Basin Sets

1. Loosely fit the tee breech into the 2 bodies and hold the assembly over the basin tap

holes to check the spacing, the tee breech can be trimmed with standard tube cutters to

adjust the width.

2. Assemble the bodies to the breech with the nuts and plastic compression rings, ensure

the spacing between bodies is correct and that the bodies and tee spigot are all perfectly

aligned, then tighten together firmly

3. Place the clear vinyl washer over the spout thread and place the assembly into the outlet hole

in the basin or benchtop.

4. Ensure that the outlet is central in the hole and that the grub screw fixing hole is facing

the back, then fasten in place with the grey plastic nut.

5. Place a body nut and red fibre washer onto each body and loosely screw all the way on.

6. Grease the 2 o-rings on the tee spigot lightly with Vaseline.

7. Bring the assembly up under the basin/benchtop and locate the tee spigot into the outlet

bore and press all the way up until the 2 o-rings are well inserted into the spout bore

making sure that the bodies are aligned with the tap holes.

8. Hold the assembly in place whilst dropping a red fibre washer onto the protruding bodies

and loosely screwing a body nut onto the top of each body

9. Screw the top body nuts on just until the top of the nuts are flush with the top of the body,

then screw the lower nuts up to the underside of the basin, now you can tighten the top

body nuts to secure in place.

10. Fit valves and tap assemblies (see below)

11. Flush water supply lines before connecting hot and cold lines to bodies.

12. Run tap and ensure all joints are watertight

Sink and Spa Sets

Follow steps 1 & 2 above before continuing below

3. Place a body nut and red fibre washer onto each body and loosely screw all the way one

4. Screw the spout fixing nut loosely all the way onto the threaded tee spigot.

5. Bring the assembly up under the basin/benchtop and locate the tee spigot through the

spout hole and the 2 bodies through the tap holes.

6. Hold the assembly in place whilst dropping a red fibre washer onto the protruding bodies

and loosely screwing a body nut onto the top of each body

7. Screw the top body nuts on just until the top of the nuts are flush with the top of the body,

then screw the lower nuts up to the underside of the sink, now align perfectly and tighten

the top body nuts to secure in place.

8. Screw the spout fastening nut up the threaded spigot just until it touches the underside

of the sink/ benchtop.

9. Place the clear pvc washer over the top of the tee spigot thread and apply thread tape to thread.

10. Screw the spout assembly over the thread until it fastens down onto the sink with the

grub screw hole facing the back.

11. Fit valves and tap assemblies (see below)

12. Flush water supply lines before connecting hot and cold lines to bodies.

13. Run tap and ensure all joints are watertight

Washing Machine Taps

1. Ensure that the ½” water supply lug is not protruding from the wall/hob more than

15mm. Remove any debris or tile glue from the lug, wind suicient thread tape onto the lug.

2. Run a liberal amount of water into a bucket to rinse the lines.

3. Place a flange/ dress ring onto the point and screw the tap back to the tiles.

4. Test the system.

Valve and Tap Assemblies

1. If you are fitting to existing bodies, check that the body seats are clean and smooth, re-

seat if necessary.

2. Note that the valves come in 2 pieces, the valve cartridge and the locknut. Do not

assemble the 2 pieces together until later in the installation.

3. Note that 1 of the valve cartridges will have a red mark on the spline, this is the Hot valve

and should be fitted on the left side.

4. Carefully screw the valve cartridge into the body by hand and nip up very gently with a

suitable sized ring spanner.

• Do not over tighten otherwise the brass cartridge can become deformed and will leak.

• Do not use vice grips, otherwise the brass and o-ring can get damaged causing leaks.

5. Once the cartridge is installed, slide a red fibre washer over the cartridge and screw on

the locknut. Tighten this firmly with a spanner.

6. Push flange onto valve coveruntill it is at the bottom.

7. Screw cover and flange assembly onto the locknut until it butts up firmly against the

surface of the wall/benchtop. Push flange back.

8. Starting with the left side (Hot tap), rotate the valve spline all the way clockwise by hand,

this is the closed position. Fit the lever over the spline in the horizontal direction with the

lever out to the left. See step 13 if needed.

9. Place nickel plated nut over valve spindle. Clip white plastic clip onto top of valve just

below spline.

10. Place handles over spline and tighten nut up with supplied spanner.

11. To fit the handle on the right side (Cold tap), first turn the valve all the way anti-clockwise,

this is the closed position. Fit the lever over the spline in the horizontal direction with the

lever out to the right.

12. Repeat above steps for other tap

13. Note that for accurate leveling of the handles, should the spline not provide suicient

adjustment, you can loosen the locknut on the valve and move the inner cartridge slightly.

The seals have adjustment built in. See the video that explains this procedure at:

https://www.youtube.com/watch?v=VU0arE1F9mg

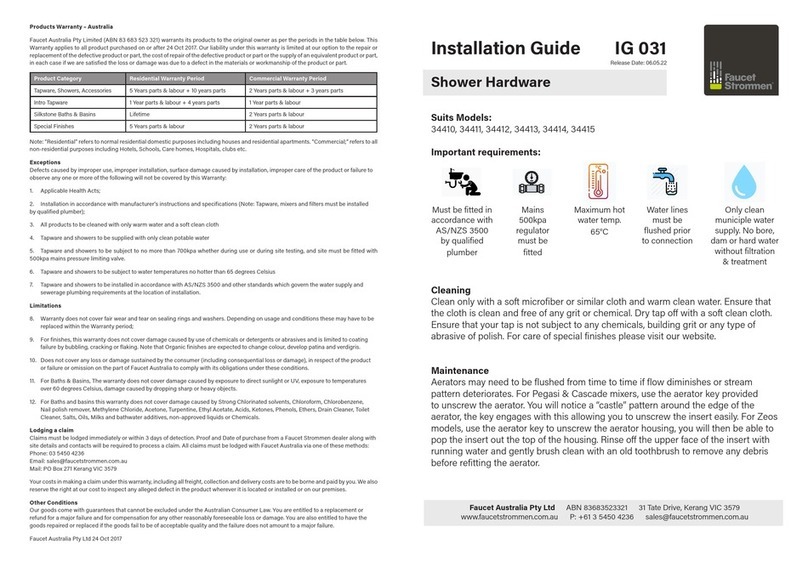

Cover

Flange

Cover

Flange

Nut

Clip

Locknut

Fibre washer

Valve cartridge

Lever handle

Hex