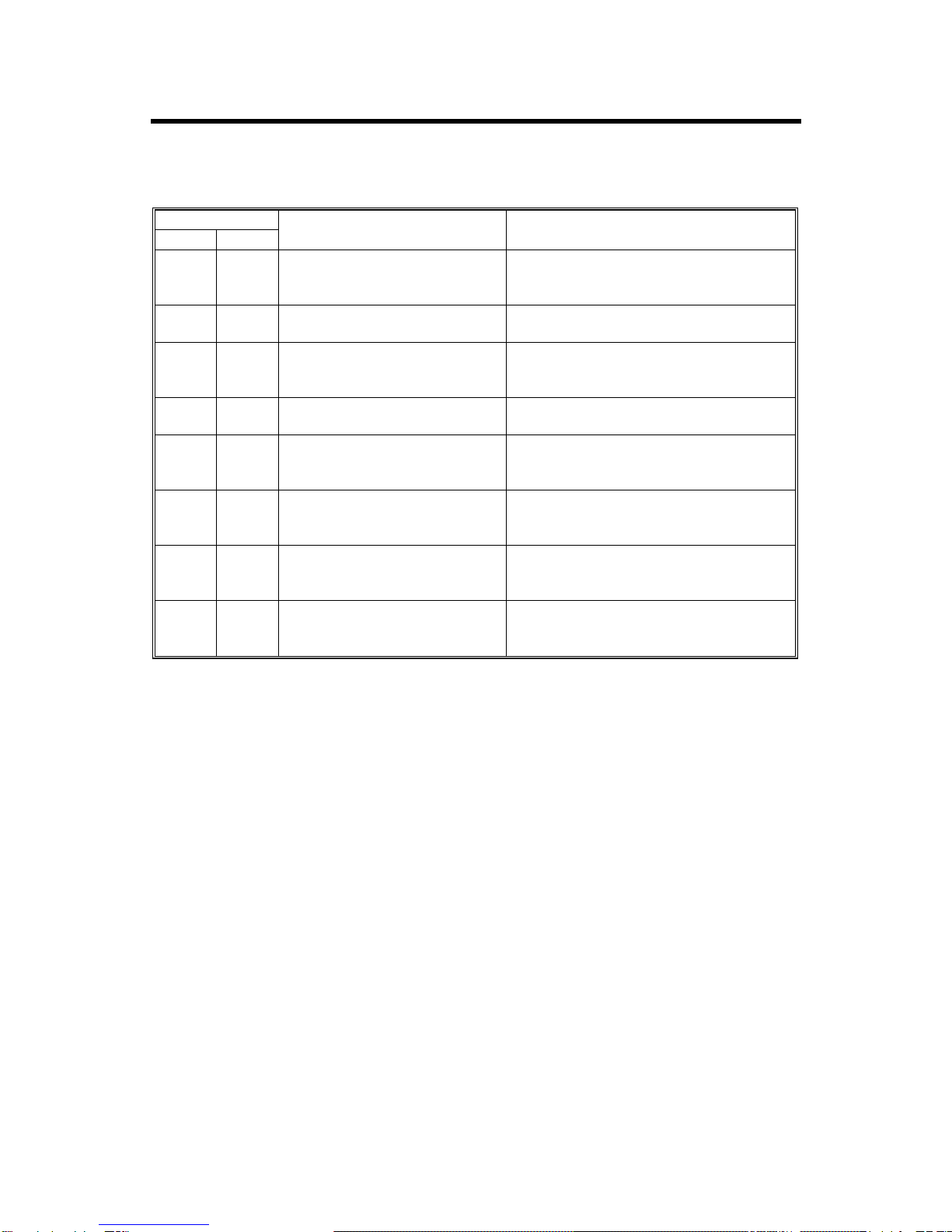

JAM DETECTION 26 July 2002

B408-8

2. TROUBLESHOOTING

2.1 JAM DETECTION

Mode

Shift Staple Jam Content

✔✔Entrance sensor:

On check The entrance sensor does not turn on

within the normal time after the main

machine exit sensor turns on

✔✔Entrance sensor:

Off check The entrance sensor does not turn off

within the normal time after it turns on.

✔Lower tray exit sensor:

On check The lower tray exit sensor does not turn

on within the normal time after the

entrance sensor turns off.

✔Tray exit sensor:

Off check The tray exit sensor does not turn off

within the normal time after it turns on.

✔Stapler tray entrance sensor:

On check The stapler tray entrance sensor does

not switch on within the normal time

after the entrance sensor switched on.

✔Stapler tray entrance sensor:

Off check The staple tray entrance sensor does

not turn off within the normal time after it

turns on.

✔Lower tray exit sensor:

On check The lower exit sensor does not turn on

after the feed-out pawl feeds out the

outputs.

✔Lower tray exit sensor:

Off check The lower exit sensor turns on when the

feed-out pawl returns to its home

position after feeding out the outputs.