F E I B A O F - 9 F P A N T H E R

DISCLAIMER:

THIS IS NOT A TOY. This is a high-performance miniature aircraft, capable of high

speeds and damage to life, limb, and property. The manufacturer and its distributors cannot

control how you assemble this model, what equipment you use to fit it out, or how you fly it,

and can assume no liability whatsoever for any damages that may occur when you fly your

aircraft. By assembling this model, you are agreeing to indemnify and hold blameless the

manufacturer and/or his agents from any and all torts and liability associated with the use of

this product. Please inspect all parts before beginning assembly. If any parts appear to be

suspect, contact your dealer or the manufacturer for repair or replacement B FOR you

begin. Once you have assembled the aircraft, you are the pilot in command and assume any

and all responsibility for the use of the model and any damages that might occur by flying or

attempting to fly this aircraft.

R/C model jets require a high level of skill in both their assembly and their flying. If you do

not feel confident in either your building or flying skills, PL AS seek assistance from more

experienced modelers. It is a wise idea, no matter what level of skills you possess, to have a

second experienced modeler go over your installation after assembly. A second set of eyes

may spot a problem you have missed. If you have not flown a model like this before, it is

HIGHLY recommended that you get an experienced turbine pilot to do your maiden flight.

Very often, the first few seconds of a maiden flight are critical until the aircraft is trimmed

out, and having an experienced pilot at the controls can make the difference between a

wrecked aircraft and once that enjoys many hundreds of flights. Be sure to select a suitable

field for flying...take the time to find a large paved runway if at all possible, especially for test

flights, until you feel comfortable getting the aircraft in and out of smaller grass fields.

BEFORE YOU BEGIN:

Keep this in mind as you proceed:

Look at V RY assembly step you finish, and ask yourself:

"Is this going to crash my airplane?"

A chain is only as strong as its weakest link, and this is a high-performance aircraft that will

be very intolerant of sloppy assembly techniques. ven the smallest component is important

and can cause the loss of your airplane, so take the time to do things right. Or R do them if

they are wrong. Careful work will result in a long-lasting plane that gives you years of

pleasure, one loose component could result in the complete loss of the aircraft and all the

components inside it, and someone can even get hurt. So pause every once in a while when

building it and double-check your workmanship.

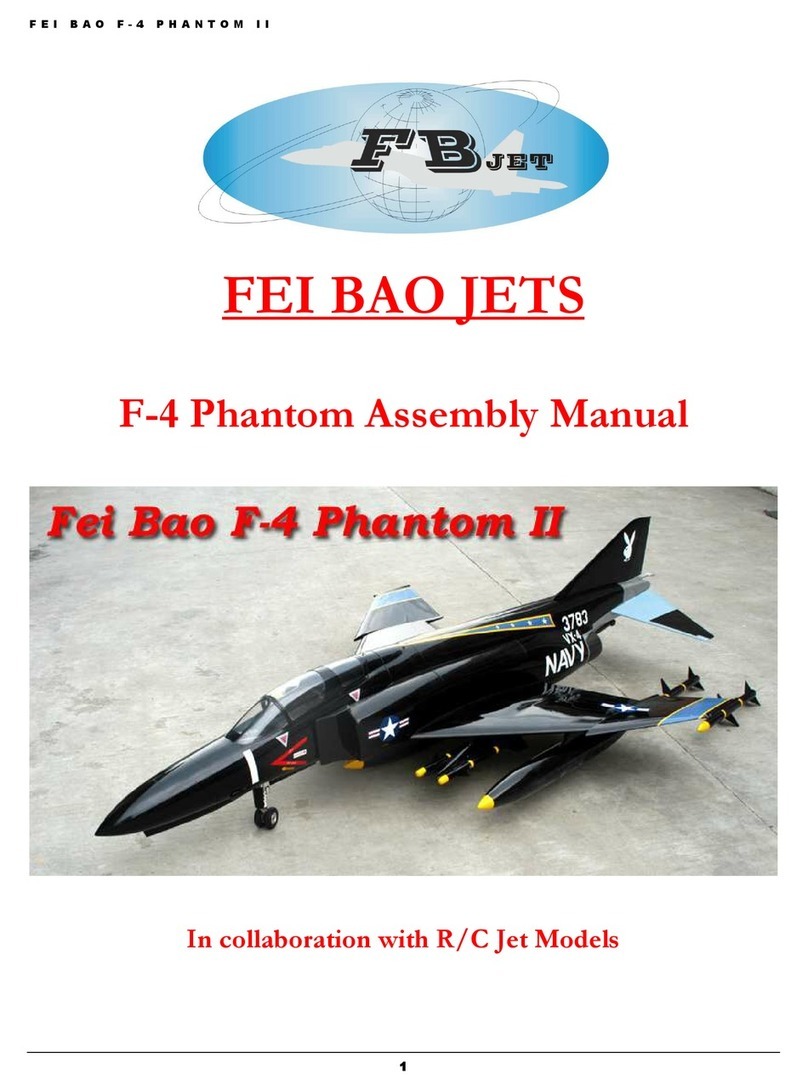

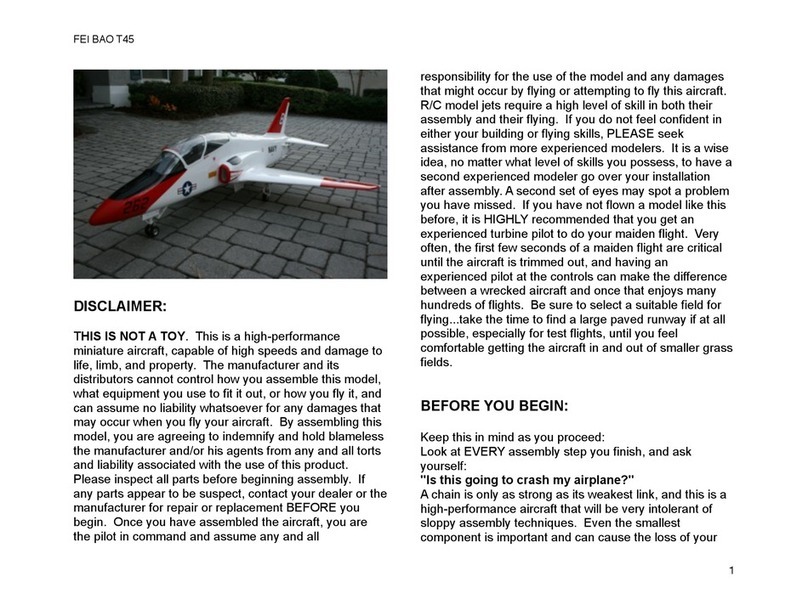

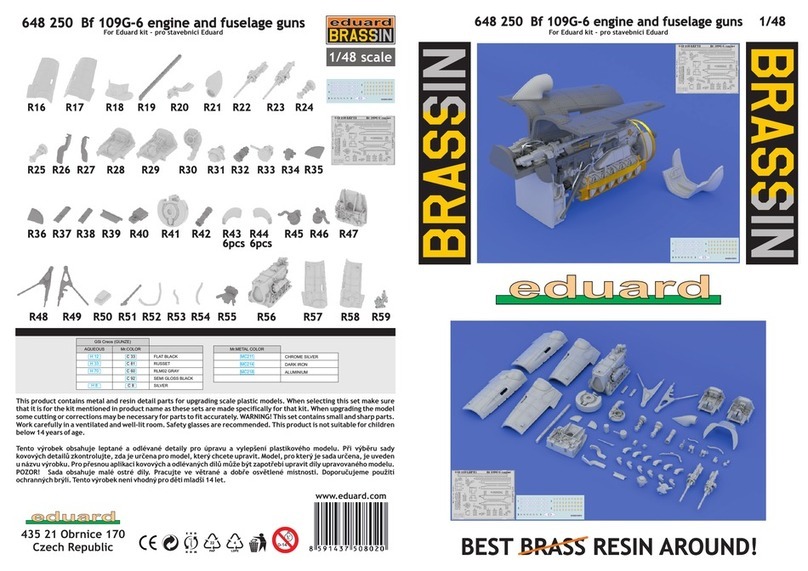

F9F as it comes from the factory ith combo and factory Installation

option:

Accessories included: