4

EASTMAN

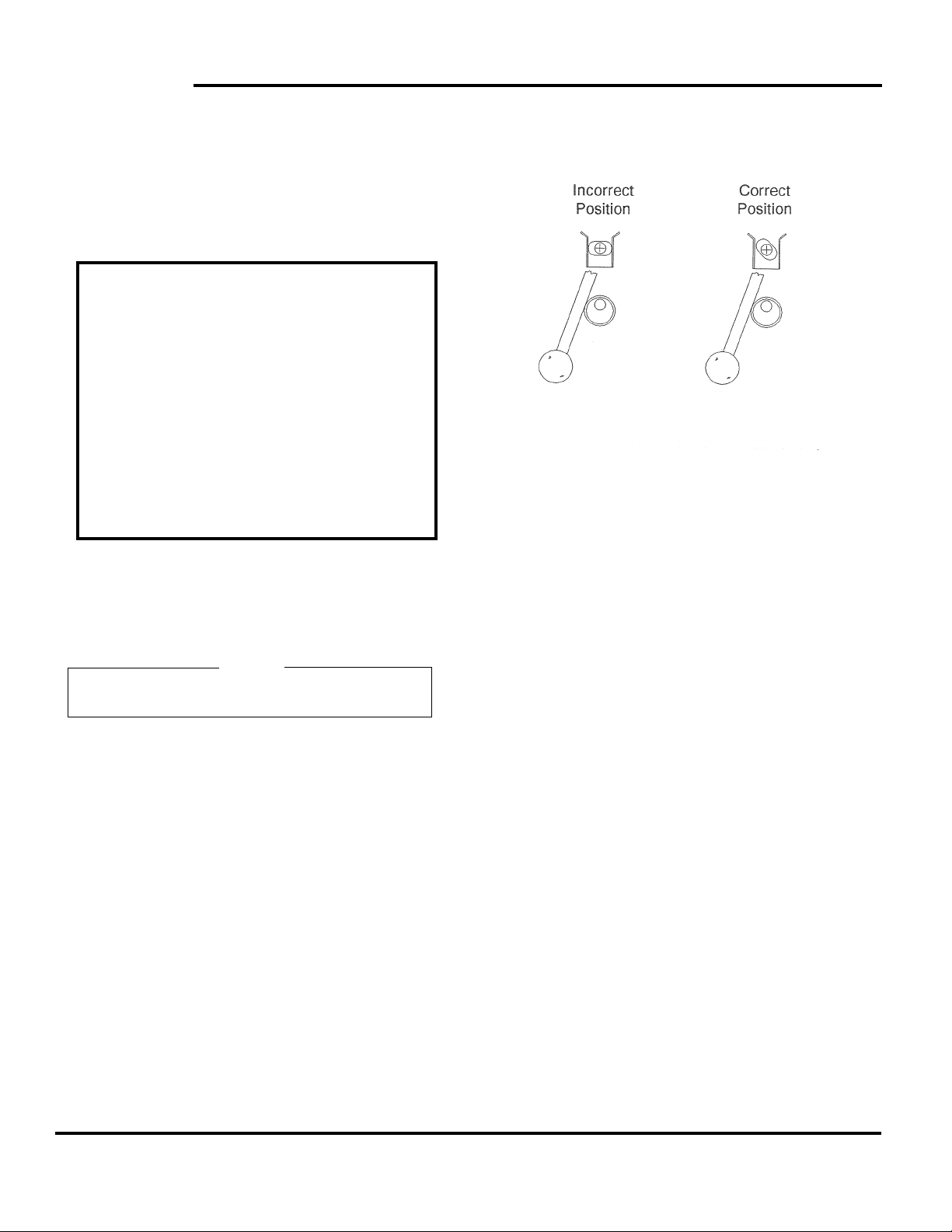

As each pin bar is moved into position the pins can be

inserted through the table top and secured. To secure the

pins, slide the eccentric knob in and swing the clamping

handle into its locking position. Pull the eccentric knob out

to lock the position. After all pins are locked in position the

pins can be lowered to 1/2" to 1" (1 to 2.5 cm.) above the

surface. Remove the marker and spread the material.

NOTE: Proper alignment of stripe, plaid or patterned materi-

als may be critical. The pins should protrude only

enough to secure the layers and care should be

taken when aligning patterns.

Spread & Pin The Fabric

Spread and cut the material to desired length. As each layer

is spread work from one end, align the pattern with the

previous layer and secure its position by pressing the

material over the pins. As the layers are spread the pins must

be raised enough to secure the next few layers. Continue

spreading until the total number of layers have been spread.

For some applications the marker can be placed over the final

layer of material, aligned and pinned in place to allow for

cutting the material from the stack. The optional Servo Cutter

offered by Eastman is equipped with a small base plate to

allow for cutting on the pin table with the pins installed. This

method will eliminate misalignment caused by transfer from

the pin table to a cutting station.

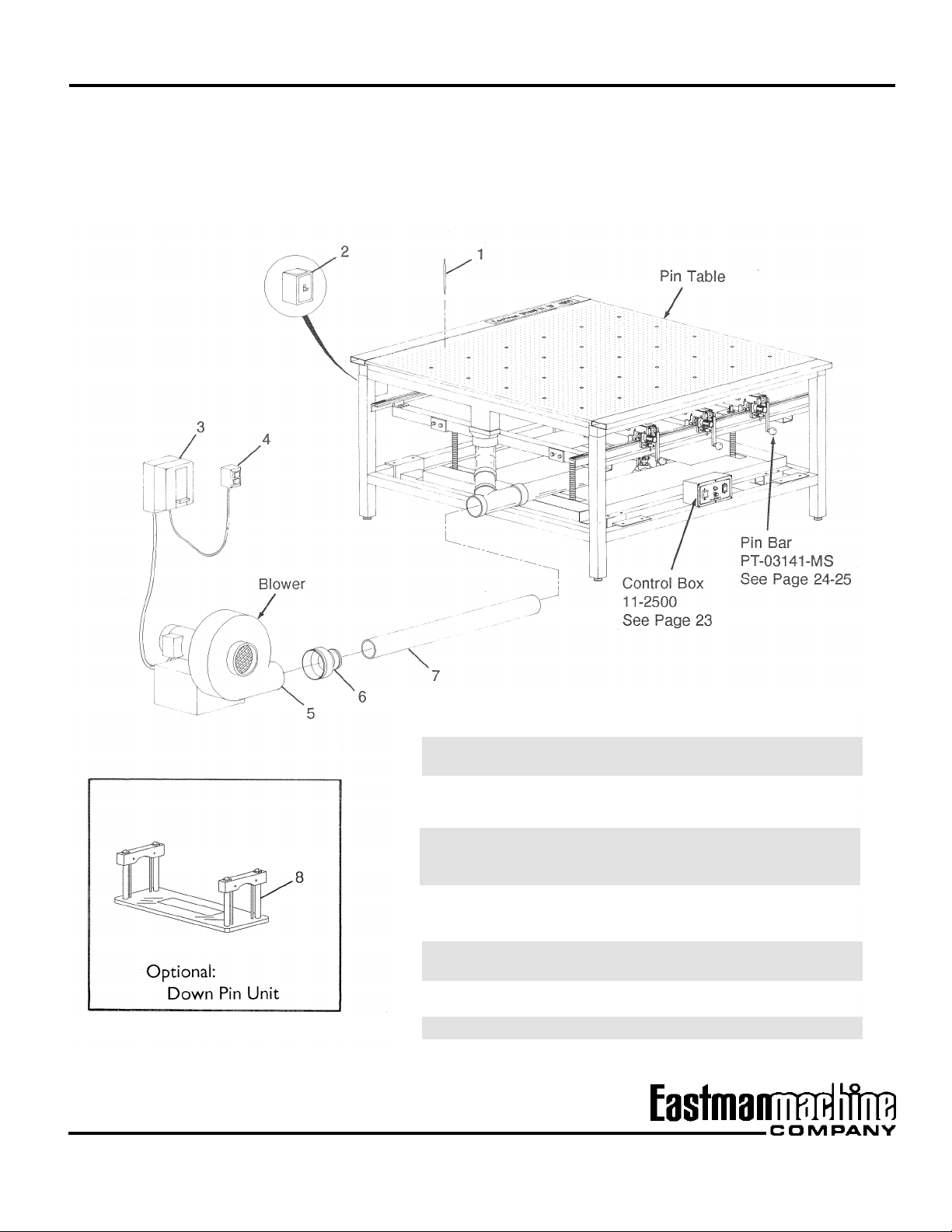

Other applications may require the material to be transported

to another station. For transportation of goods the air flotation

is used. Place down pin units on the material to secure

alignment. The down pin units should be placed away from

the cut lines on the marker and not interfere with the cut.

Lower the pins below the table surface. Press the Down

button on the control box to lower the pins. After the pins are

lowered, press the Start button on the Start/Stop switch to

begin air flotation. The air flotation allows the stack of material

to move with ease off of the table and prevent misalignment

of the material. After the spread is transferred to another

station the next spread can take place.

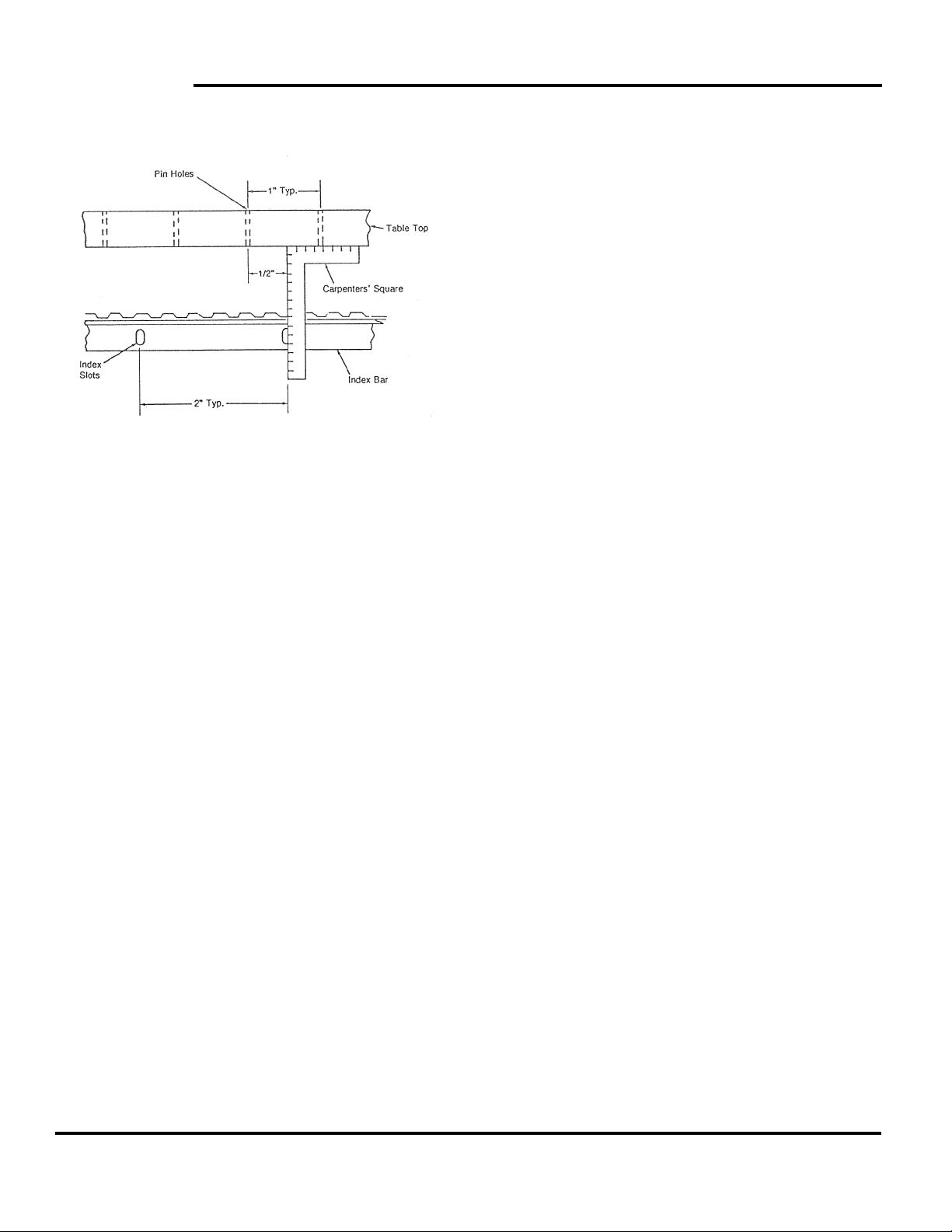

Index Alignment Procedure

When a Pin Table is first installed, the index bar must be

checked for proper alignment with the table top before the pin

bars can be installed.

To check for index bar alignment, hold a carpenters’ square

to the underside of the table top, as shown. The center of the

index slot must be centered between the pin holes (1/2" from

each hole). If the index bar is not centered, loosen the (2) two

screws on the rail bracket (operator’s side) and slide the rail

into position. Secure rail bracket into position.

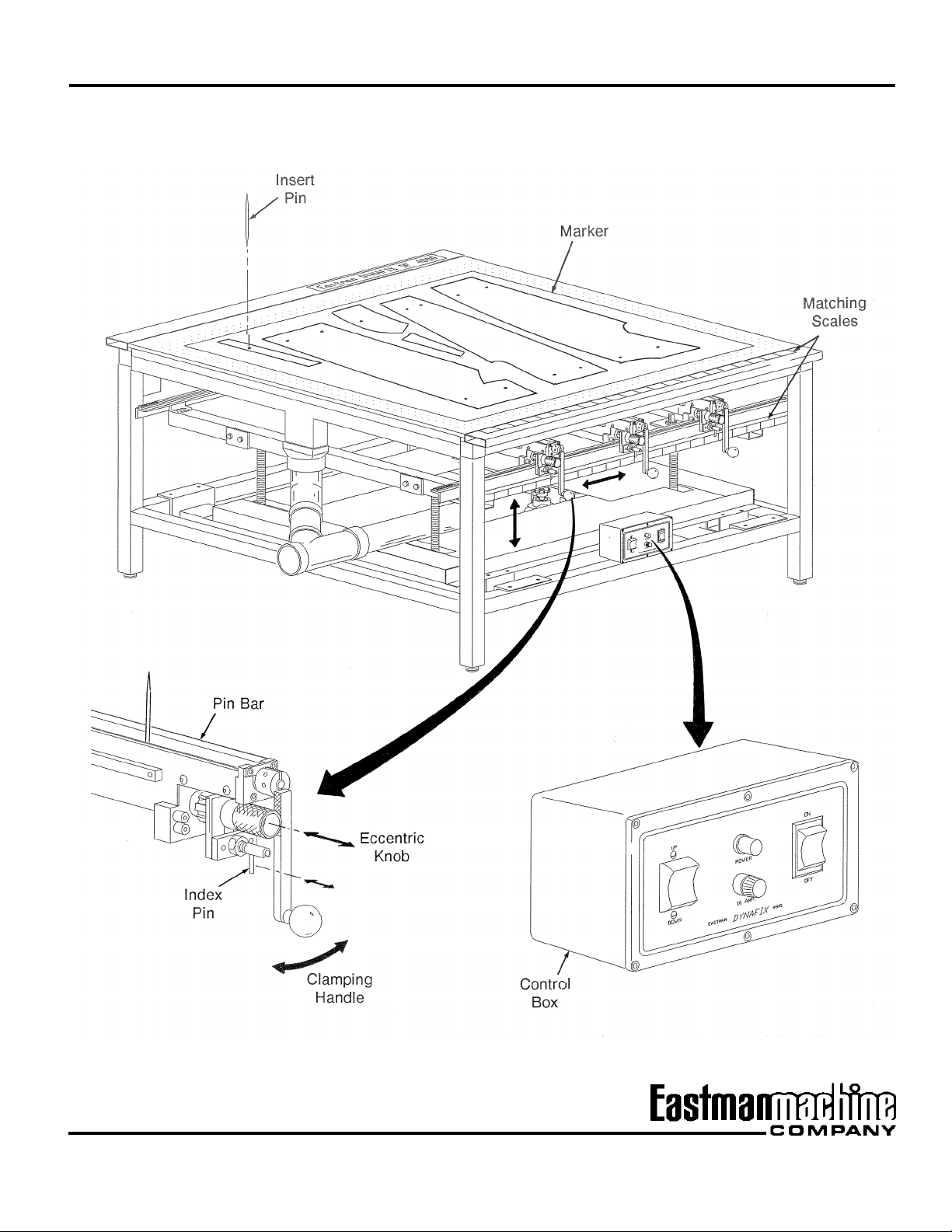

Operation

After the installation procedure has been completed, the

Eastman Dynafix DF 4800 is now ready for operation.

Place the marker on the table surface in the position the

material is to be spread (marker - print paper with a series of

pattern outlines for the purpose of cutting out material). Turn

the main power switch, located on the table frame, to the ON

position. Press the ON/OFF switch on the control box to the

ON position. The power light should light up. Using the UP/

DOWN switch on the control box, raise the pin bars up to the

top position. At this point all pin bars should be located at the

right of each section. Looking at the marker, determine where

the fix points are to be located. Move the pin bars to the

desired location. To move a pin bar pull the index pin, as

shown and move the pin bar. The index pin will lock the pin

bar in position. The matching scales on the table top and the

lift assembly will aid in aligning the pin bars with the pin holes.