Fei Bao MiG-21 Fishbed User manual

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 1 of 24

Fei Bao Jets

(Photos by Joseph Balabon)

1/5.5 Scale Mig-21 Fishbed (J)

Specifications:

Length: 98-1/2” (2500 mm)

Wingspan: 55-1/4” (1400 mm)

Weight: 24lbs (10.9 Kg) empty

Thrust Class: 20 – 28 lbs (9 – 12 Kg)

Radio: Minimum 7 channels

Written by Jim McEwen

In collaboration with RC Jet Models

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 2 of 24

DISCLAIMER

THIS IS NOT A TOY. This is a high-performance miniature aircraft, capable of high speeds and

damage to life, limb, and property. The manufacturer and its distributors cannot control how

you assemble this model, what equipment you use to fit it out, or how you fly it, and can assume

no liability whatsoever for any damages that may occur when you fly your aircraft. By

assembling this model, you are agreeing to indemnify and hold blameless the manufacturer

and/or his agents from any and all torts and liability associated with the use of this product.

Please inspect all parts before beginning assembly. If any parts appear to be suspect, contact

your dealer or the manufacturer for repair or replacement BEFORE you begin. Once you have

assembled the aircraft, you are the pilot in command and assume any and all responsibility for

the use of the model and any damages that might occur by flying or attempting to fly this

aircraft.

R/C model jets require a high level of skill in both their assembly and their flying. If you do not

feel confident in either your building or flying skills, PLEASE seek assistance from more

experienced modelers. It is a wise idea, no matter what level of skills you possess, to have a

second experienced modeler go over your installation after assembly. A second set of eyes

may spot a problem you have missed. If you have not flown a model like this before, it is

HIGHLY recommended that you get an experienced turbine pilot to do your maiden flight. Very

often, the first few seconds of a maiden flight are critical until the aircraft is trimmed out, and

having an experienced pilot at the controls can make the difference between a wrecked aircraft

and once that enjoys many hundreds of flights. Be sure to select a suitable field for flying ...

take the time to find a large paved runway if at all possible, especially for test flights, until you

feel comfortable getting the aircraft in and out of smaller grass fields.

BEFORE YOU BEGIN

Keep this in mind as you proceed. Look at EVERY assembly step you finish and ask yourself:

“Is this going to crash my airplane?”

A chain is only as strong as its weakest link, and this is a high-performance aircraft that will be

very intolerant of sloppy assembly techniques. Even the smallest component is important and

can cause the loss of your airplane, so take the time to do things right, or redo them if they are

wrong. Careful work will result in a long-lasting plane that gives you years of pleasure, one

loose component could result in the complete loss of the aircraft and all the components inside

it, and someone can even get hurt. So pause every once in a while when building it and

double-check your workmanship.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 3 of 24

A. Introduction

You have chosen a model that represents the pinnacle of ARF technology. While there is not a

lot of building to do, there is enough to keep you busy for a few evenings. Even if you have

assembled maybe other ARF jets, we highly recommend following our assembly sequence and

procedures anyway. Chances are it will save you a lot of time, prevent you from running down

dead ends, and perhaps remind you of a few small things that might end up saving your aircraft.

We have tried to arrange a construction sequence that will allow you to keep moving forward,

rather than standing around waiting for glue to dry before you can proceed to the next step.

Just because the model is almost completely built does not mean you can rush through the final

assembly.

You need to employ fine craftsmanship every step of the way, turbine models are critical. Keep

this in mind with everything you do, every part you install, look at the work you just did, evaluate

it critically, and ask yourself "is this going to potentially crash my airplane?" If there is any doubt

about the work you have done, back up, and re-do it properly.

B. Adhesives

The correct adhesive to use for all procedures is Loctite Hysol 9462. This is a very strong white

epoxy that is thixotropic. "Thixotropic" means it does not run at all, but stays only where you put

it. It is infinitely superior to regular epoxy, even slow-setting epoxy, for our purposes, because

of this characteristic. Regular epoxy will run downhill with gravity as it dries, taking it away from

where it is supposed to be. A good example is in the hinges ... using regular epoxy, a good

portion of the glue will migrate down away from the hinge into the inside of the wing as it dries,

and you won't even know it is happening. Hysol stays where you put it. The downside of Hysol

is it takes overnight to dry properly, but we have tried to arrange things to keep you busy while

waiting for glue to dry. We also highly recommend that you only use a proper Hysol dispensing

gun, and only the long-type mixing nozzles. The short nozzles do not sufficiently mix this glue,

and only a thin nozzle and gun will let you fill the hinge and control horn holes properly with

glue; you can't do it mixing your Hysol on a flat surface and trying to get the glue in the proper

place by a brush or stick. You can buy a complete Hysol setup with a gun, nozzles, and two

cartridges of glue from your dealer for approximately $60. Consider it a great investment, the

glue is the best you will use. One cartridge is plenty to assemble your MiG-21 Fishbed.

C. Using Pneumatic Systems

The Fei Bao MiG-21 Fishbed uses pneumatic brakes and retracts. If you follow a few tips, you

should have very reliable, leak-free operation. Neatness counts. All airlines should be secured

to the airframe to keep them from flopping around or getting kinked. Use tie wraps for this. The

other very important thing is to cut off the end of each airline dead square before installing it on

the nipple. This is VITAL. You can either purchase a professional tubing cutter from your

dealer (they are approximately $10), or you can make up a little jig to hold the airline and keep

a sharp, new razor blade perfectly upright as you cut. Either one works, just ensure that all

ends of all airlines are cut off dead square. Make sure all airlines are pushed ALL THE WAY

onto their nipples. They should not need to be secured otherwise, but you can add fine wire

safety wraps if you like. Make sure all left and right matching airlines are the same length,

particularly the brake lines, or you will get uneven retraction or braking action. It's worth taking

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 4 of 24

the time to get everything pneumatic right the first time, as having your landing gear fail to

retract is not THAT bad, but having it fail to deploy can really ruin you day and the paint on the

bottom of your model.

D. Additional Items Required

While the kit is comprehensive, there are additional parts required as follows:

Flight Controls Recommended Servo List

Ailerons (2): JR 3421

Elevator (2): JR 8611

Rudder (1): JR DS3301, DS3421sa or equivalent

Flaps (2): JR8611

NWS (1): JR 8611 or equivalent size and appropriate torque.

Matchbox (2) – elevators & flaps as required depending on transmitter/receiver selection.

Pneumatic Systems

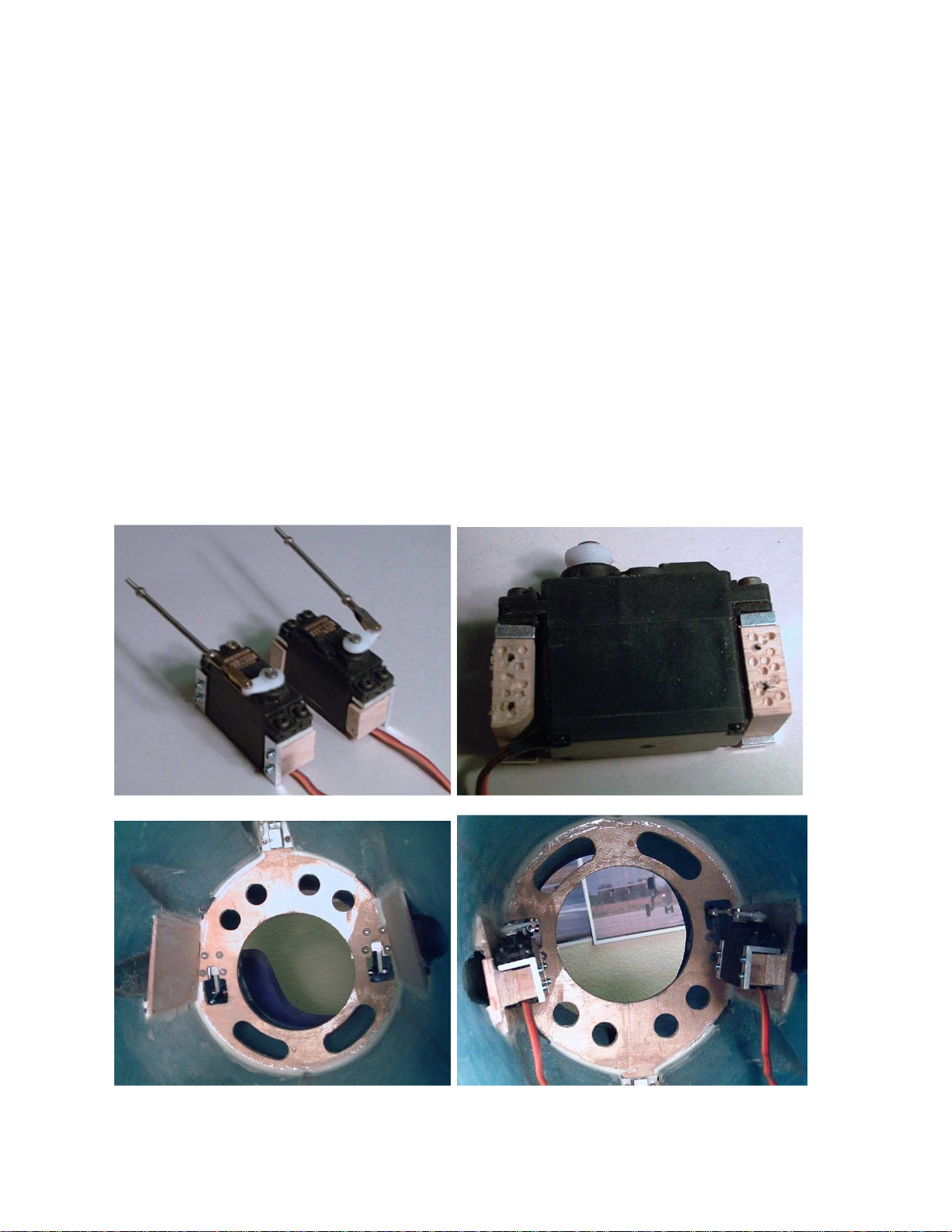

The air kit comes with a servo driven spool valve for the retracts, air brakes, and wheel brakes

but there are many “aftermarket” components available which can be used for these functions.

Several possible solutions are listed below. The individual builder may choose one of these

solutions or provide their own solution based on their experiences and preferences.

Retracts/Gear Doors

Solution #1

Retracts: Provided spool valve & JR 341 servo or equivalent

Gear doors: Pushbutton valve such as BVM #5753 Air Micro Switch

Solution #2

Retracts: Provided spool valve & JR 341 servo or equivalent

Gear doors: Provided spool valve & JR 341 servo or equivalent

Electronic sequencer

Solution #3

Ultra Precision UP-3 valve & JR 341 servo or equivalent

Solution #4

Retracts: Jet-Tronics Dual Action electronic pneumatic valve

Gear doors: Jet-Tronics Dual Action electronic pneumatic valve

Electronic sequencer

Wheel Brakes

Solution #1

Provided spool valve & JR 341 servo or equivalent (non-proportional brakes)

Solution #2

Proportional brake valve (Ultra Precision UP-6 or BVM Smooth-Stop) & JR341 servo or

equivalent

Solution #3

Jet-Tronics Low Loss electronic brake valve

Airbrakes

Solution #1

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 5 of 24

Provided spool valve & JR 341 servo or equivalent

Solution #2

Jet-Tronics Dual Action electronic pneumatic valve

Other Pneumatic Components

Many builders prefer to install pressure gauges in the retract and brake systems to easily

monitor system pressure. Dual fill valves may be installed to maintain isolation between these

two systems.

Other Parts

Ultimate Air Trap (UAT)

Fuel tank vent fitting

Manual fuel shutoff valve

Safety wire

Blue thread-locker

Glues: cyanoacrylate (CA) glue (thin, medium, and thick), Loctite Hysol, Zap-a-Dap-a-Goo

Batteries (Receiver and ECU)

Regulator and switch

Servo extensions (length may vary, depending on receiver placement)

Control linkage hardware as preferred by the builder

Additional Required Tools

X-Acto knife, #11 blades

Acetone/alcohol swabs

Felt-tip marker

Pencil

Ruler (metric and imperial)

Drill

Drill bits

Pin Vice

Sandpaper (course and fine grades)

Pliers

Side cutters

Double-sided tape

Jewelers files (various shapes)

Thread locker (blue)

Dremel tool and assorted bits

Phillips screwdriver

Various balsa and hardwood stock (servo rails)

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 6 of 24

Rudder Servo Installation and Rudder

Plywood mounts for the rudder servo have been pre-installed in the fin. A mid-mount style servo

such as the JR DS3301 can be screwed directly to the plywood. A couple of strips of ply or

hardwood should be glued to the back side of the ply mounts to increase the thickness and give

the servo screws bit more grip.

A JR DS3421sa servo which has a bit more torque can also be used. This servo only has

traditional mounts molded into the servo case and will require that the plywood mounts in the fin

be cut/ground back and hardwood blocks glued in place (contacting the fin skin, ply mounts, and

then reinforced with balsa angles). The servo is mounted to aluminum or carbon fiber

reinforced plastic angles which are, in turn, screwed to the hardwood blocks in the fin.

The servo lead routes out to the fin root without the need for a short extension.

Control Horn - A slot has been precut in the rudder to receive the control horn. The horn itself

needs to be trimmed slightly at the front so that the clevis hole aligns with the hinge line. The

photo below shows the trimmed rudder horn and a "stock" horn. The horn is roughened up with

a Perma-Grit file and Hysol'd in place. An alcohol swab is used to clean any residual Hysol from

the area.

Hinges - Three "point" style hinges are pre-glued into the rudder with the matching holes pre-

drilled in the fin. Apply a drop of light oil should be applied to the hinge pin to prevent glue from

jamming the hinge. Apply Hysol to the barbed portion of the hinge and install the rudder into the

fin. Do not push the rudder too far into the fin but ensure that the rudder can freely move to the

recommended travel limits.

Linkage - The kit includes linkages (rods with 4-40 threads, jam nuts, a threaded clevis at one

end, and a blue anodized aluminum rod end at the other) but the builder may choose to use

other linkage components based on their own preferences. Final adjustment of the pushrod,

centering the rudder, and installation of the servo cover will be done when setting up the control

throws.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 7 of 24

Nose Wheel Steering Servo Installation

Using 3mm bolts and blue Loctite, install the NWS servo mounts into the plated steel frame

attached to the nose gear strut. Adjust the NWS pushrods to the correct length to engage the

servo arm and connect the NWS pushrods to the servo.

Flap Servo and Control Horn Installation

The plywood mounts for the flap servos are also preinstalled. The servos are mounted to the

supplied CF angles which are pre-drilled to accept the 3mm supplied mounting screws. This

assembly is then positioned in the servo cutout, 1/16" pilot holes drilled in the plywood mounts,

and the assembly is screwed down.

The flap control horn needed to be modified by grinding it away slightly at the front (see rudder

control horn section) such that it fit properly in its precut slot. Be sure to sand the sides of the

horn before Hysol'ing it into place.

Connect the flap control horn to the servo arm using the provided hardware or the builder’s

preferred hardware. Final adjustment of the pushrod, centering the flap, and installation of the

servo cover will be done when setting up the control throws.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 8 of 24

Aileron Servo and Control Horn Installation

Like the rudder servo, the aileron servo plywood mounts are set up for a mid-mount style servo

(eg JR DS3301) which can be quickly and easily screwed directly to the plywood. A couple of

strips of ply or hardwood should be glued to the back side of the ply mounts to increase the

thickness and give the servo screws a bit more grip.

A JR DS3421sa servo which has a bit more torque can also be used but will require the servo

cutout to be modified to accept the servo mounts. Trim the pre-installed ply mounts, glue two

pieces of 3/16" plywood (1-1/4" x 3/4" ) to the inside surface of the lower wing skin, add some

hardwood blocks to support the new mounts and tie them to the pre-installed ply and the inner

surface of the upper wing skin. Trim the kit-supplied CF angles and drill new holes drilled to

match the servos. 1/16" pilot holes were drilled into the mounts and the angles screwed in

place. If the servo cover contact the head of the screws, countersink the holes in the CF angles

and substitute the stock screws with countersunk screws.

The control horn was trimmed at the front (like the rudder and flap horns) and Hysol'd in place.

Connect the aileron control horn to the servo arm using the provided hardware or the builder’s

preferred hardware. Final adjustment of the pushrod, centering the aileron, and installation of

the servo cover will be done when setting up the control throws.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 9 of 24

Fuel Tanks

Note: The fuel tanks may be purchased pre-plumbed by the factory. It is recommended that

you inspect the tanks to ensure that the clunk will pick up fuel regardless of the attitude of the

tank.

The saddle tanks are approximately 5" long x 7" high x 2" wide (at the widest point) and have a

capacity of 30 ounces each (60 ounces per pair). The length of the tank is less than the height

which makes it a bit of a challenge to plumb the clunk line to reach the bottom, back, and top of

the tank so that fuel flow would be maintained regardless of the attitude of the model when

flying.

The photos below show the fuel lines within the saddle tanks. The 5/32" brass tubing was

annealed using a blowtorch to allow it to be easily bent using a Dubro tube bender. Dubro fuel

line barbs were soldered to each end of the brass pieces. BVM #2804 Fuel Line was used to

connect the individual pieces of the clunk line since it maintains flexibility even when immersed

in kero for long periods. This fuel tubing will grow in length with exposure to kero so ensure that

there is you take this into account when plumbing the tanks. Tygon tubing was used as an

extension for the vent line since it tends to stiffen with long-term exposure to kero. All

connections are secured with safety wire.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 10 of 24

The 2" length of brass tubing helps to prevent the clunk line from falling forward also reduces

the clunk’s ability to reach the bottom and top of the tank. A slight bend (approx 10 degrees) in

the brass tubing at the stopper as shown in the photo below will bias the line allowing the clunk

to reach the bottom of the tank.

The bend prevents the clunk from reaching the last 4 oz of fuel in each saddle tank when the

plane is inverted. This is not an issue since the saddle tanks feed the main tank. If the model is

rolled inverted when the saddle tanks are almost empty, fuel will be supplied from the main tank.

Once the model is returned upright, any fuel left in the saddle tanks will immediately be drawn

into the main tank.

Tip: Mark the exterior of the tank with an F (fuel) or V (vent) to help prevent connection errors

when installing the fuel lines to the tanks.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 11 of 24

The main fuel tank has a capacity of approximately 60oz and is long and narrow so the internal

plumbing arrangement is more typical. A length of brass tubing in the clunk line (similar to the

2” length of tubing used in the saddle tanks) will help prevent the clunk from falling to forward in

the tank and will also limit the amount that the clunk line grows in length.

The forward face of the main tank, when installed in the model is quite close to the rear face of

the cockpit. As such, a 90 degree bend in the fuel and vent lines prevents any interference

between the lines and the cockpit.

Fuel Tank Installation

The saddle tanks fit between two bulkheads installed in the fuselage with the stopper fitting in

the slot in the forward bulkhead. Use a Dremel tool to widen/lengthen the slot as necessary to

fine-tune the fit of the tanks. There should be approximately ½” gap between the tanks at the

base. Velcro straps through the slot in the forward bulkhead and the hole in the rear bulkhead

can be used to hold the tanks in position. A piece of scrap balsa should be installed between

the rear of the saddle tanks and the rear bulkhead to prevent the tanks from chaffing against the

ends of the bolts for the wing mounting brackets.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 12 of 24

The main fuel tank is supported at the rear by the saddle tanks. A front support can be made

from 1/8” plywood screwed to hardwood blocks Hysol’d to the fuselage. Sticky-backed Velcro

can be used to secure the tank from moving forward/aft.

Horizontal Stabs – Fitting

Trial fit the H-stabs by sliding the axle into trunnion bearing blocks which are pre-installed on a

fuselage former. The axles have a notch for alignment with the control horn. The stab root

chord has a "Z-bend" which fits into a matching notch in the fuselage. This scale notch makes

the H-stab install a bit more of a challenge to install than a stab with a straight root chord if you

want to minimize the gap between the stab and the fuselage yet allow the stab to rotate through

the required travel.

Due to manufacturing tolerances installing the axle in the stab and the bulkhead in the fuselage,

the stab root chord may not perfectly match the fuselage.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 13 of 24

Portions of the root chord may be sanded down or build up using spot putty, as required, to

adjust the H-stab root contour such that it matches the fuselage. This will allow the stabs to be

installed with only a 1/32” gap between the stab and the fuselage which will enhance the look of

your model. Use touchup paint to blend any spot putty visible.

Cut away the vertical face of the notch at the fuselage root as shown below to allow the H-stab

to rotate. This area is covered by the stab so it's not visible when the stabs are at neutral.

Horizontal Stabs - Servo/Pushrod Install

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 14 of 24

The H-stab servos are mounted on plywood plates that are pre-installed in the fuselage.

Roughen the surface of the plates with some course grit sandpaper. Use angle brackets and

hardwood blocks as servo mounts as well as the clevis and pushrods that come with the kit to

make a servo "sub-assembly" on the workbench. A series of little holes were randomly drilled in

the back face of the hardwood blocks which will be glued to the ply plates in the fuselage. The

FB blue anodized rod ends were then attached to the control horns and locknuts installed.

Place the servo sub-assembly into the rear fuselage and attached the rod ends to the stab

control horns. Use tape to lock the H-stabs at neutral to give the required fore/aft position of the

servo sub-assembly on the plywood plate. Position the servo sub-assembly such that the

control rod is horizontal. Place a strip of 1/4" square balsa against the servo and tack-glued it to

the plywood plate. The strip serves as a jig to quickly locate the servo when gluing the mounting

blocks in place. Check to ensure the left and right stab servo positions matched, and glue the

hardwood blocks to the plates using super thick CA. Remove the servos and reinforce the glue

joints between the hardwood blocks and the plywood using fillets of Hysol and 3/4" balsa

triangle stock.

Grind the edges of the H-stab trunnion blocks as necessary to match the curvature of the

opening in the bulkhead for the exhaust duct.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 15 of 24

Inlet Duct Modification

While the model is equipped with full inlet ducting and a bypass, the builder may choose to

eliminate the inlet duct to simplify access to the internal components to facilitate any

maintenance. The split portion of the duct can be cut off approx 1” behind the forward former

for the nose gear unit.

Pneumatic Tubing Install - Retracts/Gear Doors/Speed Brakes

While this model is 98" long, the fuselage is only 7-1/2" wide and 8-1/2" high and the hatch for

the engine compartment is only 5" wide and 12" fortunately, the main gear doors and speed

brakes provide a bit more access but there isn't a lot of room to work and a long pair of surgical

hemostats (clamp) makes things a lot easier. Tidi-Strips are invaluable in making a clean

installation. Jets N Stuff Airline Safeties save a lot of time over using safety wire.

Safety wiring the pneumatic lines to the nose gear door cylinders is very difficult due to limited

access through the gear door opening. Airline Safeties are much easier to use in tight areas and

a puller tool (made by putting a 90 degree bend in a Dubro Ball Link Release Tool and gluing it

to a strip of hardwood) made it easy to pull the Safety over the fitting.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 16 of 24

There are many possible layouts/routing for the air lines. One possibility is shown in the photos

below but it is up to the builder to determine what works best for them and their choice and

location of the valves. Two pieces of plywood can be installed between the forward air brakes

to create a trough that will assist in retaining the bundle of air lines between the speed brakes.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 17 of 24

Servo Wire Routing

H-Stab and rudder servo wires in the rear fuselage should be protected from heat generated.

Metal tape and/or a ceramic blanket can be used to insulate the wires from heat.

The aileron and flap servo wires are routed from the cutout in the wing root forward over the

cutout for the gear strut. This area can become easily congested as several pneumatic lines

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 18 of 24

route through this area. Ensure that the air lines and servo wires are routed such that they are

not chaffed by the main wheels when the landing gear is retracted.

Bypass and Turbine Installation

The builder may opt to install a full bypass, or no bypass with a bell mouth to smooth airflow into

the exhaust duct. Many modelers forgo a full bypass in the interests of simplicity. A lower

bypass installation (as pictured below) has the advantage of providing some FOD protection,

blending the airflow into the exhaust duct, yet allows for easy access to the turbine without the

need to remove the top cover. The bypass installation is simplified if you perform it prior to

bolting on the rear fuselage.

Install a 1” wide x 3/8" thick piece of plywood to the top of the turbine mounting rails to center

the bypass in the fuselage. An additional 3/8” plywood spacer over the bypass flange is

required to center a JetCat P-120 turbine in the bypass since the flanges on JetCat mounting

straps are above the turbine centerline. Mount the turbine using screws or bolts and blind nuts.

Fuselage Joining/Exhaust Duct Installation

Remove the turbine and lower bypass and join the front and rear fuselage using the provided

bolts/washers. Test fit the double walled exhaust duct in the rear fuselage. The outer diameter

tapers slightly and the pipe should be installed such that the rear of the duct is approximately

5/8” forward of the fiberglass tailpipe to preserve the scale look of the plane. Use a Dremel tool

with a sanding drum to adjust the size of the duct cutout in the fuselage former as required.

Reinstall the lower bypass.

The forward end of the exhaust duct should extend approximately 3/8” inside the bypass. Mark

and cutoff the inner duct as required. Cut off the forward end of the outer duct approximately ½”

aft of the inner duct (not shown in photo below). This will allow cooling air from within the

fuselage to be drawn into the exhaust duct and then out of the model. Use high temperature

RTV silicon to fill any gap between the cutout in the bypass and the inner exhaust duct.

Two exhaust duct mounts are spot-welded to near the front of the exterior duct. Mark the

location where they intersect the fuselage bulkhead and bend each mount 90 degrees. Cut off

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 19 of 24

any extra material and drill a hole in the mount. Match drill a hole in the bulkhead and use

socket head screws to retain the exhaust duct.

Apply several couple of coats of BVM Heat Shield to the aft area of the bypass. The upper

portion of the bypass, if used, may be trimmed to suit the particular turbine installed and

retained with Velcro straps.

Fei Bao MiG-21 Fishbed Instruction Manual (Draft Rev 0) Page 20 of 24

Equipment Tray and Battery Mounting

The equipment tray layout is dependant upon the equipment selected and the builder’s

preferences. Many possibilities are possible with only one pictured below. Items to consider

when laying out your equipment tray and locating other components within the model are ease

of access to components for maintenance or adjustment, length of leads, routing of air lines and

servo wires, visibility, and effect on center of gravity.

Locate heavy components as required to assist in balancing the model on the required C.G.

location. In the model pictured, the ECU and receiver batteries were installed in the nose of the

model (forward of the nose gear door) using adhesive-backed Velcro and foam.

A 3/8” thick piece of hardwood was glued to the top of the rear former supporting the equipment

tray so that the installed tray would be approximately level.

Turbine Accessory Mounting

Location and mounting methods for the turbine accessories (ECU, solenoid valves, shutoff

valves, etc) will depend on the equipment selected, the builder preferences, ease of access,

and the available space. While this is a big model, the builder may run out of space quickly if

the layout and routings are not well planned. The installation of a JetCat P-120 is shown in the

photos below.

Table of contents

Other Fei Bao Toy manuals

Fei Bao

Fei Bao Mirage 2000 User manual

Fei Bao

Fei Bao T45 User manual

Fei Bao

Fei Bao F-9F Panther User manual

Fei Bao

Fei Bao MB-339 User manual

Fei Bao

Fei Bao hawker hunter User manual

Fei Bao

Fei Bao Velox User manual

Fei Bao

Fei Bao SU-27 User manual

Fei Bao

Fei Bao Velox XL User manual

Fei Bao

Fei Bao EF2000 User manual

Fei Bao

Fei Bao Mirage F1 User manual

Popular Toy manuals by other brands

Hasbro

Hasbro Playskool Play Favorites Lullaby Gloworm quick guide

Lansay

Lansay BLOpens fashion quick start guide

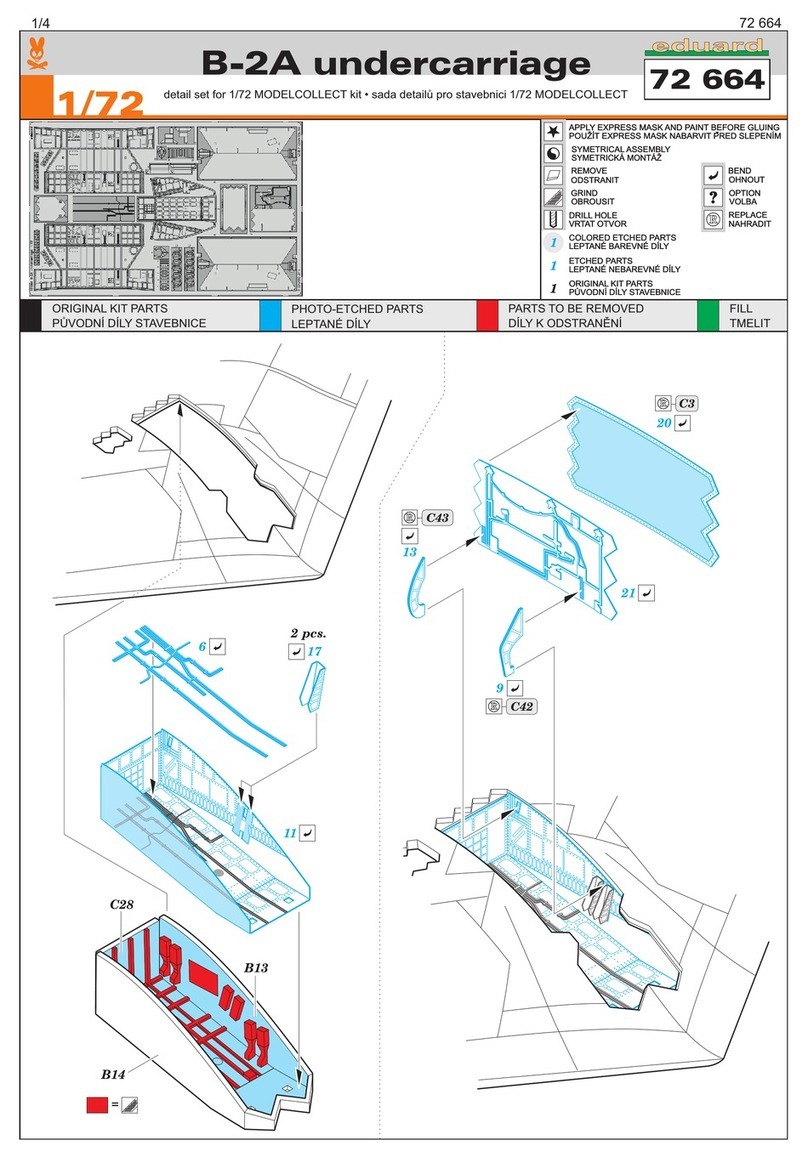

Eduard

Eduard B-2A undercarriage quick start guide

iKarus

iKarus ECO Piccolo V2 Assembly instructions

The Learning Journey

The Learning Journey Techno Gears Bionic Biplane instruction manual

Fisher-Price

Fisher-Price FYK60 instruction sheet