0-5

0

Contents

0 Safety Precautions

Notes Before it Works Serving ---------------------------------------------0-9

1 Periodic Servicing

Periodic Service Works(Finisher) -----------------------------------------1-2

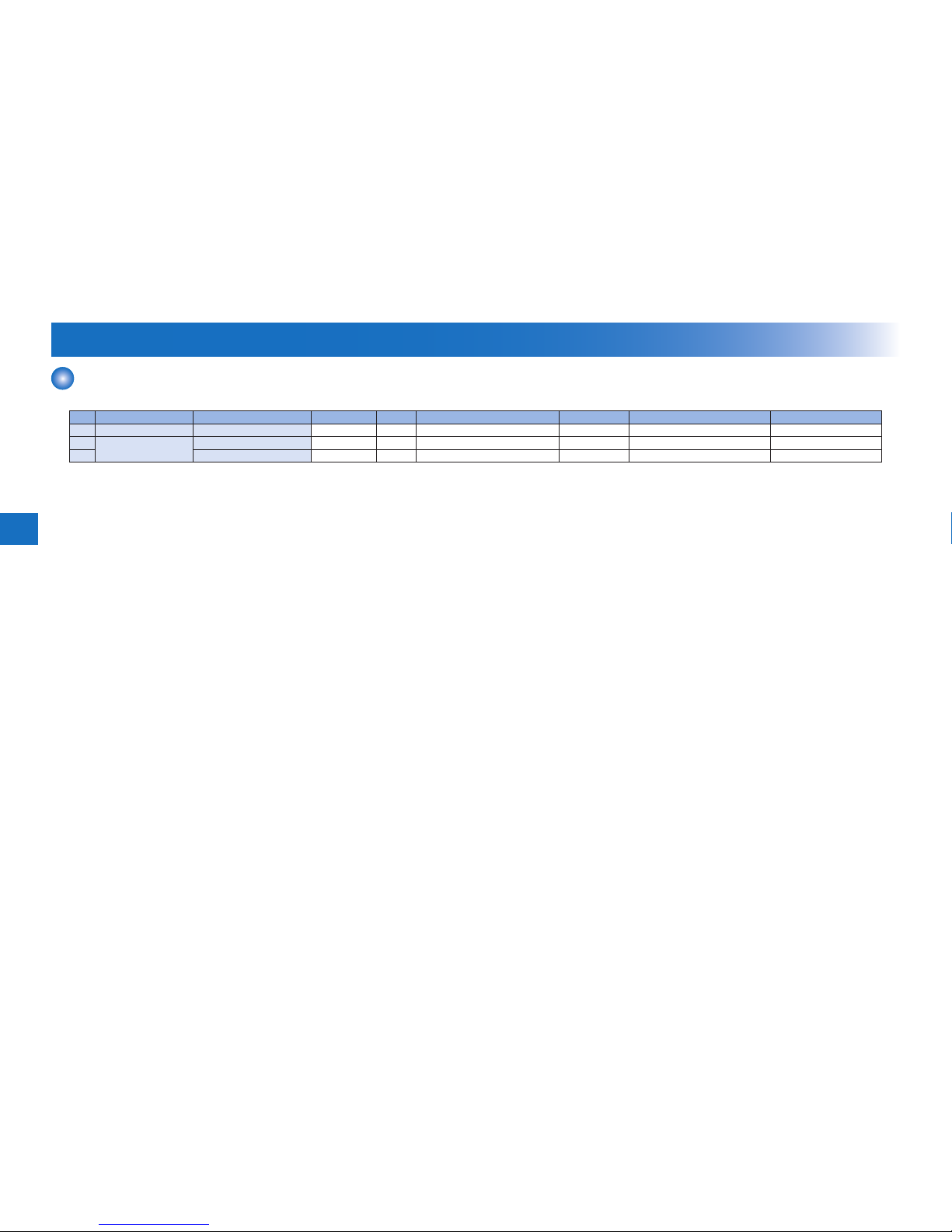

Periodical service ------------------------------------------------------------------ 1-2

2 Adjustment

Basic Adjustment ---------------------------------------------------------------- 2

Adjustment item ----------------------------------------------------------------------- 2

Adjustment -------------------------------------------------------------------------------------- 2

COUNTER --------------------------------------------------------------------------------------- 3

FUNCTION SETTING ------------------------------------------------------------------------ 3

Adjustment at Time of Parts Replacement(nisher) ------------------2-4

Action on replacing the nisher controller PCB ---------------------------- 2-4

Measures at Time of Parts Replacement. ----------------------------------- 2-4

3 Parts Placement Diagram

List of Parts(Finisher) --------------------------------------------------------3-2

Motors/Switches/Solenoids ------------------------------------------------------ 3-2

Sensors1 ----------------------------------------------------------------------------- 3-2

Sensors2 ----------------------------------------------------------------------------- 3-3

PCBs ---------------------------------------------------------------------------------- 3-3

4 Product Outline

Features(Finisher) ------------------------------------------------------------4-2

Specications(Finisher) ------------------------------------------------------4-3

Names of Parts(Finisher) ---------------------------------------------------4-5

External View 1 --------------------------------------------------------------------- 4-5

External View 2 --------------------------------------------------------------------- 4-5

External View 3 --------------------------------------------------------------------- 4-5

Cross Section ----------------------------------------------------------------------- 4-5

Basic Conguration(Finisher) ----------------------------------------------4-6

Outline of basic operation -------------------------------------------------------- 4-6

Non-sort operation-------------------------------------------------------------------------- 4-6

Offset operation ----------------------------------------------------------------------------- 4-6

Stapling operation -------------------------------------------------------------------------- 4-7

5 General Circuit Diagram

Service Tools -------------------------------------------------------------------5-2

Solvents and Oils ------------------------------------------------------------------ 5-2

Special Tools ------------------------------------------------------------------------ 5-2

General Circuit Diagram(Finisher) ----------------------------------------5-3

General Circuit Diagram(Additional Tray) -------------------------------5-4