:

For the period of twelve months from the date of purchase, repair

or replace free of charge, for the original purchaser, any part or parts

found by inspection to be defective by our factory authorized service

outlet or by the manufacturer at Helsinki, Finland. All transportation

charges on parts submitted for repair or replacement under this

warranty shall be paid for by the purchaser.

All service under this warranty will be furnished and performed by

factory authorized service stations or by the manufacturer. Warranty

service does not extend the warranty period.

This warranty is limited to the value of the product and it does not

cover damage caused by:

• Transportation

• Normalwearandtear

• Neglectedorimpropermaintenance

• Misuse

The warranty will be voided if machine’s type plate has been wholly or

partially removed or erased.

Maping Co is not responsible for any damages, including but

not limited to direct, indirect or consequential damages, loss of

material, prot or interruption of business. Maping Co may at any

time discharge its warranty by refunding the purchase price and taking

back the product.

Maping Co

Kuusiniemi 10, FIN-02710 Espoo, FINLAND

Tel. +358 9 562 6022, Fax +358 9 562 6215

Email: support@maping.com

www.fastbind.com

This manual suits for next models

1

Table of contents

Other Fastbind Binding Machine manuals