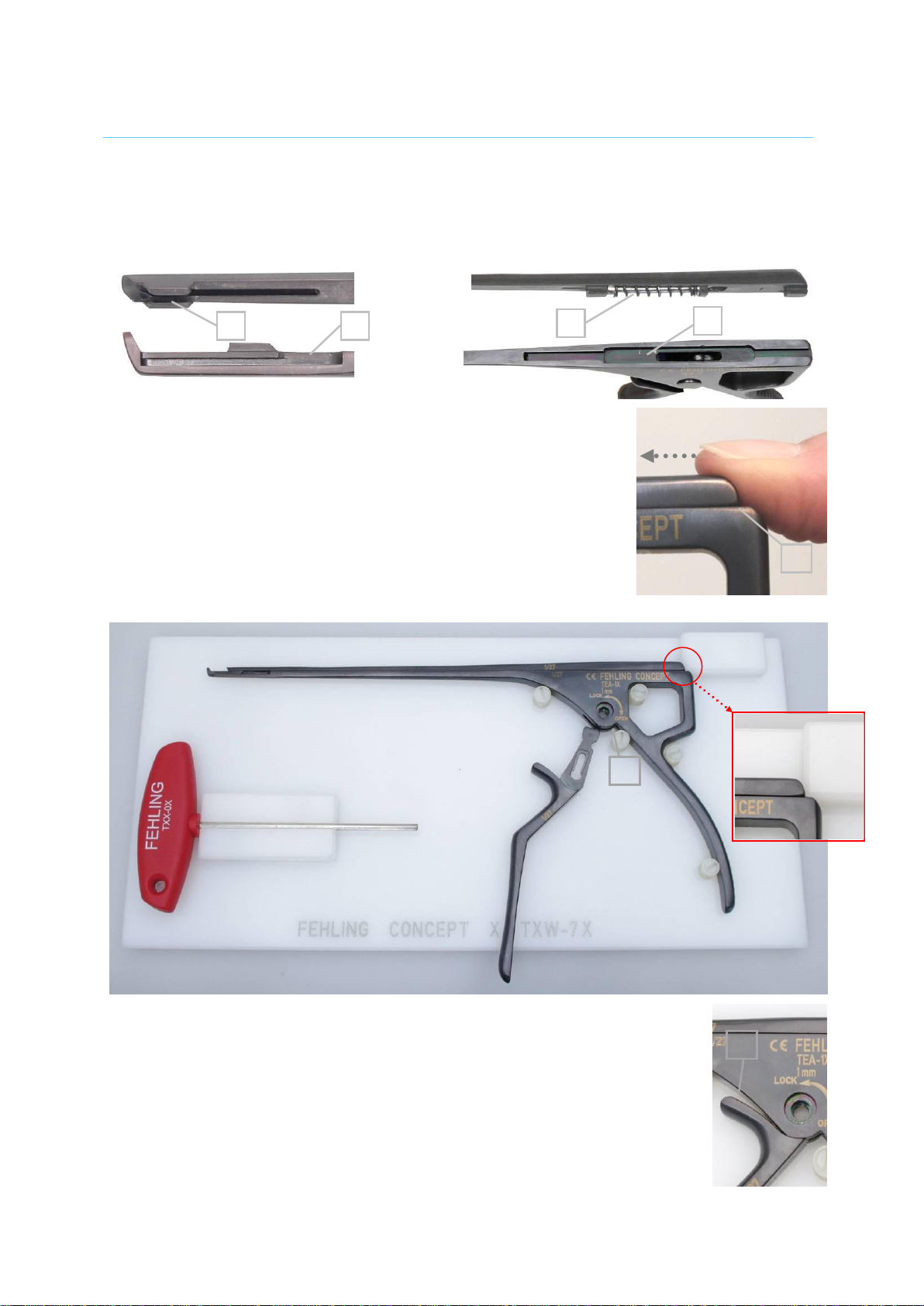

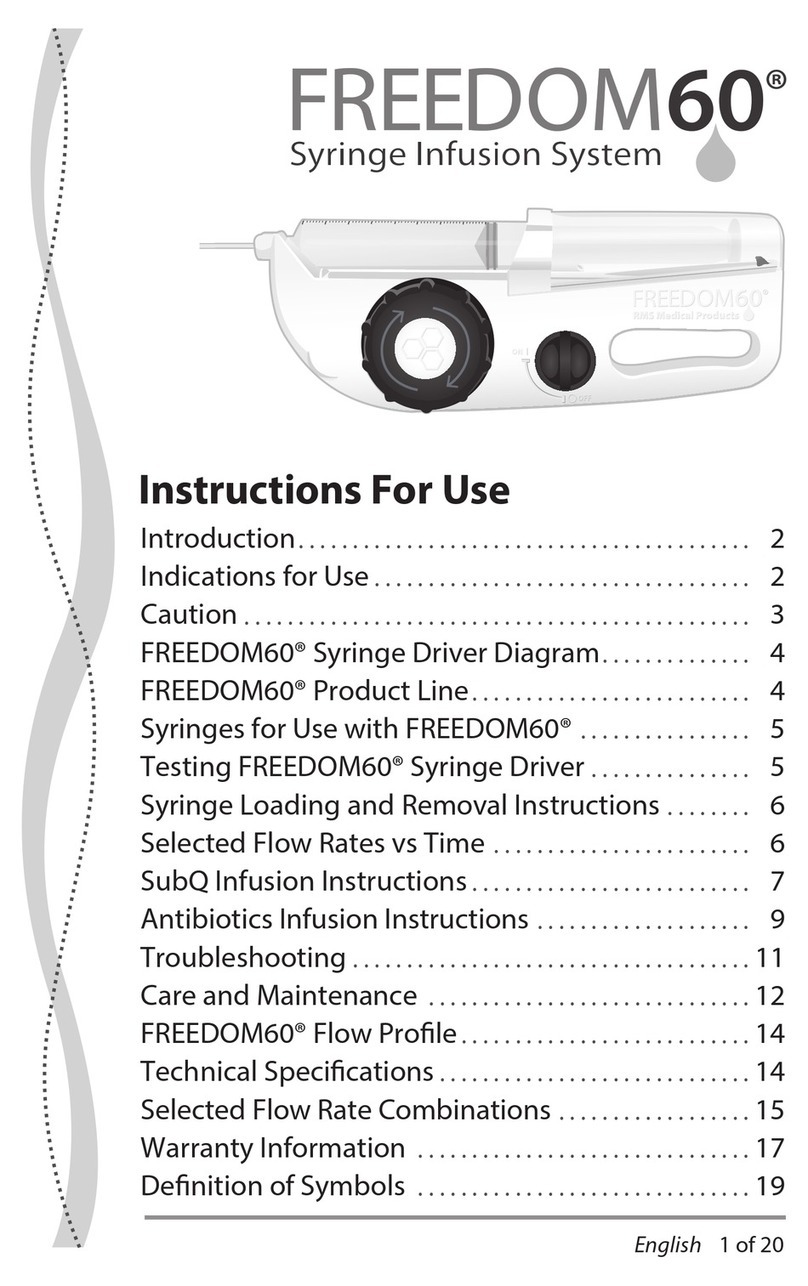

Only components belonging to the same unit may be assembled, with the exception of the

screw which fits all punches. Component compatibility can be verified by means of the identi-

fication number (pos.5) that is marked on all components (except the screw).

NOTE: Before assembling the contact areas (pos. 6) have to be lubricated.

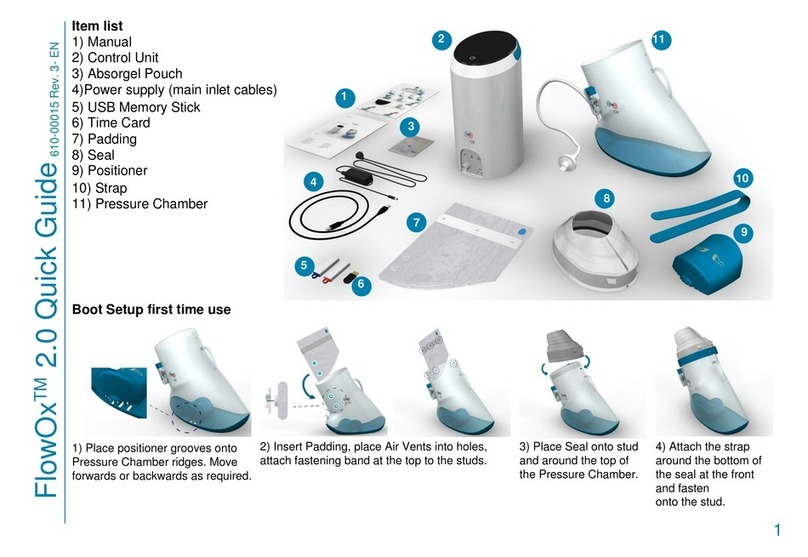

a) Before placing the punch in the fitting device the slider has

to be attached to the punch body. For doing so place the front

guide of the slider (pos. 7) on the guiding rail (pos. 8) of the

punch body, and the slider with the spring (pos. 9) on the milled

groove (pos. 10) in the punch body at the same time.

b) Push slider strongly with the thumb beyond the external edge in

direction of the punch foot until a little step (pos. 11) has formed.

Use other hand to keep the position of the slider and place the

two parts in the fitting device - the slider must push against the

upper plastic block so that it is kept automatically in this position

c) Slowly push the handle element completely into the matching recess (pos.

12) in the punch body. While pushing the handle element should be moved

plane on the fitting device and not be lifted to avoid that it gets jammed.

NOTE: The finger bow doesn’t touch the punch body in the end position

(pos. 13).

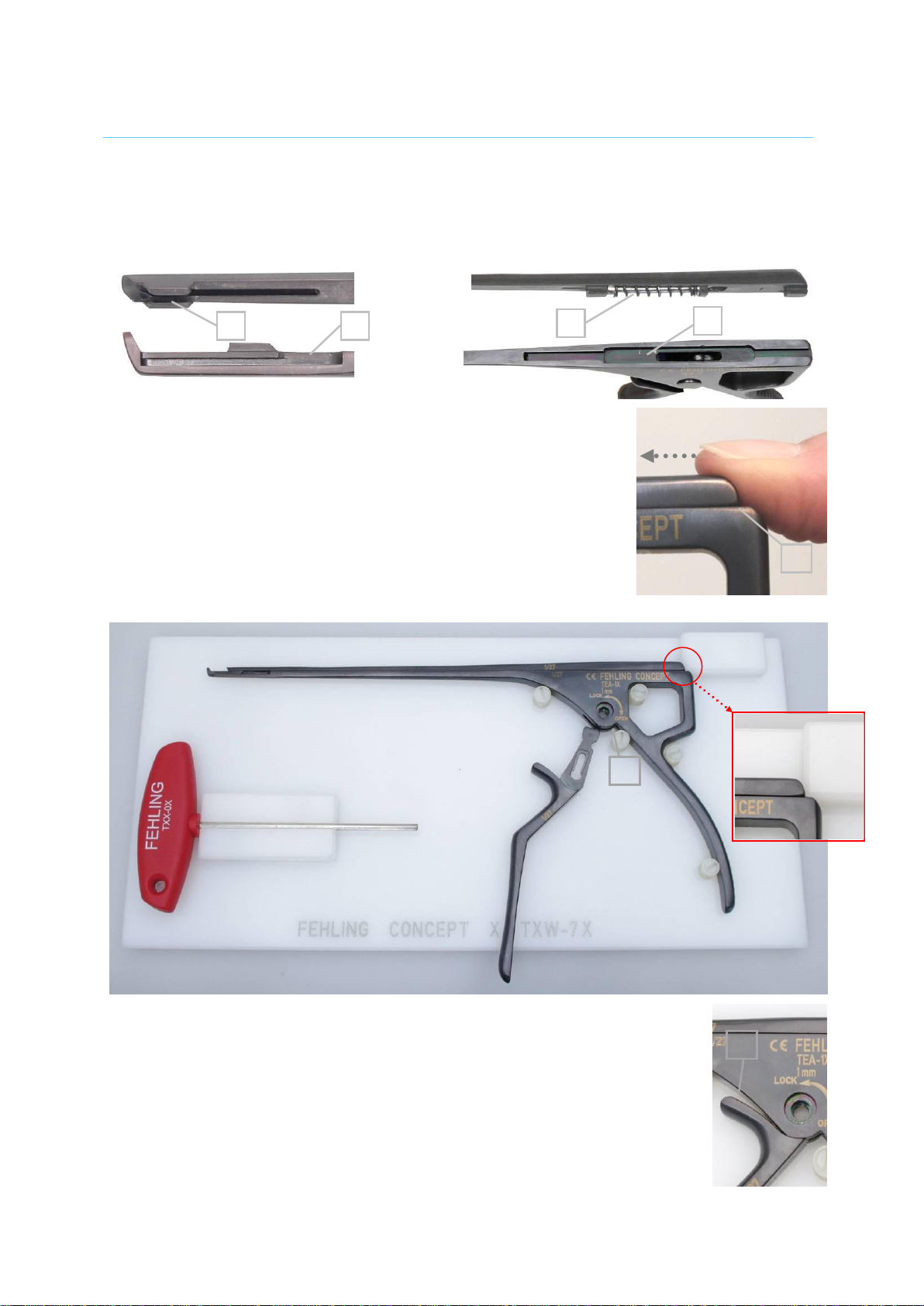

d) Screw the hex head screw counterclockwise into the provided screw hole

using the supplied screwdriver TXX-0X. Tighten the screw. ATTENTION:

Do not over-tighten.

e) The punch is ready for use after a functional test.