General Precautions for Installation/Servicing/Maintenance for the Finisher MJ-1027/1028

The installation and service should be done by a qualified service technician.

1. When installing the Finisher MJ-1027/1028 to the equipment, be sure to follow the

instructions described in the “Unpacking/Set-Up Procedure for the MJ-1027/1028”

booklet which comes with each unit of the MJ-1027/1028.

2. The MJ-1027/1028 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and

unplug the equipment first.

4. When serivcing the machines with the power turned ON, be sure not touch live sec-

tions and rotating/operating sections.

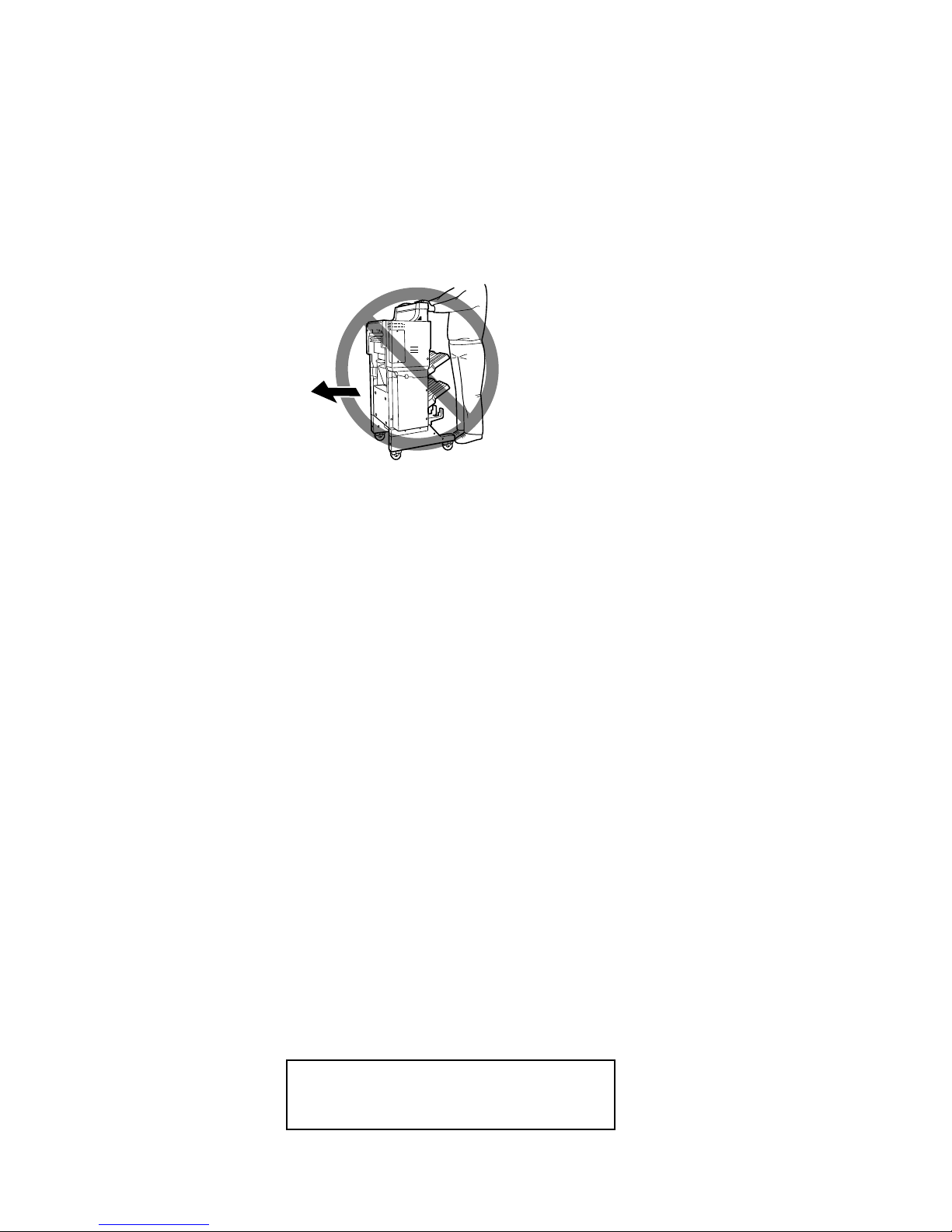

5. When selecting the installation site, avoid placing the MJ-1027/1028 and copier on

different levels or inclined floors.

6. When servicing or maintaining the MJ-1027/1028, be careful about the rotating or

operation sections such as gears, pulleys, sprockets, cams, belts, etc.

7. When parts are disassembled, reassembly is basically the reverse of disassembly

unless otherwise noted in this manual or other related materials. Be careful not to

reassemble small parts such as screws, washers, pins, E-rings, toothed washers to

the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses,

fuses, door switches, sensors, etc. if any) should be handled/installed/adjusted cor-

rectly.

10. Use suitable measuring instruments and tools.

11. During servicing or maintenance work, be sure to check the serial No. plate and other

cautionary labels (if any) to see if they are clean and firmly fixed. If not, take appropri-

ate actions.

12. The PC board must be stored in an anti-electrostatic bag and handled carefully using

a wristband, because the ICs on it may be damaged due to static electricity. Before

using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated charged objects in the vicinity.

13. For the recovery and disposal of used MJ-1027/1028s, consumable parts, packing

materials, used batteries, and RAM-ICs including litium batteries, follow the relevant

local regulations/rules.

14. After completing installation, servicing and maintenance of the MJ-1027/1028, return

the MJ-1027/1028 to its original state, and check operation.