A 1

A Correct use and application

The “Guidelines for the Correct Use and Application of Paver” complied by Dynapac are included

in the scope of delivery for the present machine.

The guidelines are part of the present operating instructions and must always be followed. Federal,

state and local regulations are fully applicable.

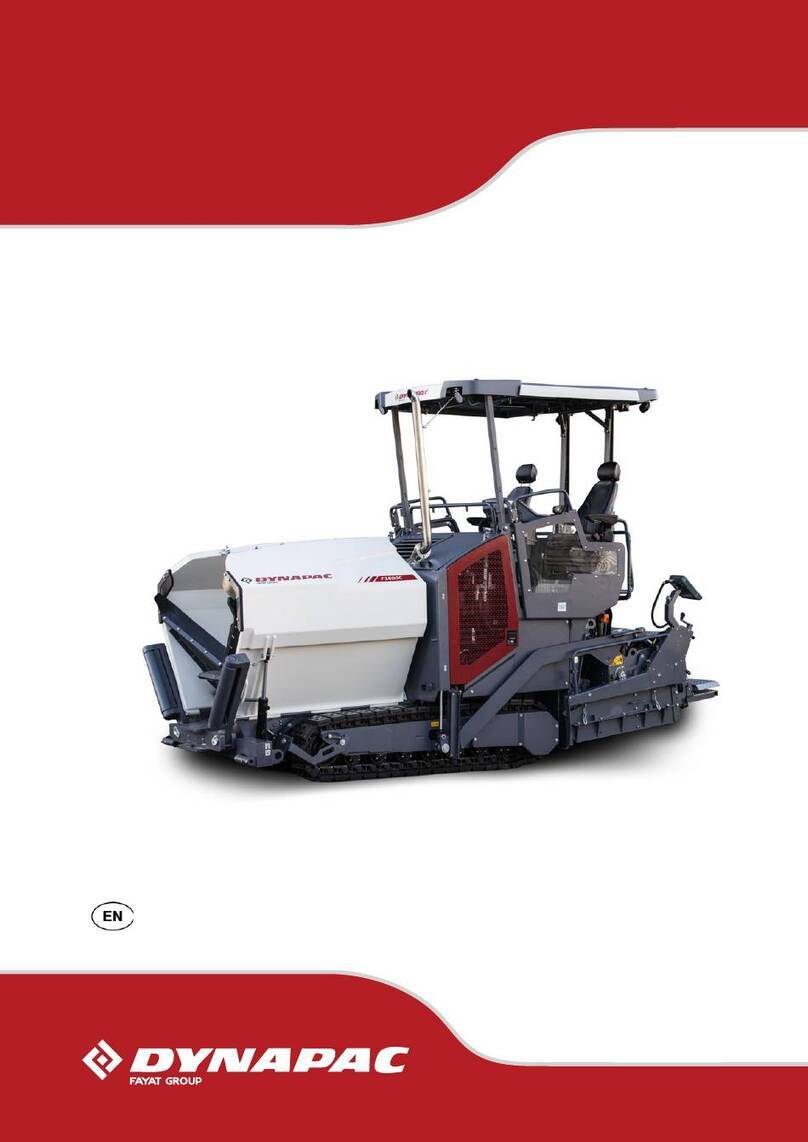

The road construction machine described in these operating instructions is a paver that is suited

for laying mixed materials, roll-down concrete or lean-mixed concrete, track-laying ballast and

unbound mineral aggregates for paving foundations

This machine shall be used, operated and maintained for the purpose of the intended work as

included in the operation manual. Any other use is regarded as improper use and can cause injury

to persons or damage to the paver or other equipment or property.

Any use going beyond the range of applications described above is regarded as improper use and

is expressly forbidden! Especially in those cases where the paver is to be operated on inclines or

where it is to be used for special purposes (i.e. construction of dumps, dams), it is absolutely

necessary to contact the manufacturer.

Duties of the user: A “user” within the meaning of the present operating instructions is defined as

any natural or legal person who either uses the paver himself, or on whose behalf it is used. In

special cases (i.e. leasing or renting), the user is considered the person who, in accordance with

existing contractual agreements between the owner and the user of the paver, is charged with the

observation of the operating duties.

The user must ensure that the paver is only used in the stipulated manner and that all danger to

life and limb of the operator, or third parties, is avoided. In addition to this, it must be ensured that

the relevant presentation regulations and other safety-related provisions as well as the operating,

servicing and maintenance guidelines are observed. The user must also ensure that all persons

operating the equipment have read and understood the present operating instructions.

Mounting attachments: The paver must only be operated in conjunction with screeds that have

been approved by the manufacturer. Mounting or installation of any attachments that will interfere

with supplement the functions of the paver is permitted only after written approval by the

manufacturer has been obtained. If necessary, the approval of local authorities has to be obtained.

Any approval obtained from local authorities does not , however, make the approval by the

manufacturer unnecessary.