Fastbind Elite User manual

www.maping.com

ELITE

ELITE

Manual Rev. d5 090804 --- multilang

1. DESCRIPCIÓN…………………………………………4-3

2. SEGURIDAD…………………………………………...4-4

3. ELEMENTOS PRINCIPALES Y CONTROLES………4-6

4. INICIO…………………………………………………..4-7

5. ENCUADERNACIÓN CON TAPABLANDA …………4-9

6. ENCUADERNACIÓN CON TAPADURA……………4-12

7. ENCUADERNADO CON CINTA ……………………4-16

8. ENCUADERNAR UN TACO (LIBRO SIN TAPA) …4-20

9. CUIDADO Y MANTENIMIENTO ……….…………4-22

10. ESPECIFICACIONESTÉCNICAS……………………4-23

11. SOLUCIÓN DE PROBLEMAS ………………………4-24

12. TÉRMINOS DE LA GARANTÍA ……………………4-25

APÉNDICE A: Instalación de las herramientas de tapa dura.4-26

APÉNDICE B: Instalación de la cizalla Fastbind……………4-27

ESPAÑOLPOLISH

1. EINLEITUNG…………………………………………3-3

2. SICHERHEIT……….………..………….....................3-4

3. HAUPTBESTANDTEILE UND BEDIENELEMENTE.3-6

4. INSTALLATION ........…………...….……………..…...3-7

5. BINDEN EINES SOFTCOVER-BUCHES............…….3-9

6. BINDEN EINES HARDCOVER-BUCHES............…3-12

7. BINDEN MIT STRIPS..............................…………….3-16

8. BINDEN EINES ABREISSBLOCKS..….…………….3-20

9. PFLEGE UND WARTUNG..............……………….…3-22

10. TECHNISCHE DATEN.................. .……….……..…..3-23

11. STÖRUNGSBEHEBUNG....... .……..…......................3-24

12. GEWÄHRLEISTUNG............... ...……..….……..…...3-25

ANLAGE A : Installation des hardcover-werkzeugs..... …...3-26

ANNEXE B : Installation des Fastbind trimmers ...........…3-27

DEUTSCH

1. CHARAKTERYSTYKA MASZYNY 5-2

2. ZASADY BEZPIECZEŃSTWA 5-3

3. GŁÓWNE CZĘŚCI I ELEMENTY STEROWNICZE 5-4

4. PRZED UŻYCIEM MASZYNY 5-5

5. OPRAWA KSIĄŻEK Z MIĘKKĄ OKŁADKĄ 5-6

6. OPRAWA KSIĄŻEK Z TWARDĄ OKŁADKĄ 5-9

7. OPRAWA W TAŚMY SAMOPRZYLEPNE 5-13

8. OPRAWA BLOCZKÓW Z KARTKAMI DO WYDZIERANIA 5-16

9.

CZYNNOŚCI ZWIĄZANE Z OBSŁUGĄ BIEŻĄCĄ MASZYNY

5-18

10. PODSTAWOWE DANE TECHNICZNE 5-19

11. WYBRANE PROBLEMY TECHNICZNE 5-19

12. WARUNKI GWARANCJI 5-19

DODATEK A:

Instalacja zestawu narzędzi do oprawy w twardą okładkę

5-26

DODATEK B:

Instalacja modułu docinającego okładki

5-27

1. DESCRIPTION…………………………………………2-3

2. REGLES DE SECURITE……….………..………….....2-4

3. PIECES PRINCIPALES ET CONTROLES....……….... 2-6

4. PREPARATIONS ........…………...….…………….…...2-7

5. RELIER AVEC UNE COUVERTURE SOUPLE …….2-9

6. RELIER AVEC UNE COUVERTURE RIGIDE........…2-12

7. RELIER AVEC UNE BANDE..................…………….2-16

8. RELIER UN BLOC-NOTES.....….….….……………..2-20

9. ENTRETIEN ET MAINTENANCE ……………….…2-22

10. SPECIFICATIONS TECHNIQUES .……….……..…..2-23

11. TABLEAU DE DEPANNAGE .……..….......................2-24

12. CONDITIONS DE GARANTIE ...……..….……..…...2-25

ANNEXE A : Installation du kit pour couverture rigide …...2-26

ANNEXE B : Installation du massicot ……..….…….....…2-27

FRANÇAIS

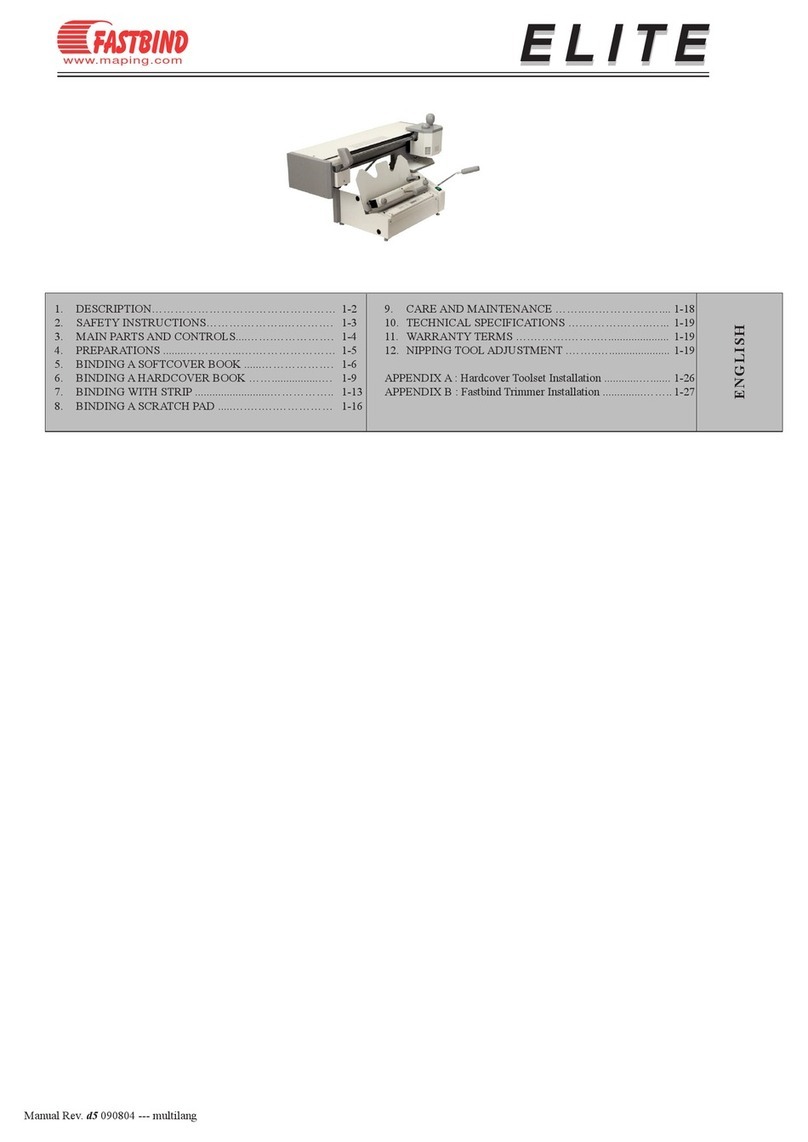

1. DESCRIPTION…………………………………………1-3

2. SAFETY INSTRUCTIONS……….………..………….1-4

3. MAIN PARTS AND CONTROLS....…….…………….1-6

4. PREPARATIONS ........…………...….…………………1-7

5. BINDING A SOFTCOVER BOOK ......……………….1-9

6. BINDING A HARDCOVER BOOK ……................…1-12

7. BINDING WITH STRIP ..........................…………….1-16

8. BINDING A SCRATCH PAD .....….….….…………1-20

9. CAREANDMAINTENANCE……..….………….…...1-22

10. TECHNICALSPECIFICATIONS….……….……..…..1-23

11. TROUBLESHOOTING….……….……..….................1-24

12. WARRANTYTERMS….……….……..…....................1-25

APPENDIXA: HardcoverToolsetInstallation............….......1-26

APPENDIXB: FastbindTrimmerInstallation ..............……..1-27

ENGLISH

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

1. Scratch pad

2. Softcover

3. Hardcover

4. Strip

Paper Guide

Model Nipping Tool

SHSH

S for softcover and H hardcovers. Please note that the Hardcover toolkit is an

accessory consisting of hardcover paperguide and hardcover nipping tool.

xx

xx

x

xx

x

x

x

x

Binding Types

and Required Tools

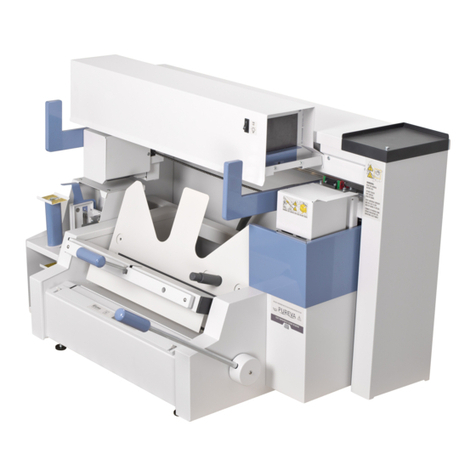

Congratulations on your purchase of the Fastbind Elite hot melt book binding

machine - the current flag ship of Fastbind models!

Elite offers Fastbinds cutting edge rotary binding technology and takes the

concept further by offering excellent binding charasteristics even with difficult

materials. New double roller roughener broadens binding material range by

providing necessary tools to open paper grain with coated papers. As before,

various cover materials can be processed without time consuming adjustments.

One binding machine to handle a whole range of paper products from simple tear-

off pads to demanding hard cover applications!

We believe that Elite brings tabletop document binding onto a completely new

level and wish you productive moments with it!

General

Elite can be used to bind various paper and cardboard products. All four binding

types can be done with two simple tool sets and with the same machine settings.

The machine is normally delivered with softcover tool set and hardcover tools are

available as an accessory. Following table lists which tools can be used each of

the four binding types:

Section 1

DESCRIPTION

Binding Possibilitiess

Elite uses hot melt adhesive for binding and works properly only with hot melt

type of adhesives. This means that adhesives designed for other purposes, or

containing organic ingredients for instance, cannot be used. The manufacturer

recommends Fastbind Hot Melts, which have optimal melting point - viscosity

combination for Fastbind machines and thus suits for all binding work done with

Elite. Moreover, this adhesive is nontoxic and can be used safely indoors.

Hot Melt Adhesives

DESCRIPTION

1 - 1

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

Before installing and operating Fastbind Elite, the safety instructions and

recommendations in this User’s Manual must be studied carefully. In this way one

can ensure to get the most out of the new binding machine and operate it safely.

Store this document within easy reach of personnel operating or maintaining the

unit.

Section 2

SAFETY

Operate Safely

Safety Symbols Following symbols are used to warn against dangers or possible sources of

danger. Become familiar with them.

WARNING: Failure to observe may result in personal

injury, death or equipment damage.

CAUTION: Hot surface or hot material. Failure to

observe may result in burns.

CAUTION: Failure to observe may result in equipment

damage.

•Note that the machine weights 52 kg (~105 lb)! When handling the

machine, two persons should always be used. Do not lift from the

rail!

•Install the machine on a stable horizontal surface, close to a power

outlet.

•Fastbind book binding machines are designed for indoor use only.

Avoid drafty, mois and dusty environment. For normal operation, the

ambient temperature range should be +15 to +30 °C.

Handling and Location

Power Supply •Before using the machine, check that the operating voltage and other

specifications indicated on machine’s identity plate match with the

specifications of the power source. This plate is located at the rear of

the machine.

•This unit may only be connected to properly earthed power outlet.

•Never damage, modify or place heavy objects on the power cord. Do

not use the machine if the power cord is bundled, knotted or damaged.

When unplugging the power cord, always grasp the plug to pull it out.

•Switch off the unit and pull out the mains plug prior to all cleaning and

maintenance.

!

!

SAFETY

170 ºC !

!

1 - 2

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

•Use only Fastbind Hot-Melt adhesives for binding. Caution: using

other than Fastbind adhesives will invalidate the warranty and the

manufacturer is not responsible for any damage caused.

•Add only new, clean and dry hot melt glue to reservoir. Collecting

accidentally dropped glue granulates from dirty floor for instance can

block glue applicator and requires expensive service work.

•Do not re-use hotmelt drops from the drop collector tray. These

contain impurities that can block the applicator! From binding

quality perspectivem, chemical properties of the recycled glue are

inferior.

•All of the machine covers, panels and safety labels must be in place

when operating the machine.

•Machine needs to warm up properly before it is ready to use (20

min). Moving adhesive applicator before adhesive has completely

liquefied will damage the machine.

•Do not attempt to alter or modify the machine. It contains high-

voltage components and unexpected faults or electric shock might

occur. Modification will invalidate the warranty.

•Turn the machine off when you have finished working with it.

Even if the machine has unlimited continuous working time, leaving it

on and idle degrades hot melt glue slowly. This can lead to adhesive

‘overcooking’, which blocks the applicator. External timer available as

an external accesory.

•Use only original Fastbind accessories and spare parts approved by the

manufacturer to ensure that the unit can be operated safely. For service

and maintenance, contact Fastbind authorized service outlet.

Operating Machine

Adhesive Applicator

!

!

170 ºC !

SAFETY

!

!

N O

NO

glue

recycling

MAX. LEVEL

DO NOT OVERFILL!

MELTED GLUE

IS HOT !

MIN. LEVEL

•Keep the glue reservoir cap on except when adding hot-melt adhesive.

Foreign objects or substances in the adhesive reservoir can seriously

damage applicator.

•Hot-melt glue and parts within the cover of the adhesive applicator

are hot and can cause skin burns. Let the machine cool down properly

before touching this area.

In case of burns:

• Immediately cool affected skin areas using cold, clean water.

• Do not forcefully remove hot melt material from the skin.

• Seek medical attention immediately.

•Glue roller under adhesive applicator is high precision part and designed

for paper contact only. Foreign objects such as paper clips or staples

damage roller easily. Do not try to rotate the roller by force.

Roughener •Roughener is intended for clean paper only. Using roughner on warm

(soft) glue will block the rollers.

1 - 3

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

Connectto grounded

poweroutlet only!

Connectto grounded

poweroutlet only!

www.maping.com

www.maping.com

Serialno xx-xx

220V, 50-60Hz

Madein inland

Serialno xx-xx

220V, 50-60Hz

Madein inland

ELITE

ELITE

23

23

26

27

28 24

25

29

Connectto grounded

poweroutlet only!

www.maping.com

Serialno xx-xx

220V, 50-60Hz

Madein inland

ELITE

12

3

4

6

8

7

9

10

11

12

13

14

15

17

18

19

20

21

5

22

16

www.maping.com

H

www.maping.com

S

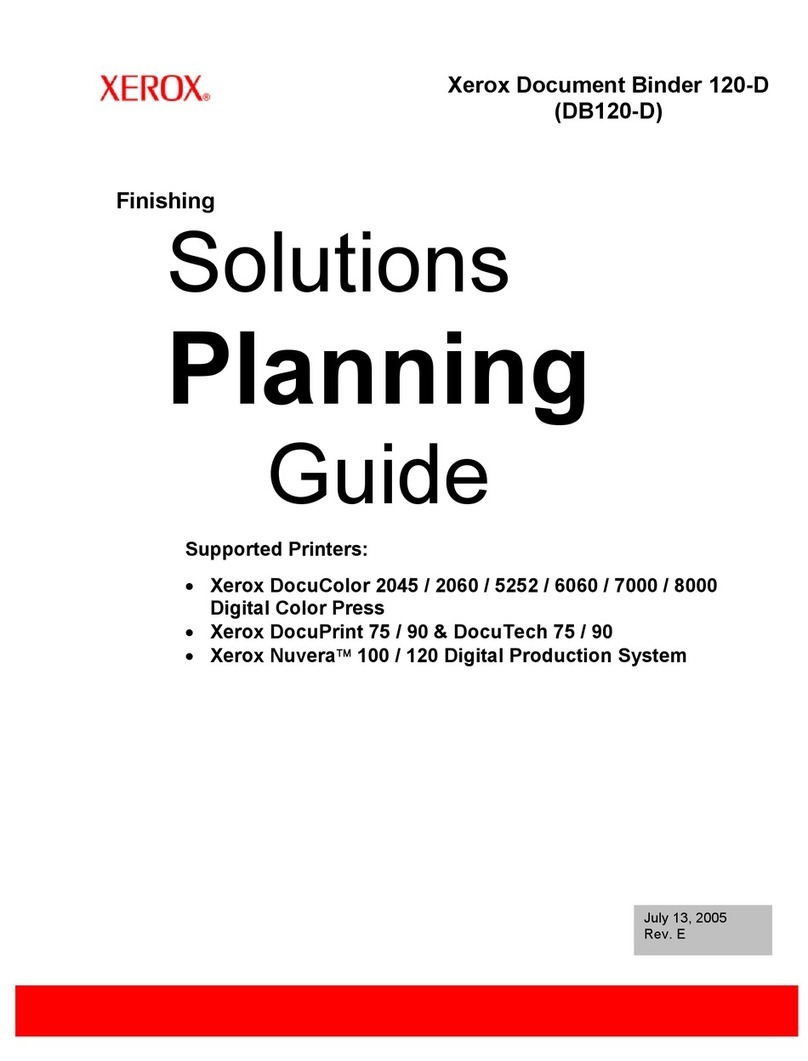

Section 3

MAIN PARTS AND CONTROLS

MAIN PARTS AND CONTROLS

Machine Overview

H -nipping tool for hard covers

Rail height adjustment screws

Rail height locking screws

Table angle adjustment (table down)

Table angle adjustment (table up)

Type plate with serial number

Main connector

Fuse holder with fuse: 230V 6.3 A (T)

23.

24.

25.

26.

27.

28.

29.

1.

2.

3.

4.

5.

6.

7.

8.

Applicator guide

Hand Knob

Reservoir Cap

Adhesive Applicator

Drop Collector with Drop Tray

Turn Table

Paper Guide (Soft or Hardcover)

Knob and Support Rod

Operating Handle

Main Switch

Clamp Handle

Leveling foot

Spine Pressing Tool (nipping tool)

Cam Driving Nipping Tool

Positioning Deck

Clamp

Back Support

Clamp Guide Rod

Roughener

Cover for adjustment elements

Roughener handle

Rail

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

S -nipping tool for soft covers

1 - 4

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

To prepare your machine for use:

a) Remove the packing and protective material. When handling the machine,

two persons should be used. Do not lift from the rail!

b) Check the delivery for any damage incurred during transportation.

Confirm that the shipment corresponds with the details in the delivery

note. Inform dealer and sender immediately about possible damages or

incomplete shipment.

Each standard package(*) contains:

• One binding machine unit equipped with

• Οne softcover paperguide and

• Οne softcover nipping plate (marked with “S”)

• One power cable

• This User’s Manual

(*) Definition of standard package may vary in different countries

c) Select a good location for your machine

• Position the machine on a steady horizontal surface close to a

power outlet

• When selecting the location, remember that the machine weights

52 kg (105 lb)

• For your own convenience, make sure that there is enough

space around the machine for papers, covers and other necessary

supplies.

d) Rotate the turntable to down (DN) position (see the printed scale next

to a operating handle). Open the clamp by pulling the clamp handle and

remove the power cord and possible test books.

e) Remove the reservoir cap and check the glue level in the adhesive

applicator. Hot-melt adhesive should always cover the minimum

level plate. This plate with

multiple holes is visible

when glue has melted and

can be seen from the filling

opening. If the glue level

is low, add more hot-melt

to the applicator. Take care

not to overfill the adhesive

reservoir. Do not re-use hot

melt drops from the drop

collector tray.

Section 4

SETUP

Initial Check-Up

!

Locating the machine

Preparations

SETUP

MELTED GLUE

IS HOT!

MAX. LEVEL

DO NOT

OVERFILL!

MIN. LEVEL

1 - 5

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

Note that the applicator can be moved only when the machine has

warmed up. At the room temperature hot melt in the reservoir is still

solid and thus blocks the roller rotation.

f) Connecting the power cord

• Once you have checked that local power supply matches with

the machine’s operating voltage, connect the mains lead.

• Press the main switch to turn the machine on. The green power

indicator light should light up green.

g) Let the machine warm up for 20 minutes. During this time glue in the

applicator’s reservoir melts, and the applicator will run easily along the

guide rail. Now the machine is ready to use.

Note that even the best hot melts degrade during the time in high

temperatures. To preserve adhesive’s chemical properties and minimize

energy consumption, turn the machine off when not working with it.

Alternatively one can use external timer to switch off the electricity after pre-

set time limit. Timer is available as an optional accessory.

SETUP

1 - 6

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

5.1.1

5.1.2

a)

a) b)

c)

b)

Before you begin, ensure that

• Τhere is glue in the applicator reservoir (Fastbind Hot-Melt)

• Machine has warmed up at least 20 min

• Soft cover nipping plate is attached (marked with “S”)

• Τhe paper guide is in place (either “S“ or optional H-model)

• Τhe turntable is in the normal position (the hand lever in

N-position)

Release and open the clamp by pulling the clamp handle

down and towards you.

a) Insert the cover between the clamp and turntable. It

will slip in easily if you lift the turntable slightly using

the clamping handle.

b) Align the cover against the paper guide. Place the

cover so that the front page faces turntable.

Place the book block between the cover and clamp.

a, b) Adjust the block from side and top carefully to

ensure that it aligns correctly with the cover.

c) Push out air between the pages with both hands.

5.1 LOADING COVER AND PAPERS

Section 5

BINDING A SOFTCOVER BOOK

Check List

Binding procedure

BINDING A SOFTCOVER BOOK

1 - 7

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

5.1.4

5.1.3

5.2.1

5.2.2

a) b)

Turn the table over (UP) by pushing the operating handle up.

a, b) Fold the cover back.

5.2. ROUGHENING AND HOT MELT APPLICATION

THICK BOOKS OR BOOKS WITH COATED PAPER:

Roughen book spine 1-3 times. Repeat if necessary.

Roughening opens the paper grain on book spine and

improves binding result with difficult materials. Note that

roughening several times increases spine width. Too heavy

roughening results unsquare book spine.

Run adhesive applicator along the book spine using four step

method illustrated below. It gives the highest binding strength

and can be recommended for all binding types shown in this

manual.

Push the clamp forward and lock it by lifting the clamp

handle up. To keep the turntable still during this action, put

your left hand on clamp’s left knob when lifting the handle.

BINDING A SOFTCOVER BOOK

Four step method. Note that glue is not applied

right to te edge with every pass.

For bindings with easy material, simply apply glue once or

twice along the whole spine length. For thicker books or

books with coated paper, apply glue 2-3 times.

1 - 8

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

5.2.3

5.3.1

5.3.2

5.3.3

a) b)

a)

Immediately after hot melt application, it is recommended to

pull slightly from the cover to secure the binding between the

cover and first pages.

Release the clamp by lowering the handle and pull it up.

Remove the book by lifting the turntable slightly with the

clamp handle.

If the cover does not require trimming, the book is ready. The

book can be blattered, but the binding has not yet reached the

maximum strength.

Complete curing time depends on the type of hot melt, but

for thick books bound with Fastbind Type 1 hot melt, the

recommended waiting time is 15 to 30 minutes. The final

strength is reached after the first 24 hours.

Push the handle down firmly and hold for 5 - 7 seconds to

press the spine and fold the cover.

Turn the table back into the starting position by pulling the

hand lever. Given that hot melt tacks (starts to dry) in 2 -

3 seconds, swift but gentle actions provide the best result.

Caution: Do not slam the table against the table limit stops

as this can damage the machine

5.3. PRESSING THE SPINE

BINDING A SOFTCOVER BOOK

5.4. TRIMMING WITH FASTBIND TRIMMER (ACCESSORY)

To cut the longer tail of the cover off, place the book in the

middle of the cutting support and slip the cover into slot.

Hold the book with your fingers and move the cutter all the

way cross the book. If necessary, trim twice.

1 - 9

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

1.1

a) b)

6.1.1

Before you begin, ensure that

• Τhere is glue in the applicator reservoir (Fastbind Hot-Melt)

• Machine has warmed up at least 20 min

• Ηard cover nipping plate is attached (marked with “H”)

• Τhe turntable is in normal position

• Τhe hardcover paper guide is attached (H- model)

PREPARATIONS:

a. Fold the hardcover in your hands to pre-form ‘folding lines’ down

the spine against the spine board.

b. Add tacky lining sheets as the first and last page of the paper block

with the silicone release paper outwards. Jog the complete block

and align them against the paper guide.

Release the clamp by pulling the clamp handle down and

towards you. Insert the cover between the clamp and turntable.

It will slip in easily if you lift the turntable slightly using the

clamping handle. Place the cover so that the front page faces

turntable.

6.1. LOADING COVER AND PAPERS

Section 6

BINDING A HARDCOVER BOOK

Check List & Preparations

Binding procedure

BINDING A HARDCOVER BOOK

a,b ) Press the cover spine against positioning deck.

Spine width

(mm)

Paper block

thickness (mm)

No. of sheets

(pages)

8 4 ± 1,0 35 - 55

10 6,5 ± 1,0 55 - 75

12 8,5 ± 1,0 75 - 95

14 10,5 ± 1,0 95 - 115

16 12,5 ± 1,0 115 - 135

18 14,5 ± 1,0 135 - 155

20 16,5 ± 1,0 155 - 175

NO. OF PAGES FOR DIFFERENT HARDCOVERS

Table applies to FASTBIND supplies only!

1 - 10

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

b)

b)

d)

b)

a)

a)

c)

a)

6.1.2

6.1.3

6.1.4

6.1.5

Secure the hardcover behind the sprung outer collar of the

paper guide.

Place the book block between the cover and clamp.

a, b) Adjust the block from side and top carefully to ensure

that it aligns correctly with the cover.

c) Push out air between pages using both hands.

d) Cover and papers properly aligned against back

support.

a) Pull out the outer collar of the guide and slide the

cover edge under its rim.

b) The spring force of this collar will hold the hardcover

in place.

Hold papers against turntable with your left hand as shown in

the picture. Push the clamp forward and lock it by lifting the

clamp handle up with right hand.

Turn the table over (UP) by pushing the operating handle up.

a,b) Fold the cover back and the block is ready for adhesive

application.

BINDING A HARDCOVER BOOK

1 - 11

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

b)

6.2.2

6.2.3

6.3.1

6.2.1

c)

a)

a) b)

6.2. ROUGHENING AND HOT MELT APPLICATION

THICK BOOKS OR BOOKS WITH COATED PAPER:

Roughen book spine 1-3 times. Repeat if necessary.

Roughening opens the paper grain on book spine and

improves binding result with difficult materials. Note that

roughening several times increases spine width. Too heavy

roughening results unsquare book spine.

For thin books (spine witdth <10 mm), apply glue once or

twice. For thicker books or books with coated paper, apply

glue 2-3 times.

Dipping: Immediately after hot melt application, dip the spine

stick quickly on glue with single back and forth movement.

a, b, c) Note how the cover is hold and pushed forward to

perform dipping action.

6.3. BOOK REMOVAL

Turn the table back into the starting position by pulling the

hand lever. Given that hot melt tacks (starts to dry) in 2 - 3

seconds, swift but gentle actions provide the best result.

Caution: Do not slam the table against the table limit stops

as this can damage the machine

a) Open the clamp.

b) Pull from hardcover tool’s outer collar to release the

book. Move the book to left.

BINDING A HARDCOVER BOOK

1 - 12

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

b)

b)

d)

a)

c)

a)

6.3.2

6.4.1

6.4.2

Turn clamp handle down, pull the clamp open. Remove the

book by lifting the turntable slightly with the clamp handle.

6.4. FINISHING THE BINDING

Pressing the spine of the hardcover book: close the book

and place it between the clamp and turntable (spine against

positioning deck).

a) Close the clamp and press the spine.

b) Open the clamp and turn the book around. To press the

other side of the spine, place the book again between

the clamp and turntable. Close the clamp and press the

spine.

Open the clamp and remove the book.

Attaching tacky lining sheets (end papers) to covers. Lift the

book on top of closed clamp.

a) Pull silicon lining paper to half way. Bend the cover

slightly to arc and close it to half way.

b) Close the cover and press it slightly. Pull the rest of the

silicon release paper off. The first cover is done.

c) Turn the book over. Repeat steps a) and b) for the

other cover.

d) To finish the spine, press your fingers together and

follow the folding line all the way down.

BINDING A HARDCOVER BOOK

1 - 13

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

a) b)

7.1.1

7.1.2

Before you begin, ensure that

• Τhere is glue in the applicator reservoir (Fastbind Hot-Melt)

• Machine has warmed up at least 20 min

• Τhat softcover nipping plate is attached (marked with “S”)

• Τhe turntable is in normal position.

• Τhe paper guide is in place (S or H-model)

PREPARATIONS:

a. Fold one A4 or letter size paper sharply along the long side so that

the folding line divides the paper in approximately ratio 30

_

:_70%

Open the clamp and place the folded paper on positioning

deck. Align the paper against paperguide.

Take a strip and make a sharp folding line on one side of the

strip.

a) Folded strip.

b) Place the folded strip on paper. Note strip’s alignment:

short folded part against the turntable while the long

tail comes towards and on top of the nipping tool.

7.1. LOADING STRIP AND PAPERS

Section 7

BINDING WITH STRIP

Check List & Preparations

Binding Procedure

BINDING WITH STRIP

1 - 14

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

b)

d)

b)

a)

c)

7.1.3

a)

7.2.1

7.1.4

7.1.5

Place the papers that make the book between the strip and

clamp.

a, b) Adjust the block from side and top carefully to ensure

that it aligns correctly with the cover.

c) Push out air between pages using both hands.

d) Since strip cannot be aligned against paperguide,

check that strip is positioned correctly: strip edge and

papers are on same line.

Push the clamp forward and lock it by lifting the clamp

handle up. To keep the turntable still during this action, put

your left hand on clamp’s left knob when lifting the handle.

Turn the table over (UP) by pushing the operating handle up.

a, b) Fold the strip back and the block is ready for

adhesive application.

7.2. ROUGHENING AND HOT MELT APPLICATION

BINDING WITH STRIP

THICK BOOKS OR BOOKS WITH COATED PAPER:

Roughen book spine 1-3 times. Repeat if necessary.

Roughening opens the paper grain on book spine and

improves binding result with difficult materials. Note that

roughening several times increases spine width. Too heavy

roughening results unsquare book spine.

1 - 15

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

a)

7.3.2

7.3.3

7.3.1

7.2.2

GLUE APPLICATION

For thin books (spine witdth <10 mm), apply glue once or

twice. For thicker books or books with coated paper, apply

glue 2-3 times.

Release the clamp by lowering the handle and pull it up.

Remove the book by lifting the turntable slightly with the

clamp handle.

Push the handle down firmly and hold for 5 - 7 seconds to

press the spine and fold the cover.

7.3. PRESSING THE SPINE

Turn the table back into the starting position by pulling the

hand lever. Given that hot melt tacks (starts to dry) in 2 -

3 seconds, swift but gentle actions provide the best result.

Caution: Do not slam the table against the table limit stops

as this can damage the machine

BINDING WITH STRIP

1 - 16

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

b)a)

c) d)

7.4.1

7.4. FINISHING THE BINDING

Attaching the strip edges to binding

a, b) Remove the silicon release paper.

c) Press to attach the strip to cover.

d) Turn binding around and repeat steps b) to c).

BINDING WITH STRIP

1 - 17

REV. d5 Elite Multilang

© 2004.12 Maping Co

www.maping.com

b)

a)

a)

8.1.1

8.1.2

Before you begin, ensure that

• Τhere is glue in the applicator reservoir (Fastbind Hot-Melt )

• Machine has warmed up at least 20 min.

• Softcover nipping plate is attached (marked with “S”)

• Τhe turntable is in normal position

• Τhe paper guide is in place (S or H-model)

PREPARATIONS:

a. Fold A4 or letter size silicon release paper sharply along the long

side so that the folding line divides the paper in approximately

ratio 30: 70%. The width of the silicon paper should be larger than

binding width. If spine pressing is preferred, the paper should be

so long that it comes on the top of the nipping tool.

Place the papers that make the book between the turntable

and clamp.

a, b) Adjust papers from side and top carefully to ensure

that it aligns correctly with the cover.

Push the clamp forward and lock it by lifting the clamp

handle up. To keep the turntable still during this action, put

your left hand on clamp’s left knob when lifting the handle.

Turn the table over (UP) by pushing the operating handle up.

Fold the silicon release paper back and the block is ready

for adhesive application.

Open the clamp and place the folded silicon paper on

positioning deck. It slides in easily when inserted from

below

a) Note the length of the silicon paper. It extends on the

top of the nipping tool. This prevents silicon paper

being crumpled when nipping tool moves.

8.1. LOADING PAPERS

Section 8

BINDING A SCRATCH PAD (BOOK WITHOUT COVER)

Check List & Preparations

Binding Procedure

BINDING A SCRATCH PAD (BOOK WITHOUT COVER)

1 - 18

www.maping.com

rev. d5 Elite Multilang

© 2004.12 Maping Co

a)

8.2.1

8.2.2

8.3.1

8.3.2

8.3.3

8.2. ROUGHENING AND HOT MELT APPLICATION

GLUE APPLICATION

For thin books (spine witdth <10 mm), apply glue once or

twice. For thicker books or books with coated paper, apply

glue 2-3 times.

Push the handle down firmly and hold for 5 - 7 seconds to

press the spine and fold the cover.

8.3. PRESSING THE SPINE

Turn the table back into the starting position by pulling the

hand lever. Given that hot melt tacks (starts to dry) in 2 -

3 seconds, swift but gentle actions provide the best result.

Caution: Do not slam the table against the table limit stops

as this can damage the machine

Release the clamp by lowering the handle and pull it up.

Remove the binding by lifting the turntable slightly with the

clamp handle.

BINDING A SCRATCH PAD (BOOK WITHOUT COVER)

THICK BOOKS OR BOOKS WITH COATED PAPER:

Roughen book spine 1-3 times. Repeat if necessary.

Roughening opens the paper grain on book spine and

improves binding result with difficult materials. Note that

roughening several times increases spine width. Too heavy

roughening results unsquare book spine.

1 - 19

Other manuals for Elite

2

Table of contents

Languages:

Other Fastbind Binding Machine manuals