Fei Bao T45 User manual

DISCLAIMER:

THIS IS NOT A TOY. This is a high-performance

miniature aircraft, capable of high speeds and damage to

life, limb, and property. The manufacturer and its

distributors cannot control how you assemble this model,

what equipment you use to fit it out, or how you fly it, and

can assume no liability whatsoever for any damages that

may occur when you fly your aircraft. By assembling this

model, you are agreeing to indemnify and hold blameless

the manufacturer and/or his agents from any and all torts

and liability associated with the use of this product.

Please inspect all parts before beginning assembly. If

any parts appear to be suspect, contact your dealer or the

manufacturer for repair or replacement BEFORE you

begin. Once you have assembled the aircraft, you are

the pilot in command and assume any and all

responsibility for the use of the model and any damages

that might occur by flying or attempting to fly this aircraft.

R/C model jets require a high level of skill in both their

assembly and their flying. If you do not feel confident in

either your building or flying skills, PLEASE seek

assistance from more experienced modelers. It is a wise

idea, no matter what level of skills you possess, to have a

second experienced modeler go over your installation

after assembly. A second set of eyes may spot a problem

you have missed. If you have not flown a model like this

before, it is HIGHLY recommended that you get an

experienced turbine pilot to do your maiden flight. Very

often, the first few seconds of a maiden flight are critical

until the aircraft is trimmed out, and having an

experienced pilot at the controls can make the difference

between a wrecked aircraft and once that enjoys many

hundreds of flights. Be sure to select a suitable field for

flying...take the time to find a large paved runway if at all

possible, especially for test flights, until you feel

comfortable getting the aircraft in and out of smaller grass

fields.

BEFORE YOU BEGIN:

Keep this in mind as you proceed:

Look at EVERY assembly step you finish, and ask

yourself:

"Is this going to crash my airplane?"

A chain is only as strong as its weakest link, and this is a

high-performance aircraft that will be very intolerant of

sloppy assembly techniques. Even the smallest

component is important and can cause the loss of your

FEI BAO T45

1

airplane, so take the time to do things right. Or REdo

them if they are wrong. Careful work will result in a long-

lasting plane that gives you years of pleasure, one loose

component could result in the complete loss of the aircraft

and all the components inside it, and someone can even

get hurt. So pause every once in a while when building it

and double-check your workmanship.

A. Introduction:

You have chosen a model that represents the pinnacle of

ARF technology. While there is not a lot of building to do,

there is enough to keep you busy for a few evenings.

Even if you have assembled maybe other ARF jets, we

highly recommend following our assembly sequence and

procedures anyway.

Chances are it will save you a lot of time, prevent you

from running down dead ends, and perhaps remind you

of a few small things that might end up saving your

aircraft.

We have tried to arrange a construction sequence that

will allow you to keep moving forward, rather than

standing around waiting for glue to dry before you can

proceed to the next step.

Just because the model is almost completely built does

not mean you can rush through the final assembly.

You need to employ fine craftsmanship every step of the

way, turbine models are critical. Keep this in mind with

everything you do, every part you install...look at the work

you just did, evaluate it critically, and ask yourself "is this

going to potentially crash my airplane?" If there is any

doubt about the work you have done, back up, and re-do

it properly.

B. Adhesives:

The correct adhesive to use for all procedures is Loctite

Hysol 9462. This is a very strong white epoxy that is

thixotropic. "Thixotropic" means it does not run at all, but

stays only where you put it. It is infinitely superior to

regular epoxy, even slow-setting epoxy, for our purposes,

because of this characteristic.

Regular epoxy will run downhill with gravity as it dries,

taking it away from where it is supposed to be.

A good example is in the hinges...using regular epoxy, a

good portion of the glue will migrate down away from the

hinge into the inside of the wing as it dries, and you won't

even know it is happening. Hysol stays where you put it.

The downside of Hysol is it takes overnight to dry

properly, but we have tried to arrange things to keep you

busy while waiting for glue to dry.

We also highly recommend that you only use a proper

Hysol dispensing gun, and only the long-type mixing

nozzles.

The short nozzles do not mix this glue enough, and only a

thin nozzle and gun will let you fill the hinge and control

horn holes properly with glue, you can't do it mixing your

Hysol on a flat surface and trying to get the glue in the

proper place by a brush or stick.

You can buy a complete Hysol setup with a gun, nozzles,

and two cartridges of glue from your dealer for

approximately $60.

FEI BAO T45

2

Consider it a great investment, the glue is the best you

will use. One cartridge is plenty to assemble your T45.

C. WORKING WITH PNEUMATIC SYSTEMS:

The T45 uses pneumatic brakes and retracts. If you

follow a few tips, you should have very reliable, leak-free

operation. Neatness counts.

All airlines should be secured to the airframe to keep

them from flopping around or getting kinked. Use tie

wraps for this.

The other very important thing is to cut off the end of each

airline dead square before installing it on the nipple.

This is VITAL. You can either purchase a professional

tubing cutter from your dealer (they are approximately

$10), or you can make up a little jig to hold the airline and

keep a sharp, new razor blade perfectly upright as you

cut.

Either one works, just ensure that all ends of all airlines

are cut off dead square. Make sure all airlines are

pushed ALL THE WAY onto their nipples.

They should not need to be secured otherwise, but you

can add fine wire safety wraps if you like. Make sure all

left and right matching airlines are the same length,

particularly the brake lines, or you will get uneven

retraction or braking action.

It's worth taking the time to get everything pneumatic right

the first time, as having your landing gear fail to retract is

not THAT bad, but having it fail to deploy can really ruin

you day and the paint on the bottom of your model.

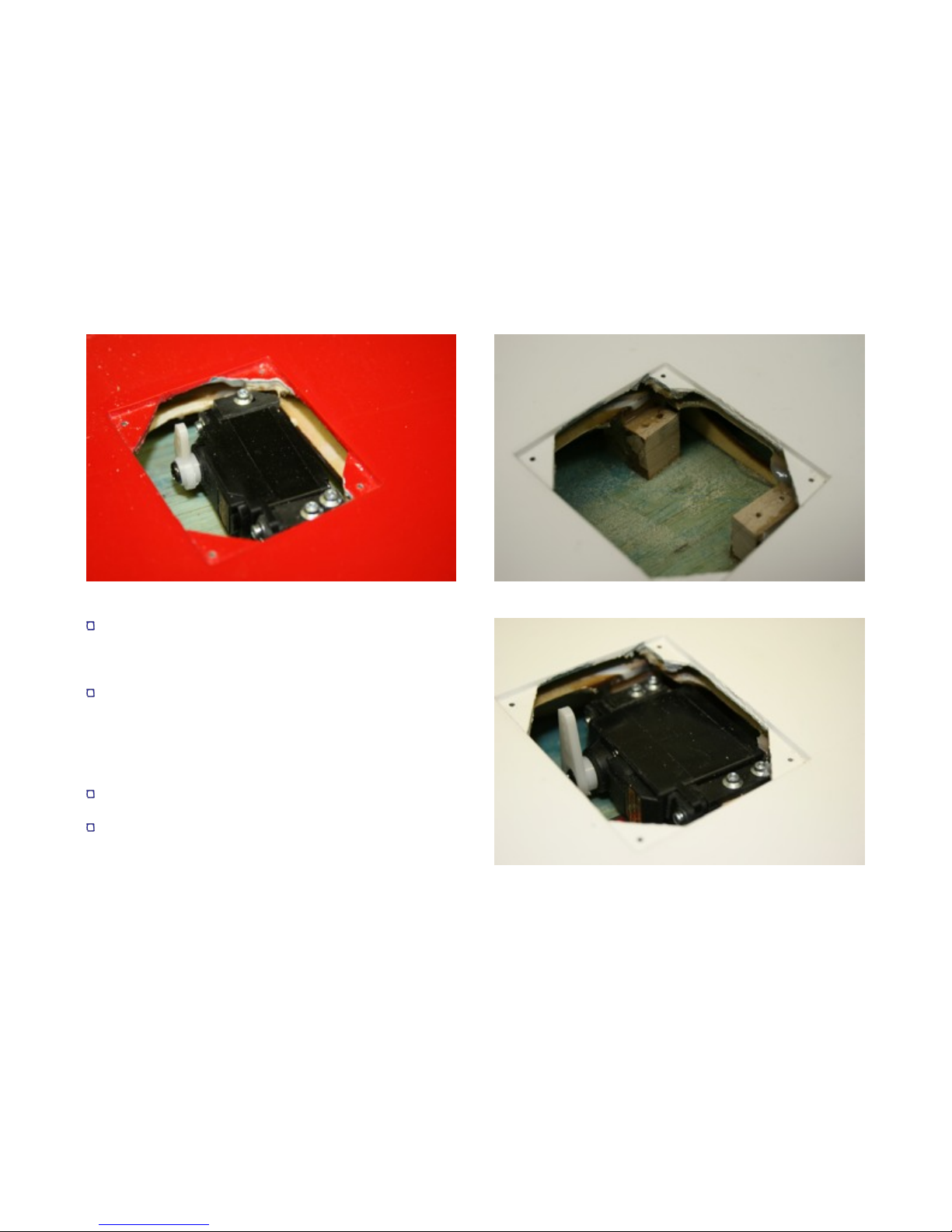

Sample Servo List:

Ailerons and Rudder: JR 3421 (3)

Flaps: JR 8611A (2)

Elevators: JR 8611A (2)

Nose Gear Steering: JR 8411

Air and Brake Systems: As necessary

Parts List:

•Forward Fuse with Component Boards and Nose Gear

•Aft Fuse

•Canopy

•Cockpit Tubs (2) and Glare Shield

•Main Upper Hatch

•Lower Aft Hatch

•Ventral Fin

•Tail Hook

•Wings, Main Gear, Ailerons and Flaps

•Wing Tube

•Aileron and Flap Covers (4)

•Vertical Stab and Rudder

•Horizontal Stab Strakes

•Wing Fences (2) (Not used on T45)

•Fuel Tanks (2)

•Bypass

•Pipe

•Air Kit

•Hardware Kit

FEI BAO T45

3

Construction

Carefully inspect all components. Check the security

of all bolts and nuts. Seal with a small amount of thin

CA for extra security. If any of the stab bearing plate

bolts are stripped, re-tap holes and replace with 6-32

cap head bolts. Reinforce bearing plate and stab

former with extra Aeropoxy. See photos

Join Fuselage Halves

Position front of fuselage to rear of fuselage. Loosely

secure in place with four XXX bolts and washers at

the aft attach points and two XX bolts and large

washers on the side attach points. Use Loctite.

Position top hatch in place and fit canopy. When

everything aligns, permanently tighten 6 bolts.

FEI BAO T45

4

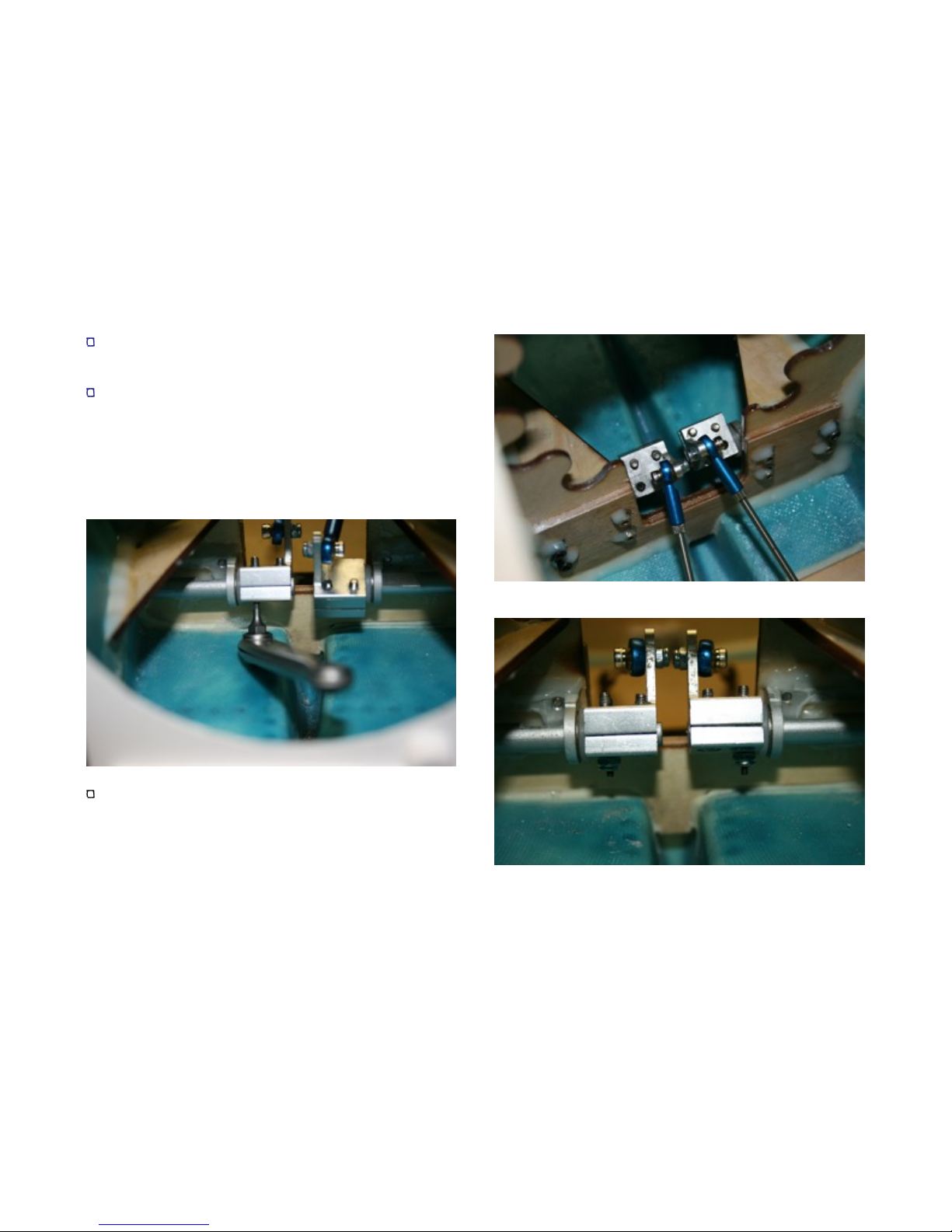

Horizontal Stabilizers

Remove lower hatch and set aside.

Slip one large and one thin nylon washer on the stab

spar and insert into bearing box. Check for at least

40mm throw as you move stab. Use the minimum

number of nylon washers to achieve clearance.

Tighten and loosen control horn bolts one time to ease

installation.

Option: you may choose to replace the FB clevis with

a heavy duty ball link (see pictures). If so, drill out the

middle hole on the control horn for the bolt that will

attach the titanium FB ball end to the horn now. Use

the wire size drill that is just large enough to insure the

bolt will fit with no play.

To tighten the horn bolts, you will need an allen

wrench, an allen bit (see photo) and patience!

FEI BAO T45

5

Slip a nylon washer over the end of the stab spar.

Loctite snugging bolts and tighten just enough that

control horn will barely slide over the stab spar.

Tighten bolts from underneath. Make absolutely sure

you push in on the stabs fully so there is no lateral

play. IMPORTANT: do not over-tighten or strip heads

on horn snugging bolts. If you need to remove in the

future use a small pencil torch to heat aluminum horn

blocks and loosen Loctite.

Option: For added security, chuck a #45 drill into a

dremel tool and machine a small hole down through

the horn block and stab spar. Insert a 1 inch 4-40 bolt

or equivalent and secure with self locking nut. See

photo for position of bolts.

FEI BAO T45

6

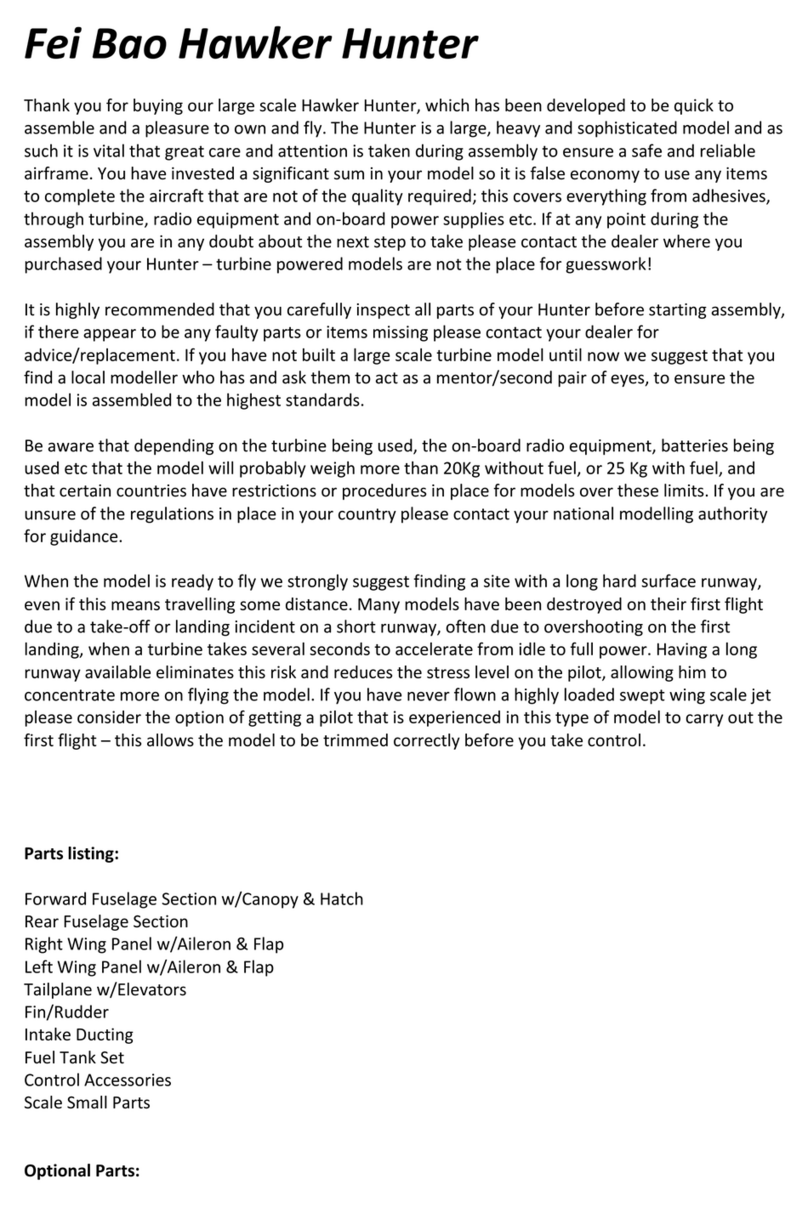

There are several ways to attach the twin stab servos

to the ply plate that is pre-installed in the fuse. FB

supplies wooden blocks with L brackets, you can buy

a commercial side mount, or make your own side

mount from ply. I elected to make my own out of ply.

Attach your servos (8611A used here) to a

matchmaker and attach heavy duty or metal arms

such that they are approximately mirror images of

each other.

Bolt servos to mounting bracket. Do not use the

rubber grommets, as you are looking for minimal

servo movement..

Make sure your linkages are equal in length.

Working one stab at a time, attach linkage to arm,

tape stab in neutral position, set servo arm at center

point (vertical) and mount to ply plate. Make sure

linkage is line up straight between servo and horn. In

the mounting method shown here, the servo brackets

were glued to the plate with 6 minute epoxy.

Repeat for the other stab, making sure the installation

mirrors the other side.

Aft Wiring Harness

Make up your aft wiring harness, You will need

extensions for both stab servos and a rudder servo,

plus air line for speed brake open and speed brake

closed. I use nylon wrap to better protect the wires

from heat in the aft section around the pipe.

Determine length based on the placement of your

equipment. I made the harness long enough to allow

the stabs and rudder servos to be plugged in at the aft

former to allow for easier maintenance in the future.

FEI BAO T45

7

Run the harness through the top holes of the two aft

formers and affix to the side former at the aft of the

engine compartment to insure the harness will stay

clear of the pipe.

Connect air lines to the speedbrake cylinders. I

recommend you check the cylinders as you attach the

air lines to make sure they do not leak. Make sure all

air lines stay completely clear of the pipe area, and do

not interfere with the operation of the speed brake

doors.

FEI BAO T45

8

Rudder and Lower Hatch

Apply Aeropoxy carefully into the hinge point holes in

the vertical stab trailing edge. Wipe away any excess.

Put a small amount on the hinge points installed in the

rudder and insert into hinge holes. Make sure you

have enough throw for the control horn slot to just

about reach the vertical stab. This will ensure full

rudder throw. Check to make sure you haven’t left

any fingerprints and set aside to dry.

Using a small carbide cutter in a Dremel tool, enlarge

the slot in the rudder for the control horn. It may also

need to be cut a little deeper for the horn to sit down

completely in the control surface. Be extra careful not

to cut through the control surface.

Drill the control horn using a wire size drill just large

enough to allow the link bolt to fit tightly. Paint the

horn white at this time.

Rough up the gluing surface of the horn with coarse

sandpaper. Mask the area around the horn slot with

tape, fill the slot with Aeropoxy and insert the horn.

Make a nice fillet and remove the tape. Let dry.

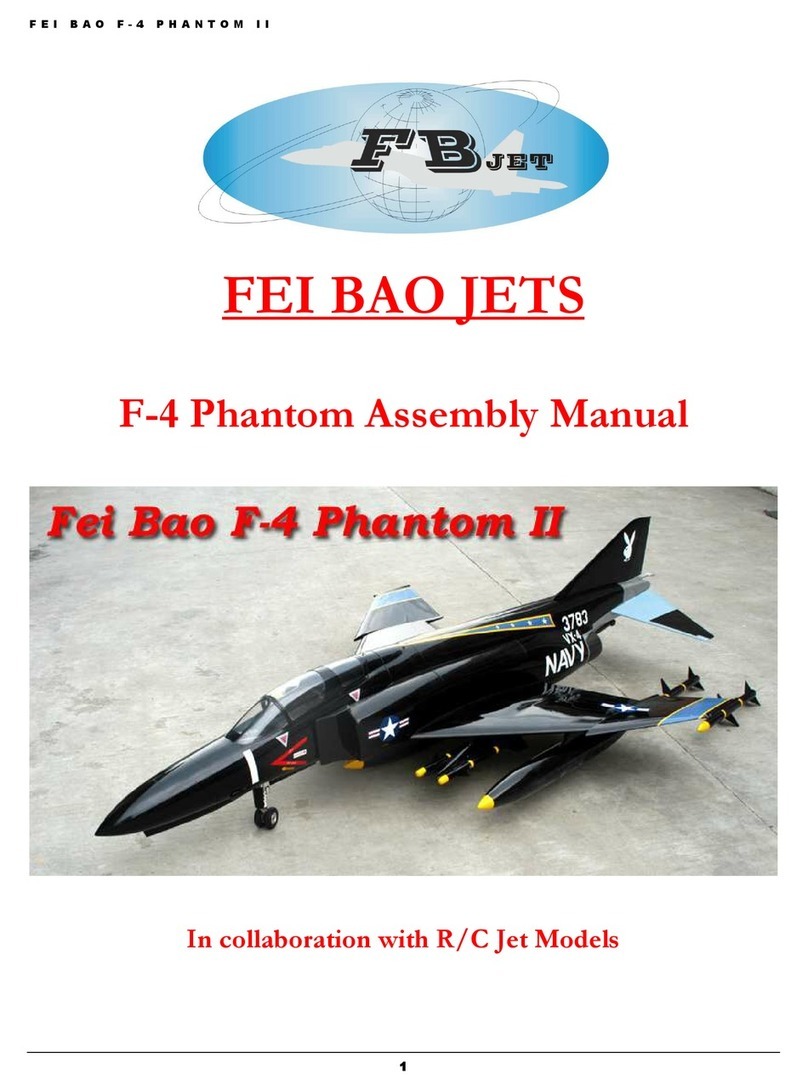

Mount the servo to wood blocks as shown, using the

aluminum mounts supplied with the kit or aftermarket

carbon fiber pieces as shown in the photo. Sand the

blocks such that they are even with the rear of the

servo, and that the servo sits as low as possible on a

flat surface.

Using a matchmaker or equivalent, find the neutral

point on the servo and attach a long single control arm

to the spindle.

FEI BAO T45

9

Make up the servo linkage. You will likely need to

remove the locking nuts and thread the links fully on

the rod to make it short enough. See photo.

It is important that the servo is positioned such that

the linkage is 90 degrees to the hinge line. You may

need to remove part of the mounting plate with a

cutter to allow positioning of the servo.

When you are satisfied, glue the blocks in place with

small amounts of 5 minute epoxy. Remove the servo,

and add Aeropoxy. It is important to glue the blocks to

the ply plates so the loads when the servo is actuated

are not transferred fully to the skin. See photo.

Remount servo. Note the heads may need to be

countersunk to allow the hatch to fit.

Cut a slot in the hatch cover, mount, and connect

linkage. Check for adequate throw.

Insert rudder into aft fuse. Tighten aft locking clamp.

FEI BAO T45

10

Using the large washer and cap head bolt, secure the

forward rudder spar. See photo.

Connect rudder servo to the harness and tape all

three connections. Secure wires such that they are

clear of the stab servos and will not drop into the

vicinity of the pipe when it is installed.

Locate aft ventral fin and trial fit the cap head bolt into

the pre-cut slot in the bottom of the fuse. Carefully

enlarge the slot if necessary to insure a tight slip fit.

Attach the ventral fin to the lower hatch with two cap

head screws and washers. If they don’t snug

securely, put a few drops of thin CA into the holes in

the ventral fins, allow to dry, and then reinsert the

bolts.

FEI BAO T45

11

Relieve the aft part of the ventral fin for the tail hook

end. See photo.

Paint the tail hook as shown.

Make a bumper block out of scrap wood and paint it

flat black.

Glue the tail hook and the bumper block in place.

Glue the bumper block to the fuse, but not to the hook.

Drill a couple of small holes in the area the bumper

block will be glued to the fuse to allow small “buttons”

of glue to strengthen the joint.

Drill a small hole through the tail hook into the bumper

block and attach with a long screw. Use thin CA to

harden the thread area in the block.

This completes the aft fuse construction. As an

option, after market vinyl graphics were applied to

dress up the rudder.

FEI BAO T45

12

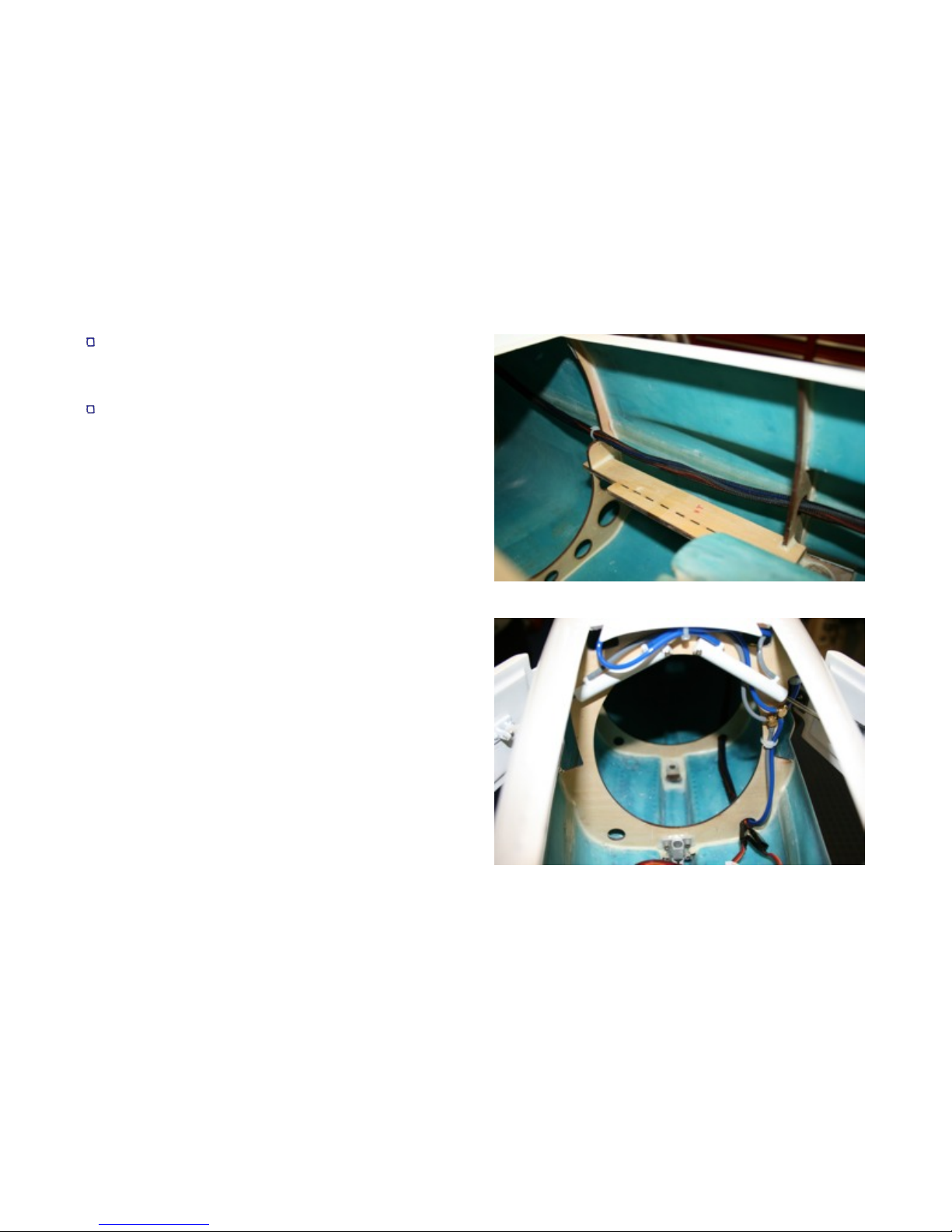

Fuel System

You can choose to install the smaller tank flat on top of

the larger tank, or if you wish to leave more room

above the engine for a smoke tank, follow the

installation procedure outlined below. Details for

smoke tank installation are at the end of the manual.

Optional: disassemble the stopper assemblies from

the tanks and inspect for kinks, tube constriction from

the cutting process or burrs at the ends of the copper

tubes. If you want to move to 3/16 inch tubes, drill the

steel stopper plates at this time. You may wish to

replace the pickup tubing supplied with high quality

large Tygon. Wire tie all internal connections.

Leak check both tanks.

Cut a piece of hard foam to sit under the main tank.

FEI BAO T45

13

Install smaller tank in front of large tank (see photo).

Fuel should flow from the large tank to the smaller

tank and then to the air trap or pump.

Cut a piece of scrap ply approximately 1/2 inch by 6

3/8 inch. Bolt in place to the formers at the top of the

small tank to keep it from moving upwards in flight.

Remove tanks, and re-plumb lines if necessary.

Reinstall tanks and hold down ply. Drill a hole in the

lower right side for the vent fitting (not supplied) and

connect line.

Using wire tie as shown, clamp small tank to ply hold

down to keep it from shifting forward in flight.

Now would be a good time to fill the system and check

one last time for leaks. When completed, plug the

lines to keep the kero from leaking as you finish work

on the airframe.

FEI BAO T45

14

Wings

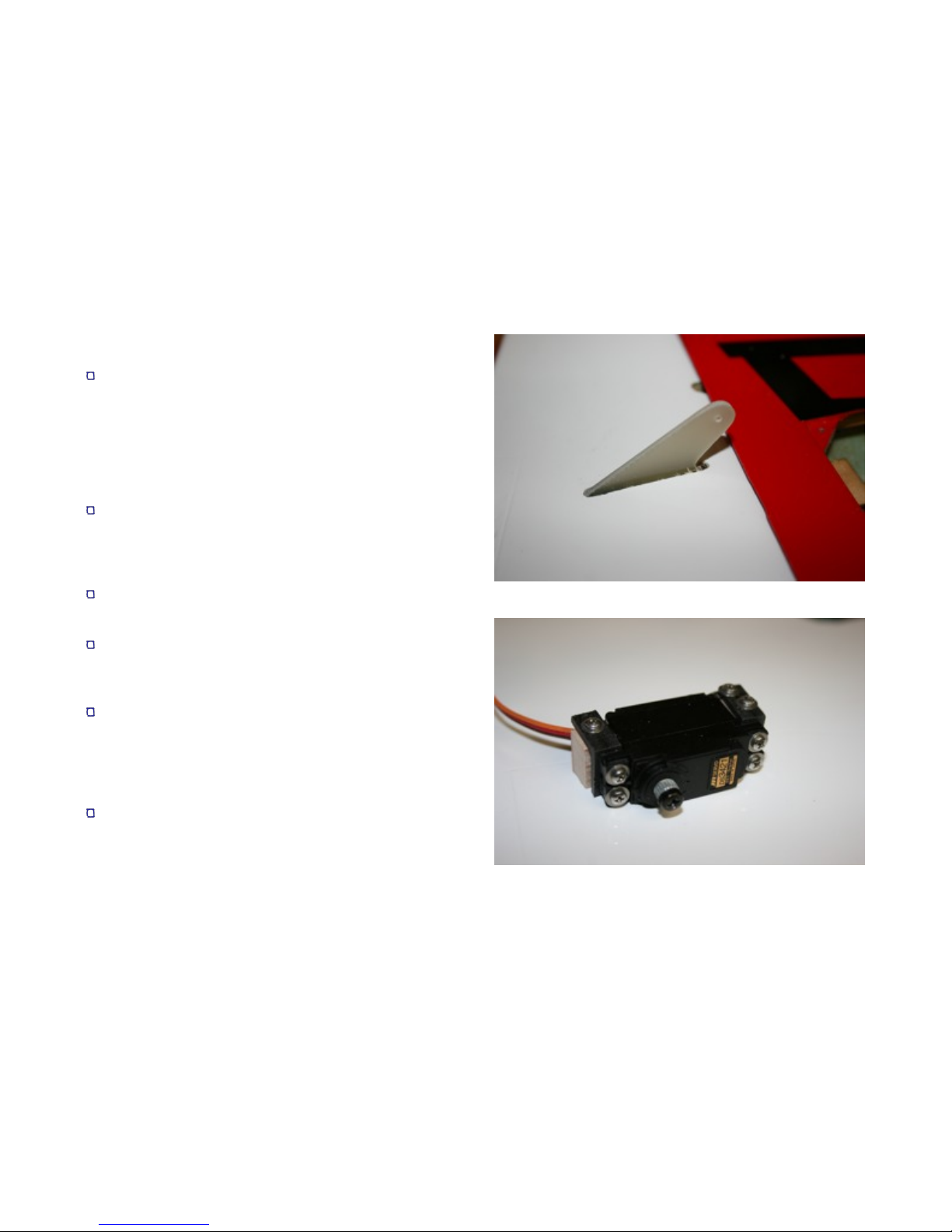

Begin construction on the wing by gluing the flap and

aileron hinges into the predrilled holes in the root edge

of the wing. Before gluing, insure that you are able to

achieve necessary throws, there is adequate

separation between flap and aileron, and that the aft

edges align. Use Aeropoxy to provide adequate time

to align and tape the parts in place.

Using a Matchmaker or receiver, center the aileron

servos and attach servo arms in mirroring positions.

Mount the servos to the aluminum L brackets.

Optional: as the brackets may need to be trimmed,

you may choose to substitute carbon fiber pieces for

the aluminum brackets supplied with the kit. These

may be easier to work with.

Remove the servo hatches, marking them for location

and orientation as you do.

Trim and position the wooden mounting blocks into the

servo pockets such that the servo arms are aligned

with the slots for the servo horns. Allow for the offset

of the ball ends. You may need to trim back the

mounting plates pre-installed in the wings to achieve

alignment. The servos are all positioned such that the

servo arm is toward the front of the wing.

When satisfied, put a drop of thick CA on the bottom

of the blocks and position in the wing. When dry,

remove the servos and use Aeropoxy to permanently

affix the blocks. Tie the servo mounting blocks into

the former structure with glue to prevent the upper

wing surface from flexing under load.

FEI BAO T45

15

When the aileron servos have been fitted, repeat

steps for the flap servos. You may wish to back up the

flap mounting blocks with scrap balsa blocks to

provide added security for the larger servos.

Add servo extensions to the aileron servos. The wires

will exit the wing at the aft hole just in front of the anti-

rotation pin. You will find it easier to fish the servo

wires through the wing if you attach a string to a large

nut and drop it down through the rib holes. Tape the

servo wire to the string and pull it through the wing.

If using 8611A servos on the flaps, the wires should be

long enough without the use of extensions.

Reinstall the servos into the wing pockets and test

with a receiver or Matchbox to make sure you have

adequate clearance for the servo arms. Trim as

necessary.

FEI BAO T45

16

As you did for the rudder servo horn, carefully route

out the mounting slot so the horns sit down fully into

the control surface.

Enlarge the hole in the phenolic control arm horns for

the ball link bolt at this time. Find the wire size drill

that is the tightest fit possible to avoid slop.

Paint the horns if desired.

Rough up the gluing surface on the horns.

Tape around the horn slots in the control surface.

Glue the horns in place using a sufficient amount of

Aeropoxy. Make a nice fillet, and remove the tape.

Insure that the horns are kept in a vertical position as

the glue dries.

When the glue has dried, fit the linkages. The two

shorter linkages are for the Ailerons, the two longer

linkages are for the flaps. To allow for the linkage

cover to fit, the ball link must be attached to the

control surface horn.

Make sure when fitting the linkages that the servo

output arms for both ailerons and both flaps are in

identical positions to avoid uneven movement.

For each servo, mark and cut slots in the servo hatch

cover for the linkage and servo arm.

Cut the aft end off the linkage covers. Position them

on the hatch such that they just clear the ball link

attached to the control surface in their lowest position.

Mark the edges of the linkage cover on the hatch.

Carefully grind away the paint just inside these lines,

to provide a good gluing surface (see photo).

Position the covers into place and lightly CA them to

the hatch only. When dry, remove the covers and

reinforce the joint from the inside with Aeropoxy.

Reinstall hatch covers.

FEI BAO T45

17

Engine and Pipe

It is highly recommended that you use at least the

lower bypass in the installation. The gear doors are

cut into the fuselage just in front of the engine intake

and a significant amount of debris might easily be

pulled into the engine intake if not protected.

Fit the pipe to the rear of the bypass. Note that the

tabs on the pipe are not exactly centered. Position the

pipe so the tabs are oriented toward the top of the

bypass.

Straighten the tabs to remove any folds. The tabs

should be relatively straight.

Make sure the pipe is fully positioned up onto the

bypass. Drill holes through the tabs and the bypass

and fit bolts. Do not tighten at this point.

Remove the pipe and paint the exhaust end with flat

black paint if desired.

Trial fit the pipe, the bypass and your engine into the

fuse. The fixed intakes may require trimming to allow

forward clearance for larger engines. The intakes

may also need to be notched at the top to allow

clearance for the starter assembly. Position the

bypass such that the engine is as far forward as

practical, while allowing the pipe to protrude slightly

from the aft of the fuselage.

Make sure the engine is centered in the bypass to the

pipe, and that you allow the appropriate separation

between the exhaust cone and pipe as specified by

the engine manufacturer.

If necessary, trim the bypass to allow the engine tabs

to sit flat on the mounting rails (see photo).

FEI BAO T45

18

Remove the engine temporarily and fix the bypass to

the mounting rails with wood screws.

Reattach the pipe to the aft of the bypass and secure

with bolts. If desired, a drop of thin CA can be used to

insure the nuts do not loosen.

Check the pipe where it passes through the aft former

for any play. If there is a lot of play and the pipe

moves freely about, cut additional supports out of

scrap wood and glue them to the aft former. Allow just

a little play so the band around the aft of the exhaust

pipe will fit through in the event it must be removed.

Insure that the wiring and speed brake lines are

secured well away from the pipe.

Completely clean the intakes, bypass and aft area of

the model with a vacuum or compressed air.

Reinstall your engine, securing it to the mounting rails

with wood screws or cap screws with blind nuts.

Check again to make sure it is centered and that the

angle of the engine matches the angle of the pipe.

Use washers under the mounting tabs if necessary to

achieve the proper alignment.

If you elect to use the upper bypass, trim, fit and

secure to the engine rails using wood screws.

The photo on the right shows a Jet Central Super

Eagle/Rhino installation. Wooden plates were used to

widen the mounting tabs to sit on the rails. Note the

smoke system tubes secured to the tops of these

mounting tabs.

FEI BAO T45

19

Component Boards

At this time, lay out your electrical, air and engine

systems on the component boards in the cockpit

area. Make sure to allow adequate clearance for

the cockpit tubs.

Remember to make all your components accessible

for maintenance. While it may look extra neat to

hide everything away, things do break and leak, and

you want to keep your repair time to a minimum.

Run air lines to all cylinders and gears. You will

need to plan for a three sequence installation, gear

and two different door cycles. The main gear doors

and forward nose gear doors close after gear

extension while the two doors that flank the nose

strut remain open. A UP2/4 valve combination or

one of the growing number of gear sequencers will

be required.

Nose Gear Steering

Install a control arm on the nose gear servo. Make

sure it is centered using a Matchmaker or receiver.

Note the orientation is along the axis of the servo,

not perpendicular as is normally the case.

Install your nose gear servo into the mount pre-

installed at the forward end of the nose

compartment.

Run steering cables to the nose gear. A nylon wire

tie may be attached to the cables with heat shrink to

act as a spreader when the gear retracts.

Make sure the steering cable is not too tight with the

gear extended to prevent binding on retraction.

FEI BAO T45

20

Other Fei Bao Toy manuals

Fei Bao

Fei Bao F-4 Phantom II User manual

Fei Bao

Fei Bao hawker hunter User manual

Fei Bao

Fei Bao F-9F Panther User manual

Fei Bao

Fei Bao SU-27 User manual

Fei Bao

Fei Bao Mirage F1 User manual

Fei Bao

Fei Bao EF2000 User manual

Fei Bao

Fei Bao Mirage 2000 User manual

Fei Bao

Fei Bao MB-339 User manual

Fei Bao

Fei Bao MiG-21 Fishbed User manual

Fei Bao

Fei Bao F18-f User manual

Popular Toy manuals by other brands

Eduard

Eduard Zoom Mosquito FB Mk.VI/NF Mk.II quick start guide

Sportsman Aviation

Sportsman Aviation POLECAT RACER .40 Building instructions

marklin

marklin 37359 user manual

Rail King

Rail King 30-2274-0 Operator's manual

Klein

Klein MIELE 6941 instructions

Hasbro

Hasbro Star Wars Revenge of the Sith Energy Blaster refill... instruction manual