faucet strommen 30401 User manual

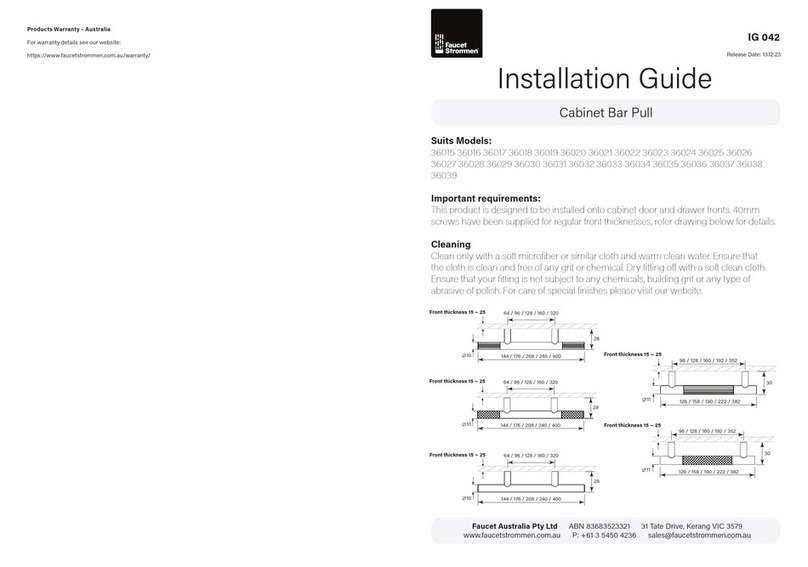

Suits Models:

30401, 30451, 30461, 30471, 30481, 30491, 30531

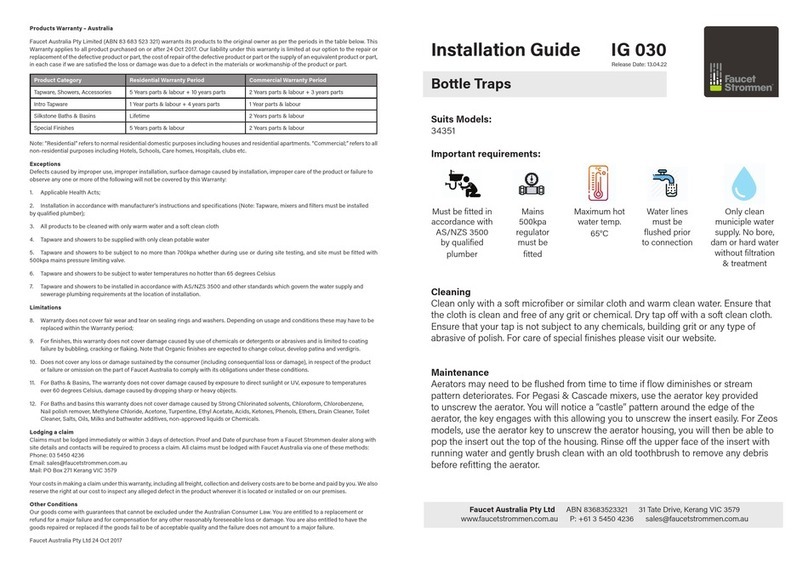

Important requirements:

Cleaning

Clean only with a soft microfiber or similar cloth and warm clean water. Ensure that

the cloth is clean and free of any grit or chemical. Dry tap o with a soft clean cloth.

Ensure that your tap is not subject to any chemicals, building grit or any type of

abrasive of polish. For care of special finishes please visit our website.

Maintenance

Aerators may need to be flushed from time to time if flow diminishes or stream

pattern deteriorates. For Pegasi & Cascade mixers, use the aerator key provided

to unscrew the aerator. You will notice a “castle” pattern around the edge of the

aerator, the key engages with this allowing you to unscrew the insert easily. For Zeos

models, use the aerator key to unscrew the aerator housing, you will then be able to

pop the insert out the top of the housing. Rinse o the upper face of the insert with

running water and gently brush clean with an old toothbrush to remove any debris

before refitting the aerator.

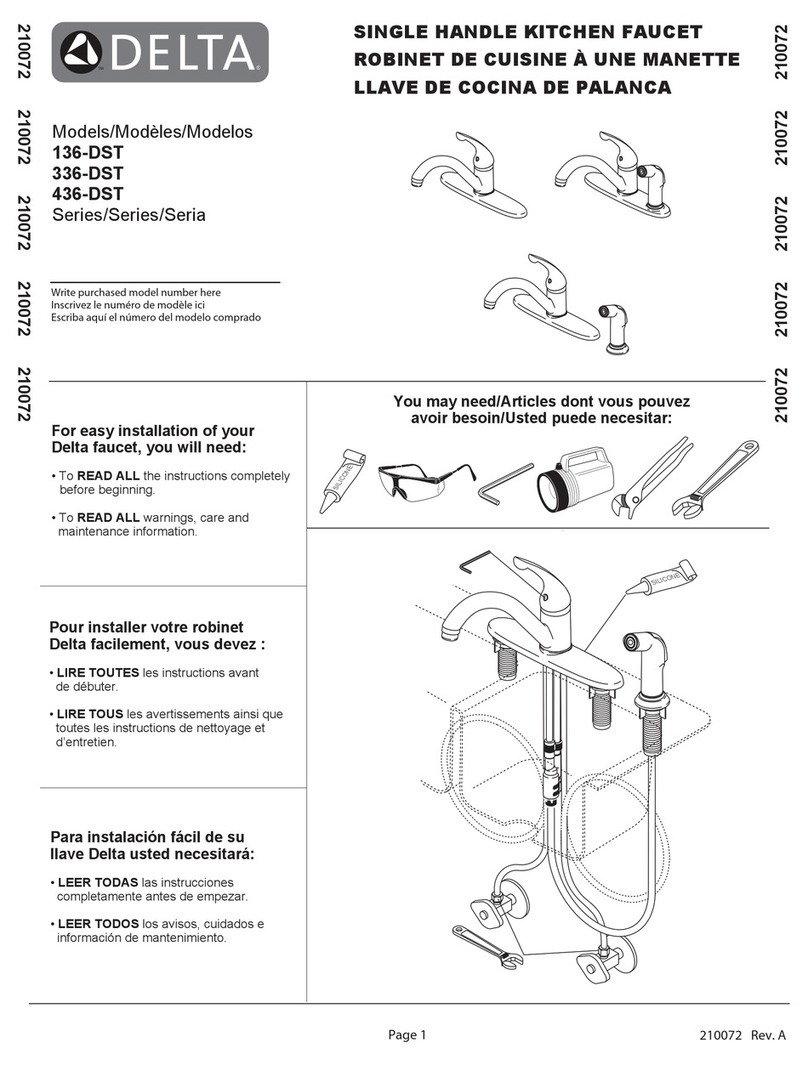

Installation Guide IG 009

Cascade Lever Taps

Products Warranty – Australia

Faucet Australia Pty Limited (ABN 83 683 523 321) warrants its products to the original owner as per the periods in the table below. This

Warranty applies to all product purchased on or after 24 Oct 2017. Our liability under this warranty is limited at our option to the repair or

replacement of the defective product or part, the cost of repair of the defective product or part or the supply of an equivalent product or part,

in each case if we are satisfied the loss or damage was due to a defect in the materials or workmanship of the product or part.

Note: “Residential” refers to normal residential domestic purposes including houses and residential apartments. “Commercial;” refers to all

non-residential purposes including Hotels, Schools, Care homes, Hospitals, clubs etc.

Exceptions

Defects caused by improper use, improper installation, surface damage caused by installation, improper care of the product or failure to

observe any one or more of the following will not be covered by this Warranty:

1. Applicable Health Acts;

2. Installation in accordance with manufacturer’s instructions and specifications (Note: Tapware, mixers and filters must be installed

by qualified plumber);

3. All products to be cleaned with only warm water and a soft clean cloth

4. Tapware and showers to be supplied with only clean potable water

5. Tapware and showers to be subject to no more than 700kpa whether during use or during site testing, and site must be fitted with

500kpa mains pressure limiting valve.

6. Tapware and showers to be subject to water temperatures no hotter than 65 degrees Celsius

7. Tapware and showers to be installed in accordance with AS/NZS 3500 and other standards which govern the water supply and

sewerage plumbing requirements at the location of installation.

Limitations

8. Warranty does not cover fair wear and tear on sealing rings and washers. Depending on usage and conditions these may have to be

replaced within the Warranty period;

9. For finishes, this warranty does not cover damage caused by use of chemicals or detergents or abrasives and is limited to coating

failure by bubbling, cracking or flaking. Note that Organic finishes are expected to change colour, develop patina and verdigris.

10. Does not cover any loss or damage sustained by the consumer (including consequential loss or damage), in respect of the product

or failure or omission on the part of Faucet Australia to comply with its obligations under these conditions.

11. For Baths & Basins, The warranty does not cover damage caused by exposure to direct sunlight or UV, exposure to temperatures

over 60 degrees Celsius, damage caused by dropping sharp or heavy objects.

12. For Baths and basins this warranty does not cover damage caused by Strong Chlorinated solvents, Chloroform, Chlorobenzene,

Nail polish remover, Methylene Chloride, Acetone, Turpentine, Ethyl Acetate, Acids, Ketones, Phenols, Ethers, Drain Cleaner, Toilet

Cleaner, Salts, Oils, Milks and bathwater additives, non-approved liquids or Chemicals.

Lodging a claim

Claims must be lodged immediately or within 3 days of detection. Proof and Date of purchase from a Faucet Strommen dealer along with

site details and contacts will be required to process a claim. All claims must be lodged with Faucet Australia via one of these methods:

Phone: 03 5450 4236

Mail: PO Box 271 Kerang VIC 3579

Your costs in making a claim under this warranty, including all freight, collection and delivery costs are to be borne and paid by you. We also

reserve the right at our cost to inspect any alleged defect in the product wherever it is located or installed or on our premises.

Other Conditions

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or

refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the

goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Faucet Australia Pty Ltd 24 Oct 2017

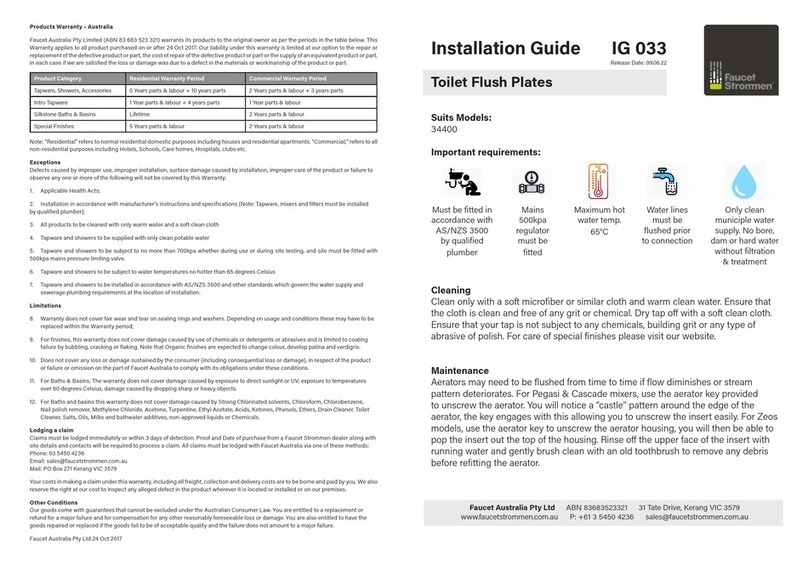

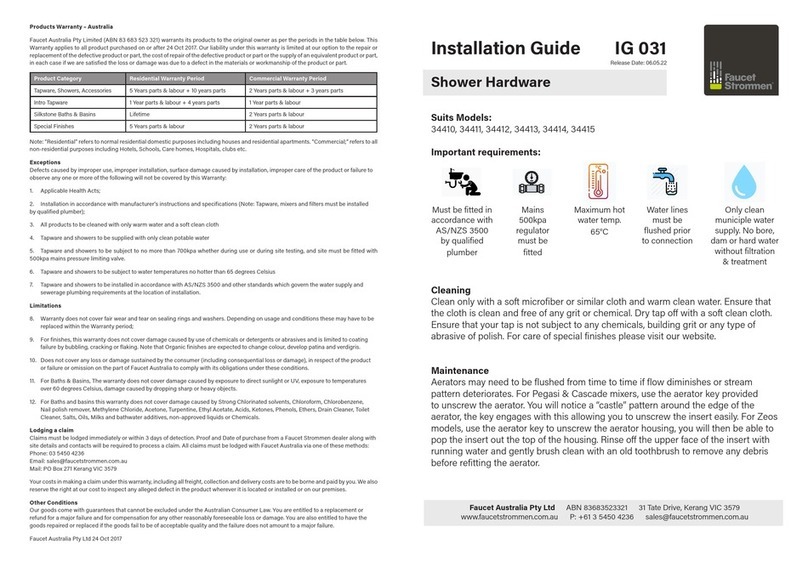

Product Category Residential Warranty Period Commercial Warranty Period

Tapware, Showers, Accessories 5 Years parts & labour + 10 years parts 2 Years parts & labour + 3 years parts

Intro Tapware 1 Year parts & labour + 4 years parts 1 Year parts & labour

Silkstone Baths & Basins Lifetime 2 Years parts & labour

Special Finishes 5 Years parts & labour 2 Years parts & labour

Faucet Australia Pty Ltd ABN 83683523321 31 Tate Drive, Kerang VIC 3579

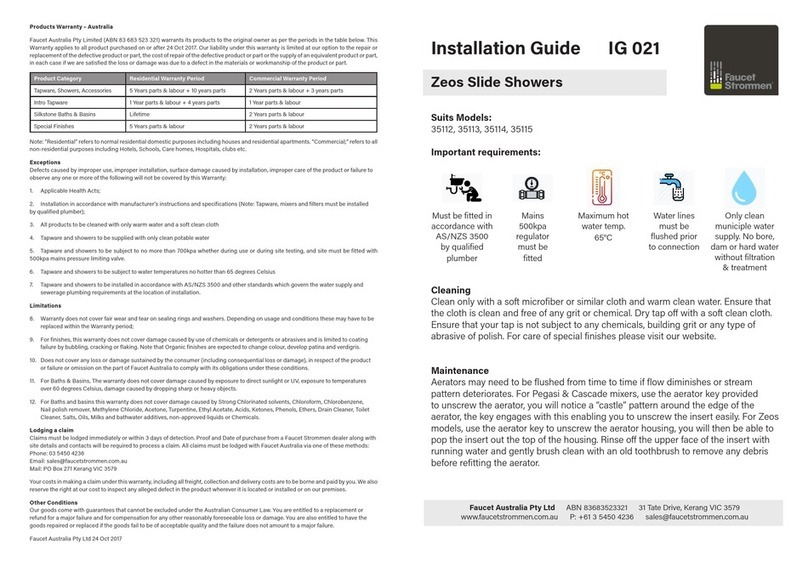

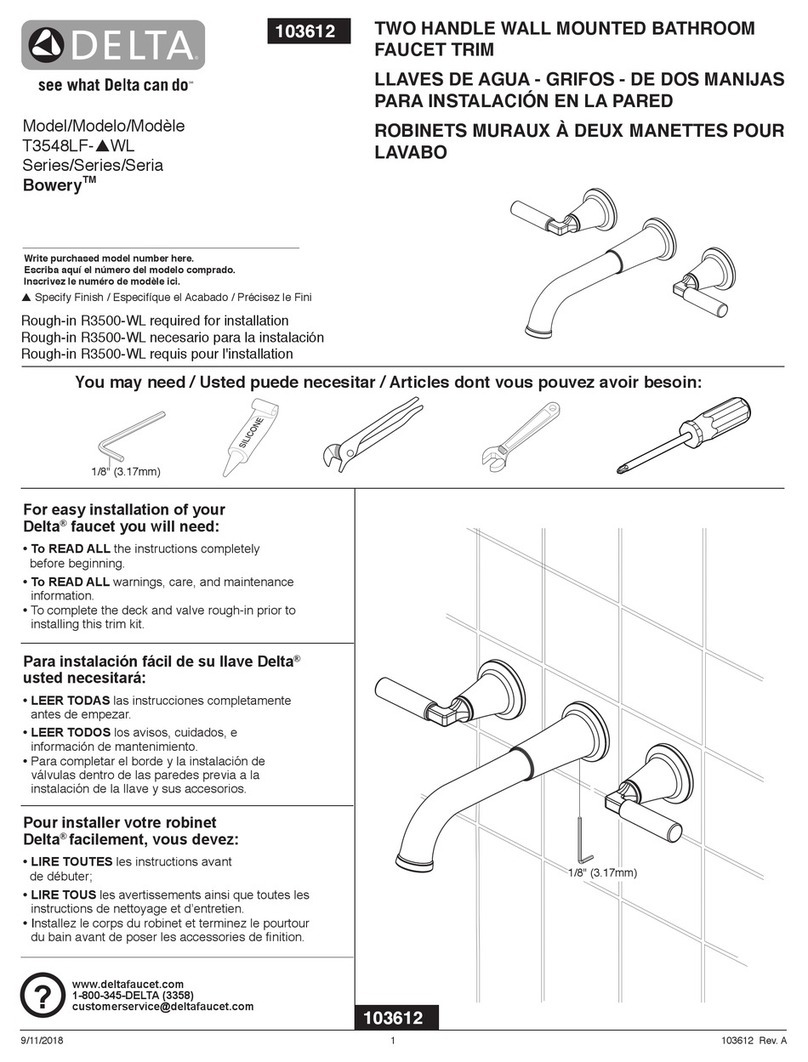

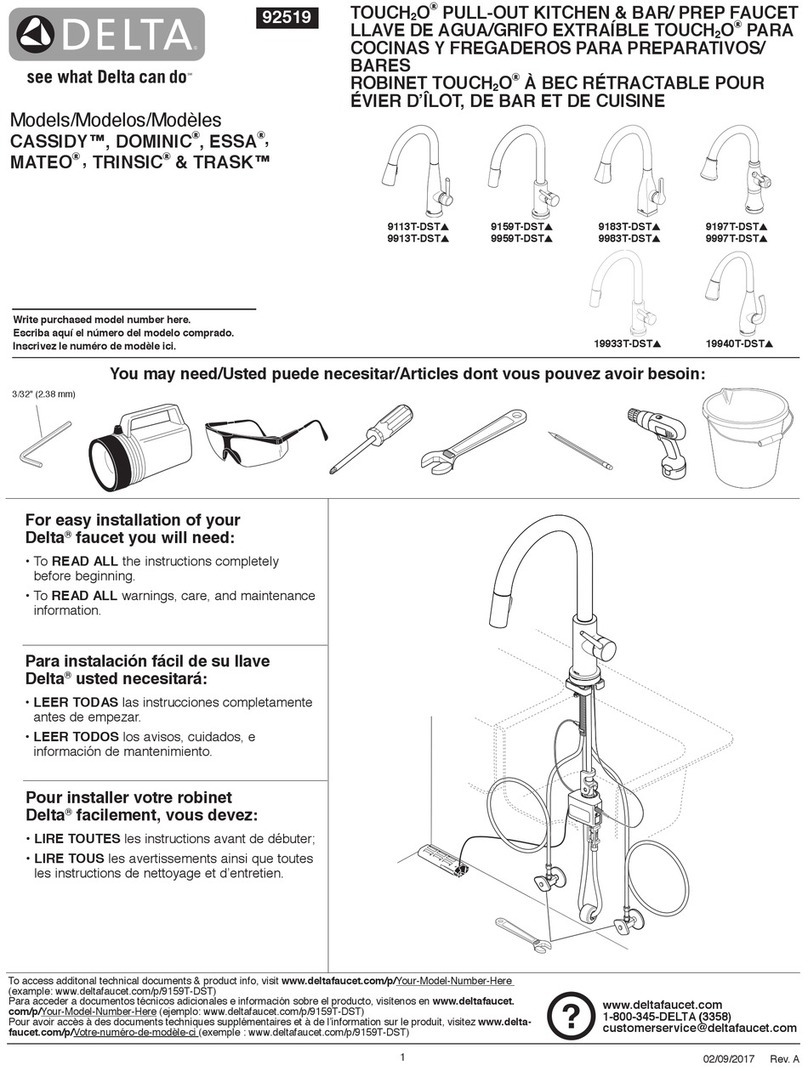

Must be fitted in

accordance with

AS/NZS 3500

by qualified

plumber

Mains

500kpa

regulator

must be

fitted

Maximum hot

water temp.

65°C

Water lines

must be

flushed prior

to connection

Mini stop

taps must

be fitted

Only clean

municiple water

supply. No bore,

dam or hard water

without filtration

& treatment

Release Date: 03.12.21

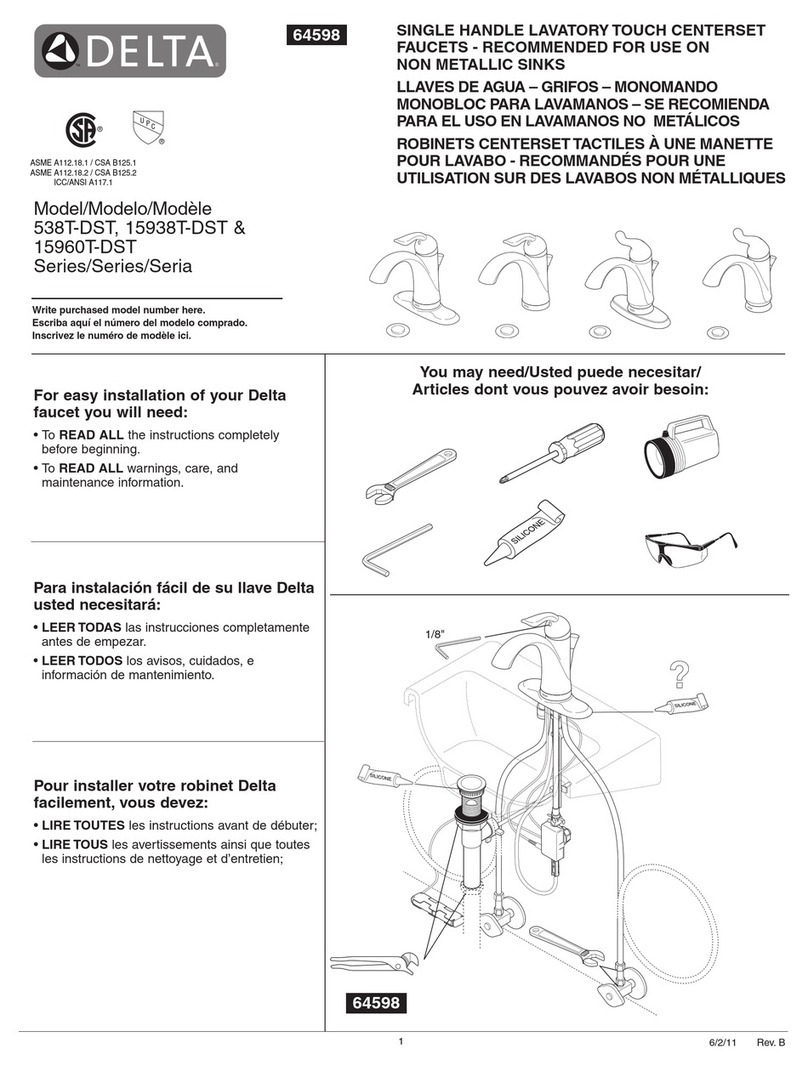

Basin Sets

1. Loosely fit the tee breech into the 2 bodies and hold the assembly over the basin tap holes to

check the spacing, the tee breech can be trimmed with standard tube cutters to adjust the width.

2. Assemble the bodies to the breech with the nuts and plastic compression rings, ensure the

spacing between bodies is correct and that the bodies and tee spigot are all perfectly aligned,

thentighten together firmly

3. Fit a dress ring to the underside of the spout assembly, place the clear vinyl washer over the spout

thread under the dress ring and place the assembly into the outlet hole in the basin or benchtop.

4. Ensure that the outlet is central in the hole and that the grub screw fixing hole is facing the back,

then fasten in place with the grey plastic nut.

5. Place a body nut and red fibre washer onto each body and loosely screw all the way on.

6. Grease the 2 o-rings on the tee spigot lightly with Vaseline.

7. Bring the assembly up under the basin/benchtop and locate the tee spigot into the outlet bore

and press all the way up until the 2 o-rings are well inserted into the spout bore making sure that

the bodies are aligned with the tap holes.

8. Hold the assembly in place whilst dropping a red fibre washer onto the protruding bodies and

loosely screwing a body nut onto the top of each body

9. Screw the top body nuts on just until the top of the nuts are flush with the top of the body, then

screw the lower nuts up to the underside of the basin, now you can tighten the top body nuts to

secure in place.

10. Fit valves and tap assemblies (see below)

11. Flush water supply lines before connecting hot and cold lines to bodies.

12. Run tap and ensure all joints are watertight

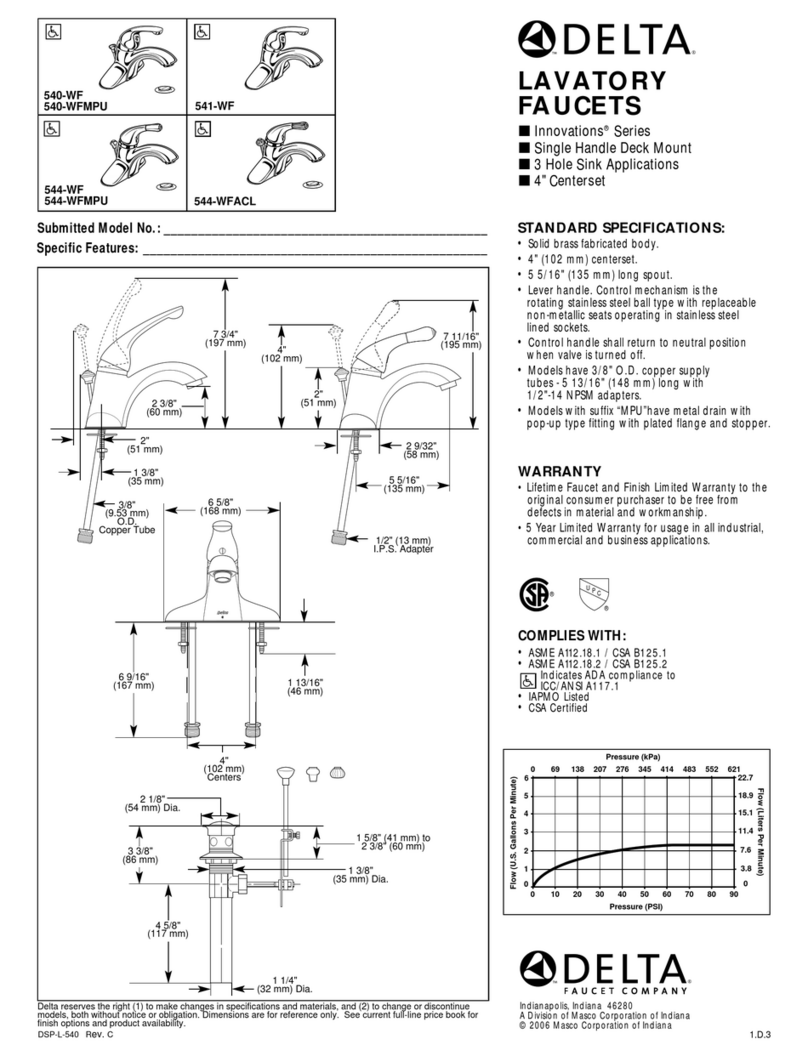

Sink and Spa Sets

Follow steps 1 & 2 above before continuing below

3. Place a body nut and red fibre washer onto each body and loosely screw all the way one

4. Screw the spout fixing nut loosely all the way onto the threaded tee spigot.

5. Bring the assembly up under the basin/benchtop and locate the tee spigot through the spout

hole and the 2 bodies through the tap holes.

6. Hold the assembly in place whilst dropping a red fibre washer onto the protruding bodies and

loosely screwing a body nut onto the top of each body

7. Screw the top body nuts on just until the top of the nuts are flush with the top of the body, then

screw the lower nuts up to the underside of the sink, now align perfectly and tighten the top

body nuts to secure in place.

8. Screw the spout fastening nut up the threaded spigot just until it touches the underside of the

sink/ benchtop.

9. Place the clear pvc washer over the top of the tee spigot thread and apply thread tape to

thread.

10. Place the dress ring over the threaded spigot and screw the spout assembly over the thread until

it fastens down onto the sink with the grub screw hole facing the back.

11. Fit valves and tap assemblies (see below)

12. Flush water supply lines before connecting hot and cold lines to bodies.

13. Run tap and ensure all joints are watertight

Washing Machine Taps

1. Ensure that the ½” water supply lug is not protruding from the wall/hob more than 15mm. Remove

any debris or tile glue from the lug, wind suicient thread tape onto the lug.

2. Run a liberal amount of water into a bucket to rinse the lines.

3. Place a flange/ dress ring onto the water point and screw tap onto the water supply lug.

4. Test the system.

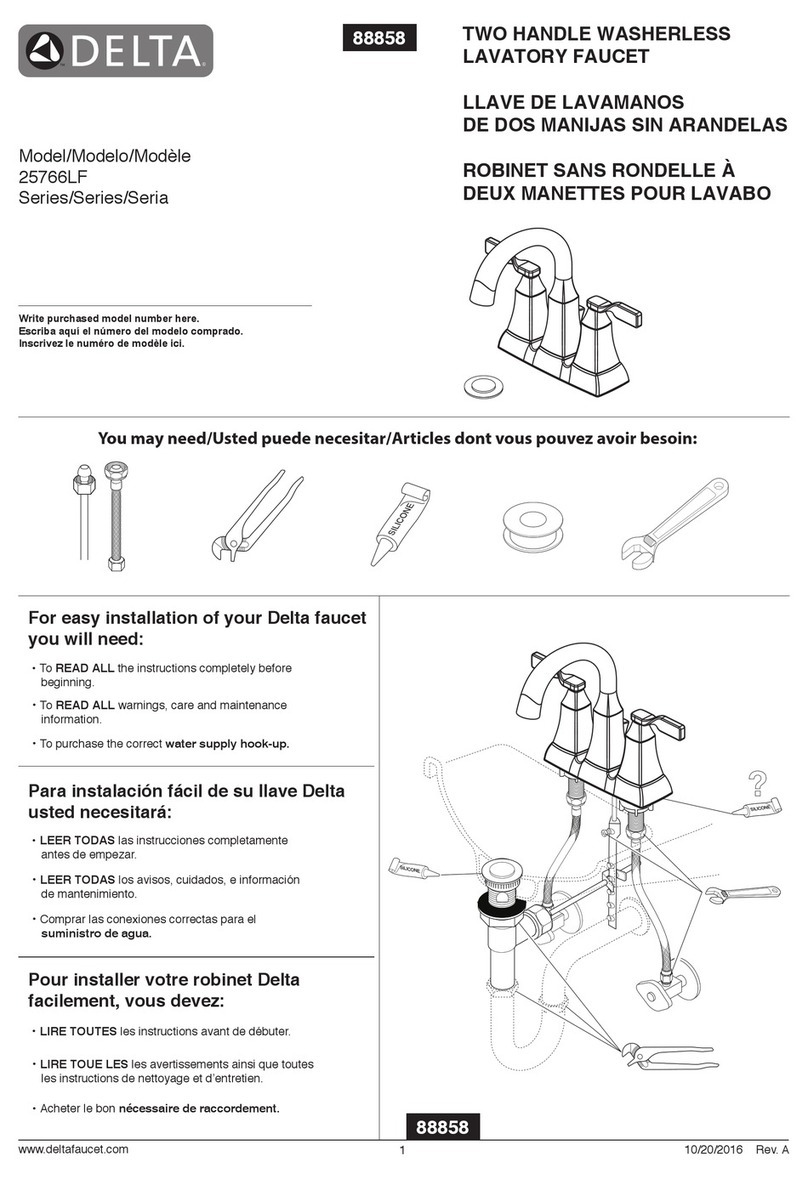

Valve and Tap Assemblies

1. If you are fitting to existing bodies, check that the body seats are clean and smooth, re-

seat if necessary.

2. Note that the valves come in 2 pieces, the valve cartridge and the locknut. Do not

assemble the 2 pieces together until later in the installation.

3. Note that 1 of the valve cartridges will have a red mark on the spline, this is the Hot valve

and should be fitted on the left side.

4. Carefully screw the valve cartridge into the body by hand and nip up very gently with a

suitable sized ring spanner.

• Do not over tighten otherwise the brass cartridge can become deformed and will leak.

• Do not use vice grips, otherwise the brass and o-ring can get damaged causing leaks.

5. Once the cartridge is installed, slide a red fibre washer over the cartridge and screw on

the locknut. Tighten this firmly with a spanner.

6. Fit the dress ring into the base of the flange and screw this onto the locknut until it butts

up firmly against the surface of the wall/benchtop.

7. Starting with the left side (Hot tap), rotate the valve spline all the way clockwise by hand,

this is the closed position. Fit the lever over the spline in the horizontal direction with the

lever out to the left.

8. Screw on the handle fastening nut by hand then fasten with an allen key

9. Clip the “H” Indicator over the fastening nut and rotate the indicator to align

10. To fit the handle on the right side (Cold tap), first turn the valve all the way anti-clockwise,

this is the closed position. Fit the lever over the spline in the horizontal direction with the

lever out to the right.

11. Now fit the fastening nut and the indicator.

12. Note that the all metal indicator buttons can be prized o with supplied green fork should

you need to access the allen hex fastener to remove the handle.

13. Note that for accurate leveling of the handles, should the spline not provide

suicient adjustment, you can loosen the locknut on the valve and move the inner

cartridge slightly. See the video that explains this procedure at: https://www.youtube.

com/watch?v=VU0arE1F9mg

This manual suits for next models

6

Other faucet strommen Plumbing Product manuals

faucet strommen

faucet strommen 30571 User manual

faucet strommen

faucet strommen 30560 User manual

faucet strommen

faucet strommen 30573 User manual

faucet strommen

faucet strommen 30909 User manual

faucet strommen

faucet strommen IG 020 User manual

faucet strommen

faucet strommen IG 033 User manual

faucet strommen

faucet strommen 34410 User manual

faucet strommen

faucet strommen 30908 User manual

faucet strommen

faucet strommen 30574 User manual

faucet strommen

faucet strommen 34351 User manual