Fei Bao F-4 Phantom II User manual

F E I B A O F - 4 P H A N T O M I I

1

11

1

FEI BAO JETS

F-4 Phantom Assembly Manual

In collaboration with R C Jet Models

2

22

2

DISCLAIMER:

THIS IS NOT A TOY.

This is a high-performance miniature aircraft, capable of high speeds

and damage to life, limb, and property. The manufacturer and its distributors cannot control how

you assemble this model, what equipment you use to fit it out, or how you fly it, and can assume

no liability whatsoever for any damages that may occur when you fly your aircraft. By

assembling this model, you are agreeing to indemnify and hold blameless the manufacturer

and/or his agents from any and all torts and liability associated with the use of this product.

Once you have assembled the aircraft, you are the pilot in command and assume any and all

responsibility for the use of the model and any damages that might occur by flying or attempting

to fly this aircraft.

R/ model jets require a high level of skill in both their assembly and their flying. If you do not

feel confident in either your building or flying skills, PLEASE seek assistance from more

experienced modelers. It is a wise idea, no matter what level of skills you possess, to have a

second experienced modeler go over your installation after assembly. A second set of eyes may

spot a problem you have missed. If you have not flown a model like this before, it is HIGHLY

recommended that you get an experienced turbine pilot to do your maiden flight. Very often, the

first few seconds of a maiden flight are critical until the aircraft is trimmed out, and having an

experienced pilot at the controls can make the difference between a wrecked aircraft and once

that enjoys many hundreds of flights. Be sure to select a suitable field for flying...take the time

to find a large paved runway if at all possible, especially for test flights, until you feel comfortable

getting the aircraft in and out of smaller grass fields.

Congratulations on your purchase o the Fei Bao F4 Phantom II.

Be ore you begin

• lean and inspect all parts. Inventory them against the parts list at the end of the manual

and notify the kit supplier of any missing components as soon as possible.

• If the paint scheme you have selected is glossy, it is recommended that you apply a coat of

wax. This will help resist dirt, stains and fingerprints during construction, and will provide

some limited protection against errant glue.

•

Vacuum out the remnants of packing materials that remain in the fuselage.

While the kit is comprehensive, there are additional parts required, as follows:

• Recommended Servo List (JR)

• Elevators: (2) 8611a

• Aileron: (2) 8611a

• Flaps: (2) 8611a

• Rudder: (1) 3421

• Nose Steering: (1) 2721

• Retracts: (2) 351 or equivalent

• Brakes: (1) 351 or equivalent

• Other Parts

• BVM UAT (optional)

• ½ inch Velcro straps to secure fuel tanks

• Wire twist tie (optional)

3

33

3

• Blue Loctite

• Glues: Thin A, 5 minute epoxy, Aeropoxy

• Electronic gear sequencer

• Brake valve

• Batteries, regulator and switch

• Servo extensions (length may vary, depending on receiver placement)

Construction

The order o construction may be changed to suit your personal pre erence,

however, there are a ew points to note:

• The fuel system is more easily accessed if the fuselage halves have not been joined

• The model is more easily worked in a tight space if work is completed on each fuselage

section before they are joined

• The incidence of the main wheels must be set prior to attachment of gear doors, thus, the

fuselage should be completed before the wings.

The retract system in the prototype is operated by two valves. The two way valve controls gear

up and gear down. The gear doors stay open with the gear extended, so the door open-air lines

are simply connected to the gear down lines. The door close airlines are connected to a second

one way valve, which is operated by an electronic sequencer. The sequencer delays the

operation of the door close valve, allowing the gear to retract.

Step 1: Fuel System

onstruction begins with the fuel system. Once the nose is bolted on the aft fuse, the forward

fuel tank that sits between the intakes is more difficult to install, so now is the time to complete

this step.

It is recommended that you disassemble and inspect the tank cap hardware. As photo 1 shows,

the process used to cut the tubes may leave behind a rim that constricts fuel flow and could

result in excess tank pressure and leakage. The vent tube to the top of the picture shows what

the constriction looks like before repair, while the fuel tube on the lower left shows what the

tubing should look like after clean up. If the tubing is not constricted, skip forward to the leak

check.

Photo 1

Loosen the Philips head screw and remove the stopper assembly from the tank.

Use a small, round Perma-Grit rat tail file or an Exacto knife to remove the excess metal.

You will need to inspect the ends of all tubes.

4

44

4

The tube that the pickup line connects to inside the tank may also need to be shortened to

approximately 12 mm for ease of installation through the tank orifice. When finished, make

sure to blow out the metal fragments and clean up any sharp edges.

While the components are apart, check the Tygon pickup line for equal lengths in both saddle

tanks. They should be long enough to reach the back of the tanks without being so long as

to restrict their ability to move to the top of the tank when the aircraft is inverted.

You should also notch the vent tube with a small file to provide for continued air flow should

the tube come into contact with the top of the tank.

Make sure the bends to the vent tubes applied at the factory have not restricted airflow to

any significant extent. Also, check the Tygon for any nicks or cuts and secure to the tubing

with wire ties before re-assembly.

Once the tanks are back together, they should be leak checked before installation in the

aircraft. onnect extra lengths of fuel tubing to the fuel and vent lines and submerge the

tank in water. Pinch off one line and gently pressurize the tank by blowing into the other,

looking for signs of air bubbles. If the tank shows evidence of air leakage around the vent

cap, tighten the Philips head screw and check again. If you have a stubborn leak, you can

re-tap the inner plate for a slight larger 6/32 cap head bolt.

It is recommended that you mount the forward fuel tank so as to be able to remove it for

maintenance in the future.

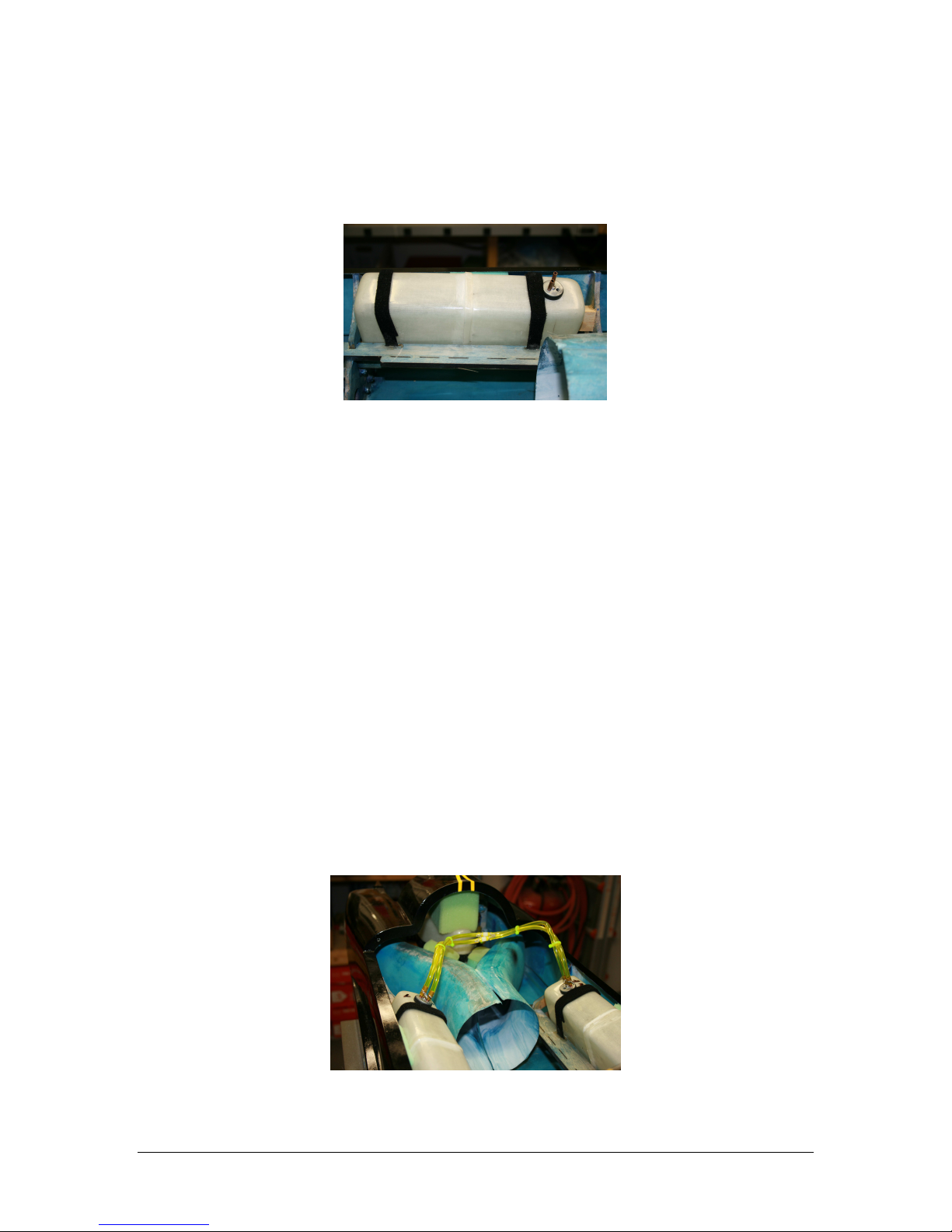

Before installing the saddle tanks, check the spar receiver bolts to make sure the nuts are

secure. Plug the wings into the spar receivers and move them up and down, tightening the

locknuts until there is no evident play.

ut two strips of 6 mm ply approximately 180 mm long by 12 mm wide. Also cut four Velcro

straps approximately 12 mm wide by 180 mm long.

Using two 7mm wood screws per strap, attach two Velcro straps approximately 20 mm from

the end of each ply rail. Be sure to attach the straps so they overlap, holding the flat part of

the tank firmly against the ply rail.

The lower rail can be glued to the inside of the front former, but the upper rail should be

attached with screws accessed from the engine compartment such that the upper rail may be

removed. Strap the tank in place.

Photo 2 Photo 3

For extra security, place several pieces of scrap foam between the tank and the intakes, and

also between the top of the tank and the top of the fuse to keep it from shifting during flight.

To mount the saddle tanks, begin by routing two narrow 12 mm slots toward the outside of

the engine mounting rails. These should be positioned approximately 60 mm inside the front

and rear formers.

ut two Velcro straps 350 mm long and thread them through the slots. Position the saddle

tank with the curvature to the outside and the stopper assembly at the front, and tighten the

straps. The tank should be canted slightly inward to allow the fuel lines to clear the inside of

5

55

5

the hatch. Place a piece of scrap foam between the top of the tank and the side of the

fuselage to hold the tank in this position.

ut a piece of scrap balsa block to act as a spacer between the front of the tank and the

former. Make sure you can access the forward wing spar mounting bolts, and then attach

the spacer block to the front former with a drop of A.

Photo 4

When you are happy with the position of the tank, test fit the hatch and check for clearance.

If everything checks out, glue the Velcro to the slots routed in the rail with 5-minute epoxy.

Also apply epoxy to the point where the Velcro strap meets the side of the fuselage, being

careful not to glue the tank to the strap. This will keep the tank from shifting.

Repeat all steps for the other saddle tank.

heck the fuel lines for nicks and cuts as you proceed through the next steps.

onnect two pieces of fuel tubing approximately 180 mm long to the fuel pickup tubes in

each saddle tank and bring them together with a “Y” fitting just above the intakes.

Repeat this process for the vent tubes in the saddle tanks.

Run a length of fuel tubing from the “Y” fitting connected to the fuel pickup tubes to the vent

tube of the main center tank.

Attach a length of tubing to the “Y” fitting connected to the vent tubes on the saddle tanks.

The vent fitting will be positioned in the forward fuselage … a pigtail of approximately 200

mm extending past the forward former should be sufficient.

onnect a length of tubing that will run to the fuel pump to the fuel pickup tube on the main

center tank.

Wire tie all connections at this time

If you use plastic wire ties to bind the fuel tubes together for a neater installation, make sure

not to over-tighten and pinch down on the flexible fuel tubing.

This completes the fuel system.

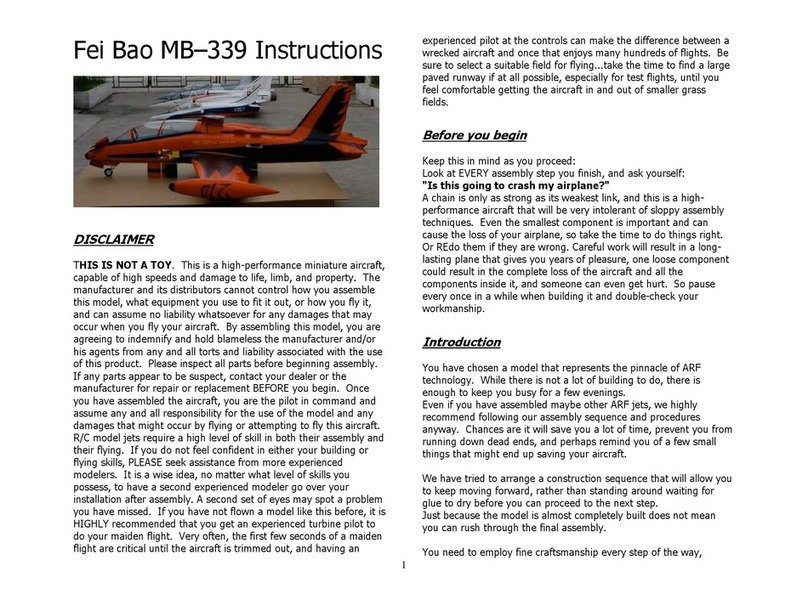

Photo 5

6

66

6

Step 2: Vertical Fin and Rudder

Before assembly begins, inspect the glue joints between the fin ribs and the outer skin. These

may be seen through the servo mounting hole and the forward inspection cut out. If there are

gaps in the glue, fill them in with a little Aeropoxy.

Mount the rudder servo, with the spindle toward the rear of the fin. You may need to

enlarge the mounting hole just slightly.

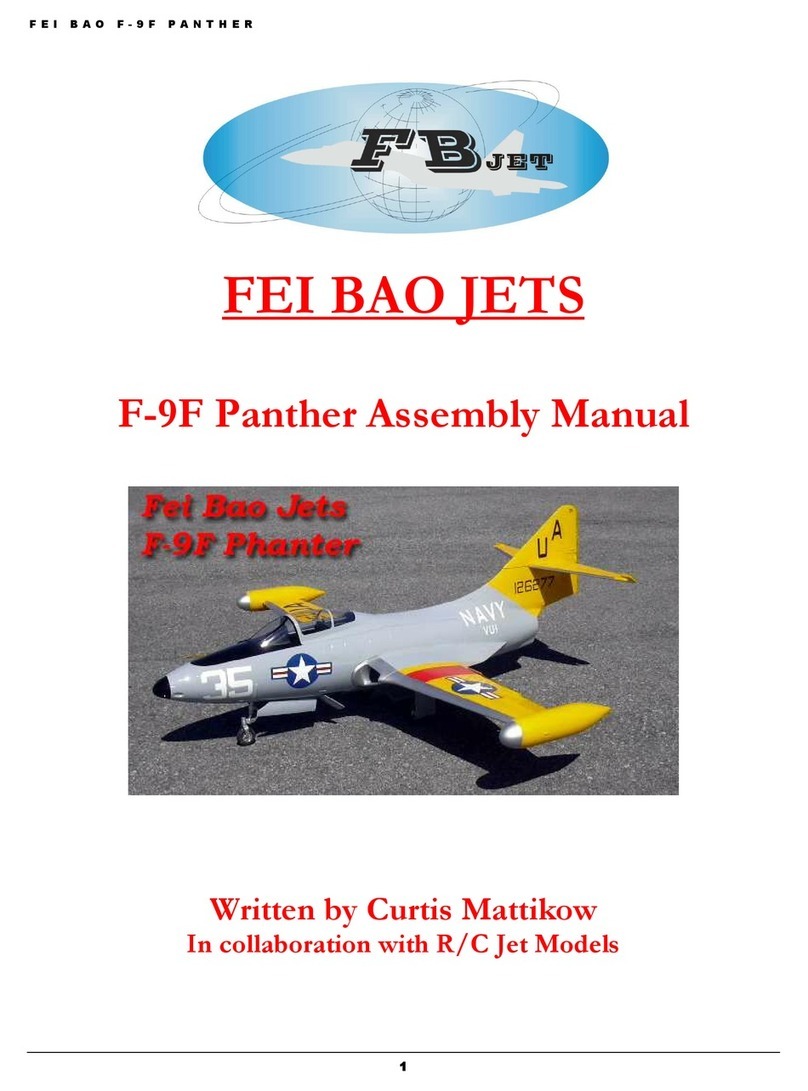

Photo 6

Using a JR Matchbox or your receiver, power up the servo and set it at neutral. Attach the

control arm at a vertical position. Enlarge the strut slot size in the fin slightly with a small file

if the arm binds.

Assemble the rudder linkage. Use the rod that is approximately 190 mm long. You will need

to enlarge the hole in the control horn with a 7/64 inch drill for the rod bolt. Do not over

tighten this bolt as the rod will bind as the rudder is actuated.

Photo 7

onnect your servo extension and secure with tape or heat shrink tubing.

Secure fin to aft fuselage with 12mm bolts and large 12mm washers. Use Loctite on the

threads.

7

77

7

Step 3: Horizontal Stabilizers

heck the nuts that bolt the stab bearings to the stab plate for tightness. Also make sure the

stab bearing covers are glued securely to the stabs. Reinforce if necessary.

File the slots in the fuse side to give the stab as much throw as possible.

Photo 8

Temporarily place the stab plate back into position in the fuselage.

Find the 115 mm linkage rods for the stabs. Make sure the rod end (with the bolt) is

completely screwed on to the linkage. Tighten the locknut.

Optionally, you may choose to stiffen the linkage by slipping an appropriately sized brass

sleeve over the linkage, between the locknuts.

Screw the clevis on the other end of the linkage rods. Make sure the two linkages are of

exactly equal length, and then tighten the clevis locknut.

Mount the aluminum L brackets to the elevator servos. Do not use the rubber damping

pieces that come with the servo. Use washers and red Loctite on the screws. Also check to

make sure the brackets are positioned so that the servo will sit flat on the mounting plate.

Make sure the servos mirror each other in a left and right set.

Using a JR Matchmaker or your receiver, find neutral for the servos and experiment with

servo arm orientation that results in matching positions. ut off the opposing arm and then

mount the arm to the servo.

Photo 9

8

88

8

onnect the clevises to the servo arms. Don’t forget the locking clips.

Screw the rod end bolts into the bearing plate arms, from the outside in. Slip the clevises in

place and position the servos on the servo mounting plate.

Photo 10

With the servo arms in a vertical position, and the stab set for a slight bit of up elevator,

mark the position of the mounting brackets.

Remove the servos and linkages. Unbolt the servo mounting plate and remove it.

Align the bottom of one servo to the exact edge of the ply plate, with the bracket on the

alignment mark you made in the previous step. Using 12 mm wood screws, bolt the

aluminum brackets to the ply plate.

Working carefully, position the other servo with the output spindle exactly opposite the first,

and the bottom of the servo aligned with the edge of the ply plate. Drill and screw this servo

to the ply board.

Now would be a good time to attach your servo extensions, using tape or heat shrink to

secure. Do not “Y” the servos, as they will be adjusted in a later step. If you are using a JR

Matchbox, it must be within 6 inches of the receiver, so two long extensions from the

elevator servos are a requirement.

Remove the stab from the fuselage. Insert the servo plate back into position and bolt it into

place with 20 mm bolts and 12 mm washers. Loctite.

Replace the stab into the fuselage and permanently bolt into place using 20 mm bolts and 12

mm washers. Loctite.

Temporarily connect the linkages to the metal arms, but do not tighten them, as final servo

adjustment will be required after installation of the receiver.

Using wire ties or wire loom, secure the rudder and elevator extension wires together.

Notch several small blocks of wood for plastic wire ties, and glue these along the top of the

fuselage well away from the pipe with 5 minute epoxy. Roughen the surface of the fuse

before gluing.

When dry, secure the cables to the blocks with wire ties.

Photo 11

9

99

9

Step 4: Tail Accessories

Trial fit the lower stab cover and trims if necessary. Temporarily attach to the fuse with flat

head screws.

Photo 12

Bolt the exhaust cones to the aft firewall.

Attach the tail hook. Roughen both surfaces to be glued and drill small holes in both parts to

act as glue “pins”. Use Aeropoxy, being careful to keep it away from the edges of the hook.

lean up any glue that seeps out immediately. Tape in place and set the aft fuselage aside.

Gently move the stab by hand and check for binding. If any is evident, take corrective steps

at this time.

This completes the aft fuselage work.

Photo 13

Step 5: Nose Doors

You will be hooking up airlines in the next section. There will be three primary connections

required: (1) gear up, (2) gear down/doors down and (3) doors closed. The system will be

operated by two valves. The primary valve will activate gear up and doors open/gear down. The

secondary valve will control the closing of the gear doors and will be delayed through use of

sequencing.

It is convenient to set the nose section on end when working through the following steps.

Inspect all of the gear door hinge and air cylinder mounting bolts for security. Put a small

drop of thin A on the gear door hinge bolts to prevent loosening of the nuts. The forward

gear door cylinder will not be attached to the forward door … this will be completed in a

subsequent step.

Reinforce the hinge to fuse joints with a little Aeropoxy for added security. Be careful not to

get glue into the hinge mechanism.

10

1010

10

Loosen the four retaining bolts and remove the forward door. Replace the screws in the

fuselage to avoid losing track of them.

Now is a good time to run airlines to the nose door cylinders while there is a little space to

work. Test for leakage and proper operation of the valves as you go, using a hand pump.

Secure the lines together with plastic wire ties to keep them organized and out of the way.

Step 6: Nose Retract Unit

Insert the retract servo from the bottom of the mounting plate, with the spindle toward the

outer end of the bracket.

Attach the servo using the bolts provided. Loctite.

Using your receiver or a Matchmaker, find neutral on the servo and mount the arm.

Attach clevises, making sure they are not so tight as to cause binding. Using plastic wire

ties, secure the servo wire well away from the end of the bracket. This area of the bracket

will pass close to the former as the retract is operating.

One at a time, remove the strut set screws, apply Loctite and reassemble, making sure they

are snug.

Attach your air lines and test the retract unit with a hand pump, making sure it will hold air

and operates smoothly.

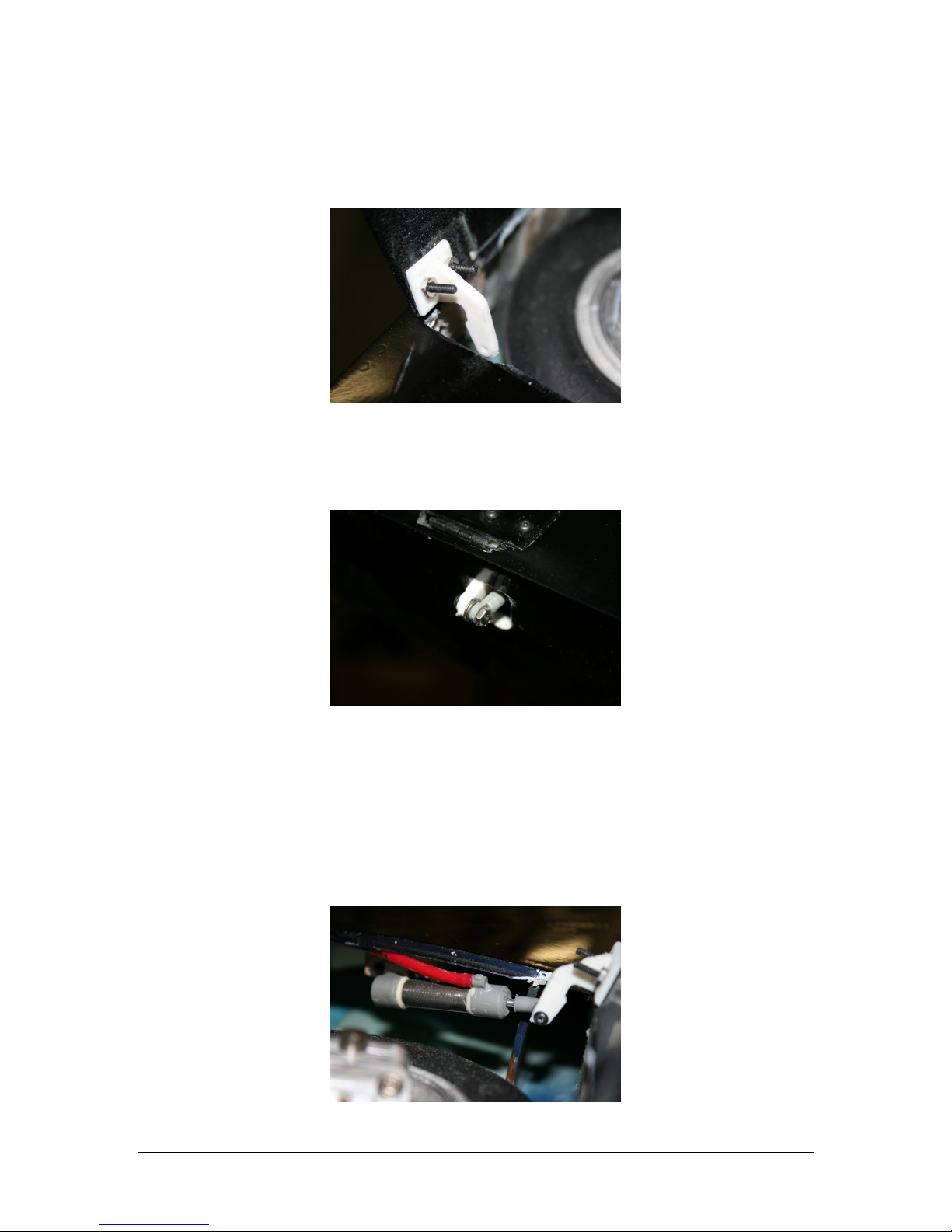

Photo 14

Position the retract unit into the retract plate from the bottom. The front of the retract unit

should be positioned approximately 10 mm behind the front former. Insure this is enough

to clear the front door when installed and that the wheels clear the aft door opening. Mark

this position with a felt pen.

Working carefully to make sure the retract unit stays in this position and aligned equally to

either side of the gear opening, drill one of the holes closest to the forward former. Insert a

bolt into the hole to hold this position.

Proceed to drill the other three holes, making sure to maintain alignment of the gear. Insert

a bolt in each hole as it is drilled.

When all four holes are drilled and you are satisfied with the alignment, remove the retract

unit.

Drill out each hole to be large enough for a blind nut. Insert these from the top and snug

them down with one of the bolts. Apply a little A to the back of the blind nuts sparingly to

hold them in place.

11

1111

11

Reinsert the retract unit and bolt in place. Loctite.

Photo 15

Remove the mounting lugs from the rear most door hinge to help with hinge clearance as the

gear swings into the retracted position.

Reinstall the nose gear door.

Attach the cylinder to the nose gear door with a small cotter pin.

Photo 16

heck the nose gear door to make sure it opens sufficiently to allow the nose gear to extend

fully without binding on the door. Trim the bottom of the door if necessary.

It will aid in the removal of the nose gear if you use quick disconnects on the air lines to the

retract unit. Use a servo clip on the steering servo as well, rather than taping or heat

shrinking this connection.

Remove the component board and set aside, if this has not already been done.

lean the forward fuselage section thoroughly.

Step 7: Joining the Fuselage

Inspect all the mounting holes to insure they are free from debris. Try the bolts and make

sure they all thread easily.

arefully position the nose section between the intakes. It will be a tight fit, so work

carefully and slowly. Do not force the section in place.

Using the 20 mm long bolts and large washers, bolt the two main bulkheads together.

Using smaller 10 mm bolts and the large 12 mm washers, secure the side sections to the

intakes.

12

1212

12

Step 8: Component Board

Trim the edges and back of the component board so that you can easily fit it through the

canopy hatch.

A suggested layout of components is shown in photos 17 and 18. This arrangement allows

easy access to the receiver and servo wires, provides good separation between the turbine

and receiver electronics and sits low enough for the cockpit to easily fit on top.

Photo 17

Photo 18

Make sure to keep the area just in front of the forward former clear of wires and airlines for

retraction of the steering servo. The nose wheels will fit right up against the bottom of the

component board when retracted, so it is recommended you have nothing extending below

the board in this area.

Now is a good time to complete installation of all servo extensions, airlines and turbine

electronics through the fuselage.

Step 9: Engine and Pipe

lean the fuselage thoroughly before installing the engine. If you need to trim the intake for

engine clearance, use a vacuum while you work. This will reduce the chance of having a foreign

object finding its way into your engine.

13

1313

13

Drill two holes on each side of the pipe mounting tabs. The first should be just in front of

the pipe mouth, the other approximately 50 mm further forward.

The tabs are positioned just above the centerline of the pipe and this is the top. Insert the

pipe into the fuselage and position the aft end about 5 mm from the end of the exhaust

cones.

Photo 19

Place the lower bypass on the engine mounting rails. Slip the pipe forward over the aft end

of the bypass. You may need to slightly trim the lower former a bit to allow the bypass to

move far enough aft to keep the rear of the pipes in position.

Position your engine on the mounting rails. Set the gap between the rear of the exhaust

cone and the mouth of the pipe to manufacturers specifications. This is usually around 20

mm. You may need to trim some material off the intakes to allow the engine to sit far

enough forward.

If required, marks the bypass for the positions of the engine mounting tabs and trim away

material such that the engine exhaust is centered on the pipe. Shims may be required under

the front engine mounting tab to insure that the angle of the engine is on line with the angle

of down thrust of the pipe.

When you are satisfied, bolt the engine to the side frames with appropriately sized wood

screws. Install the screws and then remove. oat the thread holes with thin A. This will

harden the wood around the screw holes themselves. Permanently reinstall the engine

mounting screws.

Drill and secure the bypass to the engine mounting rails with four wood screws.

Finally, drill the rear of the bypass for the pipe mounting straps and bolt in place. The heads

of the bolts should be on the inside of the bypass.

onnect fuel, gas and electrical lines up to the turbine.

Photo 20

14

1414

14

Step 10: Wing Servos

Remove the servo cover. Mark the inside front of the door so you will know how to orient it

for reassembly.

Attach the aluminum L brackets to the servos as you did for the elevators. The servos will

face in opposite directions and the servo spindle is positioned toward the rear of the wing.

Using your receiver or JR Matchmaker, find servo neutral and attach the heavy-duty servo

arm.

Enlarge the servo wire hole in the wing root to accommodate the two servo wire connections

and four air quick disconnects.

Label the servo wires for aileron or flaps.

Position the servos onto the mounting tabs. If you are using 8611a servos, you will need to

make a shim plate for the rear tabs to hold the servo just slightly off the top of the wing. If

you omit this shim, you will deform the top of the wing as you tighten the bolts.

You may also need to trim the lip of the servo well slightly to provide clearance for the

aileron servo arm.

Using great care not to pierce through the top of the wing, drill and bolt the servos in place.

Photo 21

Trim the servo cover for the servo arms and reinstall.

onnect the 70 mm linkage arms, following the same procedure used for the elevators.

Photo 22

Repeat for the other wing. Be sure to keep the linkage lengths equal.

15

1515

15

Step 11: Main Landing Gear

Install airlines on the retract units.

heck for air leaks and smooth operation of the retracts with a hand pump.

Insert the gear into the mounts and extend the gear. The wheels should be set to just a

slight amount of toe in compared to the wing root. A setting that just allows the inner door

to close over the wheel will be very close.

Retract the gear. The outboard end of the retract unit should be positioned up against the

former and the wheel itself should just clear the aft end of the wheel well. You need some

clearance in front of the wheel for the door activating cylinder placement.

If the wheel hits up against the wing root with the retract unit positioned as far outboard as

possible, you can remove one of the clips and open up the scissor assembly to access the

adjusting screw. Rotating the adjusting screw counterclockwise will shorten the gear stance.

With the wheel and retract unit in position, carefully drill one of the holes and mount the

retract in place. Again, be careful not to pierce the top of the wing.

At this point, mount the wings temporarily on the fuselage and set the final incidence. heck

again to make sure the inner door will close fully over the wheel.

When you are satisfied with the position of the gear, drill and install flat head screws in the

remaining holes.

Photo 23

heck for any binding and trim the door lip a little if necessary.

Step 12: Inner doors

If not already done at the factory, secure the forward hinge to the ply backing plate with four

short button head screws. This reinforces the hinge that will take the brunt of the force

from the door cylinder.

Photo 24

16

1616

16

for the bolt you will use to attach this door actuating ar to the cylinder end.

Temporarily bolt the door-actuating arm to the door, aligned with the lower forward corner of

the door (photo 27). Use a drop of Aeropoxy to help secure it. Put a drop of thin A on the

nuts and remove the excess bolt length, if any.

Photo 27

arefully route a hole in the wing root to allow the door-actuating arm to move through as

the door closes. You will also need to trim a little off the lip of the wheel well for the door to

close completely.

Photo 25

Attach the door cylinder to a scrap ply block approximately 15 X 25 mm. The cylinder

included with the kit may differ a little from the one shown in the photos, but the mounting

will be similar.

Bolt the cylinder end to the modified hinge. Due to the angles involved, you will need to

keep this connection somewhat loose to prevent binding.

Rough up the wheel well surface where the cylinder-mounting block will be glued with 100

grit sandpaper.

Position the door fully open and glue the wooden block in place, taking care to make sure

there is adequate clearance for the wheel to clear the cylinder.

Photo 29

17

1717

17

Add an Aeropoxy fillet around the wooden cylinder-mounting block.

If the door wants to open too far, you can add a small scrap of wood between the cylinder

end and the bottom of the wing to prevent it from flexing upward.

Route and secure the airlines and add quick disconnects.

Repeat these steps for the other wing.

Step 13: Strut Covers

Retract the landing gear and clean the portion of the strut that the strut cover will attach to

with solvent.

ut a piece of scrap ply approximately 10 mm wide of the appropriate depth such that it fills

the gap between the strut and the strut cover with the strut retracted and the cover in place.

Glue this piece to the strut cover with 5 minute epoxy.

Now apply Aeropoxy to the strut side of the wood piece and position the door in place. Tape

and allow the glue to dry overnight.

Extend the gear carefully and position the metal mounting bands around the strut. Drill

through the strut cover and bolt the bands in place. Use a little silicon-based glue on the

inside of the band to reinforce the attachment to the strut.

Photo 26

Step 14: Outer Doors

Reinforce the hinge attachment with two small button head screws. These should be

positioned at the lower part of the hinge, screwed in from the outside of the door.

You will need to attach a length of phenolic material or very thin ply to the bottom edge of

the door so it sits on top of the strut cover. This will prevent the strut cover from “catching”

on the outer door when the gear is extended.

Drill and tap the strut for a 2-56 ball link. The link is positioned in the center of the lower

strut band facing the rear of the aircraft, parallel with the outer door (photo 31).

ut a small mounting block, approximately 5 X 5 mm, from a piece of scrap ply. Mount

another ball link. The block should be just thick enough for the link. If you make it too

thick, the outer door will not close fully.

Tack glue this assembly approximately 42 mm up from the bottom edge of the door, in line

with the ball link attached to the strut.

Make a double looped link from carbon fiber thread or thin cable. You will need to

experiment a bit, but a good starting point is a length that holds the outer door up against

the strut cover.

18

1818

18

Photo 27

When you are satisfied with the operation of the outer door, add a fillet of Aeropoxy around

the wood block.

lean up any excess glue from the struts and use a bit of touch up paint as necessary.

Run the brake lines, making sure they don’t interfere with the operation of the retract units

or doors.

Step 15: Cockpit

Now is a good time to install your batteries. In the prototype, these were attached to the

nose gear plates on either side of the nose retract. If the air tanks have not been installed

yet, place them in the nose, packed in foam.

The glare shield should not be mounted permanently to ease maintenance in the future. It

can be attached with duct tape from the inside, or if you prefer, several small dabs of silicone

glue.

The cockpit tub comes pre-trimmed, and should simply drop into place.

The canopy also comes pre-fit at the factory and should be latched in place.

Step 16: Radio Programming

The prototype was set up on 10 channels as follows:

Throttle

2 aileron

2 flap

Rudder

Elevators (use matchbox)

Nose gear steering

Brakes

Retracts

Make sure the elevator linkages are disconnected when you turn the radio on for the first time.

Begin by reversing and programming one servo, and then match the operation of the other servo

to the first, using the instructions that come with the Matchbox.

Once you are satisfied with the programming of the elevator linkages, reattach the hatch

cover with flat head screws.

Find the four small curved swash plate covers. If these have been predrilled at the factory,

match the covers up with their respective holes and screw in place with small button head

screws.

heck the operation of the elevators one last time for freedom of movement.

Step 17: CG and Control Throws

19

1919

19

Set the enter of Gravity approximately 290 mm rear of the leading edge of the wing. The

G should be determined after the plane has been filled and drained of fuel, with the gear in

the extended position.

It is likely that nose weight will be required. One easy way to accomplish this is to tape the

required lead weight to the end of a basswood stick and insert fully to the front of the nose.

Secure the basswood piece to one side of the front former with a screw. This will make it

easy to remove and reinsert the ballast weight as you fine tune G.

Flaps, rudder and elevator should be set to maximum servo throws possible without binding

for the first flights. Elevator throw will be in the 45-50 mm range in both directions. Set the

elevator for a small amount of up trim for the initial flight.

Aileron throw should be approximately 40 mm in each direction for the first flight. Adjust this

in subsequent flights to suit your flying style.

Maintenance Tips:

To keep the stabs from moving during transport, wedge pieces of scrap foam between the

stab and fuse sides.

Remove the lower stab cover occasionally and inspect the stab mounting bolts for security.

heck the stab for excessive play before each flying session.

Inspect the inner door cylinder bolt each time you mount the wing.

When inverting the aircraft, put a short piece of fuel tube with a plug on the drain fitting.

This will prevent fuel from leaking into the missile rail channel and then into the seam

between the forward and rear fuselage sections.

ycle the gears before each flying session, checking for binding and proper door operation.

heck the struts for play, indicating the clamping set screw needs to be tightened.

Congratulations, you have completed construction on your Fei Bao F-4

Phantom II. See step 17 or balance and control throws.

Table of contents

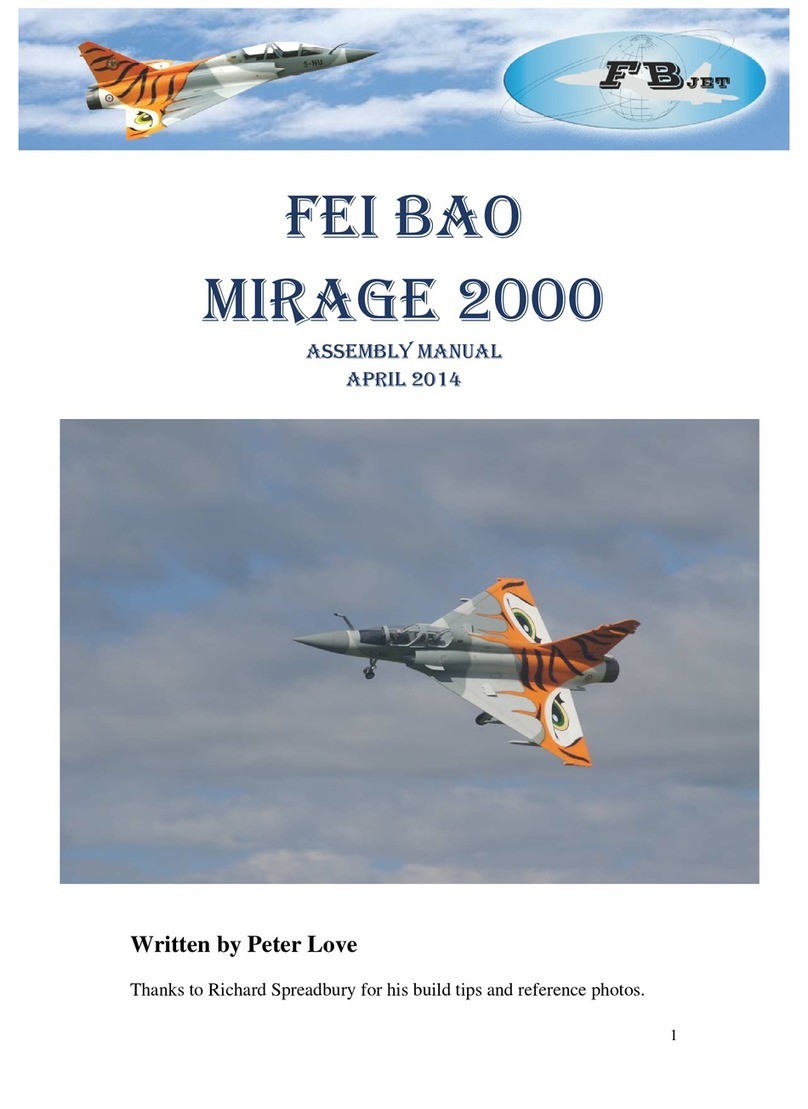

Other Fei Bao Toy manuals

Fei Bao

Fei Bao F-9F Panther User manual

Fei Bao

Fei Bao Mirage 2000 User manual

Fei Bao

Fei Bao MB-339 User manual

Fei Bao

Fei Bao EF2000 User manual

Fei Bao

Fei Bao Velox User manual

Fei Bao

Fei Bao MiG-21 Fishbed User manual

Fei Bao

Fei Bao L-39 User manual

Fei Bao

Fei Bao F18-f User manual

Fei Bao

Fei Bao hawker hunter User manual

Fei Bao

Fei Bao T45 User manual

Popular Toy manuals by other brands

LEGO

LEGO CITY 60110 Building instructions

Fisher-Price

Fisher-Price OVERHEAD GYM W0128 instruction sheet

Fisher-Price

Fisher-Price M9974 quick start guide

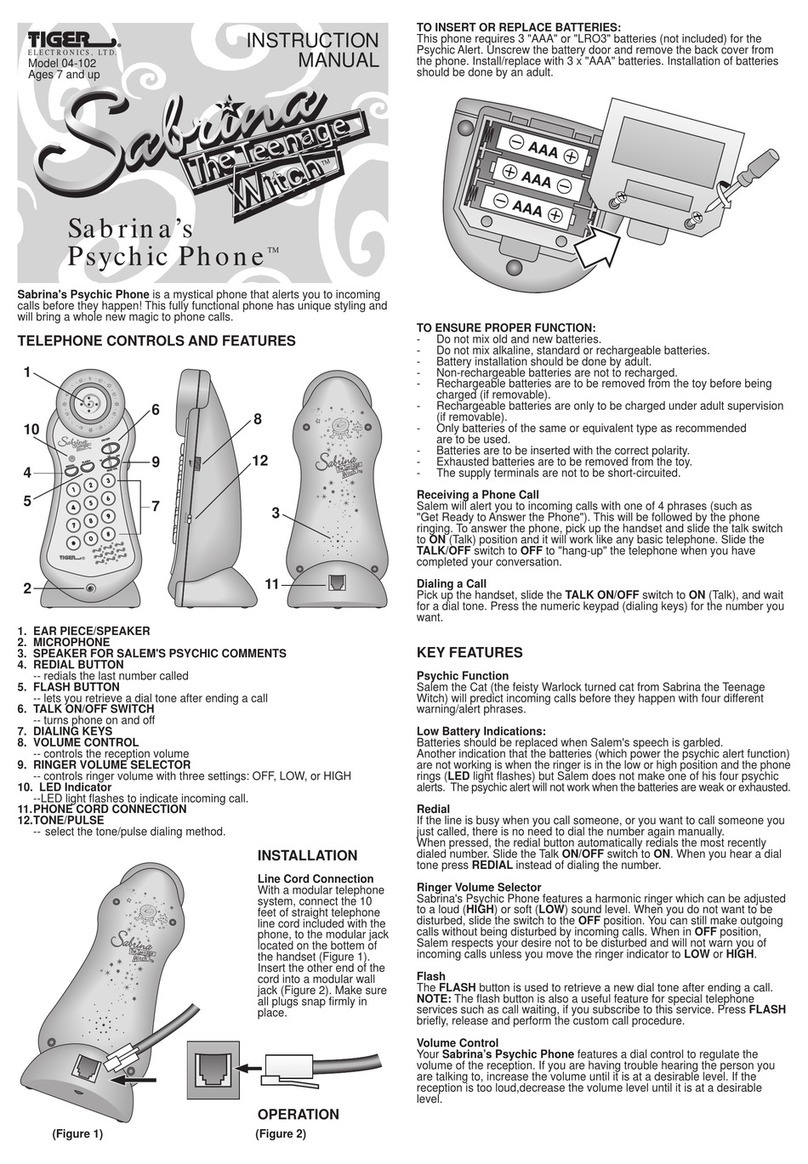

Tiger Electronics

Tiger Electronics Sabrina's Psychic Phone 04-102 instruction manual

Apogee

Apogee Midge user manual

Fisher-Price

Fisher-Price PowerMax Rescue Heroes Billy Blazes Firefighter... instruction sheet