FAURE HERMAN Ultraflux Minisonic II User manual

Instruction manual

Minisonic II

A trademark of

Ultraux

Ultrasonic flowmeters

Introduction

2 3

Contents

Introduction 2

Contents 3

Safety instructions 4

General characteristics 5

Wiring the Minisonic 8

Minisonic conguration 14

Installation and commissioning 28

Application example 34

Software update procedure 36

Logger / Retrieving recordings 38

Measuring signal gain adjustment mode 39

Thank you for choosing the Minisonic: we hope you will appreciate all its metro-logical

qualities

and ease of use.

The purpose of this manual is to guide you as simply as possible towards using the

instrument

condently to achieve results that match your expectations.

Specializing in ultrasonic ow meters since 1974, Ultraux develops, manufactures and

sells

solutions based on the principle of differential ultrasonic transit times.

This method provides non-intrusive, constant and bi-directional ow measurements.

Ultraux ow meters allow non-intrusive or intrusive, constant or occasional ow

measurements

on any type of homogeneous uid (liquid or gas) and through any type of homogeneous

material.

Always aiming to better serve its customers’ needs while preserving the environment,

Ultraux

has been committed for many years to a quality improvement and sustainable

development

policy.

Since it started in 1974, Ultraux has developed and manufactured all its products in France,

in

order to ensure that its production processes are reliable and meet the standard required.

ISO Certications

Ultraux is certied ISO 9001 and ISO 14001.

You can download the certicates : ISO9001– ISO14001

http://www.ultraux.net/downloads

Electrical Certications

Minisonic complies with the Low Voltage Directive (DBT) according to EN 61010-1

ATEX Certications

Some Ultraux products are also certied for use in ATEX hazardous areas.

General characteristics

Ultrasonic ow measurement by transit time measurement.

2 measuring cords (i.e. 4 probes)

Power supply: continuous 12-24Vdc or 110-220 Vac - Consumption: 7W typical, 15W peak.

Protection class: IP67 closed case

Dimensions / Weight

Width: 216mm / Height: 268mm / Depth (thickness): 90mm

Weight: 3.6 kg (with wall mounting plate)

Mechanics / Ergonomics

• Aluminum housing

• Wall mounting: special sheet metal rear panel + hole for locking screw accessible at the bottom of

the meter

• Monochrome graphic OLED display 128x64 pixels

• Lexan keyboard with 7 keys

• Blue LED: ultrasonic operation

• RGB LED for diagnostics (operation to be described according to the errors to be reported to the

user)

Cable glands

3x M20 type cable gland

Note: The M20 cable gland must be able to accommodate a reducer for the connection of two Pt100.

1x dedicated to the power supply

2x dedicated to In / Outputs and optional (module IN et module COM).

1x specically assigned to the ethernet cable

2x M25 type double cable gland : dedicated to probes connection (1x double cable gland per cord)

Integrated wiring compartment / integrated connection

Basic functions

Power supply : 3,5mm 3 ways connector (base plate with pluggable screw terminal block)

USB : vertical USB type A socket

Ethernet : horizontal RJ45 socket

In/Output (4/20mA and 2 ways Digital output) :

Connectors with 3.5mm pitch (base plates with spring-cage (pluggable) terminal blocks)

Probe connection: on stepped connector (socket strips with pluggable screw terminal blocks)

Optional function / Modules

Module « IN » : 4/20mA Input or Double Pt100 (2 or 3 wires)

Module « COM » : RS485 or RS232 with automatic detection by the device

Connectors with 3.5mm pitch (base plates with spring-cage (pluggable) terminal blocks)

Electrical characteristics Inputs / Outputs

Digital output: Maximum output voltage of 500V between contact and its ground

Current 1 mA at a frequency of 10 kHz

Modules In:

Galvanic insulation between modules: 500V

54

Safety instructions

Using the device

The device, equipped with ultrasonic probes, enables the ow measurement of a uid (gas or liquid) in a pipe.

It is important to set up the device correctly so that the measurement results are correct.

Your local Ultraux qualied contact is always available to assist with technical advice and on-site

assistance. This is strongly recommended if your equipment is used to control a process, to intervene in

a monitoring system, or in the case of other applications where incorrect ow measurement would entail risks.

Always ensure your Ultraux device is stored and operated according to the information in the technical

specication

The modication or disassembly of the unit must only be carried out by Ultraux personnel.

Always ensure the supply power is isolated before making connections to the equipment

Ultraux declines all responsibility for any incidents that may occur as a result of failure to observe these

instructions.

Equipments connected to the device

All equipment connected to the device must comply with the relevant safety standard and have SELV circuits.

(double insulation between primary and secondary)

Caution: The supply voltage of the measuring probes is high (may exceed 200V).

Maintenance work on the device

Maintenance of the device must only be carried out by Ultraux trained personnel and using only parts

supplied by Ultraux.

Temperature limits for Minisonic electronics

Use from -10°C to +40°C

Storage from -35°C to +60°C

Recycling the device

In accordance with decree no. 2005-829 of 20 July 2005 and decree no. 2009-1139 of 22 September

2009 concerning the obligations to collect, treat and dispose of electrical and electronic equipment,

batteries and accumulators in France, Ultraux delegates responsibility for the nancial and logistical

recovery to users who will manage their waste themselves. Separate collection and recycling of your

waste at the moment of disposal will help preserve natural resources and guarantee recycling

respectful of the environment and human health. For more information on the recycling centre nearest

to your site, contact your City Hall or waste disposal department.

CE marking

Ultraux Minisonic owmeters comply with CE certications.

Contact address

For any request for information, do not hesitate to contact us:

Postal address

Bâtiment Texas

9Allée Rosa Luxemburg

ÉragnyParc – Parc desBellevues

95610Éragny surOise

Delivery address

Bâtiment Texas

9Allée Rosa Luxemburg

ÉragnyParc – Parc desBellevues

95610Éragny surOise

After-sales

sav@ultraux.fr

+33(0)1 30 27 29 30

Email address contact@ultraux.fr

EN 55016-2-1 Conducted emissions measurements - criterion A

EN 55016-2-3 Radiated emissions measurements from 30MHz to 6GHz

EN 61000-4-6 Immunity to induced conducted disturbances - Criterion B

EN 61000-4-2 Immunity to electrostatic discharges - Criterion B

EN 61000-4-3 Immunity to radiated electromagnetic elds - Criterion A

EN 61000-4-4 Electrical Fast Transient / Burst Immunity - Criterion B

EN 610004-5 Surge immunity - Criterion B

IEC 60529 Degree of protection provided by the envelopes (IP)

76

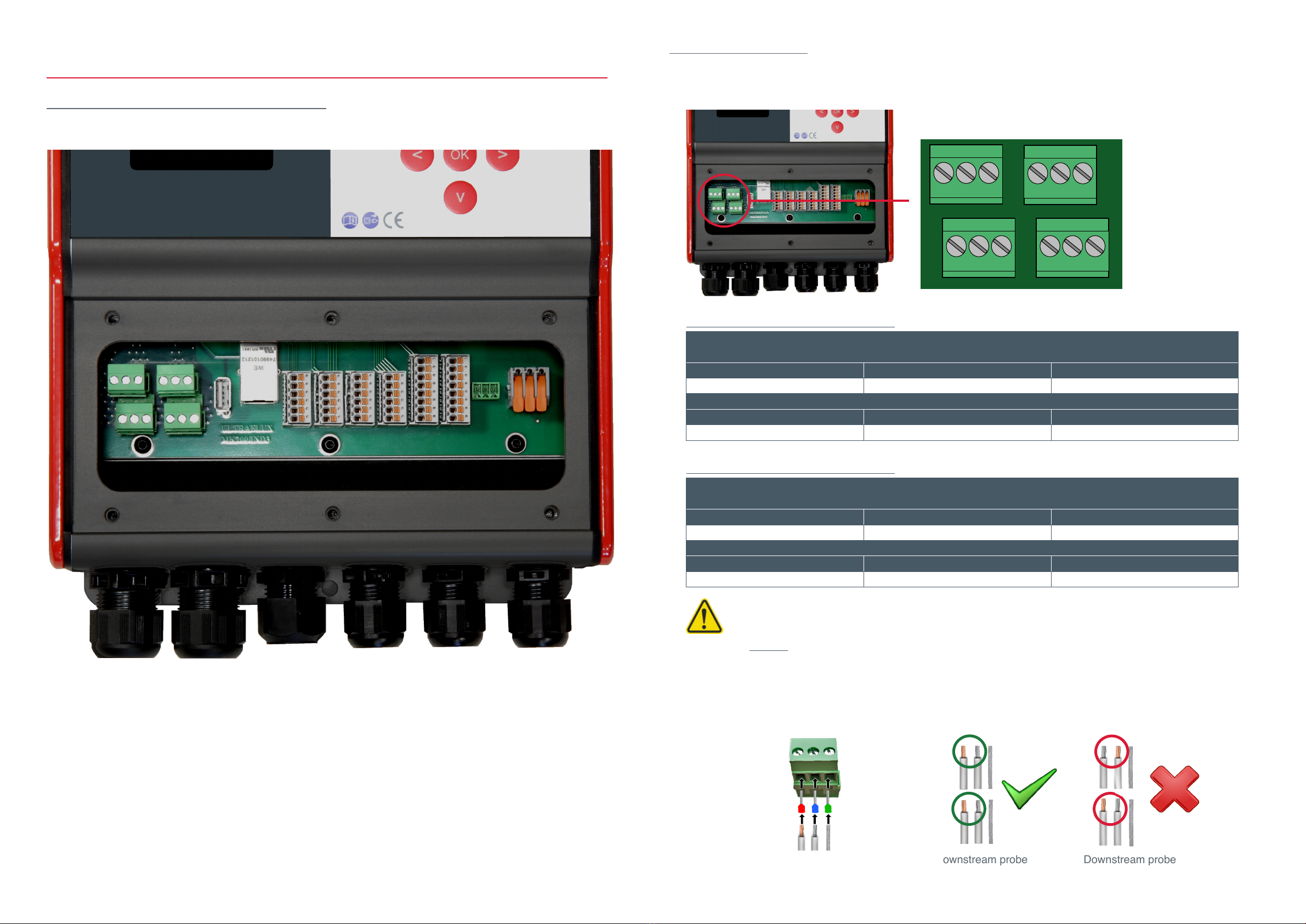

Probes connection

Connection of cord no. 1 (pair of sensors no. 1) and cord no. 2 (pair of sensors no. 2)

Note:

There is no + or - plug for connecting the sensors.

The choice of wire (silver or gold) for the upstream sensor must be the same for the downstream sensor

Example:

If the "gold" wire of the upstream sensor is connected to "upstream sensor +", then the "gold" wire of the

downstream sensor must be connected to "downstream sensor +" Caution: The supply voltage of the measuring

probes is high (may exceed 200V): Use electrical terminals

Upstream probe Upstream probe

Downstream probe Downstream probe

Fitting of electrical terminals recommended

Cord 1

Probe 1 / Upstream probe

PIN 1 PIN 2 PIN 3

Upstream probe + Upstream probe - Upstream probe ground

Probe 2 / Downstream probe

PIN 4 PIN 5 PIN 6

Downstream probe + Downstream probe - Downstream probe ground

Cord 2

Probe 1 / Upstream probe

PIN 1 PIN 2 PIN 3

Upstream probe + Upstream probe - Upstream probe

Probe 2 /Downstream probe

PIN 4 PIN 5 PIN 6

Downstream probe + Downstream probe - Downstream probe ground

Cord n° 1 - Pair of sensors n°1

Cord n° 2 - Pair of sensors n°2

Minisonic

Cord n° 1Cord n° 2

Probe 1

Probe 2Probe 4

Probe 3

123123

4 5 64 5 6

98

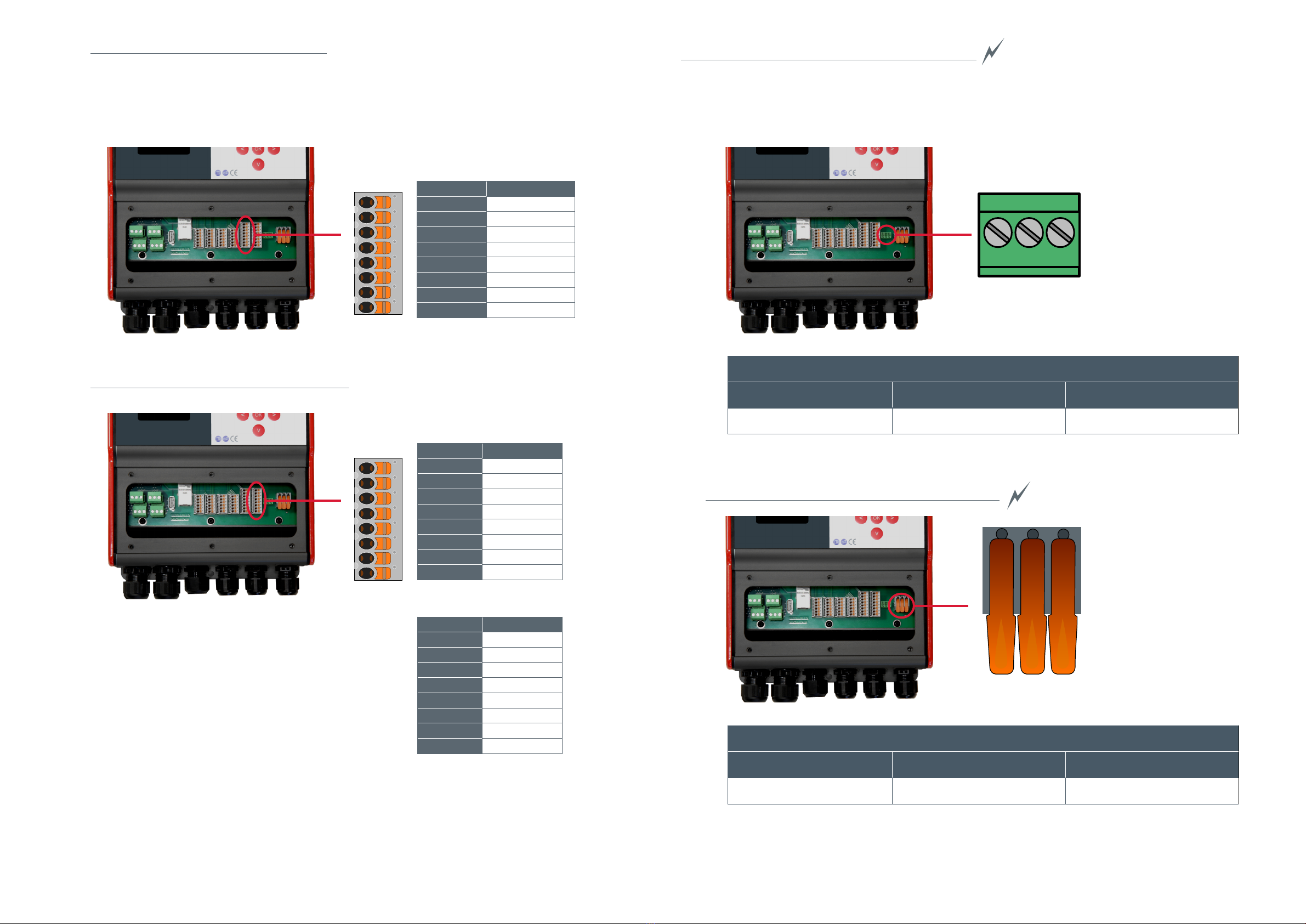

Wiring of the Minisonic

Overview of the connection compartment

Minisonic

Analogic 4-20 mA output

Connexion option

Digital output connection

Minisonic

PIN Function

1Contact 1 - A

2Contact 1 - B

3Contact 2 - A

4Contact 2 - B

5Contact 3 - A

6Contact 3 - B

Minisonic

PIN Function

124V

2S4-20 +

3S4-20 - (Ground)

4S4-20- (Ground)

5

6

Minisonic

PIN Function

1

2

3

4

5

6

1110

Minisonic

Minisonic

Minisonic

PIN Function

1RS485 A

2RS485 B

3Ground

4Ground

5RS232 TX

6RS 232 RX

Ethernet connection

USB socket

RJ 45 Ethernet socket

Through supplied specic cable gland

Connection of the serial link 232 - 485

1

2

4-20 mA active output

2

4

3

4-20 mA passive output

Powered by the loop

Or

USB Connection

Vertical USB type A socket for software update and logger download

DC Power supply connection DC 12-24 Vdc

AC Power supply connection 110 - 220 Vac

Minisonic

Minisonic

1 2 3

Power supply DC 12-24 Vdc

PIN 1 PIN 2 PIN 3

Ground 12-24 Vdc -12-24 Vdc +

Power supply alternating current 110 - 220 VAC

PIN 1 PIN 2 PIN 3

Ground Neutral Phase

123

1312

Minisonic

Current / Voltage input connection

Minisonic

Pt 100/1000 Temp. Probes connection

PIN Fonction

124V (IN1)

2IN1 +

3IN1 - (masse)

424V (IN2)

5IN2 +

6IN2 - (masse)

7IN V1

8IN V2

PIN Fonction

1Pt1 white

2

3Pt1 red

4Pt1 red

5Pt2 white

6

7Pt2 red

8Pt2 red

Connection 3 wires probe

PIN Fonction

1Pt1 white

2Pt1 red

3Pt2 white

4Pt2 red

5Pt3 white

6Pt3 red

7Pt4 white

8Pt4 red

Connection 2 wires probe

Minisonic conguration

The Minisonic is equipped with a screen and a keypad for conguration and viewing measurements directly.

Keypad

The keypad has seven keys which have different uses in different menus. However, navigation

between the elds and menus is always based on the same principles:

The menusdetailed in this manualcorrespond to the

Normal

modeof the setup level menu.

Switches between the measurementviewing

screens and the mainconfiguration menu

Takesyou back to the previous screen.

Changes measuringscreen, moves within the

menusor changes parameter values.

Goes into the menusin reverse video and is used

to validate the parametersselected.

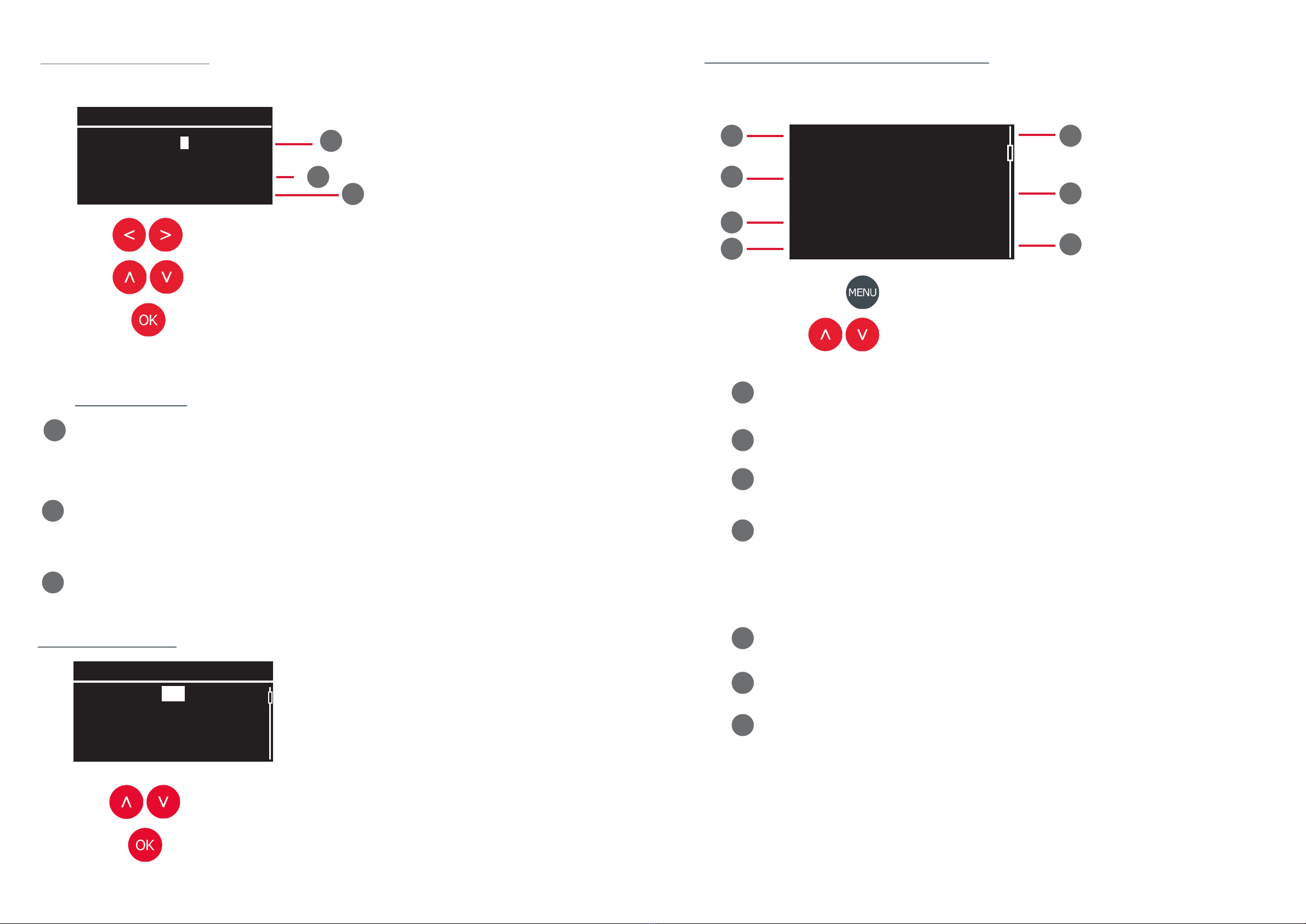

Description of navigation

1514

LED Display

Flash indicating the emission of ultrasonic waves

Flash indicating measurement status

If on at least one pipe all chords are working: green ash

If at least one chord does not work, or if there is an error on the input/output: orange ash.

If at least one line does not have a measurement: red ash

1Fields currently being edited

Allows the eld being edited. Select a character using the multi-directional keys

and then select a character from the keypad to replace it.

2Select the characters to be placed in the eld by pressing "OK".

3"Delete" key : This key is used to delete the characters in the eld being edited.

"CapsLock" key switches from the keyboard with upper case keys to the keyboard with lower case keys.

"OK" key validates the eld and exits the screen.

2

13

4

5

Types of screen

The Minisonic Fixed is based on several types of screens which are found throughout the

navigation and work in the same way.

0 12 34 5 6 78 9 _ -

A B C D E F G H I J K L

M N O P Q R S T U V W X

YZ . ,

<-

Example 1.

cl

ok

These screens are used to edit all the alphanumeric elds of the device, such as driving name, conguration

names etc...

Figure 14 - Alphanumeric eld edit screen

<-

Example 1.

cl

ok

0 12 3 4 5 6 7 8 9 _ -

A B C D E F G H I J K L

M N O P Q R S T U V W X

Y Z .,

Screen for editing alphanumeric elds:

4

5

l/h

Display unit

l/d

m3/s

m3/h

l/h

List selection screen

Choice among the proposed list

Validates the modication and returns to the previous level

1716

Numeric eld edit screen

This type of screen allows entry all the numerical parameters in the device.

Currently edited eld :

The number being edited appears in black on a white background. The value of the eld is changed

using the up and down keys. Move from left to right using the direction keys to change the

number being edited.

Minimum eld value :

This number indicates the minimum value that can be set.

Maximum value of the eld :

This number indicates the maximum value that can be set.

Moving from digit to digit

Increases or decreases the value of the selected digit.

Validates the modication and returns to the previous level

Ext. Diameter

00022,20 mm

Min : 6,00 mm

Max : 10000,00mm 2

1

3

3

2

1

Presentation of the measurement screens

Main measurement variable

Example: Volume ow / Speed ...

Value of the main measurement unit

Designation of the secondary measurement variable

Example: Totalizer / speed / velocity / velocity / gain ...

Quality index

Indicates the percentage signal strength

This factor makes it possible to evaluate the difculty of measurement, for example it is lower

in the presence of loaded or aerated water. The higher the index, the simpler the

measurement is for the device to carry out.

Value of the secondary measurement variable

Physical unit of the main measurement variable

Physical unit of the secondary measurement variable

Access to menus

Views of the various measurement screens

Flowrate IQ100%

20,000m³/h

Totalizer

000000000026 m³

1

2

3

4

7

6

5

4

1

2

3

5

6

7

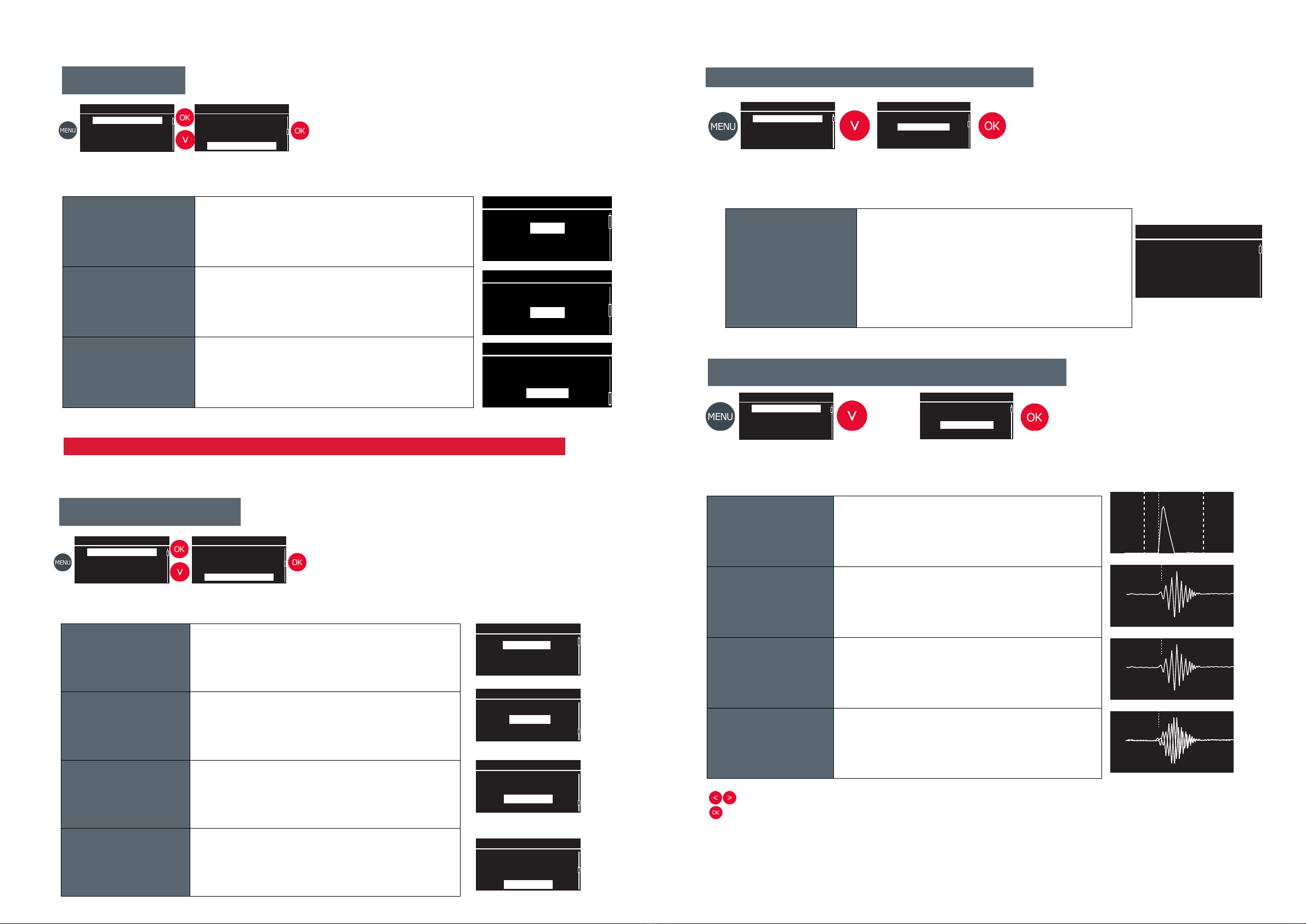

Parameter setting of the characteristics of line A and line B if multi-line.

Ext. Diameter

00048,30 mm

Min : 10,00 mm

Max : 10000,00mm

Ext. circumference

00069,12 mm

Min : 18,85 mm

Max : 31415,93mm

Thickness 1

003,20 mm

Min : 00,00 mm

Max : 500,00 mm

Material 1

PRV

PVC

PVC HP (rigid PVC)

PTFE

Roughness (RZ)

000,20 mm

Min : 00,00 mm

Max : 99,00 mm

l/h

Displayed unit

l/j

m3/s

m3/h

l/h

Pipe

Fluid

Water (Sea)

Water 05°C

Water 10 °C

Water 20°C

Setting the characteristics of the measured uid

Fluid

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Ext. diameter Adjustment of the outer diameter of the pipe.

Ext. circumference The outer circumference can be adjusted if the diameter is not measured.

Thickness Pipe thickness adjustment

In case of mufti-layer piping: 3 thicknesses can be set in the EXPERT setting mode

Material

Choice of driving material from a list.

In the case of multi-layer piping: possibility of setting 3 materials in EXPERT setting

mode

Roughness Specic roughness the inner wall of the pipe

Displayed unit Choice of volume ow unit

Determines the physical unit associated with the volume ow rate display.

Example: m3 /h - l/min...

Note: The choice of uid will be differentiated between Pipe A and Pipe B if Multi-pipe.

Fluid Choice of the uid to be measured from a list

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Ext. Diameter

73.00 mm

1918

Pipe - A

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Fluid

Acetone

Fluid - A

Note: The setting sub-menu for line A is the same for line B if the multi-line option is selected.

Menu

Measurement config.

Probe Distance

US Signal display

Auto zero

Conguration menus

Choice of chapter

Conrms the entry in the chapter in "inverse video" display.

Back to the previous chapter

Back to the measurement screen

Measurement conguration

Conguration of the set of characteristics of a measuring point.

In this menu, you will set up the device to operate on a specic application: Pipe characteristics / Fluid

characteristics / Characteristics of the used probes

Probe distance States the distance to be set between the sensors according to the data set in "Measurement

Conguration"

US signal display

Displays the nature and quality of the measurement echo. It is a key factor in the analysis of

the measurement conditions and can help you to identify any conguration error (diameter - thickness of

the pipe ...).

Auto-Zero

Gives you the possibility to rene the response of the unit under the strict conditions of "Full pipe + Flow

at standstill".

This operation is essential to obtain optimal uncertainty

Advanced meas. Gives you access to additional diagnostic information

System Conguration Setting the language information / Date Time / Custom features

Setting of the probes used with the device

Pairs of probes

Note :

The parameter setting of the probes is the same for probe pair 1 and probe pair 2 in the case of

multi-cords.

If the "number of pipes" is set to "2", each pipe has only one sensor pair. If only one line is

congured, it has the option of using 2 pairs of sensors.

Filtering - A

Memory

5 s

Filtering - A

Flowrate cut off

100,000 l/s

Measurement ltering settings

Damping

Damping time of the measurement.

Setting to be made in the sub-menu for editing a numeric eld (Unit in

seconds)

Memory

Maintain measurement in case of signal loss.

Setting to be made in the sub-menu for editing a numeric eld (Unit in

seconds)

Flowrate cut off

Flow threshold below which the measurement is forced to zero.

(Display and outputs)

Setting to be made in the editing sub-menu of a numeric eld

(Threshold value and unit).

Setting the totalizer

Activate

Yes

Totalizer - A

Mode

+

Totalizer - A

Weight

1 m³

Totalizer - A

Reset Totalizer

No

Totalizer - A

Activate Activates the totalizer of line A

Mode Mode selection: "Forward ow + " " Reverse ow - " " Net +/- " ".

Weight Adjusting the totalizer increment weight

Reset Totalizer Zeroing the totalizer

Entrées / Sorties

Enregistreur

Mode basse conso.

2120

Entrées / Sorties

Enregistreur

Mode basse conso.

Setting the number of pipes

Conguration Mesure / Paramétrage mesure/ Nombre de conduites

Numbers of pipes

The Minisonic is a owmeter that can manage ow measurement on 2 different

pipes.

Minisonic has the capacity to drive 2 pairs of probes:

• 2 different pipes with 1x pair of sensors each

• 1 Pipe with the possibility of using 2 pairs of sensors on it

Number of pipes

2

Min: 1

Max: 2

QT Setting

Conguration Mesure / Paramétrage mesure/ QT

QT

• QT is the mathematical operation carried out with the 2 possible

measurements on the Minisonic:

Either an addition of the 2 measurements / A difference ....

• The unit of display of this total ow rate is congurable.

• In the event of a measurement failure, it is possible to signal a loss of signal

either with only one channel faulty or with both channels faulty

simultaneously.

Note: The setting sub-menu for line A is the same for line B if the multi-line option is selected.

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe

Pipe - A

Fluid

Pairs of probes

Filtering

Probes

SE 1790

Pair of probes

Filtering

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Damping

0 s

Filtering - A

Filtering - A

Damping

5 s

Totalizer

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe - A

Fluid

Pairs of probes

Filtering

Totalizer

Activate

No

Totalizer - A

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Measurement settings

Pipe - A

Pipe - B

Number of pipes

QT

Number of pipes

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Measurement settings

Pipe - A

Pipe - B

Number of pipes

QT

QT

Pipe A

+

QT

Pipe B

+

QT

Dispalyed unit

m³/h

Faults

All Q fault

QT

QT

Pair of probes

SE 1662-10

SE 1515

SE 1815

SE 1790

Ultrasonic path

Direct (/)

1 reection (V)

2 reections(N)

3 reections(W)

Delta T Zéro

+00,50 ns

Min : -300,00ns

Max : 300,00ns

Probes Choice of probe model from a scrolling list

Mounting type Choice of probe mounting type

ZERO Difference in transit time of the sound wave at zero ow.

Value set automatically after "Auto Zero".

Gain mode See appendix / Description of the gain adjustment on page 30

Time offset

Pair of probes

Gain mode

ESC

Pair of probes

Time offset

0,00 µs

2322

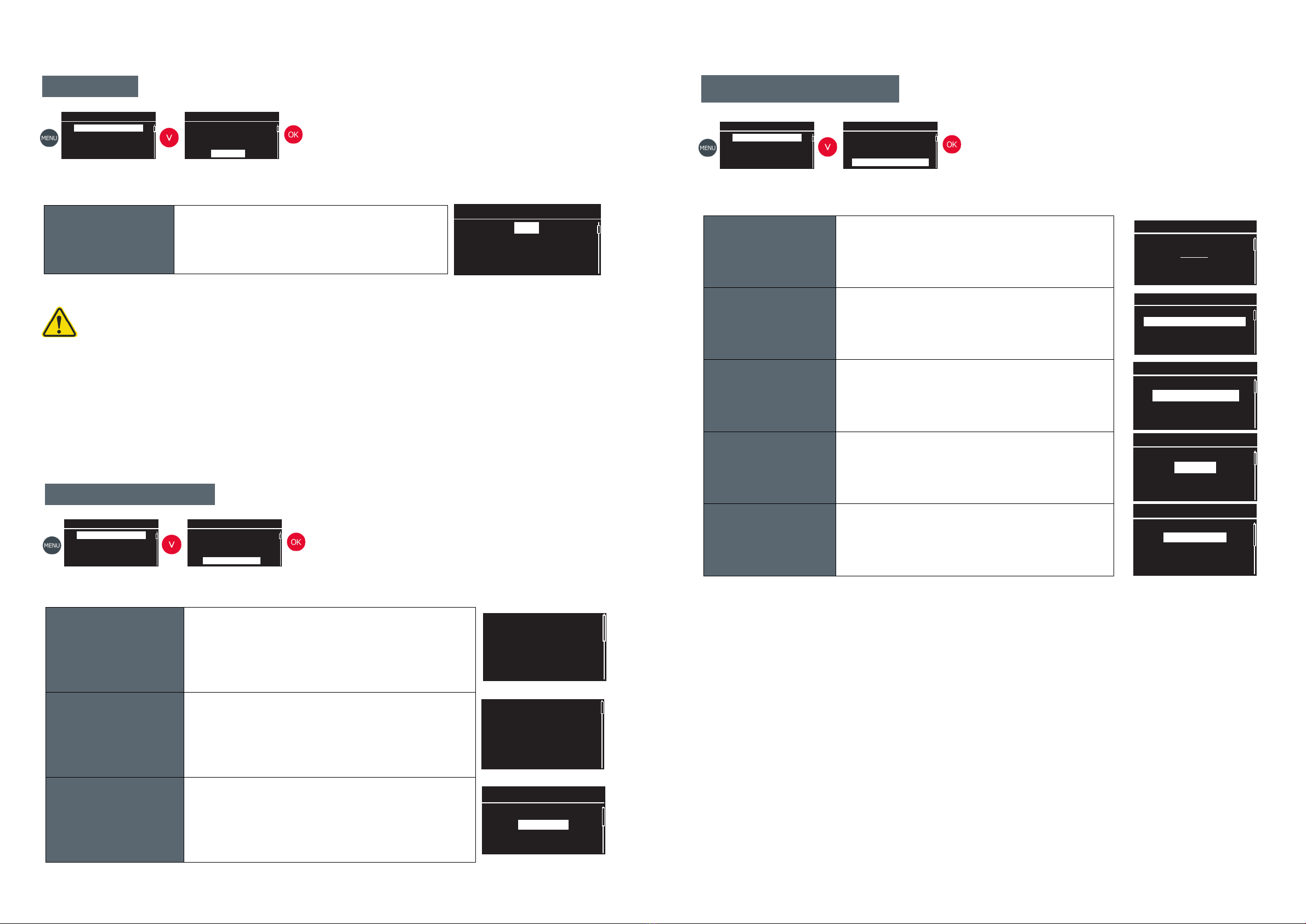

Setting Inputs / outputs

Current ouput 1

Contact output 1

Function selection: Counting / Alarm / Test On / Off

Counting :

Choice of ow variable (A / B / A+B pipe)

Counting direction (Direct + / Reverse - / Net )

Pulse length

Pulse weight (value and unit)

Alarm :

Choice of the variable linked to the alarm

Contact output 2

Function selection: Counting / Alarm / Test On / Off

Counting :

Choice of ow variable (A / B / A+B pipe)

Counting direction (Direct + / Reverse - / Net )

Pulse length

Pulse weight (value and unit)

Alarm :

Choice of the variable linked to the alarm

PT100 input (1-2-3-4)

Setting the characteristics of the Pt 100 input

• Number of wires

• Setting the temperature oset

Tests Test mode of the analogue and contact outputs

Caution: in test mode, the output values will be changed.

Conguration of the internal recorder

Logger

File name

Test

File name Dene the name of the recording le associated with the measurement

point.

Number of data Setting the number of variables to be recorded

Period Choose a sampling period from a scrolling list

Data 1..2..3..

Dene the nature of each variables

Pipe: Physical quantities (Flow, Speed, Speed...)

General: Device status, battery charge status

Type

Choose the type of value applied to all data

• Average

• Average + Min + Max

• Average + Min + Max + Standard deviation

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Logger

Settings

File management

Logger

Logger

Number of data

3

Logger

Period

10 s

Logger

Data 1

Pipe - A

Flow

Logger

Type

AVG, Min, Max

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Inputs / Outputs

Current output 1

Contact output 1

Contact output 2

PT100 input 1

Inputs / Outputs

Inputs / Outputs

Inputs / Outputs

Inputs / Outputs

Inputs / Outputs

Inputs / Outputs

PT100 input 2

PT100 input 3

PT100 input 4

Tests

Current output 1

Contact output 1

Contact output 2

PT100 input 1

Current output 1

Contact output 1

Contact output 2

PT100 input 1

Current output 1

Contact output 1

Contact output 2

PT100 input 1

Current output 1

Contact output 1

Contact output 2

PT100 input 1

Adjustment of the characteristics of the 4-20 mA analogue output

Activation / deactivation /

• Selection of the variable to be assigned to this output

• Flow rate corresponding to 4 mA

• Flow rate corresponding to 20 mA

• Flow rate unit

• Default value in case of fault (in mA)

Display of the probe spacing distance

Measurement cong. / Probe distance

Probe distance

Pair of probe 1 - A

54.4 mm

Pair of probe 1 - B

48.6 mm

Menu

Measurement config.

Probe distance

US Signaldisplay

Auto Zero

Menu

Measurement config.

Probe distance

US Signaldisplay

Auto Zero

Probe distance

Displays the distance between the sensors.

This distance is calculated by the device according to the congured

parameters:

• Diameter / thickness / pipe material

• Type of uid

• Type of probes

The example on the right shows the distance to apply between the

probes of the Pipe A and Pipe B

Visualisation of measurement echoes

Measurement cong. / US signal display

79.7µs

13 dB

13dB AB

0.5 ns

13dB BA

0.5 ns

13dB ABBA

79.3 ns

Allows the viewing window to be moved for signal assessment

Allows the display to be centred on the measuring point.

Large view Wide visualisation of the quality of the measurement signal according

to the programmed parameters and measurement conditions

Echo from A to B

Visualisation of the ultrasonic echo emitted from probe A and

received on probe B

Echo from B to A

Visualisation of the ultrasonic echo emitted from probe B and

received on probe A

Phase shift AB-BA Visualisation of the 2 echoes and the difference in transit time of the

ultrasonic wave between the AB and BA paths

2524

Settings level

Simple

Normal

Advanced

Simple

Normal

Advanced

The Minisonic has been designed to adapt to your level of knowledge of ultrasonic measurement.

The menus detailed in this manual correspond to the Normal mode of the setting level menu.

Settings level

Simple Contains the minimum parameters necessary to do ow measurement

with the minimum of parameters to be set

Normal Gives access to more features and settings to rene the measurement

Advanced Contains all the parameters available in the unit. Simple

Normal

Advanced

Reset cong.

Deletes the data in the current conguration and returns to the

default conguration.

A warning message will pop-up on the screen to ask for reset

conrmation

Save cong.

Saves the current conguration

Ask a name for this conguration so that you can use it again latter

Load cong. Uploads the parameter data of a saved conguration

Delete cong. Deletes selected or all conguration les

Conguration management

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Settings level

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Logger

Inputs / Outputs

Settings level

Cong. Management

Config. Management

Config Management

Reset config.

Save config.

Load config.

Delete config.

Config Management

Reset config.

Save config.

Load config.

Delete config.

Config Management

Reset config.

Save config.

Load config.

Delete config.

Config Management

Reset config.

Save config.

Load config.

Delete config.

Settings level

Settings level

Menu

Measurement config.

Probe distance

US signal display

Auto Zero

Menu

Measurement config.

Probe distance

US signal display

Auto Zero

(....)

Setting the device system data

System conguration

Main

Langue

English

Custom data

Custom probes

Custom uids

Custom materials

Communications

Serial conguration

IP network

Informations

Firmware

Hardware

Serial number

Date and Time

Date format

Date

Time

Main

Denition of :

• Display and programming language

• Distance units mm or inches

Custom data

The Minisonic allows the customised setting of:

• Probes

• Fluids

• Pipe materials

Communication • Serial communication setting

• IP Setting

Information

Display of:

• Software version (Firmware)

• Electronic board version (Hardware)

• Serial number of the device

Date et heure

Adjustment and adjustment of:

• Format DD/MM/YY ...

• Date

• Time

2726

Minisonic zero ow adjustment

Auto Zero

30s

Auto Zéro

Caution, this operation can only be carried out under the strict conditions of:

• Full pipework

• Zero ow

This operation is essential in order to obtain optimal accuracy. The actual stabilisation of the uid ow

at zero ow can take + or - time. This stabilisation depends on the diameter of the pipe and the type of

shut-off devices. Make sure that the ow is actually mechanically shut off (valve....).

Auto Zero Determines the duration of zero point adjustment.

Visualisation of diagnostic variables and failures

Advanced meas.

4 Faults

Flowrate - A

Velocity - A

Flowrate - B

Velocity - B

Pipe -A

Flowrate 124.30

m³/h

Velocity 1.25 m/s

S. Of sound 1482 m/s

IQ 100 %

Faults Total list of faults found by the device.

Flowrates View of advanced variables allowing adjustment, reliability

or validation of measurement quality.

IP network Network

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Menu

Probe distance

US Signal display

Auto zero

Advanced meas.

IP network

IP network

Network faults

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Menu

US Signal display

Auto zero

Advanced meas.

System conguration

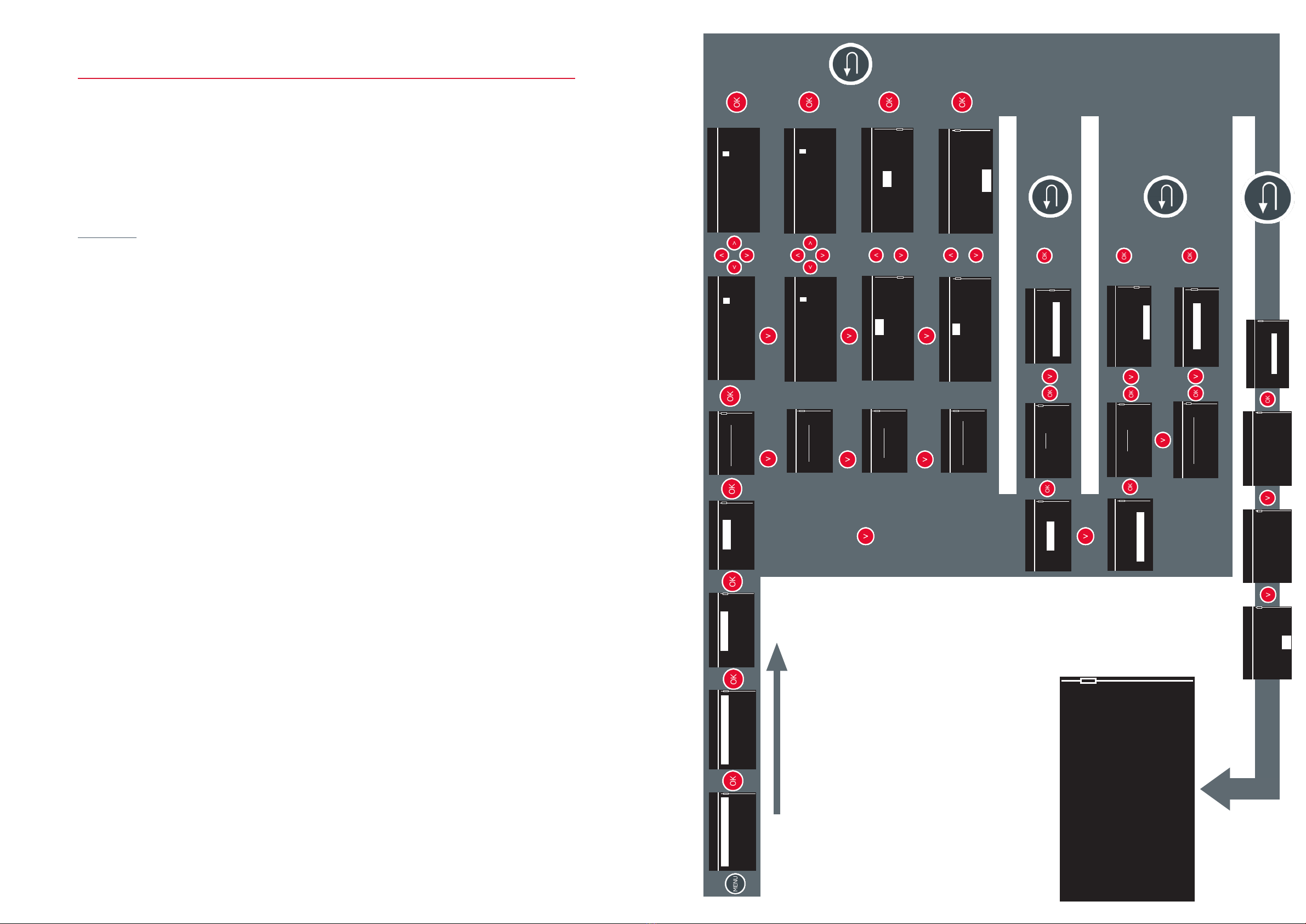

Installation and Commissioning

Setting up a measuring point

Your local Ultraux trained representative will be happy to provide advice on site selection and

provide other technical assistance installing the owmeter

In addition to the control unit, either or external or insertion probes will be requiered

External sensors

A pair of potted cable probes with the required cable length

Suitable mounting brackets and xing systems

Insertion probes

A pair of intrusive probes equipped with their mounting system (e.g. Valve / Boss...).

The required cable length between the sensors and the electronics.

Choosing a location for the probes

The following sets out the main precautions to be taken when choosing a location for the probes.

To achieve the most accurate measurement possible, it is necessary to have what is called ‘a developed

ow prole’. The aim is to obtain a hydraulic prole which is as predictable and symmetrical as possible.

Choosing the measurement mode

The external sensors can be installed in different ways, depending on the number of reections of the

ultrasonic wave on the pipe wall. There are four programmable types in the device:

Figure 12-Profil hydraulique asymétrique

2928

Figure 10a- Symmetrical hydraulic prole Figure 10b- Asymmetrical hydraulic prole

«Direct» or«/» «Reflex» or«V»

«N» «W»

The preferred mounting method is the V-shaped mounting, which is suitable in most cases.

The longer the distance, the better the measuring principle is exploited. (signicant difference in travel time

upstream and downstream).

However, the ultrasonic echo will be all the weaker and more distorted as the number of reections

increases and may be difcult to process. A compromise must therefore be found between precision and ease

of transmitting and receiving ultrasound. This compromise depends on the application (uid, wall quality, diameter,

etc...).

In practice, multiple reection modes are reserved for smooth pipes without fouling or corrosion.

Probe positioning

The measuring probes must be placed in such a way as to avoid areas at risk of air bubbles and sediment.

Measuring near an elbow

Reex mode V : Distance > (3x) pipe diameter

Direct mode / : Distance > (5x) pipe diameter

Reex mode V : Distance > (15x) pipe diameter

Direct mode / : Distance > (20x) pipe diameter

Reex mode V : Distance > (15x) pipe diameter

Direct mode / : Distance > (20x) pipe diameter

Reex mode V : Distance > (3x) pipe diameter

Direct mode / : Distance > (5x) pipe diameter

Reex mode V : Distance > (15x) pipe diameter

Direct mode / : Distance > (20x) pipe diameter

Respect for straight pipe lengths

We know the rules to be followed according to the layout of the pipes to obtain the ideal measuring

conditions. The following paragraphs provide information on the general rules to be observed.

For liquids, the following instructions show the minimum distances (L) before and after a

disturbance as a function of the inside diameter of the pipe (D) so that the errors induced by these

disturbances remain below ± 1 %.

Measuring close to a valve

Measuring close to a divergent

Measuring close to a convergent

Reex mode V : Distance > (15x) pipe diameter

Direct mode / : Distance > (20x) pipe diameter

Reex mode V : Distance > (5x) pipe diameter

Direct mode / : Distance > (8x) pipe diameter

Reex mode V : Distance > (30x) pipe diameter

Direct mode / : Distance > (40x) pipe diameter

Reex mode V : Distance > (3x) pipe diameter

Direct mode / : Distance > (5x) pipe diameter

Reex mode V : Distance > (10x) pipe diameter

Direct mode / : Distance > (15x) pipe diameter

Reex mode V : Distance > (3x) pipe diameter

Direct mode / : Distance > (5x) pipe diameter

3130

Recommended locations:

Pipework with ascending ow.

Choice of probe type

The choice of the sensor pair depends on the pipe diameter.

The frequency of the probe has an important effect on the quality of the measurement.

The Minisonic can be used with many probes that are suitable for different pipe diameter ranges.

The following table denes the average operating ranges of the probes according to their frequencies:

Note: The values given in the table correspond to the internal diameter of the pipe (or nominal).

Frequency Pipe diameter

2 MHz 10 - 400 mm

1 MHz 40 - 2 500 mm

500 kHz 100 - 10 000 mm

Installation of the Clamp-on probes

Installation of the elastomer strip

It can be used for any surface temperature between -30°C and +100°C.

Grease the line with grease where

the probes are located (Do not

use silicone grease).

Découper un morceau dʼélastomère

de la dimension de la sonde +5mm

Enlever le lm protecteur

Cut a piece of elastomer the size

of the probe +5mm.

Remove the protective lm

Apply grease to the outside of the

elastomer strip.

Place the sensor and its holder and secure them by tightening the stainless steel

clamps.

Place the clamping screws of the clamps preferably opposite the probes.

NB: The observation of the evolution of the gain (dB) measured by the owmeter can

allow to identify the degradation of the coupling and to foresee its replacement.

Pipe preparation

Installation of one of the probes

After determining where the sensors are to be

installed, clean the pipe surface by removing

dirt, rust and any roughness (paintwork is not

a problem if it is in good condition).

3332

Comments :

The values indicated must be multiplied by 2.5 for gases.

Convergent pipework with an overall angle of less than 16° are not taken into account and are considered as

straight lengths (this is not the case for divergent pipework).

Locations not suitable:

Vertical pipe with downow, especially in the case of free ow

Application example

Flow measurement with an ultrasonic owmeter requires the following information:

• Pipe characteristics (External diameter + Thickness + Material)

• Fluid characteristics

• Probes used (Model)

Application

• PVC pipe / Outer diameter 48.3mm / Thickness 3.2mm

• Fluid measured: Fresh water at 12°C.

• Probes used: SE 1790, V-mounting

Use the overview on the next page to congure the unit according to the data in the example.

34

(...)

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Ext. Diameter

73.00 mm

Pipe - A

Thickness 1

1.50 mm

(...)

Pipe - A

Material 1

PRV

Pipe - A

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Fluid

Acetone

(...)

(...)

Fluid - A

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Probes

SE 1815

Pair of probes 1 - A

Ultrasonic path

Direct (/)

Pair of probes 1 - A

Pair of probes 1 - A

SE 1662-10

SE 1515

SE 1815

SE 1790

Fluid

Water (Sea)

Water 05°C

Water 10 °C

Water 20°C

Ext. Diameter

00073,00 mm

Min : 10,00 mm

Max : 10000,00mm

Thickness 1

001,50 mm

Min : 00,00 mm

Max : 500,00 mm

Material 1

PRV

PVC

PVC HP (rigid PVC)

PTFE

l/h

Displayed unit

l/j

m3/s

m3/h

l/h

Ext. Diameter

00048,30 mm

Min : 10,00 mm

Max : 10000,00mm

Thickness 1

003,20 mm

Min : 00,00 mm

Max : 500,00 mm

Material 1

PRV

PVC

PVC HP (rigid PVC)

PTFE

l/h

Displayed unit

l/h

l/d

m3/s

m3/h

Ultrasonic path

Direct (/)

1 reflexion (V)

2 reflexions (N)

3 reflexions (W)

Displayed unit

l/h

Pipe - A

Setup validation

5 datas have been

modied :

Use modications

Discard modications

Probe distance

Pair of probe 1 - A

54.4 mm

Pair of probe 1 - B

48.6 mm

Probe distance

Validate this screen

only after having

Positioned the probes

Correctly so that the

Probe distance

Measurement starts

under good conditions

Thank you

OK

Flowrate IQ100%

20,000m³/h

Totalizer

000000000026 m³

Software update procedure

In order to reach the specic area for system modication and software update you must:

• Save the update le on the root of a USB key.

• If there are several update les, the unit will ask you to leave only one.

• Connect the USB key to the unit's USB port.

• Switch on the Minisonic with the USB cable and the key connected to the unit.

System Menu

Update

Informations

Battery

Battery indicator reinit.

ULTRAFLUX

MINISONIC

54R 3RO 2ROL

•During the ignition phase which lasts 3 seconds

Successively press and release then

• A countdown timer appears in the upper right-hand corner for 5 seconds.

• Enter the password before the countdown reaches 0 : ROL (Right-OK-Left)

• Extract - about 30s

• Programming - Up to 4 minutes

• Switch o the unit and wait 1 minute;;;;;;

• Switch the unit back on

•Attention, the device does not give any sign of life: this is normal.

•Wait about 5 minutes for the device to restart with the new version.

•In case of an error in entering the code, the unit will start normally.

• Switch it o and restart the procedure

• In the "System Menu" press OK to start the loading procedure.

ULTRAFLUX

MINISONIC

ULTRAFLUX

MINISONIC

ULTRAFLUX

MINISONIC

ULTRAFLUX

MINISONIC

Software update procedure / FAQ

If the device restarts immediately, what happens?

• Either the device was already in the right version

• Or the update only concerned spelling corrections in one or more languages.

After 10 minutes without any sign of life, the device does not restart, what can I do? ?

The recovery procedure must be carried out

Switch off the unit and wait 2 seconds

• Switch the unit back on, the device does not give any sign of life: this is normal.

• Wait 5 minutes for the device to restart :Either with the new version or Or with the internal

back-up version if the update has failed, in which case the complete update procedure must be

started again

3736

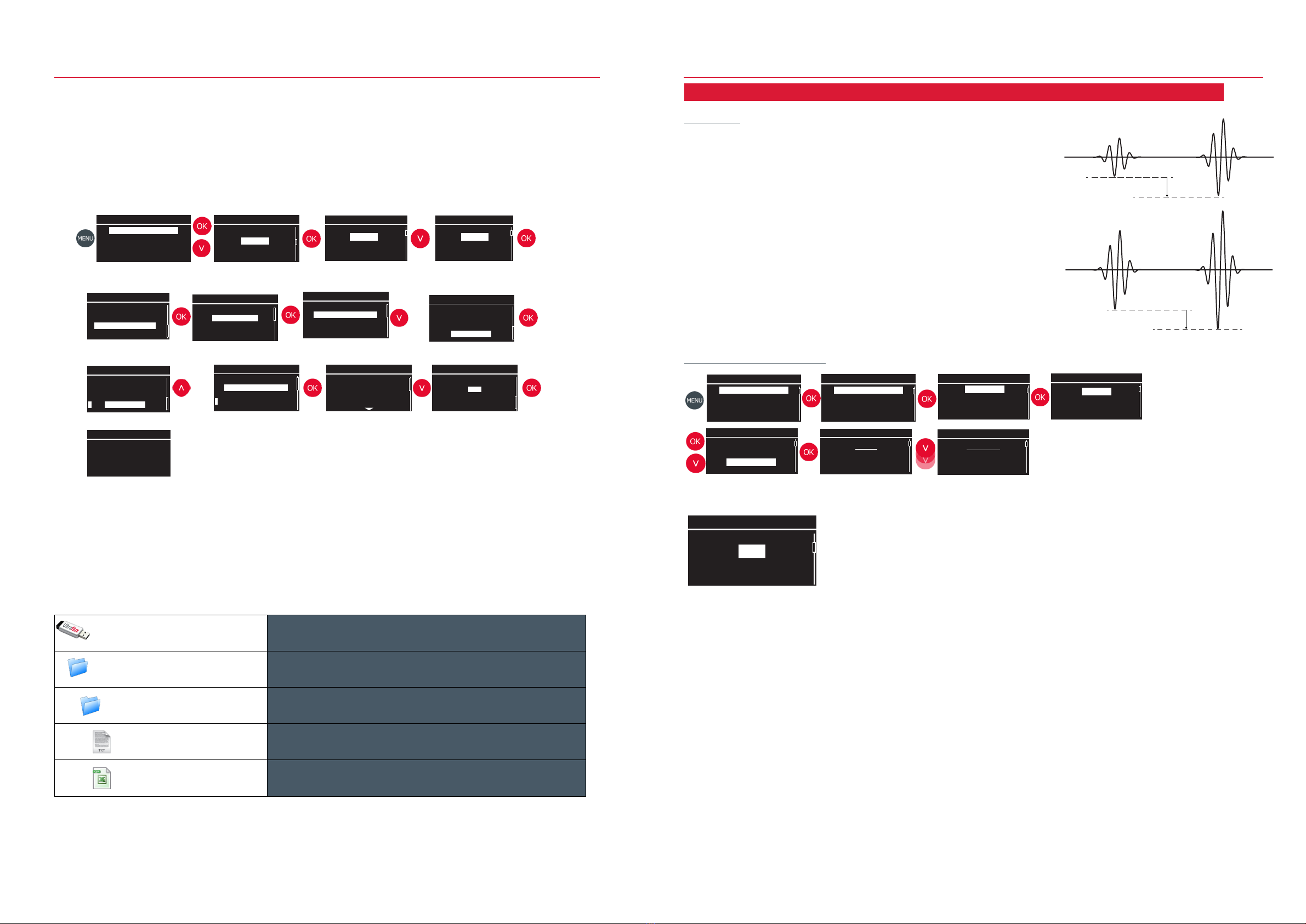

Logger

Settings

Files management

Export to USB

Export selection

Select all

Test rec # 1

File management

Export to USB

Delete files

Logger / Retrieving recordings

Export to USB

Export

Select all

Test rec # 1

Export to USB

Exporter la sélection

Sélectionner tout

Test rec # 1

• Connect the USB key to the unit's USB port.

• In the export to USB submenu, select and mark the le(s) to be exported.

• Export the selection.

When the export is complete, the structure appears as shown below:

The purpose of this procedure is to inform you:

• The path to the menu for retrieving the recording les

• The procedure for selecting the les to be recovered

• The effective recovery of the le(s) on the USB key

• Importing the registration le into Excel

(....)

USB key Physical media: USB key

Ultraflux_Minisonic SN00017 File indicating the serial number of the device (e.g. SN00017)

Logger_Example 1 File indicating the name of the registration (e.g. Example 1)

Example 1_2017.11.22_23h38_config.txt Text le containing the settings of the unit at the time of this recording.

Example 1_2017.11.22_23h38.ind001.log FSpreadsheet le containing logger record data

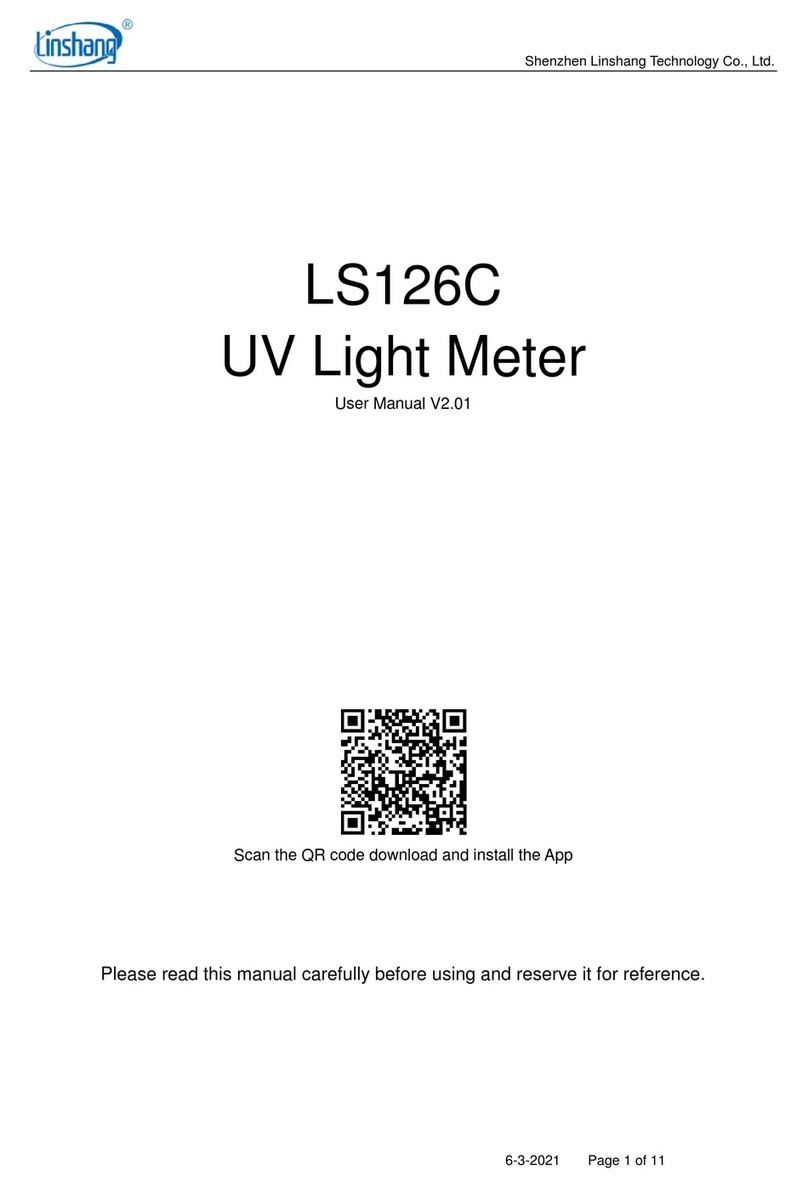

The information detailed in this chapter corresponds to the EXPERT mode of the menu setting level.

Measuring signal gain adjustment mode

The Minisonic can work on the positive or negative polarity of the

signal.

The Minisonic determines at each reception of the measurement

signal, the Gain to be applied so that the peak of this signal reaches

the detection threshold (example presented on a negative polarity).

To this Gain must be added an additional gain, called Margin,

allowing the peak of the signal to be well above the threshold.

The Minisonic offers several Gain and Margin adjustment modes

Gain

Seuil

Marge

Seuil

Gain mode

Path to gain type setting

ESC then Auto

Switching from ESC mode (see below) to perform the rst measurement and then

permanently to Automatic mode (see below) for the rest. This mode is to be recommended

for long term measurements on an installation without major changes in the application

conditions.

ESC (Echo Shape Control)

This mode selects the best Gain to be applied to the signal and the most appropriate

Margin.

This mode is to be recommended when using a portable owmeter that performs point

measurements on different applications.

This mode requires a few seconds of signal analysis before indicating the ow rate value.

In case of signal loss due to a disturbance in the measurement conditions ( passing of

bubbles...) the device starts a new ESC.

Automatic

In this mode, only the Gain is determined automatically, the Margin must be indicated

manually. If the Margin is set too high, the ow rate measurement may be performed on

a peak in the middle of the signal. However, the measurement is of better quality if it is

carried out on the rst alternation. This mode is to be recommended on an installation

without strong modications of the application conditions, for long term measurements.

Manual

The Gain and Margin values are determined by the user.

This mode is useful if signal disturbances make the gain too unstable for automatic search.

Foreword

3938

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Logger

Settings

File management

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Logger

Settings

File management

Question

Are you sure you want

To export data to

A USB key ?

Question

OK

Cancel

Export to USB

Export selection

Select all

Test rec # 1

(....)

Processing

Please wait

°°°°

Menu

Measurement cong.

Probe distance

US Signal display

Auto zero

Measurement cong.

Measurement settings

Logger

Inputs / Outputs

Settings level

Pipe - A

Measurement settings

Pipe - B

Number of pipes

QT

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Probes

SE 1790

Pair of probes 1 - A

Pipe

Pipe - A

Fluid

Pairs of probes

Filtring

Gain mode

ESC

Pair of probes 1 - A

ESC then Auto

ESC

Automatic--

Manual

Other manuals for Ultraflux Minisonic II

1

This manual suits for next models

1

Table of contents

Other FAURE HERMAN Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Dwyer Instruments

Dwyer Instruments 477-000-FM Installation and operating instructions

LINSHANG

LINSHANG LS126C user manual

senva

senva EM-PULSE installation instructions

Triplett

Triplett GSM250 user manual

HALaser Systems

HALaser Systems HALscan X20 user manual

Honeywell

Honeywell C7355A1050 Mounting instructions