Fei Bao MB-339 User manual

1

Fei Bao MB–339 Instructions

DISCLAIMER

THIS IS NOT A TOY. This is a high-performance miniature aircraft,

capable of high speeds and damage to life, limb, and property. The

manufacturer and its distributors cannot control ho you assemble

this model, hat equipment you use to fit it out, or ho you fly it,

and can assume no liability hatsoever for any damages that may

occur hen you fly your aircraft. By assembling this model, you are

agreeing to indemnify and hold blameless the manufacturer and/or

his agents from any and all torts and liability associated ith the use

of this product. Please inspect all parts before beginning assembly.

If any parts appear to be suspect, contact your dealer or the

manufacturer for repair or replacement BEFORE you begin. Once

you have assembled the aircraft, you are the pilot in command and

assume any and all responsibility for the use of the model and any

damages that might occur by flying or attempting to fly this aircraft.

R/C model jets require a high level of skill in both their assembly and

their flying. If you do not feel confident in either your building or

flying skills, PLEASE seek assistance from more experienced

modelers. It is a ise idea, no matter hat level of skills you

possess, to have a second experienced modeler go over your

installation after assembly. A second set of eyes may spot a problem

you have missed. If you have not flo n a model like this before, it is

HIGHLY recommended that you get an experienced turbine pilot to

do your maiden flight. Very often, the first fe seconds of a maiden

flight are critical until the aircraft is trimmed out, and having an

experienced pilot at the controls can make the difference bet een a

recked aircraft and once that enjoys many hundreds of flights. Be

sure to select a suitable field for flying...take the time to find a large

paved run ay if at all possible, especially for test flights, until you

feel comfortable getting the aircraft in and out of smaller grass

fields.

Before you begin

Keep this in mind as you proceed:

Look at EVERY assembly step you finish, and ask yourself:

"Is this going to cr sh my irpl ne?"

A chain is only as strong as its eakest link, and this is a high-

performance aircraft that ill be very intolerant of sloppy assembly

techniques. Even the smallest component is important and can

cause the loss of your airplane, so take the time to do things right.

Or REdo them if they are rong. Careful ork ill result in a long-

lasting plane that gives you years of pleasure, one loose component

could result in the complete loss of the aircraft and all the

components inside it, and someone can even get hurt. So pause

every once in a hile hen building it and double-check your

orkmanship.

Introduction

You have chosen a model that represents the pinnacle of ARF

technology. While there is not a lot of building to do, there is

enough to keep you busy for a fe evenings.

Even if you have assembled maybe other ARF jets, e highly

recommend follo ing our assembly sequence and procedures

any ay. Chances are it ill save you a lot of time, prevent you from

running do n dead ends, and perhaps remind you of a fe small

things that might end up saving your aircraft.

We have tried to arrange a construction sequence that ill allo you

to keep moving for ard, rather than standing around aiting for

glue to dry before you can proceed to the next step.

Just because the model is almost completely built does not mean

you can rush through the final assembly.

You need to employ fine craftsmanship every step of the ay,

2

turbine models are critical. Keep this in mind ith everything you

do, every part you install...look at the ork you just did, evaluate it

critically, and ask yourself "is this going to potentially crash my

airplane?" If there is any doubt about the ork you have done, back

up, and re-do it properly.

Adhesives

The correct adhesive to use for all procedures is Loctite Hysol 9462.

This is a very strong hite epoxy that is thixotropic. "Thixotropic"

means it does not run at all, but stays only here you put it. It is

infinitely superior to regular epoxy, even slo -setting epoxy, for our

purposes, because of this characteristic. Regular epoxy ill run

do nhill ith gravity as it dries, taking it a ay from here it is

supposed to be. A good example is in the hinges...using regular

epoxy, a good portion of the glue ill migrate do n a ay from the

hinge into the inside of the ing as it dries, and you on't even

kno it is happening. Hysol stays here you put it. The do nside

of Hysol is it takes overnight to dry properly, but e have tried to

arrange things to keep you busy hile aiting for glue to dry.

We also highly recommend that you only use a proper Hysol

dispensing gun, and only the long-type mixing nozzles.

The short nozzles do not mix this glue enough, and only a thin

nozzle and gun ill let you fill the hinge and control horn holes

properly ith glue, you can't do it mixing your Hysol on a flat surface

and trying to get the glue in the proper place by a brush or stick.

You can buy a complete Hysol setup ith a gun, nozzles, and t o

cartridges of glue from your dealer for approximately $60.

Consider it a great investment, the glue is the best you ill use.

One cartridge is plenty to assemble your MB339.

Working with pneum tic systems

The MB339 uses pneumatic brakes and retracts. If you follo a fe

tips, you should have very reliable, leak-free operation. Neatness

counts. All airlines should be secured to the airframe to keep them

from flopping around or getting kinked. Use tie raps for this.

The other very important thing is to cut off the end of each airline

dead square before installing it on the nipple. This is VITAL. You

can either purchase a professional tubing cutter from your dealer

(they are approximately $10), or you can make up a little jig to hold

the airline and keep a sharp, ne razor blade perfectly upright as

you cut. Either one orks, just ensure that all ends of all airlines are

cut off dead square. Make sure all airlines are pushed ALL THE WAY

onto their nipples. They should not need to be secured other ise,

but you can add fine ire safety raps if you like. Make sure all left

and right matching airlines are the same length, particularly the

brake lines, or you ill get uneven retraction or braking action.

It's orth taking the time to get everything pneumatic right the first

time, as having your landing gear fail to retract is not THAT bad, but

having it fail to deploy can really ruin you day and the paint on the

bottom of your model.

3

Construction

Prelimin ry steps

• Clean and inspect all parts. Inventory them against the parts list

at the end of the manual and notify the kit supplier of any

missing components as soon as possible.

• If the paint scheme you have selected is glossy, it is

recommended that you apply a coat of ax. This ill help resist

dirt, stains and fingerprints during construction, and ill provide

some limited protection against errant glue.

• Vacuum out the remnants of packing materials that remain in

the fuselage.

While the kit is comprehensive, there are additional parts required,

as follo s:

• Recommended Servo List (JR)

• Elevators: (2) 8611a

• Aileron: (2) 8611a

• Flaps: (2) 8611a

• Rudder: (1) 8411

• Nose Steering: (1) 8611a

• Retracts: depends on retract and door solution selected

• Speed Brake: (1) 351 or equivalent

• Brakes: (1) 351 or equivalent, or an electronic brake unit

• Other Parts

• BVM UAT (optional)

• Fuel tank vent fitting

• Festo fuel shutoff valve

• Wire t ist tie (optional)

• Blue Loctite

• Glues: Thin CA, 5 minute epoxy, 30 minute epoxy,

Aeropoxy, Zap-a-Dap-a-Goo

• Electronic gear sequencer, or UP2/UP4 combination

• Brake valve

• Batteries, regulator and s itch

• Matchboxes, Po erbox, Smartfly EQ10 or equivalent

• Servo extensions (length may vary, depending on receiver

placement)

Gener l Construction Notes

The order of construction may be changed to suit your personal

preference, ho ever, the model is more easily orked in a tight

space if ork is completed on each fuselage section before they are

joined. The tail surfaces must be attached before the aft fuse is

joined to the for ard fuse, as the pipe must be in place during this

step and it blocks access for iring.

The retract system doors operate in t o different ays. The main

gear doors and the large nose gear door open, the landing gear

cycle either up or do n, and the doors close again. For this action,

you ill need t o separate valves ith a sequencer or an Ultra

Precision UP-2 valve. The small doors that bracket the nose heel

strut must remain open hen the gear is extended. There are t o

ays this may be accomplished. The simple approach is to connect

the cylinder open line to the gear do n line, and the door close line

to a pressure s itch that is connected to the gear up line and

activated by the nose gear steering servo hen in the retracted

position. This is the method that is sho n in these instructions. If

you use a UP-2 valve for the larger doors, you can add a UP4 valve

to the system for the smaller nose gear doors.

You ill likely need to match t in rudder and t in elevator servos.

This may be accomplished ith servo reversing “Y” harnesses, JR

Matchboxes, the Smartfly EQ10, a Champion Po erbox or equivalent

gear.

4

Step 1: Check Forw rd Fusel ge

Remove the fuel tanks from the fuselage.

Also remove the t o for ard component boards. No ould be

a good time to put a coat of paint on these parts if you ould

like to protect the ood surfaces.

Vacuum and thoroughly clean the fuselage.

If the nose gear as installed at the factory ith bolts and lock

ashers, check these for security no .

Put a very small dab of thin CA on the three nuts that secure the

nose gear door cylinders to the door actuating arms. A small

toothpick helps limit the amount of glue applied.

Repeat this step for the three nuts that attach the door cylinders

to their respective mounting blocks.

Check all door hinges for security.

Ne er kits have carbon fiber reinforcement in the nose section.

Older kits ill require that this be added. Start adjacent to the

intakes and epoxy carbon fiber strips for ard to the nose.

Run a bead of Aeropoxy do n the sides of the three nose

formers to reinforce the joint ith the fuselage side. See

photo

1.

photo 1 – optional fuse strengthening

Step 2: Prepping the Fuel System

Disassemble and inspect the tank cap hard are. As

photo 2

sho s,

the process used to cut the tubes may leave behind a rim that

constricts fuel flo and could result in excess tank pressure and

leakage. The vent tube to the top of the picture sho s hat the

constriction looks like before repair, hile the fuel tube on the lo er

left sho s hat the tubing should look like after clean up. If the

tubing is not constricted, skip for ard to the leak check.

photo 2 – correct tube constriction if necessary

Loosen the Philips head scre and remove the stopper assembly

from the tank.

Use a small, round Perma-Grit rat tail file or an Exacto knife to

remove the excess metal. You ill need to inspect the ends of

all tubes.

When finished, make sure to blo out the metal fragments and

clean up any sharp edges.

While the components are apart, check the Tygon pickup line for

equal lengths in both saddle tanks. They should be long enough

to reach the back of the tanks ithout being so long as to

restrict their ability to move to the top of the tank hen the

aircraft is inverted. Allo a small amount of play to allo the

tubes to stretch slightly over time.

5

You should also notch the vent tube ith a small file to provide

for continued air flo should the tube come into contact ith the

top of the tank.

Make sure the bends to the vent tubes applied at the factory

have not restricted airflo to any significant extent. Also, check

the Tygon for any nicks or cuts and secure to the tubing ith

ire ties before re-assembly.

Reassemble and mark the tank for vent and fuel for later

reference.

Once the tanks are back together, they should be leak checked

before installation in the aircraft. Connect extra lengths of fuel

tubing to the fuel and vent lines and submerge the tank in

ater. Pinch off one line and gently pressurize the tank by

blo ing into the other, looking for signs of air bubbles. If the

tank sho s evidence of air leakage around the vent cap, tighten

the Philips head scre and check again. If you have a stubborn

leak, you can re-tap the inner plate for a slight larger 6/32 cap

head bolt.

Step 3: T nk Inst ll tion

photo 3 – lo er foam support

Re-attach the Tygon tubing to the main saddle tanks. Make sure

the lines are of equal length. Exercise care not to break the

tanks hile fitting the Tygon. Slo ly iggle the tubing into

place. Wire tie for security.

Cut a scrap piece of fairly stiff foam 3” x 5” x ½” and secure to

the bottom of the fuse at the rear of the saddle tank bay ith a

fe drops of thin CA (

photo 3

).

Insert the saddle tanks into position, slipping the Velcro hold-

do n strap into place as you do.

Cut another piece of scrap foam 2” x 3” x ¾” and slip it bet een

the saddle tanks at the bottom of the fuse.

Cut t o pieces of scrap foam 2” x 3” x 1” and secure these to

the sides of the fuse at the rear upper corner of the tanks ith a

fe drops of CA to provide added support (

photo 4

).

photo 4 – side foam support

You ill need to make t o center tank supports from scrap ply. The

tank needs to sit far enough back from the cockpit for fuel lines to

clear the back of the main hatch area. It also needs to incline

slightly from rear to front to insure adequate clearance for the

engine hatch.

Temporarily position the lo er engine bypass on the mounting

rails.

Slip the intake extension into place and secure ith the aft

Velcro strap.

6

Position the center tank on top of the intakes, far enough aft of

the canopy area to allo clearance for the fuel lines.

Fashion a rear tank support from ¼” scrap ply and position it on

top of the intake extension. You ill need to radius this piece

slightly ith a Dremel tool to match the incline of the extension

tube.

photos 5 and 6 – rear and front center tank supports

Check the position of the tank once more ith the engine hatch

in place. When satisfied, tack glue the tank support in place

ith a fe drops of CA (

photo 5

).

Shape a front tank support from scrap ply. The ply piece ill be

glued bet een the intakes and should be notched at the top to

keep the tank from slipping for ard during flight (

photo 6

).

Secure ith a fe drops of CA.

photo 7 – Aeropoxy tanks supports in place

Remove the center tank and secure these tanks supports in

place ith a generous amount of Aeropoxy (

photo 7

).

There are various ays to secure the intake in place to keep it

from sliding to ard the rear of the plane, but the simple ay to

do it is to attach it to the for ard former ith ire ties. This

makes it immediately removable in the event the saddle tanks

must be serviced (

photo 8

).

Fashion a rear tank stop from scrap ood and attach it to the

intake at this point. Secure ith Aeropoxy. Replace the center

tank and secure the Velcro hold-do n strap. (

photo 9

).

Check the fuel lines for nicks and cuts as you proceed through the

next steps.

Connect the t o fuel pickup lines from the saddle tanks together

ith a “T” fitting.

7

Connect this “T” fitting to the vent line of the center tank.

Connect the t o vent lines together from the saddle tanks ith a

“T” fitting.

photos 8 and 9 – securing intake and rear tank stop

Attach this “T” fitting to a fuselage vent fitting. It is suggested

you place this just ahead of the right intake, slightly up from the

bottom of the fuse. This ill prevent “catching” the fitting if you

slide the fuselage on a foam transport pad. Reinforce the

fuselage ith a scrap piece of carbon fiber to add a little

strength to this area (

photo 10

).

photos 10 and 11 – vent tube reinforcement and UAT installation

Connect the fuel pickup from the center tank to the optional UAT

or to the fuel pump. In the prototype, the UAT is located just

above the right intake. (

photo 11

).

Step 4: Nose ge r

Working from inside the aircraft, scre the nose steering servo

to the bracket (

photo 12

). Do not use rubber grommets and

make sure to use Loctite on the scre s. The servo is oriented

ith the output spindle to ard the top of the plane. If your

servo has a reinforcing ridge on the mounting tab, you may

need to remove it ith a razor knife to allo the servo to sit flat.

photo 12 – installing nose gear steering servo

Lo er the gear.

Adjust the steering arm clevises until they are approximately the

same length, ith the servo arm positioned on the servo spindle.

Using a Matchmaker or similar device, center the servo and

mount the arm. Readjust the clevis if there is any evidence of

binding (

photo 13

).

When satisfied, use a small drop of thin CA on each clevis to lock

it on to the threaded rod.

Step 5: Nose Doors

It ill be helpful at this point to locate the positioning of the air

system valves. A sample installation is sho n in

photo 14.

photo 13 – nose gear steering linkages

photo 14 – sample layout of air systems on for ard component board .. leave room

for cockpit above and air tanks belo

9

In the prototype, the larger of the three air tanks serves the gear

and doors, hile the smaller tanks serve brakes and air brake

respectively.

Refer to the general construction tips for an explanation on

gearing up the air systems.

Install three air tanks in the space beneath the for ard

component board, ith the large tank in the middle. Use several

dots of a silicone based glue such as Zap-a-Gap-a-Goo. Don’t

overdo the glue, ho ever, as you may ant to remove the tanks

in the future and the component board ill hold the tanks

partially in place in any case.

When the glue is dry, run air system lines to the tanks. In the

prototype, all air and fuel fill lines are run to the rear hatch so

that the cockpit may be left in place hile servicing the plane.

Lay out the air system components on the for ard component

board and then bolt the board into place ith four small ood

scre s.

Run air lines to the nose gear and nose door cylinders. A little

patience and good skills ith a forceps ill be required. Test

each line as you go ith a hand pump for leaks. It ill also help

to follo a color coding scheme for future line identification and

trouble shooting.

photo 15 – air micro s itch to active small nose gear doors

As described in the general notes, the t in doors that flank the

nose gear strut in the prototype are activated by an air micro

s itch. Make a small platform of scrap ply and attach the micro

s itch ith a ire tie or a bracket. Push the s itch up against

the bottom of the steering servo hen it is in the retracted

position and secure to the top of the retract unit ith ire ties

(

photo 15

).

Step 6: Vertic l Fin nd Rudder

Before attaching the aft section of the fuse, the vertical fin and

horizontal stabilizers need to be attached and the ires run from the

servos. This is because the pipe must be in the aft section hen

installed, and access to the iring is restricted once the pipe is in

place.

In most kits, the hinges are preinstalled in the control surfaces, but

must be glued into the flight surface.

When removing the servo ell covers, label appropriately for proper

re-installation.

Trial fit the rudder into the vertical stab. You may need to snip

about 1/8 inch off the bottom hinge as it butts up against the

rear aluminum spar. Trim and sand to achieve the maximum

thro your servo arm ill allo .

Attach t o aluminum “L” brackets to an 8411 servo or

equivalent. Position the brackets such that the spindle of the

servo faces for ard hen installed in the servo ell. Do not use

the rubber grommets supplied ith the servo, but bolt it directly

to the brackets. Use Loctite.

Using a JR Matchmaker or your receiver, po er up the rudder

servo and set it at neutral. Attach the control arm at a vertical

position.

Position the servo on the t o ply mounting tabs and attach the

“L” bracket ith 15mm ood scre s.

Run the servo ire out of the bottom of the vertical stab.

Trial fit the phenolic control arm in the slot routed in the rudder

at the factory. You may need to use a small carbide cutter to

enlarge the slot slightly for a good fit. Be careful not to route

through the other side of the control surface. A small piece of

10

tape rapped around the cutter at the proper depth ill help

prevent a mishap.

Roughen the surface of the control arm here it ill glue into

the rudder ith 100 grit sandpaper.

Tape around the slot ith masking tape and apply a liberal

amount of Aeropoxy into the slot (

photo 16

).

photo 16 – Installation of control horns

Secure the hinges into the vertical stab and the control horn into

the rudder ith Aeropoxy. Remove the masking tape and allo

to dry overnight. Make sure to check the vertical stab for any

glue marks or fingerprints before setting it aside.

Locate t o 15mm bolts and large ashers. Trial fit these in the

vertical stab mounting posts.

Insert the vertical stab into the aft section of the fuselage and

secure ith the t o bolts.

Install a servo extension of the proper length to reach your

receiver and secure the connection ith a large piece of heat

shrink or tape.

Step 7: Horizont l St bilizers

The horizontal stabs build up in a similar fashion to the vertical

stab. Repeat all steps, including the installation of the servos,

elevator hinges and control horn.

Before installing the servos, use a Matchmaker or equivalent to

center the servos and match the positions of the control arms.

If you are using JR Heavy Duty Arms and the positions don’t

match, try rotating one arm 180 degrees before deciding hich

half of the arm to trim off.

If you are installing 8611 servos, you ill need to trim the ply

mounting tabs and metal arms to get a good fit (

photo 17

).

photo 17 – elevator servo installation

You can make the horizontal stabs easier to remove if you install

the servo extension such that the servo plugs in at the fuse

joint.

Install the t o carbon fiber spars through the aft fuse.

Find the 20mm horizontal stab mounting bolts and trial fit into

the metal threaded tabs.

Working carefully, enlarge the hole in the top of the aft fuse

such that the stab mounting bolt ill sit flush ith the top of the

fuse. Do not drill this hole straight through, but make it just

large enough for the head of the bolt. In the prototype, the

11

proper diameter as achieved ith a conical bit and then the

depth as cut ith a small carbide cutter (

photo 18

).

Slip one horizontal stab on the spars and secure ith a bolt

(

photo 19

). Loctite.

photos 18 and 19 – installation of horizontal stabilizer bolt

Push the spars fully into the stab that you just mounted, and

then slip the other stab on the spars, securing ith a bolt.

Loctite.

Run all extensions for ard through the aft fuse, making sure

they are adequately secured a ay from the pipe.

Step 8: H tch Covers nd Link ges

Cut slots for the control arms in the servo covers for the vertical

and horizontal stabs and reinstall.

You may ant to paint the control horns to match the paint

scheme at this point.

With control arms in the vertical position and the control surface

centered, adjust the linkages to the proper length for both

elevators and the rudder.

With the t o elevator servos activated through the Matchmaker,

set the length of control linkage such that the elevators are

equally centered and attach (

photo 20

). Make sure not to over-

tighten the bolts such that the arm binds.

photo 20 – elevator linkage

12

Step 9: Aft Fusel ge

Drill a hole in the pipe mounting tabs at their mid-point.

Position the pipe on the rear of the lo er bypass. The tabs are

slightly offset to one side of the pipe … this is the top.

With the pipe fully on the lo er bypass, and the mounting tabs

equally spaced from the top, drill holes through the lo er bypass

for the tab mounting bolts.

Trim the mounting tabs back a bit if necessary to insure they

don’t interfere ith the fit of the upper bypass.

Insert the pipe into the aft fuse.

Attach the aft fuse to the for ard fuse ith four bolts. Loctite.

Secure the ire harness to the side of the fuse to keep it a ay

from the pipe (

photo 21

).

photo 21 – mounting aft fuselage

Step 10: Engine nd Pipe

Clean the fuselage thoroughly before installing the engine. If you

need to trim the intake for engine clearance, use a vacuum hile

you ork. This ill reduce the chance of a foreign object finding its

ay into your engine.

Move the pipe aft and position the lo er bypass on the

mounting rails. Trim the engine rails as necessary for a good fit.

Bolt the pipe mounting tabs to the lo er bypass.

Position the aft end of the exhaust pipe even ith the lo er fuse

at the rear exhaust opening. (

photo 22

).

Trim the intake such that it extends inside the lo er bypass by

approximately ¼ inch.

Slide the pipe/bypass assembly to the rear again, and slip your

engine into the lo er bypass. Move the entire assembly for ard

into position.

photo 22 – position of aft pipe

Adjust the location of your engine to obtain the clearance

specified by the manufacturer bet een the exhaust cone and

the pipe mouth. It is likely it ill extend into the intake.

13

photo 23 – engine mounted in lo er bypass

Shim the engine as necessary to make sure it is centered in the

pipe and is aligned ith the slope of the pipe from front to rear.

When you are satisfied, bolt the engine to the side frames ith

ood scre s. Remove the scre s and coat the thread holes

ith thin CA. This ill harden the ood. Connect service lines

to the turbine and bolt permanently in place (

photo 23

).

photos 24 and 25 – rear component board. Note receiver position on upper right.

Drill and secure the bypass to the engine mounting rails ith

four ood scre s if necessary.

If the pipe is loose as it passes through the rear former, glue a

piece of ply at the top of the former to hold the pipe more firmly

in place. Access is from the rear.

Complete the installation of engine components on the rear

component board. Remember to leave clearance for the cockpit

above. The placement of components in the prototype,

including the smoke system, is sho n in

photos 24

and

25

. The

rear component board has been raised slightly for installation of

smoke tanks beneath.

Resist the temptation to hide ires a ay under the component

boards, as it ill make future maintenance more difficult. Keep

things neat but accessible.

Step 10: Wing L nding Ge r nd Doors

You ill find it easier to route air and servo lines if you enlarge

the access hole in the ing root ith a carbide cutter (

photo

26

).

14

photo 26 – enlarge air line and servo ire access hole in ing root

Extend main gear, remove the small scre that attaches the

strut cover linkage to the strut, and remove the main gear.

Put a drop of thin CA into each scre hole to strengthen the ply

in the area of the bolts.

If not already done, attach air lines to the main gear and check

for leaks ith a hand pump.

Attach brake line and check for operation of the brakes and

leaks ith a hand pump.

Optional step: The gear door cylinder may be attached to a

small extended “ear” on the door hinge. To reduce the risk that

this ear fails, you may ish to move the ball link attach point to

the hole immediately next to the “ear”, but drilled through the

main arm itself. If you undertake this optional step, you ill

also need to move the bolt location on the cylinder base

mounting plate so as to maintain appropriate thro s (

photo

27

).

photo 27 – optional repositioning of main door cylinder attach bolt

Attach air lines to the door cylinder if not already accomplished.

Test for leaks.

Put a drop of thin CA on the small nuts at both door cylinder

bolt locations to reduce the risk that they loosen over time.

Route all air lines to the ing root.

Reinstall main gear. Check for smooth operation ith a hand

pump.

Wire tie the brake line to the main strut and check operation of

the gear once more to make sure brake line has adequate

length and clearance.

Reinstall small bolt to secure door linkage. Use a small amount

of thin CA to secure bolt into strut. Also put a drop on the nut

attaching the linkage to the door itself.

See

photo 28

for picture of completed main gear and door

cylinder installation.

Wire tie and then cut off air lines at ing root. Install quick

disconnects. It is recommended you leave some extra length,

particularly on the brake line, in case lines need to be removed

and the ends clipped for maintenance or to repair a leak.

Repeat all steps for the other ing.

15

photo 28 – completed main gear and door installation

Step 11: Aileron nd Fl p Servos

Remove the aileron and flap servo covers. Mark the inside front

of the covers so you ill kno ho to orient them for re-

assembly.

Attach the aluminum L brackets to the servos as you did for the

tail surfaces. The servos ill face in opposite directions and the

servo spindle is positioned to ard the front of the ing.

Using your receiver or JR Matchmaker, find servo neutral and

attach the heavy-duty servo arms to obtain matching positions.

If you are using a double-sided arm, you may find that rotating

the arm 180 degrees achieves a better match, so complete this

step before trimming off the unused side of the arm.

Temporarily fit the ailerons and flaps to the ing if not already

completed at the factory.

Position the servos onto the mounting tabs, paying attention to

the position of arm relative to the control horn slot marked on

the control surface.

Using great care not to pierce through the top of the ing, drill

and bolt the servos in place (

photo 29)

.

photo 29 – flap servo installation

You ill need to use an extension on the aileron servo lead.

Make sure to tape the connection and secure the iring to ribs

as it passes through the gear door compartment to prevent

fouling of the extension on the heel. Label the servo ires for

aileron or flaps.

Trim the servo covers for the servo arms and reinstall.

Repeat for the other ing.

Step 12: Fl ps nd Ailerons

Measure the thro s for ailerons and flaps. Make sure you can

achieve 45 degrees of thro on the flaps and at least 20 mm in

either direction on the ailerons. Carefully trim a ay the gap

cover if needed to get the appropriate travel. Also make sure

there is no binding at the point that the flaps and ailerons come

together.

When satisfied, Aeropoxy the hinge points into the ing

permanently.

With a small carbide cutter, route out the slots for the control

horns.

Rough up the mounting surface of the control horn, tape around

the slot and glue the horn into each control surface ith

Aeropoxy.

16

Set the ings aside for the glue to cure. Double check to make

sure there are no fingerprints or excess glue on the ing

surfaces.

When the glue has cured, install the linkages.

Insert the ing tip tanks into the mounting holes. When the

pins are fully inserted, tighten the locking clamp bolts through

the small holes in the bottom of the ing.

Locate the spar tube. Note there are holes drilled and tapped at

both ends of the tube through the hard ood filler block. Insert

the tube into one ing and check to see if the hole aligns. If

not, remove the tube and invert. When you find the proper

orientation, mark the tube for left and right for future reference.

Run the spar tube through the fuse, connect service lines and

bolt ings in place.

Air up system and connect a Matchmaker or similar device to the

retract servo. Test the system, correcting any leaks or other

issues at this time.

Step 13: Wing Fences

There is one large ing fence and t o smaller ing fences on each

ing. The t o smaller fences are located to ard the outer tip and

the large fence is approximately t o thirds of the ay to the tip.

The locations for the fences are molded in the top surface of

the ing.

Mark the locations of the mounting tabs on the fences on the

ing surface

Route the tab slots in the ing, orking carefully ith a razor

knife.

Insert the fence into the slots and ick thin CA into the tab

area. Tilt the ing and let the CA ick do n the length of the

fence, being careful not to apply so much that it puddles or runs

at the end of the fence. Take your time on this step.

Repeat for the remaining fences.

Step 14: Cockpit

Trim the edges of the cockpit area so that the rear tub sits do n

fully into the for ard fuselage (

photo 30

).

photo 30 – trim the sides of the cockpit area such that the tubs drop in place

Repeat for the for ard tub. Make sure both tubs clear any

electronic gear sitting on the component boards.

At this point, you may ish to paint the tubs, rear instrument

panel and glare shield ith flat black paint.

Position the rear tub over the canopy frame and trim the back

panel to a size just slightly smaller than the rear of the canopy

(

photo 31

).

Trial fit the rear tub into the canopy. You may need to trim the

lo er cross member of the canopy slightly to move the tub fully

aft. When satisfied, attach the tub to the canopy frame ith

several dots of Zap-a-Dap-a-Goo. When orking ith this glue,

make sure not to get any “threads” of glue on the canopy itself.

17

photo 31- use the cockpit as a template to trim the back of the aft tub to shape

Attach the rear instrument panel to the tub in the same fashion

(

photo 32

).

photo 32 – glue the rear tub and instrument panel into the cockpit frame

Carefully fit the front tub into place, trimming as necessary.

Glue into place ith Zap-a-Dap-a-Goo (

photo 33

). Recheck the

fit of the canopy into the for ard fuse before the glue fully dries.

photo 33 – front tub glued in place on top of canopy rails

While the for ard glare shield may be permanently glued in

place, taping from inside ill allo for easier access to batteries

and nose gear for maintenance. Duct tape orks ell for this

application.

Step 15: R dio Progr mming

Complete the installation of your radio gear and batteries. In

the prototype, the s itches ere mounted in the rear hatch area

so as to be able to leave the cockpit in place for routine

servicing. Batteries ere mounted to the nose gear former.

Set your radio for the follo ing thro s:

Ailerons: 20 mm in either direction

Elevators: 30 mm in either direction

Rudder: max thro allo able

Flaps: 15 degrees takeoff, 40-45 degrees landing

1

Step 16: Weight nd B l nce

Test fuel the aircraft. Check for leaks, then drain.

Set your CG. For the initial flights, the plane should balance

slightly nose do n ith the CG on the ing spar, fuel in the UAT

only, ith the gear do n.

Adjust CG as necessary.

Step 17: Test Flight

Before any test flight, make sure all systems are fully tested on

the ground and there are no kno n problems.

Try to conduct test flights under ideal eather conditions, at a

flying facility that offers plenty of “outs” in case of problems.

During the first flight, spend the majority of time on slo flight

and approaches. Your primary goal in the first fe flights is to

get a good feel for thro s, CG and most importantly, the landing

characteristics of the aircraft.

This is a heavy aircraft, so make sure to carry sufficient po er to

touchdo n to avoid ear and tear on the airframe.

Equipment Inst ll tion Photos

Equipment, including fueling tubes, s itches, air fill, air gauges and

remote ECU board ere all installed in the aft hatch area so as to be

accessible ithout removing the canopy. Also, the iring for the

ECU and for the servos ere run do n opposite sides of the fuselage

to avoid interference. The receiver as mounted to the fuse side

just to the left of the fuel tanks. This is a good location for both

conventional receivers and 2.4 GHZ units, due to the central

location, high mounting point and absence of carbon fiber in the

area. If you are using multiple 2.4 receivers, this general location

allo s for additional units both fore and aft. The positioning also

allo s for the shortest run of extension ires.

Receiver and ECU batteries ere located on either side of the nose

gear former, secured ith Velcro straps glued or scre ed to the ply

mounts.

Photos 34-37 sho some of the installation details.

Photos 34 and 35 – right side – air systems and remote ECU board

19

Photos 36 and 37 – left side – receiver batteries, s itches and air gauges

P rts List

• For ard Fuselage and Component Boards

• Aft Fuselage

• Engine Hatch

• Canopy

• Horizontal Stabs, Elevators (2)

• Carbon Fiber Spars for Horizontal Stabs (2)

• Vertical Fin, Rudder

• Wings, Flaps, Ailerons (2)

• Wing Tip Tanks (2)

• Main Spar Tube

• Main Landing Gear (2)

• Nose Gear ith Integrated Steering Bracket

• Kevlar Saddle Tanks (2)

• Main Center Tank

• Fiberglass Intake Extension

• Front and Rear Cockpit Tubs, Rear Instrument Panel

• Glare Shield

• Dual Wall Exhaust Pipe ith Mounting Tabs

• Upper and Lo er Bypass

• Large Wing Fences (2)

• Small Wing Fences (4)

• Linkage Assemblies (7)

• Air Support Kit

• Hard are Kit

Table of contents

Other Fei Bao Toy manuals

Fei Bao

Fei Bao L-39 User manual

Fei Bao

Fei Bao F-4 Phantom II User manual

Fei Bao

Fei Bao EF2000 User manual

Fei Bao

Fei Bao hawker hunter User manual

Fei Bao

Fei Bao Mirage 2000 User manual

Fei Bao

Fei Bao MiG-21 Fishbed User manual

Fei Bao

Fei Bao F-9F Panther User manual

Fei Bao

Fei Bao Mirage F1 User manual

Fei Bao

Fei Bao SU-27 User manual

Fei Bao

Fei Bao T45 User manual

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price R7879 instruction sheet

Rail King

Rail King Camelback 4-6-0 operating instructions

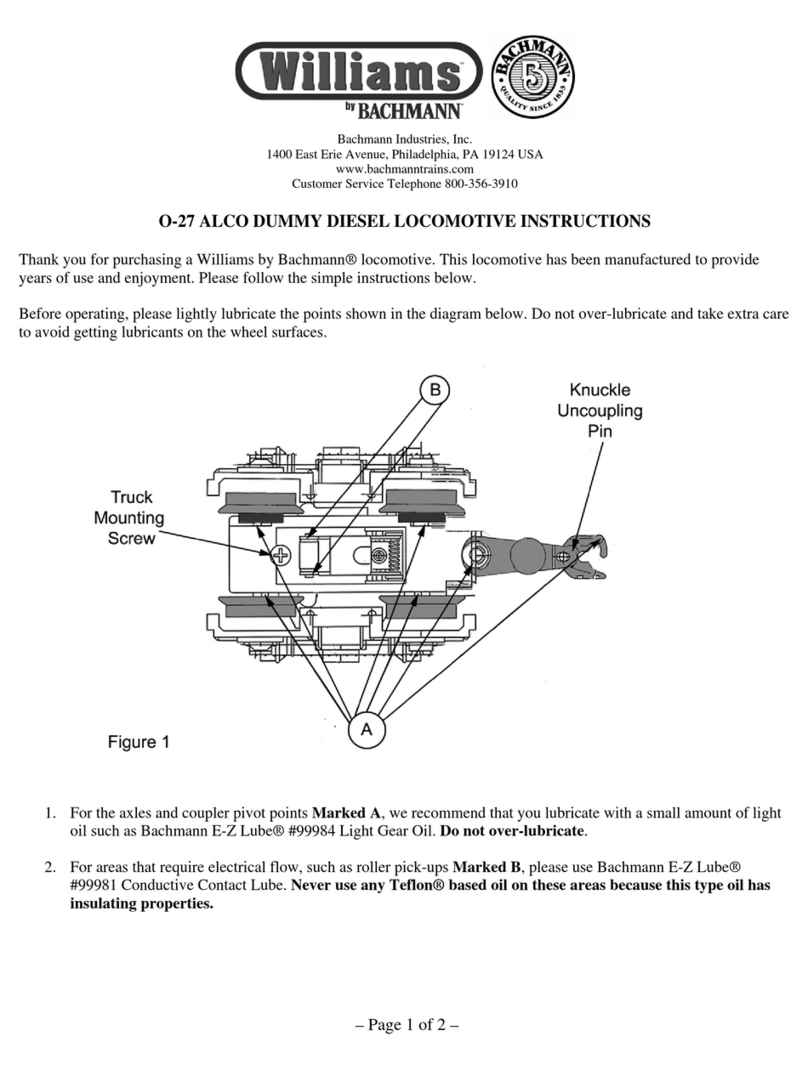

Bachmann

Bachmann Williams O-27 ALCO DUMMY instructions

Italeri

Italeri 3951 manual

REVELL

REVELL F-14D Super Tomcat Assembly manual

Black Horce Model

Black Horce Model FIESELER FI156C STORCH - EP Instruction manual book