FAURE HERMAN HELIFLU TZN User manual

HELIFLUTM TZN

User’s Manual

FAURE HERMAN

Route de Bonnétable

BP 20154 – 72406 La Ferté Bernard

Cedex France

Tel : + (0)2 4 60 28 60

Fax : + (0)2 4 60 28 70

E-mail : fhprojects@idexcorp.com

FAURE HERMAN METER

4702 N Sam Houston Pkwy West

Suite 100

Houston, TX 77086 (U.S.A)

Tel : +1 71 62 0808

Fax : +1 71 62 2 2

E-mail: FHH-Sales@idexcorp.com

FAURE HERMAN

Office #7 8, Building #6EB

Dubai Airport Freezone (DAFZA)

Dubai (U.A.E)

Tel : +971 4260 0 81

Fax : +971 4260 0 19

Email : fhsalesme@idexcorp.com

www.faureherman.com

Page 2 / 37

Ta le of Contents

Chapter 1: Introduction to TZN Meters (STD & CUS) ...........................................................................................

Chapter 2: Meter Components by Meter Size ...................................................................................................... 4

Chapter : Equipment Receipt, Storage and Handling ......................................................................................... 6

Chapter 4: Installation and Operation ................................................................................................................... 7

Chapter 5: Commissioning ................................................................................................................................... 1

Chapter 6: Maintenance ....................................................................................................................................... 14

Chapter 7: Troubleshooting ................................................................................................................................. 14

Chapter 8: Replacement – Repair ........................................................................................................................ 15

Chapter 9: Equipment removal ............................................................................................................................ 19

Appendix 1 – Alternative configurations ............................................................................................................. 20

Appendix 2 – Meter drawings by size and type .................................................................................................. 21

Appendix 2 - K-factor – Flowrate/Frequency ...................................................................................................... 27

Appendix - Operating restrictions & Special recommendations .................................................................... 28

Safety Consideration ............................................................................................................................................. 29

Ta le of Figures

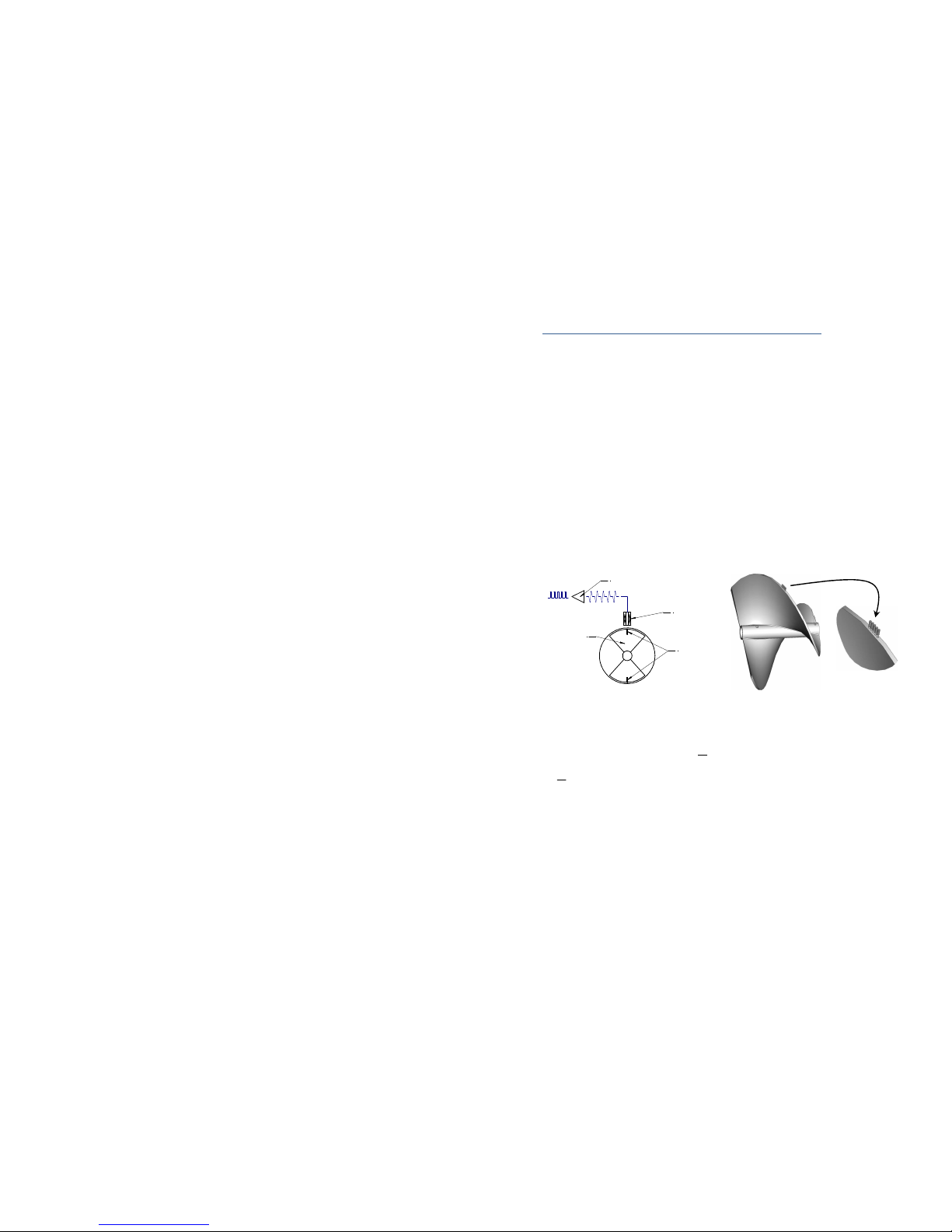

Figure 1. Mechanics of Signal Generation of Helical Turbines ............................................................................

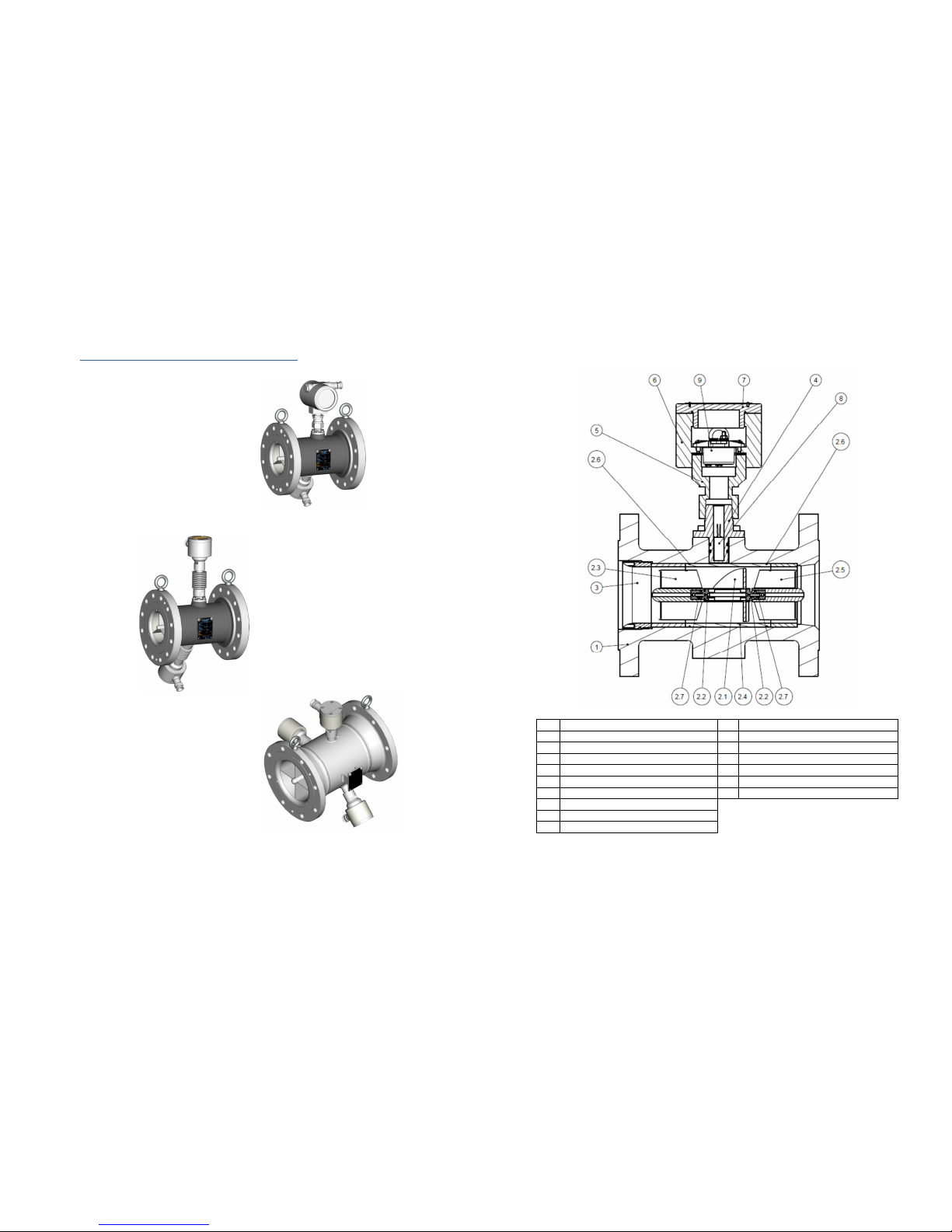

Figure 2. Meter body types by size ......................................................................................................................... 4

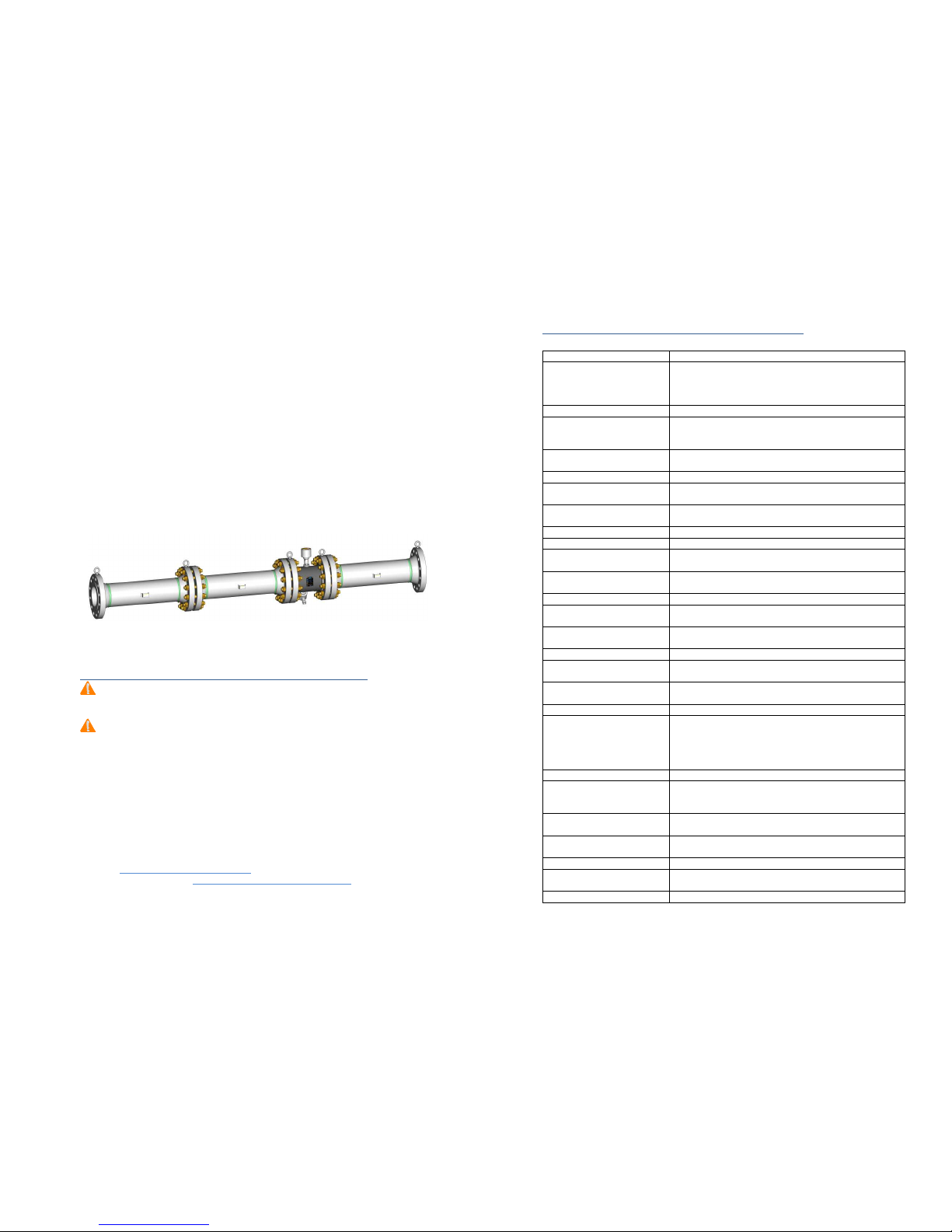

Figure . Cartridge types by size ............................................................................................................................. 5

Figure 4. Complete Meter run with upstream/downstream spool pieces and flow conditioner ...................... 6

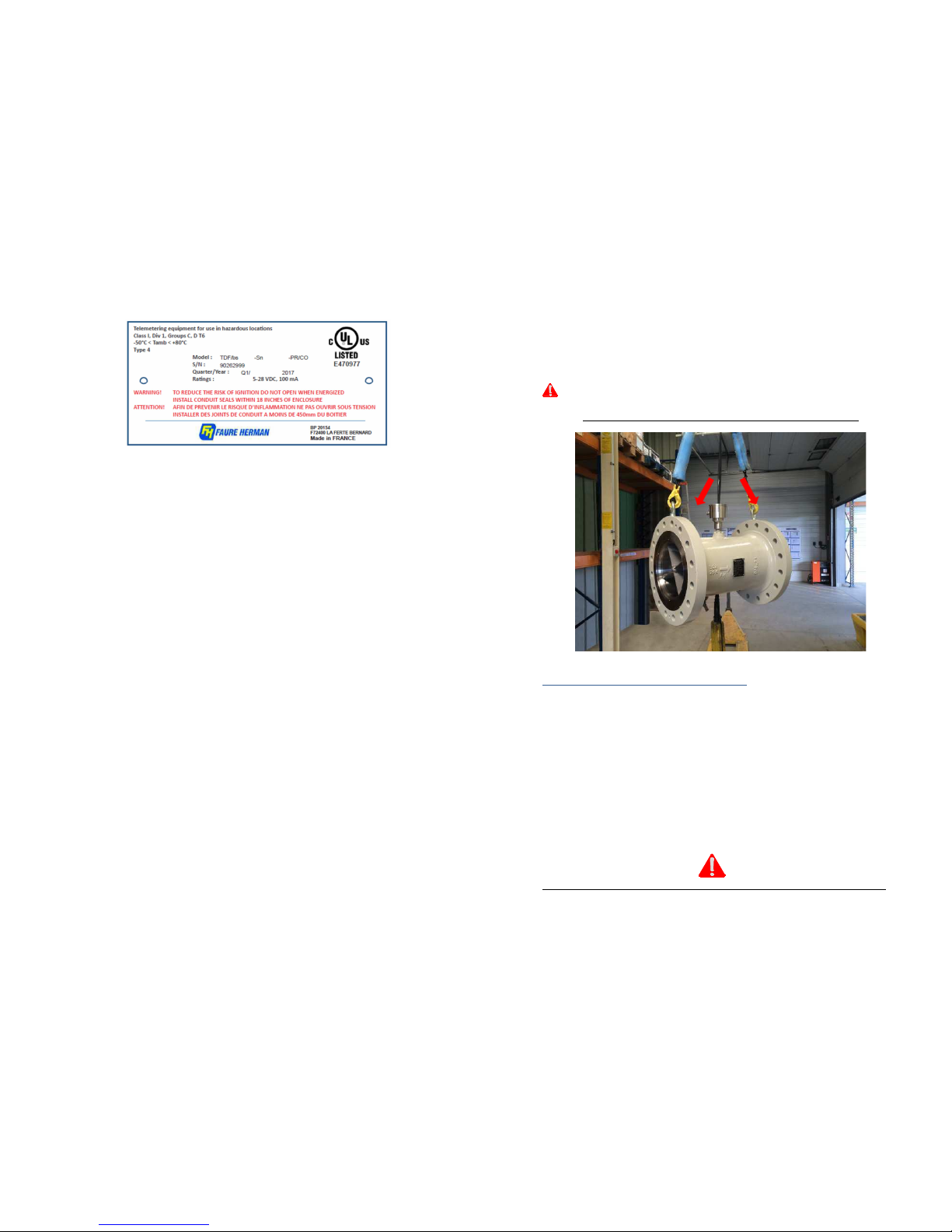

Figure 5. Proper lifting technique for meters > 6 inches ...................................................................................... 7

Figure 6. Proper pipe alignment for meter installation......................................................................................... 8

Figure 7. Recommended tightening torque for Klingersil gasket type ................................................................ 9

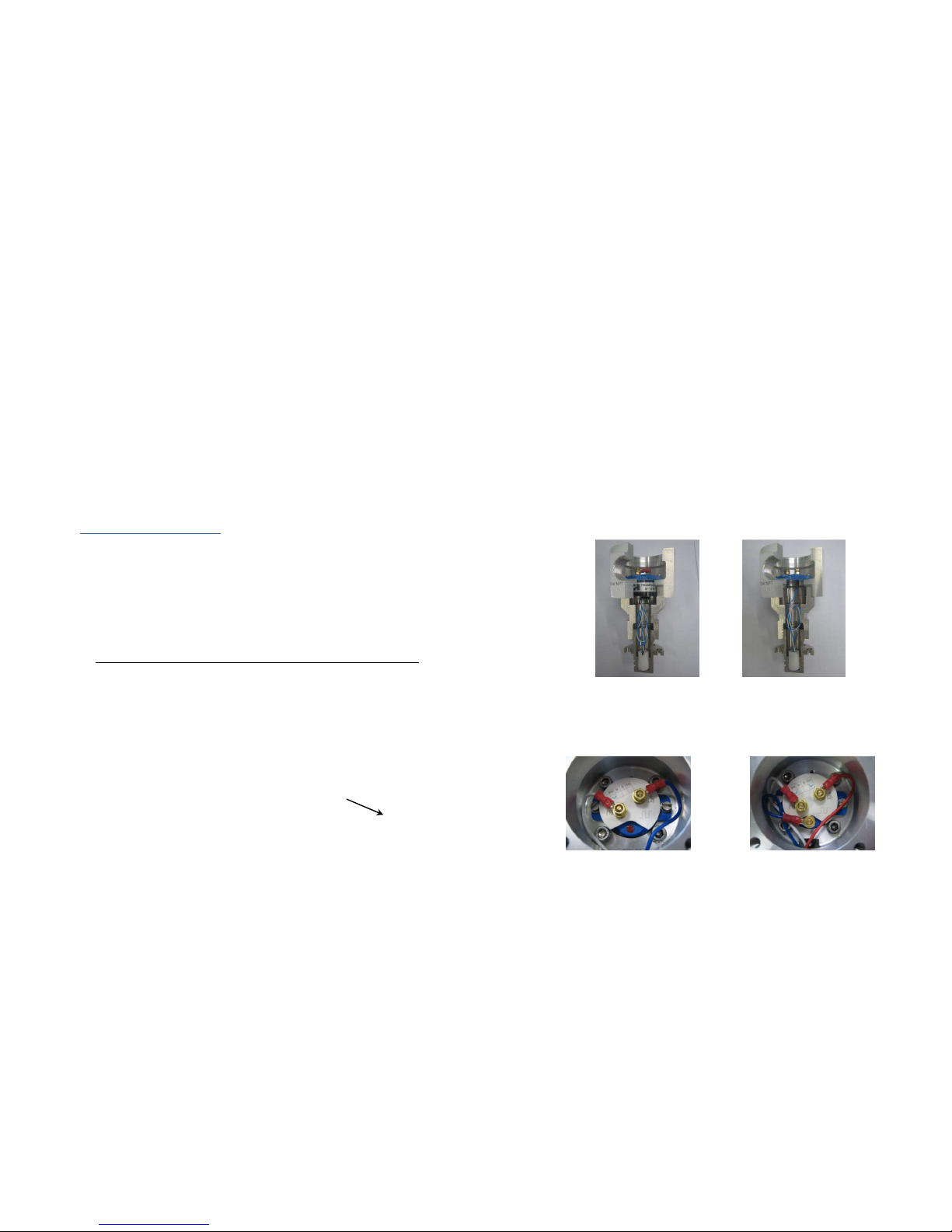

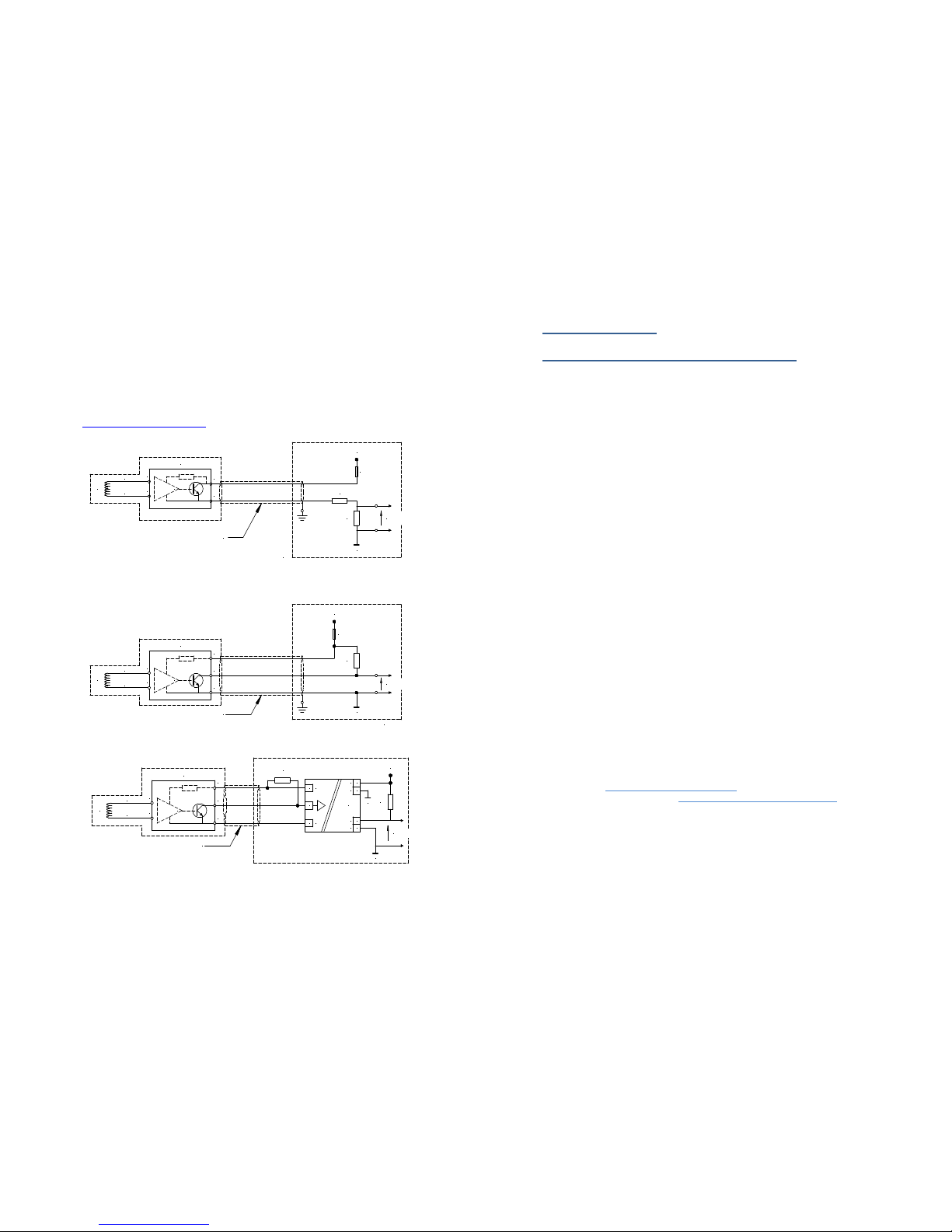

Figure 8. Factory wiring of pickup coil: with and without preamp ................................................................... 11

Figure 9. Types of preamplifiers........................................................................................................................... 11

Figure 10. Typical wiring diagram for 2 wires FH71with Input Impedance greater than 10 kΩ ..................... 12

Figure 11. Typical wiring diagram for wires FH71 (Open Collector) ............................................................... 12

Figure 12. Example wiring diagram for wires FH71 (Open Collector) with isolator ..................................... 12

Figure 1 . Typical 2 wires FH71 connection to SPIRIT Flow-X Flow Computer ................................................ 1

Figure 14. Typical wires FH71 connection to Emerson S600 FloBoss Flow Computer ................................. 1

Figure 15. Typical 2 wires FH71 connection to OMNI 000/6000 Flow Computer .......................................... 1

Figure 16. Illustration of Preamplifier Replacement .......................................................................................... 15

Figure 17. Illustration of Removal of Metal Ring type pickup coil ..................................................................... 16

Figure 18. Illustration of Removal of Engineered Polymer Ring type pickup coil ............................................ 17

Figure 19. Cartridge replacement – meters < ’’ ................................................................................................. 17

Figure 20. Cartridge replacement for meters 4’’ - 14’’ ....................................................................................... 18

Figure 21. Cartridge replacement – meters >16’’ ............................................................................................... 18

Figure 22. CUS Cartridge removal ........................................................................................................................ 19

Figure 2 . TZN with local totalizer ....................................................................................................................... 20

Figure 24. TZN with thermal extensions .............................................................................................................. 20

Figure 25. TZN with pulse outputs .................................................................................................................... 20

Figure 26. Nominal Size STD ≤ '' ......................................................................................................................... 21

Figure 27. Nominal Size CUS ≤ '' ......................................................................................................................... 22

Figure 28. Nominal Size STD 4''-14'' ..................................................................................................................... 22

Figure 29. Nominal Size CUS 4''-14'' .................................................................................................................... 24

Figure 0. Nominal Size STD > 16'' ....................................................................................................................... 25

Figure 1. Nominal Size CUS > 16''....................................................................................................................... 26

Page 3 / 37

Chapter 1: Introduction to TZN Meters (STD & CUS)

The simple, rugged construction of TZN turbine meters provides excellent accuracy and

measurement repeatability for a wide range of industrial applications. All TZN flow meters, both

STD and CUS, are designed to provide high quality liquid volume measurement across a wide range

of viscosities (0. to >1,000 cSt).

The TZN CUS model was specifically developed to measure fluids containing fibers, paraffin, or

DRA (Drag Reducing Agents). The patented TZN CUS shaft and bearing system minimizes negative

impacts of these substances on measurement accuracy.

The removable measurement sub assembly (also referred to as ‘cartridge’) design allows

pressure to be equalized between the cartridge and meter body, thus eliminating sensitivity to fluid

pressure variations. Additional benefits of this design enables factory calibration of the cartridge,

independent of the meter body, which allows rotation of cartridges in challenging operational

environments (remote installations, limited access of onsite site provers, high pressure

applications, etc.), as well as selecting a different cartridge to meet changes in operational flow

rates (within calibrated flow parameters). This can significantly reduce operational downtime and

maintenance costs.

Generation of Signal

The operating principle of helical turbine flow meters is based on the electromagnetic field

generated by the rotational velocity of magnets imbedded in blades of the helical rotor passing by

a pick-up coil positioned in the flowmeter body.

Dual blade

helical rotor

Coil

Preamplifier (optional)

Embedded

magnets

Figure 1

. Mechanics of Signal Generation of Helical Tur ines

Measuring the electrical signal generated allows calculation of the liquid flow rate flowing into the

pipe through the following expression:

600,

Kf

F

Q×=

, and the transferred volume through:

Kf

N

V=.

With Q Instantaneous flow rate in m

/h [l/min, GPM, BPH …]

F Output signal frequency in Hz

Kf Measurement cartridge Kfactor in pulses/m

[p/l, p/USG, p/bbl …]

Kfactor is established during measurement cartridge calibration.

V Volume in m

[litres, Gallons, Bbls]

N Number of pulses

Page 4 / 37

Chapter 2: Meter Components y Meter Size

TZN flowmeters include the following components:

1. Body

2. Measuring sub-assembly / cartridge

. Inlet ring

4. Detection sub-assembly / Electronics enclosure

5. Flow conditioner (Optional)

½ to ” TZN

4 to 14” TZN

16 to 20” TZN

Threaded type TZN (Size ≤ 2”)

Wafer style (Size ≤ 2”)

Figure 2. Meter ody types y size

Page 37 / 37

TEC 02

-

05

-

01 EN Rev A

(05/2017)

Page 36 / 37

Corrosion erosion

Choose proper materials.

Apply an additional corrosion

thickness. Application of painting systems adapted to the

environment.

Corrosion cavitation Choose proper materials. This is metrological equipment, the

user must set up devices to avoid cavitation.

Abrasion

Choose proper materials

–

Apply an additional corrosion

thickness. It remains under user responsibility to periodically

check the condition of the equipment.

ATEX Recommendations

When applicable, this equipment is ATEX certified and complies with the essential Health and Safety

requirements relating to the design and construction of equipment intended for use in potentially explosive

atmospheres (2014/ 4/EU Directive).

For safe operation, please ensure that this equipment is used in total compliance with the instructions given on

the ATEX certificate and nameplate. Please consult the user manuals, equipment installation and maintenance

manuals regarding the various parts used in this device. This equipment must be installed and serviced by trained,

specialized staff who understand the languages used in the manual.

If you require a manual or any additional information, please contact the FAURE HERMAN Customer support

team:

FAURE HERMAN - Route de Bonnétable – 72400 La Ferté Bernard – France

+ (0)2 4 60 28 60 -

+ (0)2 4 60 28 70 - support@faureherman.zendesk.com

Page 5 / 37

Meter Body

The meter body is most commonly made of carbon steel or stainless steel (AISI 16/ 16L or

equivalent); other materials are available upon request (Duplex, Hastelloy …).

The meter body contains a removable cartridge. Depending upon meter size and operational

preferences, the body can be fitted with one, two or three bosses, allowing generation of single or

dual pulse signals to flow computer, as well as the addition of a localized readout via a totalizer if

desired. The position of the electronic enclosures is arranged so that pulse trains delivered by the 2

coils are 90° out of phase.

The meter body will contain the following markings:

•An arrow indicating the direction of fluid flow

•A manufacturer's nameplate with specific equipment identification

NOTE: TZN CUS cartridges are distinguished from TZN STD versions by their specific fixed rotor

shaft and the presence of bearing supports in the crosspieces.

Measurement Cartridge Types y Size

Nominal sizes ≤ " The cartridge is centered and

fastened into the body by means of an upstream

stainless steel threaded ring. NOTE: on older models, the

ring is part of the cartridge.

Nominal sizes 4” ≤ 14” The

cartridge is centered and

fastened into the body by

means of an upstream stainless

steel ring fixed with screws.

Nominal sizes ≥ 16" The piece cartridge is centered and fastened into the body by means of

upstream and downstream stainless steel cross pieces containing the rotor. The outer rings are

fixed into the meter body to hold the cartridge in place with screws.

Figure 3.

Cartridge types y size

Page 6 / 37

Detection Su -assem ly / Electronic Enclosure

The detection sub-assembly is housed in a flame-proof box which permits the use of the

flowmeter in electrically classified areas (UL/cUL Class 1 Div 1 Group C & D; ATEX/IECEx II1G – IIC

T6). The electronic enclosure integrates the following elements:

•A pick up coil housed in the bottom of each boss and kept in position by means of a ring

•A coil/pre-amplifier connection cable

•An optional pre-amplifier which allows operators to significantly increase the maximum

distance between the flowmeter and the electronic display and/or flow computer (up to

5,000 meters/16,000 ft)

Flow Conditioning

According to API MPMS Chapter 5. and ISO 2715, “The performance of turbine meters is

affected by swirl and non-uniform velocity profiles that are induced by upstream and downstream

piping configurations, valves, strainers, pumps, fittings, joint misalignment, protruding gaskets,

welding projections, or other obstructions. Flow conditioning shall be used to overcome the

adverse effects of swirl and non-uniform velocity profiles on turbine meter performance.”

Faure Herman can supply the flow conditioning assembly which integrates upstream piping,

flow conditioning element (plate, straightening vanes, etc.) and downstream piping (to be utilized

at time of meter calibration).

Figure 4. Complete Meter run with upstream/downstream spool pieces and flow conditioner

Chapter 3: Equipment Receipt, Storage and Handling

Upon receipt of the TZN turbine meter, inspect the packing case for any shipping damage. The

meter must be carefully removed from the packing case and inspected for potential damage or

missing parts (including documentation)

Before installation, the unit should remain stored in its original packing, protected against

adverse weather conditions, and maintained at temperatures between -20 /+70 °C (-4 /+158 °F).

If the meter isn’t installed within a month, FH recommends maintaining the metering assembly

in an inerted atmosphere (nitrogen) or fluid filled state (light hydrocarbons). Please check

applicable regulation to ensure that all calibration requirements have been met.

Prior to installing the TZN, visually inspect the turbine meter; pay particular attention to name

plate (check for serial number, process conditions, direction of flow …), flange rating and general

conditions.

Should the product be damaged or documents missing, please contact the Faure Herman

Worldwide Customer Support & Service via phone, email or website:

Hotlines: +1 (71 ) 597 4827 (North America)

+ (0)2 4 60 28 55

Email: su[email protected]m

Online Assistance website: https://faureherman.zendesk.com/hc/en-us

Page 35 / 37

Risk analysis according to Directive 2014/68/EU

Suita le resistance

Requirements

Excess temperature and

pressure

Temperatures and pressure limits should be considered during

the design phase.

The limitations are indicated on the equipment; the user is

responsible to set up equipment properly.

Wind / Snow influence

NA:

Without influence considering the small surface

areas

Earthquake

The equipment is not intended for use in a seismic zone. If

operated as such, it is the responsibility of the user to provide

adapted devices.

Support, binding and piping

reaction

The equipment is

designed to be

joined

to other piping

;

it

does not have its own supports.

Thermal fatigue

Design

c

hoice of materials follow

s

ASME B 1. .

Mechanical fatigue

This is metrological equipment; i

t

is the

user’s

responsibility to

install properly to avoid mechanical stress.

Vibration This is metrological equipment; it is the user’s responsibility to

install

away from

sources of vibration.

Handling and operation

Comments

Closing and opening

NA: t

he equipment does not have

an

aperture or closure.

Dangerous emissions from

valves

NA: the equipment does not have a valve.

Access to the inside

NA: t

he equipment does not have access (inspection hatch,

manhole).

Surface temperature

T

he user

is responsible for indication of

hot surfaces.

Decomposition of unstable fluid NA: The equipment is used for the transfer of fluid not

storage.

Handling

E

quipment

>

0kg is equipped with lifting rings

for safe

handling.

Draining and venting

Comments

Pressure wave

This is sensitive metrological equipment; i

t

is the

user’s

responsibility to install properly to avoid pressure waves.

Vacuum collapse

Minimal service pressure of 0 b

ar.g indicated on the plate.

This

equipment is not

designed

to work

under

vacuum.

Corrosion and chemical attack

Comments

Uniformly generalized

Consideration of corrosion

thickness.

Choose proper materials and application of painting systems

adapted to the environment.

It remains under user responsibility to periodically check the

condition of its installation.

Selective

Choose proper materials

Galvanic

Choose proper

materials and review compatibility of

materials. It is the user’s responsibility to set up adapted

devices, groun

ding

strap

s

, cathodic protection…

By differential aeration

Choose proper materials

–

Maintain the equipment full of

fluid.

By puncture, crev

ice,

intergranular

Choose proper materials. Review c

ompliance with NACE

MR0175 requirements if applicable.

Ammonia

Choose proper materials

Under stress

Choose proper materials. Review c

ompliance with NACE

MR0175 requirements if applicable.

Wear

Comments

Page 34 / 37

Page 7 / 37

Handling recommendations: Meter sizes

≥

6"(DN 150) or weighing > 5 kg [77

lbs]

The TZN must be carefully handled with lifting rings (when applicable) or with straps on both

sides of the body.

Electronic detection system enclosures must not e used for lifting.

Figure 5. Proper lifting technique for meters > 6 inches

Chapter 4: Installation and Operation

TZN turbine flowmeters can be installed horizontally or vertically (ascending flow) provided the

flow direction indicated on the cartridge and meter body are followed.

For custody transfer applications, turbine flowmeters require the integration of a minimum

upstream pipe length at least equal to 10 times the pipe diameter and at least equal to 5 times the

pipe diameter downstream.

Mechanical Preparation of Pipe Prior to Meter Installation

Prior to flowmeter installation on the pipe, check the following to ensure proper operation:

•Cleanliness of the pipe upstream from the flowmeter

•Flow direction indicated by an arrow on the nameplate

•Correspondence between flanges and joint faces, on pipe and flowmeter sides

•Flowmeter alignment with upstream and downstream pipes and absence of obstacles

preventing the correct liquid flow (gaskets, …)

•Follow recommended tightening torques in Appendix IV when bolting flanges

•Position of electrical connections to avoid binding

As a measuring instrument, tur ine flowmeters must e handled with care.

Page 8 / 37

Meter installation

Before installation, keep the equipment in its original packing, sheltered from bad weather and

possible impacts.

The meter should be installed in the measurement line with proper alignment of upstream and

downstream flanges so that stress on the equipment body is avoided.

Figure 6. Proper pipe alignment for meter installation

The equipment must be installed by using the proper tools (wrenches):

•Never use a hammer

•Use impact wrenches with caution; pay attention to torque recommendations

•Specific tools can be used, when necessary, for the spacing between flanges.

If used, leave lift mechanisms in place until all bolts have been tightened.

Gaskets

Check to ensure that the proper gaskets are installed according to flange type: ASME B16.20 and

ASME B16.21 or NF EN 1514 and NF EN 12560 standards.

NOTE: Spiral wound gaskets are forbidden for flanges rated below class 00 or PN 6 .

Never reuse gaskets.

Page 33 / 37

1

Category

A

rea in which an atmosphere at risk of explosion as

a mixture of air

and inflammable gases, vapors or mists is continuously or frequently

present or present

for long periods.

G

Gas/Dust

Gas

Ex

Electrical device

d

Type of protection

Flameproof

II

Gas group

Surface above ground industries

C

Gas subgroup

Most easily ignited e.g. hydrogen

or

acetylene

Gb

Protection level

Equipment for use in explosive atmospheres due to the presence of

gas, with a 'high' level of protection that is not the source of ignition in

normal operation or when subject to expected malfunctions, although

not on a regular basis.

T6

85°C

-50°C

≤

Fluid Temperature

≤

+80°C

UL & cUL Installation

Magnetic sensor assemblies are UL and cUL certified for use in Class I, Div 1, Groups C and D

hazardous locations, with several combinations of coils and preamps.

Ambient temperature must remain within -50 and 80°C. An optional thermal extension can be

used to handle liquids heated up to 150°C.

Page 32 / 37

ATEX Electrical Component Criteria

Electrical components are covered LCIE 0 ATEX 62 0X certification which allows use in

intrinsically safe or flameproof applications.

ATEX Intrinsically Safe Data Ta le and Tag Example

The intrinsically safe model certification depends on whether a preamplifier is used and the

temperature range of application (Table 2).

•without preamplifier II 1 G EEx ia IIC T6 to T ; ambient temperature (Ta) between -20 &

+180°C

•with FH71 preamplifier

II 1 G EEx ia IIC T6 to T5; ambient temperature (Ta) between -20 &

+80°C

Table 2.

ATEX mark

II

Equipment Group

Equipment for places with a potentially explosive atmosphere, other

than mines susceptible to firedamp.

1

Category

A

rea in which an atmosphere at risk of explosion as

a mixture of air

and inflammable gases, vapors or mists is continuously or frequently

present or present

for long periods.

G

Gas/Dust

Gas

Ex

Electrical device

ia Type of protection Intrinsically safe

II

Gas group

Surface above ground industries

C

Gas subgroup

Most easily ignited e.g. hydrogen or

acetylene

T6 85°C; Ta

≤

80°C

T5 100°C; Ta

≤

95°C

T4 1 5°C; Ta

≤

1 0°C

T 200°C; Ta

≤

180°C

Additional parameters applying to ATEX Intrinsically Safe certification

Without

preamplifier

Ui

≤

10 V Ii

≤

2 mA Ri ≥ ,420 Ω Ci

≅

0 Li

≤

.2 H

With FH71 preamplifier Ui ≤ 28 V Ii ≤ 150 mA Pi ≤ 1 W Ci ≅ 0 Li

≤

0

ATEX & IEC Ex Flameproof Data Ta le and Tag Example

The flameproof models are certified II 1 G Ex d IIC T6 Gb & IECEx LCI 12.001 X. Ambient

temperature (Ta) must remain between -50 and + 60°C.

Table

ATEX mark

II

Equipment Group

Equipment for places with a potentially explosive atmosphere, other

than mines susceptible to fire damp.

Page 9 / 37

Flange olts

The material of flange bolts shall be chosen in ASTM A 19 B7 (bolts) and ASTM A 194 2H

(nuts) according to ASME B16.5 standard for temperature between -45°C and +480°C.

Tightening torque

If the flowmeter is equipped with a flow straightener, the bolts must be checked and

retightened before commissioning. A label affixed to the flanges calls attention to this requirement.

Bolt size and tightening torque

–

non coated

Bolt size and tightening torque

-

coated

M

N.m

NPS

ft

-

lb

M

N.m

NPS

ft

-

lb

14

110

1/2

60

14

85

1/2

45

16

160

5/8

120

16

1 0

5/8

90

20

50

/4

210

20

250

/4

160

24

550

7/8

50

24

450

7/8

250

27

800

1

500

27

650

1

400

0

1,150

1 1/8

750

0

900

1 1/8

550

1,550

1 ¼

1,050

1,200

1 ¼

800

6 2,040 1

⅜

1,400 6 1,600 1

⅜

1,050

9

2,650

1 ½

1,800

9

2,050

1 ½

1,400

42

, 50

1

⅝

2, 50

42

2,550

1

⅝

1,800

Figure 7. Recommended tightening torque for Klingersil gasket type

Condition of Liquids Measured

Flowmeter life duration and measurement reliability can be seriously impacted by the

presence of gas and/or solid particles in the flowing liquid.

The presence of gas, in the form of bubbles or emulsions, can cause serious degradation of

measurement performance. Gas "pockets" between two liquid sections can destroy the rotor

bearings, leading to serious measurement errors and/or damage to the cartridge assembly.

To ensure accurate measurement and minimize possibility of damage, FH recommends

eliminating the possibility of gas injection upstream from the measurement point and providing,

when required, a draining or degassing system upstream from the flowmeter. We recommend

positioning the flowmeter to minimize the possibility of gas pocket formation resulting from

contraction of volumes during an interruption of flow.

The presence of small-sized solid particles within the flowing liquid may result in a gradual

deterioration of the flowmeter fixed or mobile elements (bearing support cross pieces, bearing,

rotor), which can lead to a gradual deterioration of performance. Larger solids can cause significant

damage requiring replacement of these parts (bearing support cross pieces, bearing, and/or rotor).

Page 10 / 37

Recommended Strainer Size y Meter

Protection of turbine meter (and associated instrumentation) can be critical during new

installations start-up and when a system is restarted after heavy work upstream of the meter run.

To minimize the risk of solid particle injection upstream from the measurement point, we

recommend installation of a strainer with mesh sizes as listed in the table below:

TZN Model (CUS & STD)

Recommended

Filtration

TZN Model

mm

m

/h (max)

inches

BPH (max)

(mm)

MESH

TZN 16

-

012

TZN 16-025 16

0.12

0.25 1/2

0.75

1.5 0.15 100

TZN 20-05

TZN 20-01 20 0.5

1 /4 .1

6. 0. 55 45

TZN 25-2

TZN 25-

TZN 25-5

TZN 25-10

25

2

5

10

1

1

20

0

6

0.425 40

TZN 2

-

8

TZN 2-12

TZN 2-15

TZN 2-20

2

8

12

15

20

1 1/4

50

75

94

126 0.5

5

TZN 40

-

8

TZN 40-12

TZN 40-15

TZN 40-20

TZN 40-40

40

8

12

15

20

40

1 1/2

50

75

94

126

250

TZN 50- 0

TZN 50-50

TZN 50-70

50

0

50

70

2

190

20

440

0.85 20

TZN 80-70

TZN 80-110

TZN 80-150

80

70

110

150

440

690

94

1.4

14

TZN 100-200

TZN 100- 00 100 200

00 4 1,260

1,890 1.7 12

TZN 150-400

TZN 150-600 150 400

600 6 2,520

,770 2. 6 8

TZN 200-800

TZN 200-1000

TZN 200-1200

200

800

1,000

1,200

8

5,0 0

6,290

7,550

2.8 7

TZN 250-1200

TZN 250-2000 250 1,200

2,000 10 7,550

12,600 . 5 6

TZN 00-2400

TZN 00- 000 00 2,400

,000 12 15,100

18,900

TZN 50- 500 50 ,500 14 22,000

4 5

TZN 400-4000

TZN 400-4500 400 4,000

4,500 16 25,200

28, 00

TZN 450-4800

TZN 450-5500 450 4,800

5,500 18 0,200

4,600

TZN 500-6000 500 6,000 20 7,800 4.75 4

IMPORTANT: After a period of critical monitoring, the filtration degree can be relaxed to reduce

strainer maintenance and pressure losses, e.g. MESH 6 to MESH 4 on a 12” meter (consult

manufacturer).

Page 31 / 37

ATEX Non electrical certification Data Ta le and Tag Example

The mechanical part is a non-electrical part as defined under the certificate LCIE 05 ATEX

60 5X. This equipment is manufactured with a protective system as defined by European standards

NF EN 1 46 -1 and 1 46 -5 and is certified II 2 G c T6 to T1 within fluid temperatures between -

50 and + 50 °C (Table 1).

Table 1.

ATEX mark

II Group

Equipment for pl

aces with a potentially explosive atmosphere, other

than mines susceptible to firedamp.

2 Category

E

quipment designed to be capable of functioning in conformity with

the operational parameters established by the manufacturer and

ensuring a high level of protection.

Equipment in this category is intended for use in areas in which

explosive atmospheres caused by mixtures of air and gases, vapors or

mists or by air/dusts mixtures are likely to occur.

The means of protection relating to equipment in this category

ensures the requisite level of protection, even in the event of

frequently occurring disturbances or equipment faults which are

normally taken into account.

G

Gas/Dust

Gas

c

Type of protection

Protection by

constructional safety

“safe by design”.

T6 85°C -50°C

≤

Fluid Temperature

≤

+80°C

T5

100°C

+80°C

<

Fluid Temperature

≤

+95°C

T4

1 5°C

+95°C

<

Fluid Temperature

≤

+1 0°C

T 200°C +1 0°C

<

Fluid Temperature

≤

+195°C

T2

00°C

+195°C

<

Fluid Temperature

≤

+290°C

T1

450°C

+290°C

<

Fluid Temperature

≤

+ 50°C

NOTE: For models containing aluminum parts (rotor), fluid temperatures are limited from -50 to

+100°C

Complete unit ID plate

(mechanical & electrical)

Page 30 / 37

If the flowmeter is equipped with lifting rings, they must be used. The flowmeter must never

be handled, lifted or secured by the electronic enclosures.

Unpacking

Upon receipt of the TZN turbine meter, inspect the packing case for any shipping damage. The

meter must be carefully removed from the packing case and inspected for potential damage or

missing parts (including documentation). Protective devices such as end caps must be removed

prior to installation.

Storage

If the flowmeter is not installed as soon as it is received, it must be stored and protected from

the elements. In case of extended storage (more than a year), check applicable regulation to ensure

that all calibration requirements have been met.

Return

Contact Faure Herman prior to any return. If the flowmeter has been used with hazardous,

corrosive, or toxic substances, the operator must make sure that it has been correctly rinsed,

cleaned, and decontaminated before being returned to Faure Herman.

ATEX & IEC Ex Installation

This equipment is ATEX and IEC Ex certified and complies with the essential Health and Safety

requirements relating to the design and construction of equipment intended for use in potentially

explosive atmospheres (2014/ 4/EU Directive).

Please ensure this equipment is used in total compliance with the instructions given on the

ATEX certificate and nameplate. Consult the user manuals, as well as equipment installation and

maintenance manuals for this device to ensure safe operation of this equipment.

This equipment contains non-electrical and electrical components which are both ATEX

certified relating to the design and construction of equipment intended for use in potentially

explosive atmospheres (Directive 2014/ 4/UE).

General Safety Information

The meter must be de-energized for all installation and maintenance activities.

For safe operation, the equipment must be used in compliance with its’ ATEX / IEC Ex

certificate and nameplate criteria. Observe all instructions for equipment and component parts

contained in user manual.

The equipment must be installed and operated only in areas complying with its hazardous

protection rating as specified on the plate attached to the meter.

If the equipment is connected to ancillary devices, check to ensure the electrical protection

systems are fully compatible.

According to ATEX Directive, turbine meter consists

of both mechanical and electrical parts. Each

component has its own certification which

combines to provide the complete meter protection

system and parameters.

Electrical components

ID plate

Page 11 / 37

Should a filter and air elimination system be used simultaneously, we recommend placing the

air eliminator as the last device upstream of flow conditioning.

In order to avoid erratic measurements caused by liquid cavitation, minimum back pressure

must remain greater than P

min

according to the expression:

vmin

P25.1P2P ×+∆×>

with P

min

Minimum back pressure in bar [

psi

]

ΔP Meter pressure at flowing conditions in bar [

psi

]

P

v

Liquid vapor pressure at flowing conditions in bar [

psi

]

Note:

For LPG, minimum back pressure should be set at P

v

+ 1 bar [

+ 14.5 psi

]

Electrical Installation

TZN turbine meters integrate two (or three) detection systems allowing generation of two out

of phase pulse trains. An integrated preamplifier FH71 (required for distance between meter and

control room greater than 600 ft) receives low level signals from the pick-up coil, and converts

these into positive square wave signals for long distance transmission (greater than 600 ft).

Preamplifiers are available in either a 2-wire (Intrinsically Safe versions) or -wire (non IS)

configuration.

Connection between the coil and preamplifier (or terminal) is completed in factory.

2 or wire preamp No preamp

Figure 8. Factory wiring of pickup coil: with and without preamp

Hazardous area classification must be checked prior to connection (refer to ATEX or UL plate).

Depending on preamplifier type (2 wire Standard, NAMUR or wire Open Collector); connect

the field shielded wire according to figures below.

2 wire preamp

(Standard / NAMUR)

wire preamp

(Open Collector)

Figure 9. Types of preamplifiers

Page 12 / 37

Wiring diagrams

Electrical connection to site (flow computer) depends on:

•

Protection type (Intrinsic Safety, Explosion Proof)

•

Flow Computer inputs characteristics (Impedance …)

•

Connection wire characteristics (resistance, inductance …) …

Wiring diagrams (below) can be used as ‘typical’. Additional configurations available on FH web site

(https://faureherman.zendesk.com).

2 wires FH71

A

B

Coil

2

1160

Ω

± 5%0.5W

470

Ω

± 5%

1 W

Ref Power Supply (0V)

Protection

fuse > 100 mA

24 VDC

Power Supply

AWG 16 shielded wire L < 500m (1,500 ft)

2.5 <VDT <10 V

(VDT: Voltage Detection Threshold)

white

blue

Figure 10

. Typical wiring diagram for 2 wires FH71with Input Impedance greater than 10 kΩ

3 wires FH71

A

B

Coil

3

1

white

blue

2

3.5 <VDT <20 V

Ref Power Supply (0V)

1.5k

Ω

± 5%

0.5W

Protection

fuse > 100 mA

5 to 28VDC

Power Supply

(VDT: Voltage DetetcionThreshold)

AWG 16 shielded wire L < 500 m(1,500 ft)

Figure 11. Typical wiring diagram for 3 wires FH71 (Open Collector)

0 < VDT < 12V

3 wires FH71

A

B

Coil

3

1

white

blue

2

AWG 16 shielded wire L < 500 m (1,500 ft)

1

k

Ω

± 5%

250 mW

4

5

1

14

13

11

12

+

-

+

-

+

-

MTL5532 0V

1 k

Ω

± 5%

1 W

Ref Power Supply (0V)

24 VDC

Power Supply

Figure 12. Example wiring diagram for 3 wires FH71 (Open Collector) with isolator

Page 29 / 37

Safety Consideration

Important Information Needed for Installation

This manual contains important instructions and safety information. It is essential to read and

understand the operating procedures prior to installation, connection, and commissioning of the

equipment.

Failure to observe these instructions and warnings may damage the flowmeter and/or

endanger personnel.

Personnel Requirements

Make sure that operators and maintenance personnel have all safety equipment applicable to

the area (safety glasses, protective headgear, safety shoes …) and are trained to operate the meter.

Unauthorized personnel should not have access to the operation of the meter.

Hazards arising from failure to o serve the instructions and warnings

Failure to observe these instructions and warnings may:

•

Expose personnel to mechanical, electrical, or chemical risk

•

Damage the equipment (meter)

•

Pollute the environment by releasing hazardous substances

Safety instructions

Power supply must be disconnected and flow meter must be depressurized before servicing to

avoid electrical and/or pressure hazards. The safety instructions in this manual, as well as all

accident prevention and occupational safety regulations in force in the country of installation, must

be observed.

Conditions of operation

Conditions of use indicated on the data plate must be observed; equipment reliability is

guaranteed only if it is installed and used as described in these manuals.

Installation and maintenance operation shall be done using the proper tools. Never use a

hammer or any tools which can create sparks or damage the equipment’s electrical protection

(enclosure, cable gland, conduit …). If impact wrenches are used, pay attention to torque

recommendations listed in TZN Manual.

Installation, maintenance and repair of the equipment shall be carried out by suitably trained

personnel; all spare parts shall be approved by Faure Herman. No operation or repair which can

affect the protective system can be done on this equipment without authorization by Faure

Herman.

For specific installation and maintenance advice, contact the Faure Herman Worldwide

Customer Support & Service via phone, email or website:

Hotline: +1 (71 ) 597 4827 (North America)

+ (0)2 4 60 28 55

Email: support@faureherman.zendesk.com

Online Assistance website: https://faureherman.zendesk.com/hc/en-us

Repair and maintenance

Repair, maintenance or potential modifications are allowed only after consultation with Faure

Herman. If any parts other than those approved by Faure Herman are used, Faure Herman cannot

be held liable for the consequences.

Transport, handling, and storage

The flowmeter must be handled with care to avoid damage. End caps are used to protect the

flanges during transport and handling.

Page 28 / 37

Appendix 3 - Operating restrictions & Special recommendations

The nominal operating process envelope is specified on the nameplate. This envelope is mainly

defined in terms of:

•

Minimum / Maximum – Flowrate

•

Maximum – Pressure

•

Minimum / Maximum – Temperature

Flowrate restrictions specify the equipment optimal performance envelope (measurement

accuracy and repeatability). The maximum value also sets the permissible continuous operating

limit. The maximum limit may occasionally exceed 120 % of the set value without negative impacts.

The pressure and temperature restrictions involve exclusively the equipment mechanical sizing

and define the authorized operating envelope.

Note: W en operating temperature is ig er t an t e indicated value, t e maximum aut orized

pressure s all be reduced, in strict application of t e ASME B16.5, NF EN 1759-1 or NF EN 1092-1

Standard.

Page 13 / 37

2 wires FH71

A

B

Coil

2

1

130

Ω

± 5% 0.25 W

510

Ω

± 1%

1W

Ref Power Supply (0V)

Protection

fuse > 100 mA

24VDC

Power Supply

AWG16shielded wire Lup to more than 1,000 m(3,000 ft)

white

blue

0V

(SPIRIT)

DIGITAL

INPUT(1)

Channels number 1 to 16: Select threshol 12V in Digital I/O settings

Figure 13. Typical 2 wires FH71 connection to SPIRIT Flow-X Flow Computer

3 wires FH71

A

B

Coil

3

1

white

blue

2

Ref Power Supply (0V)

1.2 k

Ω

± 5%

0.5W

Protection

fuse > 100 mA

12 to 24 VDC

Power Supply

AWG 16 shielded wire L < 500 m (1,500 ft)

Pulse +

Pulse -

S600 Pulse input

CH1 CH2 CH3 CH4

4 3 2 1

23 22 21 20

Pulse+

Pulse-

SKT-C

P148MezzanineCard:

Figure 14. Typical 3 wires FH71 connection to Emerson S600 FloBoss Flow Computer

2 wires FH71

A

B

Coil

2

1

620

Ω

± 51%

1W

Ref Power Supply (0V)

Protection

fuse > 100 mA

24VDC

Power Supply

AWG 16 shieldedwire L < 500 m (1,500 ft)

white

blue

0V

(OMNI)

PULSE

INPUT(1)

To be connected to terminal #5 or #6 on Type E Combo Module

Figure 15. Typical 2 wires FH71 connection to OMNI 3000/6000 Flow Computer

Chapter 5: Commissioning

After meter installation on pipe and completion of electrical connections, proceed with filling

of the pipe with liquid.

During initial filling of system, make sure any gas present in the pipe is purged by utilizing available venting

systems or by passing through the flowmeter at very low flow rate.

Avoid sudden filling of the flowmeter; this helps prevent formation of gas “pockets”, which can damage the

rotor and / or bearing system.

Avoid extended use of the flowmeter beyond the specified operating maximum flow rates.

Page 14 / 37

Chapter 6: Maintenance

The design of TZN flowmeter requires minimal maintenance when used within its operating

limits. A general recommendation is to replace the shaft and bearing assembly every three to five

years depending on process conditions such as continuous measurement, start and stop …

In the event of extended operational interruption, it is recommended to keep the flowmeter

full of liquid to keep the bearings from seizing, except when the liquid may crystallize or solidify.

Chapter 7: Trou leshooting

Problem Potential Cause(s)

Flowmeter overrates

1

–

2

–

5

-

7

–

8

–

9

–

10

–

11

Flowmeter underrates

1

–

2

–

-

4

–

5

–

6

–

8

–

9

–

10

–

11

Erratic indications

1

–

2

–

8

–

9

–

10

–

11

No signal 2 – – 4 – 6

Underlying Issue

Possible Solution(s)

1 Erratic pulses

Check cable shield and connection

Check for proper resistor selection (refer to wiring diagram)

Inspect pickup coil and/or preamplifier; replace if necessary.

2 Coil and/or preamp. defect

Check for proper wiring and resistor selection

Check for preamp type selection (N, S, CO)

Replace coil and/or preamp.

Loss of magnets

Replace the rotor

4 Damaged shaft or bearings

Replace bearing and/or shaft

Depending upon damage, possibly replace rotor and/or

crosspieces.

5

Damaged rotor

Replace

the rotor

6 Blocked rotor Inspect and clean bearing system, crosspieces and cartridge

Replace the cartridge if necessary

7 Deposits on internal walls

Clean all the cartridge components

Check installation conditions

Check/Inspect upstream elements such as strainer, flow

conditioner …

Replace the cartridge if appropriate

8 Flow profile deformation

Clean all the cartridge components

Check installation conditions

Check/Inspect upstream elements such as strainer, flow

conditioner …

Replace the cartridge if appropriate

9 Presence of gas in the flow

Eliminate the source of gas

Check installation conditions

Install a deaerator

10 Cavitation

Check installation conditions

Check/Inspect upstream elements (strainer, flow

conditioner)

Increase line pressure

11 Performances Recalibrate

Replace the cartridge if appropriate

Page 27 / 37

Appendix 2 - K-factor – Flowrate/Frequency

TZN Model Min Kfactor Linear Flow Range

Frequency

Range

mm -

m

/h

Inches -

BPH

p/m

(p/litre)

p/Bbl

(p/USG) m

/h BPH ~ Hz

16

–

012

0.5

–

0.

7

5

(5,200)

(19,700)

0.012

–

0.12

0.075

–

0.75

17

.

5

–

175

16

–

025

0.5

–

1.

5

(2,600)

(9,850)

0.025

–

0.25

0.157

–

1.57

18

–

180

20

–

05

0.75

–

.1

(1,600)

(6,060)

0.05

–

0.5

0. 14

–

.14

22

–

220

20

–

1

0.75

–

6.

(415)

(1,572)

0.1

–

1

0.6

–

6.

11

.

5

–

115

25

–

2

1

–

1

(125)

(47 )

0.2

–

2

1.

–

1

7

–

70

25

–

1

–

20

(125)

(47 )

0.

–

2

–

20

10.5

–

105

25

–

5

1

–

0

(125)

(47 )

0.5

–

5

–

0

17.5

–

175

25

–

10

1

–

6

(125)

(47 )

1

–

10

6.

–

6

5

–

50

2

–

8

1.25

–

50

( 8)

(145)

0.8

–

8

5

–

50

8.5

–

85

2

–

12

1.25

–

75

(29)

(110)

1.2

–

12

7.5

–

75

9.5

–

5

2

–

15

1.25

–

94

(18)

(68)

1.5

–

15

9.4

–

94

7.5

–

75

2

–

20

1.25

–

126

(18)

(68)

2

–

20

12.6

–

126

10

–

100

40

–

8

1.5

–

50

( 8)

(145)

0.8

–

8

5

–

50

8.5

–

85

40

–

12

1.5

–

75

(29)

(110)

1.2

–

12

7.5

–

75

9.5

–

95

40

–

15

1.5

–

94

(18)

(68)

1.5

–

15

9.4

–

94

7.5

–

75

40

–

20

1.5

–

126

(18)

(68)

2

–

20

12.6

–

126

10

–

100

40

–

40

1.5

–

250

(18)

(68)

4

–

40

25

–

250

20

–

200

50

–

0

2

–

190

(20)

(75)

–

0

19

–

190

16.5

–

165

50

–

50

2

–

20

(12)

(45)

5

–

50

2

–

20

16.5

–

165

50

–

70

2

–

440

(12)

(45)

7

–

70

44

–

440

2 .5

–

2 5

80

–

70

–

440

5,000

795

7

–

70

44

–

440

9.5

–

95

80

–

110

–

690

5,000

795

11

–

110

69

–

690

15

–

150

80

–

150

–

945

5,000

795

15

–

1

5

0

94.5

–

945

21

–

210

100

–

200

4

–

1,260

2,050

26

20

–

200

126

–

1,260

11.5

–

115

100

–

00

4

–

1,890

1,600

254

0

-

00

189

–

1,890

1 .5

–

1 5

150

–

400

6

–

2,520

900

14

40

–

400

252

–

2,520

10

–

100

150

–

600

6

–

,770

650

10

60

–

600

77

–

,770

11

–

110

200

–

800

8

–

5,0 0

80

60

80

–

800

50

–

5,0 0

8.5

–

85

200

–

1,000

8

–

6,290

80

60

100

–

1,000

629

–

6,290

10.5

–

105

200

–

1,200

8

–

7,550

80

60

120

–

1,200

755

–

7,550

12.5

–

125

250

–

1,200

10

–

7,550

150

2

120

–

1,200

755

–

7,550

5

–

50

250

–

2,000

10

–

12,600

150

2

200

–

2,000

1,26 12,600

8.5

–

85

00

–

2,400

12

–

15,100

90

1

240

–

2,400

1,510

–

15,100

6

–

60

00

–

,000

12

–

18,900

90

1

00

–

,000

1,890

–

18,900

7.5

–

75

50

–

,500

14

–

22,000

70

11

50

–

,500

2,200

–

22,000

7

–

70

400

–

4,000

16

–

25,200

50

8

400

–

4,000

2,520

–

25,200

5.5

–

55

400

–

4,500

16

–

28, 00

50

8

450

–

4,500

2,8 0

–

28, 00

6

–

60

450

–

4,800

18

–

0,200

40

6.5

480

–

4,800

,020

–

0,200

5.5

–

55

450 – 5,500 18 – 4,600 40 6.5 550 – 5,500 ,460– 4,600 6 – 60

500 – 6,000 20 – 7,800 0 5 600 – 6,000 ,780– 7,800 5 – 50

Page 26 / 37

Figure 31. Nominal Size CUS > 16''

1

Flanged body

4

Boss

2

Measurement cartridge

5

Enclosure adapter

2.1

Rotor

6

Enclosure

2.2

Shaft

7

Enclosure cover

2.

Upstream crosspiece

8

Coil

2.4

Central section

9

Preamplifier or Terminal

2.5 Downstream crosspiece

2.7

Bearing

2.10

Upstream thrust

2.11

Downstream thrust

2.12

Tightening set

Page 15 / 37

Chapter 8: Replacement – Repair

Preamplifier replacement

This operation is performed when the equipment is de-energized. Refer to magnetic sensors

manual:

•

Cut the sealing system (if any)

•

Unscrew the explosion-proof enclosure cover (4 screws)

•

Disconnect the pre-amplifier from the site wiring

•

Remove both fastening screws from the pre-amplifier in the enclosure

•

Remove the pre-amplifier from enclosure; take care to avoid stressing the coil

connection wiring

•

Disconnect the coil / pre-amplifier connection wiring

Figure 16.

Illustration of Preamplifier Replacement

•

Perform above in the reverse order to install the new pre-amplifier

•

Re-position and screw the enclosure cover. Reposition and tighten the screws to a 6 Nm

[

4.4 ft.lb

] torque.

•

Replace the sealing system (if required).

Page 16 / 37

Coil replacement

Metal Retaining Ring

This operation can only be performed after removal of the pre-amplifier (if present):

•

Disconnect the coil / pre-amplifier connection wire

•

Withdraw the coil while removing the retaining ring using specific tool (ref 870046)

•

Insert the new coil and retaining ring and push in place using the other part of the tool

kit

(ref 870046).

Figure 17. Illustration of Removal of Metal Ring type pickup coil

Engineered Polymer Retaining Ring

This operation can only be performed after removal of the pre-amplifier (if present):

Disconnect the coil / pre-amplifier connection wire

•

Insert tool (ref 870045) into the boss, taking care not to damage the wires, until the

adapter connects, and then unscrew the adapter.

•

Place the new coil in the polymer ring with wires coming through the top of ring

•

NOTE: Make sure the coil wires aren’t crimped when inserting the new coil into the base

of enclosure.

Page 25 / 37

Figure 30. Nominal Size STD > 16''

1

Flanged body

Retaining ring

2 Measurement cartridge 4 Boss

2.1

Rotor

5

Enclosure adapter

2.2

Shaft

6

Enclosure

2. Upstream crosspiece 7 Enclosure cover

2.4

Central section

8

Coil

2.5

Downstream crosspiece

9

Preamplifier or Terminal

2.6

Elastic ring

2.7 Fixed bearing

2.9

Bearing shaft

Page 24 / 37

Figure 29. Nominal Size CUS 4''-14''

1

Flanged body

4

Boss

2

Measurement cartridge

5

Enclosure adapter

2.1

Rotor

6

Enclosure

2.2

Shaft

7

Enclosure

cover

2.

Upstream crosspiece

8

Coil

2.4 Central section 9 Preamplifier or Terminal

2.5

Downstream crosspiece

2.7

Bearing

2.10

Upstream thrust

2.11 Downstream thrust

2.12

Tightening set

Page 17 / 37

•

Holding the coil wires, insert the ring in bottom of enclosure and screw into the base of

well, taking care to avoid crimping the wires or stripping the polymer threads, and then

remove the tool.

Figure 18. Illustration of Removal of Engineered Polymer Ring type pickup coil

Measurement cartridge replacement

For nominal size equal or lower than ", the cartridge is centered and fastened into the body

by means of an upstream stainless steel threaded ring.

Unscrew the inlet threaded ring and push the cartridge from the downstream direction to

remove it.

Figure 19. Cartridge replacement – meters <3’’

Note the direction of engraved arrow on the outer surface before inserting the cartridge into

the body and re-fitting and tightening the inlet ring. The cartridge upstream face must be on inlet

ring side.

For 4 to 14” nominal size, the cartridge is centred and fastened into the body by means of an

upstream stainless steel ring fixed with screws.

Remove the retaining screws from the inlet ring before pushing the cartridge out of the body.

Inlet Ring

Cartridge

Page 18 / 37

Figure 20. Cartridge replacement for meters 4’’ - 14’’

Note the direction of engraved arrow on the outer surface before inserting the cartridge into

the body and re-fitting and tightening the inlet ring. The cartridge upstream face must be on inlet

ring side.

IMPORTANT: For meters greater than 4”, it is strongly recommended to remove the cartridge

with the meter in a vertical position.

For meters equal or greater than 16", the cartridge is centered and fastened into the body by

means of an upstream and downstream stainless steel cross pieces integrating the cartridge parts.

Outer rings are fixed into the meter body to hold the cartridge in place with screws.

Figure 21. Cartridge replacement – meters >16’’

For STD bearing design, place the turbine in a vertical position with the upstream crosspiece

facing up, unscrew the screws holding the upstream crosspiece and remove the crosspiece.

Remove the rotor and the center part of the cartridge. Once all other components are removed,

turn the meter body over, remove the screws and the downstream crosspiece.

For CUS bearing design, place the entire turbine assembly in a vertical position with the

downstream face up, remove the brake pin and axle nut. Remove the center pieces. Unscrew the

screws holding the downstream crosspiece and remove the crosspiece. Remove the rotor and the

center part of the cartridge. Turn the turbine over before disassembling the upstream crosspiece.

Inlet Ring

Screws

Cartridge

Screws

Upstream Crosspiece

Rotor

Cartridge center part

Downstream Crosspiece

Downstream Crosspiece

Shaft

Page 23 / 37

1

Flanged body

Retaining ring

2

Measurement cartridge

4

Boss

2.1

Rotor

5

Enclosure adapter

2.2 Shaft 6 Enclosure

2.

Upstream crosspiece

7

Enclosure cover

2.4

Central section

8

Coil

2.5

Downstream crosspiece

9

Preamplifier or Terminal

2.6 Elastic ring

2.7

Fixed bearing

2.8

Adjustable bearing

2.9

Bearing shaft

Page 22 / 37

Figure 27. Nominal Size CUS ≤ 3''

1

Flanged body

4

Boss

2

Measurement cartridge

5

Enclosure adapter

2.1 Rotor 6 Enclosure

2.2

Shaft

7

Enclosure cover

2.

Upstream

crosspiece

8

Coil

2.4

Central section

9

Preamplifier or Terminal

2.5

Downstream crosspiece

2.7

Bearing

2.10

Upstream thrust

2.11

Downstream thrust

2.12

Tightening set

Figure 28. Nominal Size STD 4''-14''

Page 19 / 37

Figure 22. CUS Cartridge removal

Chapter 9: Equipment removal

The equipment is designed to operate under pressure and must be depressurized and drained

before removal (complete disassembly or removal of a component under pressure).

If the bolts must be loosened to drain liquid into a recovery tank, make sure the line is completely

depressurized prior to loosening bolts.

Axial nut &

Centering pieces

Rotor

Upstream Crosspiece

Cartridge center part

Page 20 / 37

Appendix 1 – Alternative configurations

Figure 23. TZN with local totalizer

Figure 24. TZN with thermal extensions

Figure 25. TZN with 3 pulse outputs

Page 21 / 37

Appendix 2 – Meter drawings y size and type

Figure 26. Nominal Size STD ≤ 3''

1

Flanged body

Retaining ring

2

Measurement cartridge

4

Boss

2.1

Rotor

5

Enclosure adapter

2.2

Shaft

6

Enclosure

2.

Upstream crosspiece

7

Enclosure cover

2.4

Central section

8

Coil

2.5

Downstream crosspiece

9

Preamplifier or Terminal

2.6

Elastic ring

2.7

Fixed bearing

2.9 Bearing shaft

Table of contents

Other FAURE HERMAN Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics 482C27 General operations manual

Balluff

Balluff BNI IOL-802-000-Z036 user guide

Endress+Hauser

Endress+Hauser Tank Side Monitor NRF590 technical information

Long-run

Long-run LRF-3000S user manual

Impact Subsea

Impact Subsea ISFMD Installation & operation manual

Delta

Delta DVP08NTC-S instruction sheet