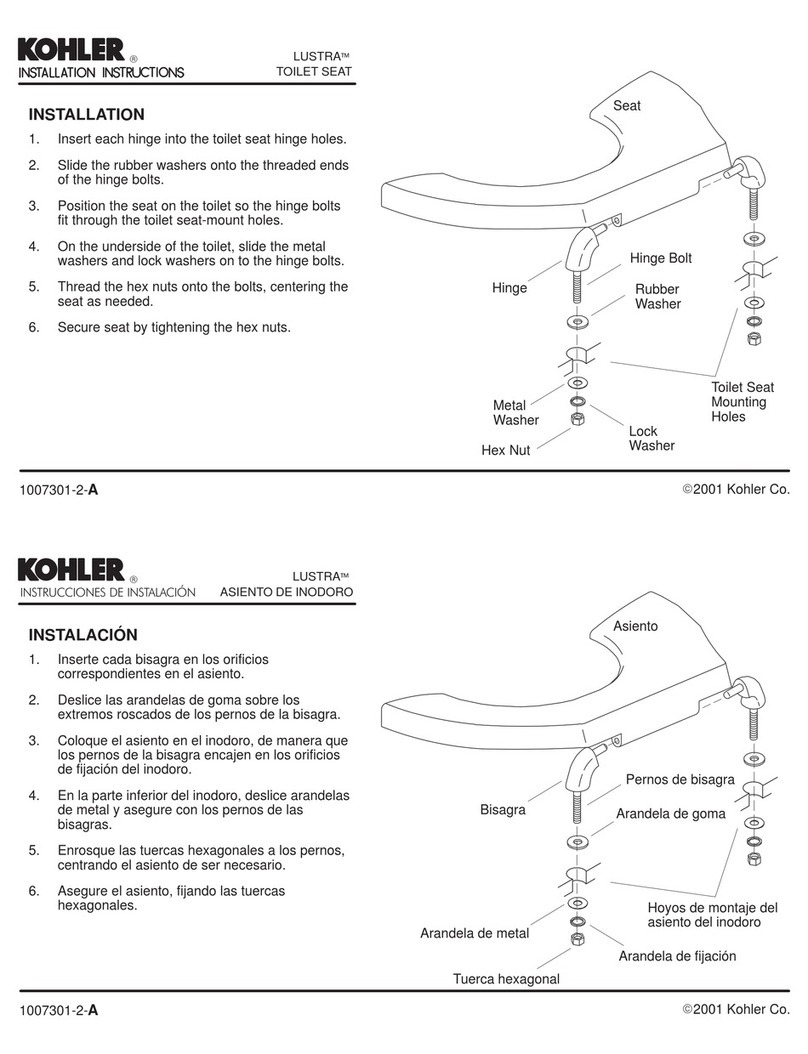

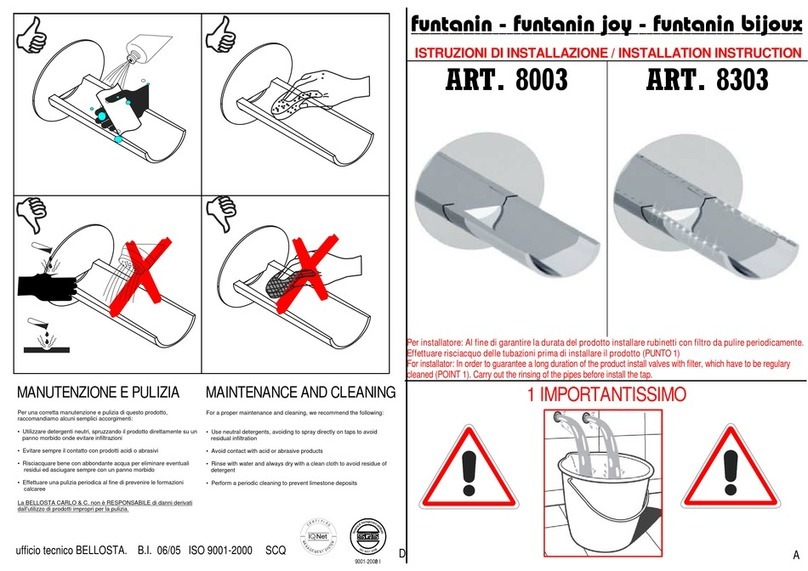

Rough In

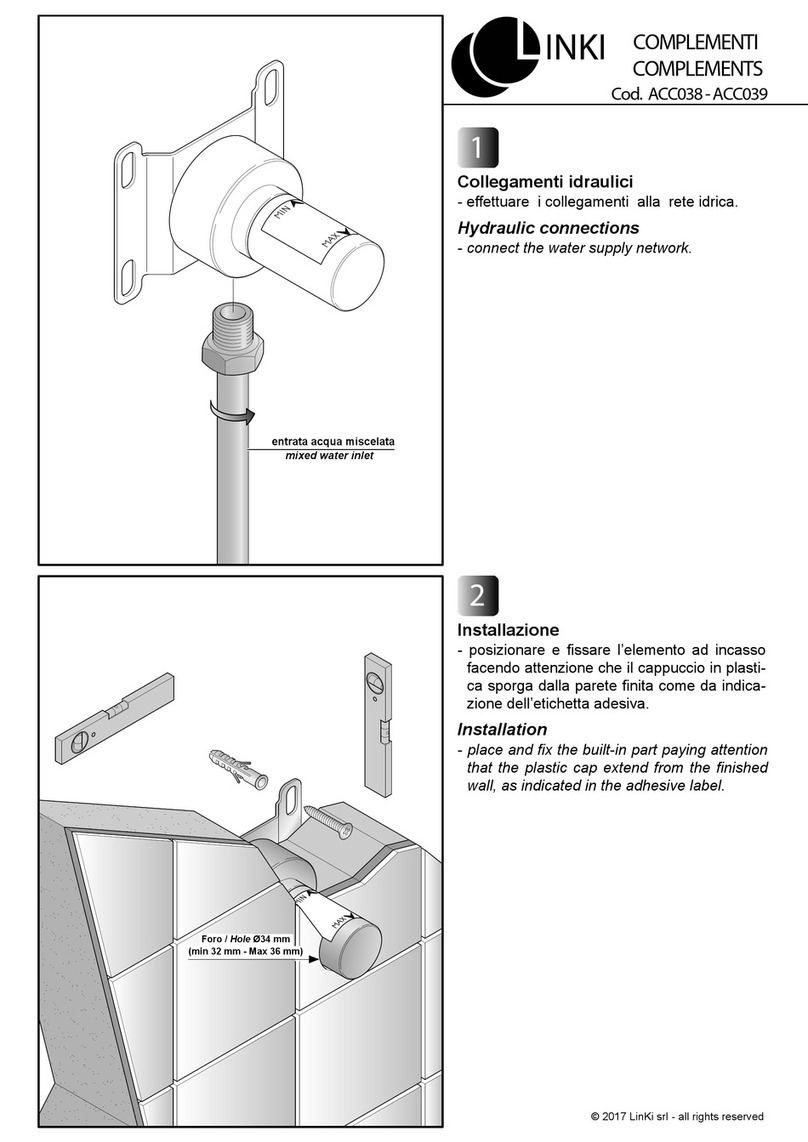

1. Ensure that the in-wall nogging depth is correct and that the nogging is plumb. Position

the noggin such that the front face of the noggin is 62mm behind the front face of the

finished tiled surface. (note that there is a maximum of ± 8mm adjustment at fit o).

See diagram A

2. Fix the body to the stud with the outlet facing upwards, Cold inlet to the right & hot

inlet to the left. Mount the plate level . See diagram B

3. Connect the Hot supply to the inlet port on the left marked “H” and the Cold supply to

the right side Inlet marked “C” and connect the outlet line to the top outlet port.

4. Once plumbing is all connected pressure test the system. Do not exceed 500kpa

pressure testing whether dynamic or static. Testing over 500 kpa will void the

warranty for this product.

5. The body is fitted with a black shroud (also a tile guide). This should always remain in

place. The red dust cover may be removed for testing, but otherwise should remain in

place.

6. Wall sheeting and tiling can be laid close to the shroud and waterproofing membrane

and grout can be adhered to the shroud.

7. An indicator on the end of the shroud shows the range that can be accommodated at fit

o for the finished tile face position.

8. When tiling, note that the dress ring is 51mm diameter, so be sure to tile close to the

shroud so there are no gaps showing after fit o. See diagram C

Fit O

1. Remove excess tile grout from around the shroud to allow a flush fitment of the cover

ring.

2. Remove the red dust cap and use a sharp knife to cut away the black shroud that

protrudes past the finished tile surface and ensure that the area around the shroud is

flat and free of protrusions.

3. Place the red fiber washer onto the locking sleeve and screw the sleeve onto the body

until up against the tiles. Nip up gently being careful not to damage or crack the tiles.

See diagram C

4. Note that there are 2 splined adaptors supplied. For shallower installations use the

shorter adaptor, for deeper installations use the longer adaptor. (tip, if you had to cut o

more than 8mm of black plastic shroud, use the short adaptor, if you cut o less than

8mm of shroud use the long adaptor)

5. Note that the valve spline and the adaptor spline have un-splined segments it is

important that these properly mesh and align when the adaptor is fitted.

6. Ensure that the valve is in the o position (all the way anticlockwise), then fit the

adaptor to the valve spline such that one of the milled slots is facing up and the other

to the left.

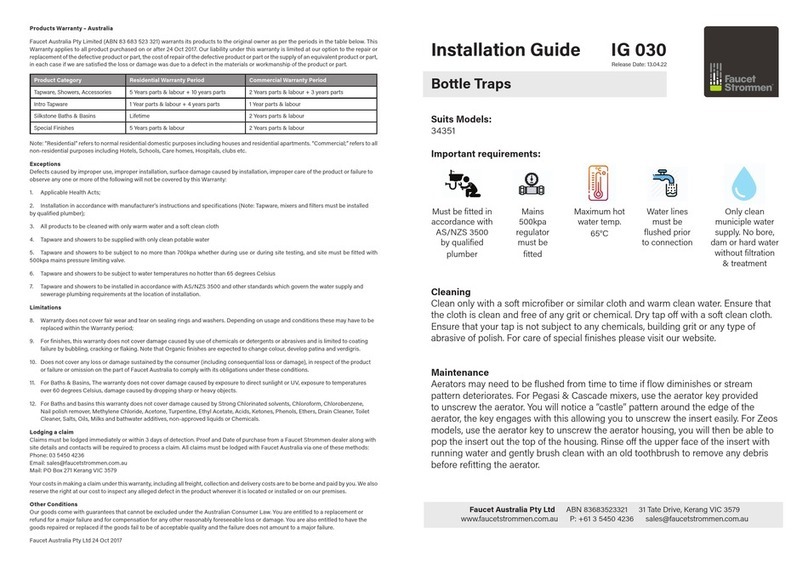

7. Ensure that the adaptor is oriented such that the grooved face is facing out, See

diagram D

8. Press the adaptor all the way on and fasten in place with the hex drive screw provided.

9. Note that the dress ring includes indication markings. Place the ring over the locking

sleeve and position such that the “I” symbol is facing the top, then loosely fit the 3

attachment screws.

10. To ensure that the dress ring is perfectly concentric to the valve, we have supplied a

round plastic Concentricity spacer. Slide this over the adaptor and locate it into the

cover ring, then fasten the ring in place ensuring the “I” symbol is to the top.

11. Remove and discard the concentricity spacer.

12. Note that there is a pre inserted grub screw in the handle that just protrudes into the

bore.

13. Place the black slip ring onto the step machined in the back of the handle then press

the handle onto the tap with the wave form to the top. The handle should slide over the

adaptor with the grub screw engaging in the slot.

14. The handle should slide on until it presses smoothly up to the dress ring, square and flat.

15. To fasten, rotate the handle through 90 degrees clockwise until the waveform passes

over the small fastening hole in the dress ring. Inters the allen key through the hole and

tighten the handle by fastening the grub screw onto the adaptor.

16. The handle should now operate smoothly and freely to control the tap through 180

degrees (half a turn)

1 7. Progressive valves open clockwise, over the first 90 degrees of rotation the cold water

opens to full flow, then from 90-180 degrees the valve goes from warm to hot.

18. Thoroughly check operation and seek assistance from Faucet Strommen should anything

not be functioning to expectation.

Diagram D