Fei Bao F18-f User manual

F E I B A O F 1 8 – f

FEI BAO JETS

F18-f Assembly Manual

Written by Jeff DeCaluwe

In collaboration with R/C Jet Models

1

F E I B A O F 1 8 - f

DISCLAIMER:

THIS IS NOT A TOY. This is a high-performance miniature aircraft, capable of high speeds

and damage to life, limb, and property. The manufacturer and its distributors cannot control how

you assemble this model, what equipment you use to fit it out, or how you fly it, and can assume

no liability whatsoever for any damages that may occur when you fly your aircraft. By

assembling this model, you are agreeing to indemnify and hold blameless the manufacturer

and/or his agents from any and all torts and liability associated with the use of this product.

Please inspect all parts before beginning assembly. If any parts appear to be suspect, contact your

dealer or the manufacturer for repair or replacement BEFORE you begin. Once you have

assembled the aircraft, you are the pilot in command and assume any and all responsibility for

the use of the model and any damages that might occur by flying or attempting to fly this

aircraft. R/C model jets require a high level of skill in both their assembly and their flying.

If you do not feel confident in either your building or flying skills, PLEASE seek assistance from

more experienced modelers. It is a wise idea, no matter what level of skills you possess, to have

a second experienced modeler go over your installation after assembly. A second set of eyes may

spot a problem you have missed. If you have not flown a model like this before, it is HIGHLY

recommended that you get an experienced turbine pilot to do your maiden flight. Very often, the

first few seconds of a maiden flight are critical until the aircraft is trimmed out, and having an

experienced pilot at the controls can make the difference between a wrecked aircraft and one that

enjoys many hundreds of flights. Be sure to select a suitable field for flying...take the time to find

a large paved runway if at all possible, especially for test flights, until you feel comfortable

getting the aircraft in and out of smaller grass fields.

Congratulations on your purchase of the Fei Bao F18-f Jet.

BEFORE YOU BEGIN:

· Clean and inspect all parts. Inventory them against the parts list at the end of the manual

and notify the kit supplier of any missing components as soon as possible.

· If the paint scheme you have selected is glossy, it is recommended that you apply a coat of

wax. This will help resist dirt, stains and fingerprints during construction, and will provide some

limited protection against errant glue.

· Vacuum out the remnants of packing materials that remain in the fuselage.

While the kit is comprehensive, there are additional parts required, as follows:

· Recommended Servo List (Hitec)

· Elevators: (2) 5955TG

· Aileron: (2) 5245mg

· Flaps: (2) 5955TG

· Rudder: (2) 5125mg

· Nose Steering: (1) 5955TG

· Retracts: (1)HS81mg or equivalent

· Brakes: (1) HS81mg or equivalent

· Air Brakes: (1) HS81mg or equivalent

2

F E I B A O F 1 8 - f

· Other Parts

· Buna smoke tubing for inside the fuel tanks

· BVM UAT or alike highly recommended

· Wire twist tie (optional) but recommended or alike

· Blue Loctite

· Glues: Medium CA with accelerator, 35 minute epoxy, Aeropoxy or Hysol kit

· UP3 Control Valve or Electronic gear sequencer

· Brake valve

· Batteries, regulator and switch

· Servo extensions (length may vary, depending on receiver placement)

· Smoke system (Optional)

· 3mm Air line, 5 different colors, approx.. 1 to 2 meters each.

· Cockpit with pilots (Optional)

Keep this in mind as you proceed: Look at EVERY assembly step you finish, and ask yourself:

“Could this step cause my airplane to crash?”

A chain is only as strong as its weakest link, and this is a high-performance aircraft that will be

very intolerant of sloppy assembly techniques. Even the smallest component is important and can

cause the loss of your airplane, so take the time to do things right. Or Redo them if they are

wrong. Careful work will result in a long-lasting plane that gives you years of pleasure, one loose

component could result in the complete loss of the aircraft and all the components inside it, and

someone can even get hurt. So pause every once in a while when building it and double-check

your workmanship.

Introduction:

You have chosen a model that represents the pinnacle of ARF technology. While there is not a

lot of building to do, there is enough to keep you busy for more than a few evenings.

Even if you have assembled other ARF jets, we still highly recommend following our assembly

sequence and procedures anyway. Chances are it will save you a lot of time, prevent you from

running down dead ends, and perhaps remind you of a few small things that might end up saving

your aircraft.

We have tried to arrange a construction sequence that will allow you to keep moving forward,

rather than standing around waiting for glue to dry before you can proceed to the next step.

Just because the model is almost completely built does not mean you can rush through the final

assembly. You need to employ fine craftsmanship every step of the way, turbine models are

critical. Keep this in mind with everything you do, every part you install...look at the work you

just did, evaluate it critically, and ask yourself "is this going to potentially crash my airplane?" If

there is any doubt about the work you have done, back up, and re-do it properly.

3

F E I B A O F 1 8 - f

We start assembly in a sequence as:

1. Installing door hinges, doors and all air cylinders, for a minimal fee, the factory will

install them all for you, which I believe is well worth every cent.

2. Pneumatic lines for doors, retracts, brakes and air brakes.

3. Fuel tanks, replacing internal lines and installing external lines with a vent exiting the

fuselage, (Optional) Smoke tank with fuel lines and vent to exit fuselage.

4. Gluing the flap hinges, aileron hinges and rudder hinges also all control horns.

5. Elevator balancing, servos, extensions and linkages

6. Wing and rudder servo covers, servos, extensions and then linkages to each horn

7. Installing Ordnance on wings.

8. Front wheel servo with pull-pull linkages or another Non pull-pull assembly (Optional)

9. Cockpit with pilots (Optional)

10. Preparing the Equipment tray, Header tank, ECU, turbine valves, Fuel pump with shutoff

valve, Air valves, Servos for the air valves, receiver, voltage regulators with switches,

(Optional) Smoke pump with shutoff valve. (Optional) Air failsafe, and or (Optional)

Steering Gyro.

11. Installing equipment tray and making room for cockpit

12. Connecting the forward to the aft fuselage

13. Carbon fiber bypass, thrust pipe & engine

14. CG (Center of Gravity), Batteries and Air tanks

15. Transmitter setup & Maiden Flight

Before we start, Some info about Adhesives:

The correct adhesive to use for most procedures is either white Hysol 9462 made by Locktite or

white Aeropoxy made by BVM and for a little faster setting time there is a clear Vpoxy made by

BVM. These are very strong epoxies which are thixotropic. "Thixotropic" means it does not run,

Hence it stays where you put it. It is infinitely superior to regular epoxy, even slow-setting

epoxy, for our purposes, because of this characteristic. Regular epoxy will run down hill with

gravity as it dries, usually taking it away from where it is supposed to be. We will be using this

process with regular epoxy only once to balance the elevators. A good example is in the

hinges...using regular epoxy, a good portion of the glue will migrate down away from the hinge

into the inside of the wing as it dries, and you won't even know it is happening. Hysol or BVM’s

poxy stays where you put it. The downside is it takes overnight to dry properly, but we have tried

to arrange things to keep you busy while waiting for the glue to dry. We also highly recommend

that you only use a proper dispensing gun, and only the long-type mixing nozzles.

We have found over extended use that the short nozzles do not mix this glue enough, and only a

thin nozzle and gun will let you fill the hinge and control horn holes properly with glue, you can

not do it by mixing it on a flat surface and then trying to get the glue in the proper place by a

brush or stick. You can buy a complete kit with a gun, nozzles, and two cartridges of

glue from your dealer for approximately $60 to $80. Consider it a great investment, the glue is

the best you will use. One cartridge is plenty to assemble your F18-f.

4

F E I B A O F 1 8 - f

1: INSTALLING DOOR HINGES, DOORS AND CYLINDERS:

This ARF has the doors and all cylinders already installed by the factory and has been omitted

from the manual at this time. If you have to install the cylinders and doors, try to view the next 5

pictures for there placement. As they say a picture can say a thousand words.

WORKING WITH PNEUMATIC SYSTEMS

The F18-f uses pneumatic brakes and retracts. If you follow a few tips, you should have very

reliable, leak-free operation. Neatness counts.

All airlines should be secured to the airframe to keep them from flopping around or getting

kinked. Use tie wraps or holders for this. The other very important thing is to cut off the end of

each airline as square as possible before installing it on the nipple. You can either purchase a

professional tube cutter from your dealer (they are approximately $10), or you can make up a

little jig to hold the airline and keep a sharp, new razor blade perfectly upright as you cut.

Either one works, just ensure that all ends of all airlines are cut off dead square.

Make sure all airlines are pushed ALL THE WAY onto their nipples. They should not need to be

secured otherwise, but you can add fine wire, safeties wraps or even shrink tubing if you like.

Make sure all left and right matching airlines are the same length, particularly the brake lines, or

you will get uneven retraction or braking action. It's worth taking the time to get everything

pneumatic right the first time, as having your landing gear fail to retract is not THAT bad, but

having it fail to deploy can really ruin your day and the paint on the bottom of your model.

2: PNEUMATIC LINES FOR DOORS, RETRACTS & AIR BRAKE.

Attach Orange air line to each door cylinder so that when air is applied it will cause the gear

doors to open. Do this for each door cylinder. To understand how to route and show

approximately how much line is needed for each cylinder, view the next 5 pictures.

Repeat last step but use Yellow air line on the opposite side of each cylinder which will make

the doors close.

Next connect the same colors with “Y” adapters ending with that color exiting the front of the

mid section of the fuselage and having approx. 1 foot extra length sticking out to connect to the

air valves later.

Repeat again for the front nose section. But only have the end of the lines be about even with

the rear of the mid section to connect to the air values later. Remember neatness is vital, using

tube holders at key points helps a lot, as the following pictures show.

5

F E I B A O F 1 8 - f

.

Connect 2 - 8" pieces of any colored airline (I have used blue on one side and white airline on

the other side for clarity, but that is not included in the kit) to both air brake cylinders then tee

the same colors together and add an other piece about 12” to extend forward from the center of

the fuselage to the nose like the other lines to connect to a air control valve later.

6

F E I B A O F 1 8 - f

Attach Red air line to each retract cylinder so that when air is applied it will cause the gears to

deploy. Use enough line to have the lines exit 1 foot as the previous door lines did before.

Repeat the previous again but use Purple air line on the retract side of the gear cylinders.

Attach a 14" length of CLEAR tubing to each brake nipple.

Like you did for the other airline colors, connect the remainder of the clear brake line to a Y

connector and to the two brake lines.

Secure the brake lines to the struts by using clear tape or tie wraps. Do not over tighten the tie

wraps and restrict the air flow through the lines. There are also clips especially designed for this

that can be purchased from you dealer.

Check that each retract is properly secured into place.

Check the wheel alignment for toe in and toe out. The first spring should be compressed before

you adjust the wheels by putting the weight of the model on a table. The wheels should be

pointing straight forward. If they are not straight, loosen the trunion bolts to straighten them and

then retighten the trunion bolts. It is good practice to recheck tightness of all bolts just in case

the factory missed something.

Blue thread lock is also a good practice to use on any threaded bolts as it works like a lock

washer.

Never use the Red thread lock as it is for a permanent install and requires lots of heat to be

removed.

3: FUEL TANK SYSTEM

The F18-f has a 3 tank fuel system. The main is 88 oz with 2 - 40oz saddle tanks which are just

behind the CG of approx. 5½” to 6¼” from the wings leading edge. They are connected in

parallel, then “Y” connected to the main tank and then to a UAT or similar header tank of choice.

The total capacity is 168oz or 5.25 Liters. BVM UAT

There is not much to go wrong, but like the pneumatic system it does need to be done right the

first time with some careful craftsmanship. Like the airlines, all fuel lines should be cut off

square. Each fuel connection must be given a tie-wrap or fine wire for extra leak security.

7

F E I B A O F 1 8 - f

Everything needs to be very clean, especially the inside of the tanks. Depending on the kind of

header tank you use, The BVM UAT as shown above should be installed at an approx. 45-degree

angle to allow air bubbles to exit from the top fill line. You can also make up your own header

tank with a bubbles filter, or a geometrically centered pickup, but any way you do it, you should

not attempt to fly without a header tank system or you will most likely have flame outs all the

time caused by air bubbles.

The tanks will be installed in the fuselage and secured with Velcro but you should double

check each one by removing them and then removing the stoppers as explained next, then blow

them out, be sure that no debris of any sort is left in them before proceeding. This is a vital step,

do not omit this step.

It is recommended that you disassemble and inspect the tank cap hardware also as the next

picture shows, the process used to cut the tubes may leave behind a rim that constricts fuel flow

and could result in excess tank pressure and leakage. The vent tube to the top of the picture

shows what the constriction looks like before repair, while the fuel tube on the lower left shows

what the tubing should look like after clean up.

To remove the stoppers loosen the center screw about 10 or 15 turns and then try to wiggle the

stopper back and forth as you pull on the tubes and rubber stopper slightly, you may need to use

a screw driver to pry on the rubber to break the seal..

If the tubing is not constricted, skip to the next step. Use a small, round Perma-Grit rat tail file

or an Exacto knife to remove the excess metal. You will need to inspect the ends of all tubes.

When finished, make sure to blow out the metal fragments and clean up any sharp edges.

8

F E I B A O F 1 8 - f

There is also a problem with the internal tubing supplied at the factory in the tanks. After some

time in kerosene the tubing tends to get stiff and hard. We recommend changing these lines with

flexible black buna smoke tubing which remains flexible.

After getting the assembly out, remove the factory provided tubing and reinstall with the

recommended tubing, Assemble as the above right picture shows. Insert the assembly and check

that you use enough tubing to allow the clunk to touch in the bottom back corners. When

satisfied, use tie wraps or fine safety wire for security to prevent the tubing and clunk from

falling off. Gently bend the vent line to reach the top of each tank, You should also notch the

vent tube with a small file to provide for continued air flow should the tube come into contact

with the top of the tank.

Insert the stopper and clunk assembly into the tanks and tighten the screw. Do not over tighten

the screw and strip out the stopper assembly. It only needs to be tight enough to prevent leaks.

Mark a “V” over the vent line on each tank to remind you where the vent line is.

Testing tanks for leaks, attach some tubing to one of the tanks, immerse the tank into water,

and blow into the tubing to check for leaks. Do this for each tank. When satisfied there are no

leaks, put the tanks aside. Do not use a compressor or hand pump to test the tanks as too much

pressure could blow the tanks apart at the seams. Then you will have a big job to repair them

which would be to scuff, clean and glue them again with an epoxy. The next step is not required

but may be done to your liking just as an extra security seal on the tanks.

Optional Fuel Tank Reinforcement

It has been experienced on a couple of occasions were the fuel tanks have leaked. They were

caused by too much pressure during the fueling process. The concave side of the tanks, tend to

flex under this pressure and may crack the lapped glue joint. The following modification has

cured the problem. It is also sensible to be careful during the fueling procedure to slow the rate

of fuel going in as the tank becomes near full.

a) Solvent clean outside surface then use #80 grit sandpaper to scuff the surface area.

9

F E I B A O F 1 8 – f

b) Drill (5) 1/16” holes about 1/2” apart with the middle hole near the center of the concave side

of the tank. Center the holes fore and aft on the lap joint. Have a helper hold a vacuum nozzle

such that the drilled residue is removed.

c) Use a PermaGrit # RF9UF countersink tool (with vacuum) to allow the Poly Ply Screw head

(BVM Part# 5725) to seat near flush with tank surface. Solvent clean 10 Poly Ply screws then

apply a small amount of poxy to each hole and insert the screws.

d) Tape the area as shown and apply a coat of epoxy. Remove the tape while glue is wet.

Put aside overnight to dry / cure.

4: GLUING FLAP, AILERON, RUDDER HINGES & CONTROL HORNS

While there are many ways of doing this, this method will let you do all the surfaces at once,

assures proper alignment and movement, and lets you move on to other assembly work while the

glue on the hinges dries. Most techniques involve gluing one side of the hinges, letting it dry and

then doing the other side the next night. This method lets you do both sides at once, and

guarantees proper alignment if needed. This model has the control surface hinges pre glued on

the control surface sides by the factory for alignment purposes and to help keep each surface in it

placement left and right. All you have to do is glue the other half to the wings and rudders.

Follow the procedure fully for best results whether gluing both sides or not.

Put a towel, cloth or something soft like foam down on your bench to prevent the painted

surfaces from being scratched. If not in place, locate all the control surfaces to their correct place

on the wings and rudders. Check for proper mating, hinge location, and movement on all

surfaces. Starting with either wing

Remove the control surfaces.

10

F E I B A O F 1 8 - f

Coat the center portion of each hinge with petroleum jelly. Use enough to keep any glue from

sticking, but make sure you do not get any petroleum jelly on the ribbed portion of the hinge that

needs to be glued. If you get any on this portion you must clean it off with Acetone or some

other kind of strong cleaner, then sand / scuff to allow adhesion. If you do not get proper

adhesion, the control surface could come out in flight, which in turn would most likely cause a

crash, depending on your flying skills.

. Coat the leading edge of each control surface with a thin layer of petroleum jelly to keep any

glue from sticking.

Note the flap hinges closest to the fuselage has been shortened at the factory to prevent them

from protruding into the carbon fiber spar.

Use a piece of 40 grid sand paper to scuff up the short ends by sanding them in a round

motion to roughen in a grove that gives a ribbed affect, like the larger ones have. Giving some

extra attention on these should give you proper adhesion.

11

F E I B A O F 1 8 - f

Get a wing and fill the three holes with Hysol or BVM epoxy. Be fairly generous with the

glue. The ONLY place where glue should be is in the hole itself...clean up any excess right away.

To help for an even better adhesion you may want to put some glue around each hinge staying

away from the pinned area with petroleum jelly on it.. Only use enough to get the hinge covered

with a thin film using to much glue just adds weight and will collect around the holes entrance.

Keeping the hinges at 90 degrees to the control surface, gently push the control surface into

place on the wing / rudder. Keeping it at right angles keeps the hinges from getting pushed

further into the surface and getting misaligned. When you get to the final quarter inch or so of

insertion, start reducing the angle of the surface until the surface slides home the final bit.

Carefully align the trailing edges of the flap and aileron surfaces, using the trailing edge of the

wing at the tip, and the paint stripes, as a guide.

Check for adequate freeness and movement on the surfaces, paying particular attention to

having enough downward movement on the flaps.

When you are satisfied, tape both the flap and aileron into place with masking tape to prevent

any misalignment while drying, set this assembly aside, and do the same procedures to the other

wing.

Repeat last 8 steps for the rudders. When completed set all these assemblies aside to dry

overnight.

12

F E I B A O F 1 8 – f

5: ELEVATOR BALANCING, SERVOS, EXTENSIONS & LINKAGES

Some may say not to balance your elevators because it may cause flutter but I tend to differ, If

your servo gear mesh and linkage is tight with out any play there should not be a problem

whether it is balanced or not and if there is play in the gear mesh or linkage then you will

probably get flutter either way. By balancing the elevators you reduce the extra strain on the

servos gear train and with the precise digital servos we have today, balancing will stop the

bussing sound you will get from the weight of the elevators pushing down from the gravity.

To balance the elevators drill a hole approx. ½” in diameter with either a dremel or a drill on

the inside flat edge of the elevator, approx. 3½” from the corner of the leading edge, view picture

below. If you decide to use a drill, a tip to prevent breaking the elevators seam is to start out

with a smaller bit and then go bigger till it is approx. ½”. I have used about 80 grams of BB’s for

weight but anything like small pieces of lead, pellets, buckshot or birdshot will work in the hole

to get the elevator to balance. To create a centerline, use a ruler and make a mark with a pencil at

the edge of the elevator straight inline with the center of the shaft protruding from the elevator.

Use your finger on this pencil spot as a balance point and another finger as a resting area for the

shaft. Keep adding weight till it starts to stay down or not move in a horizontal position. Do not

let the elevator fall backwards from a horizontal position to prevent the weights falling to the

trailing edge. After you get it close to balance. You will need to take out enough weight to

account for the epoxy you are going to put in the hole to secure the weight inside. Approx. 1oz of

30 minute epoxy which weighs about 30 grams should do the trick. Mix and pour the epoxy in

the hole then cover the hole with some tape and let it stand vertical so the weight is on the

bottom but at a slight angle to allow the epoxy to cover the hole as it dries.

13

F E I B A O F 1 8 - f

Repeat previous step for the other elevator.

Install the elevator servos as show in the pictures below and do not use the rubber grommets as

they may cause flutter if there is to much play.

Attach a 36" heavy-duty 22-gauge extension to each servo. Tape the connections for safety.

You can also drill a hole through the bottom on each side of the rear fuselage to allow easy

access to the hex bolts that secure the elevators which allows easy removal to transport your

model..

6: WING & RUDDER SERVO COVERS, SERVOS, EXTENTIONS

Remove the servo cover from the rudder servo bay. Keep the orientation of the servo cover

correct, do not flip or rotate the servo covers, as there may be slight variations in the screw holes

and they may not fit perfectly if you rotate the covers. You can do both rudder servo assemblies

at the same time, if you like.

Test fit your rudder servos. You want a metal-geared, high-powered mini servo. A standard

servo will not fit, and full micro servos generally lack enough mounting area on their ears to

make them really safe, even though many of them have plenty of power for your rudders. You

could also fit a surface-mounted flat servo. In this case, the Hitec 5125MG is excellent for this

application. Beware of just gluing the servos into place...if you break a servo gear and have to

remove the servo for maintenance, you are in big trouble.

Attach a 36" heavy-duty 22 gauge extension to the servo. Tape the connection for safety.

Feed the extension through the rudder

14

F E I B A O F 1 8 - f

You can hold the servo with wooden blocks by cutting 3 for each side then drill holes through

them then screw them to the servo, then put a little epoxy on the side that goes to the inner wing.

And clamp it there over night to dry or you can purchase servo wing holders from your dealer

that glue on the inside of the wing and then there is 3 screws that hold the servo in place as seen

in the pictures.

Cut a slot in the cover for the servo horn approx. 1” long which should do for the movement of

the servo then drill a hole at each end like the lower picture shows and draw a line on each side

as shown then use a new sharp exacto blade to cut the lines. After satisfied with the slot screw

the cover back in place.

Attach the provided linkage to the servo horn

Prepare all 6-control horns. Roughen up the bottom portion on both sides by using 40 grit

sandpaper or a dremel to give you a better gluing bond.

15

F E I B A O F 1 8 - f

You will also need to open up the top holes to accommodate the bolts for the ball links. Go

very slowly on this, if the holes end up oversize, you will need to replace them. Or they will give

you flutter. Do all 6 control horns at once.

Bolt a horn into place, and adjust the linkage to the correct length

Put a piece of masking tape on the surface of the rudder where the horn will go. This tape will

protect the surface while you work there, and keep any markings you need to make from being

on the surface itself.

Mark the location of the horn.

16

F E I B A O F 1 8 - f

Cut the slot for the horn. Power tools are a little dangerous here, as if they slip. you can drill all

the way through to the other side of the surface. Use an exacto and many small strokes, only

resort to the Dremel if you run into a really hard portion. You do not want the slot to be a super

tight fit on the horn, you want room for glue in there, but nor do you want huge gaps.

If you wait until all the horns on all the surfaces are done, you can glue them all at once, which

will save you glue, glue tips, and time. So hold off for now on gluing.

Place a wing on your towel to install the servos for the flaps and ailerons.

Fit the supplied aluminum mounts to the servo, using the supplied screws. Do not over tighten

and strip the screws. The screws appear to be smaller than the hole and strip easily. You may

need to get new screws if they strip. Do not use any grommets or other servo hardware.

As any play could cause flutter. Secure the screws with the medium strength blue thread

locktite.

Drill pilot holes in the wooden mounts and secure the servo with the kit-provided screws.

Do not over tighten and strip the screw holes. You may wish to strengthen the wooden threads by

unscrewing the screws and then putting a drop of thin CA in the holes then let it dry before you

screw the servos back in.

17

F E I B A O F 1 8 - f

Repeat the last 8 steps for the flaps and ailerons when you are done mounting the servos.

You will need 12" extensions on the aileron servos. The flap servos, of course, only travel

down, so adjust your linkages and servos accordingly, so that they are all the way at one end

when the flaps are up(neutral, level with the wing), and all the way at the other end when flaps

are down. Note that you will need a servo reverse / programmer, a JR Matchbox, a reversed

servo, or two separate channels for normal setup of the flaps, or one will work backwards. If you

are using the now popular Spektrum DX7 radio, you will not have a spare channel to program

the second flap to move correctly. Here is a trick to allow you to run both flap servos off one

channel with just a regular servo y-harness.

Install the flap servo into the right wing normally. For the left wing, do this: Cut two scrap

plywood blocks as shown, the same width as the existing servo mounts, but about 1" long.

Epoxy those blocks into place, level with the existing mounts. Do not epoxy them to the

mounts, but only to the wings and to the little corner triangular blocks that hold the servo cover

hold-down screws.

when the new blocks are thoroughly dry, cut away the old ones. A few strokes of a sharp

exacto will do it.

Trim the blocks for your servo. Make a cutout for the servo lead

18

F E I B A O F 1 8 - f

Install the flap servo as shown, along with the linkage and horn. Note that they may not be

much structure beneath this new slot to hold the horn, pay extra attention to using lots of Hysol

or epoxy glue when you glue this horn in or you could use blocks that are bigger to go a bit

under the wing foil.

Now you have both flap servos facing the same direction and traveling the same way. After the

horns are glued in, you can plug both wings into a y-harness and adjust the linkages for matched

travel.

All of your servos are installed, now it is time to glue in the horns. Follow the same procedures

for all six horns. First use masking tape to tape the control surfaces to keep them from moving.

Surround each control horn slot with masking tape, leaving a 1/8" border all around. Do not

tape the area in front of the horn, only the two sides and the rear

Fill the slot completely with Hysol. Inject the glue as far in as you can go, it's much better to

have excess glue here than too little. This application is another great reason to use the Hysol

glue gun and nozzles; It is very difficult to get the glue down inside the slot without a glue gun.

19

F E I B A O F 1 8 – f

Add a bead of glue to each side of the control horn. Be sure to use your nozzle to inject glue

into the small holes in the horn, they need to be filled with glue for proper strength of the joint.

Insert the control horn into the slot, making sure it is 90' to the surface, and not too deep and not too

shallow in the slot.

Smooth out the fillet of glue on each side of the horn with a dowel or your finger. If you do not

have a nice, complete fillet on both sides of the horn, add more glue until you do.

Remove the masking tape before the glue dries, and all the excess glue will go with it, leaving

you a nice 1/8" fillet around the horn.

Table of contents

Other Fei Bao Toy manuals

Fei Bao

Fei Bao T45 User manual

Fei Bao

Fei Bao Velox XL User manual

Fei Bao

Fei Bao MiG-21 Fishbed User manual

Fei Bao

Fei Bao EF2000 User manual

Fei Bao

Fei Bao MB-339 User manual

Fei Bao

Fei Bao Mirage F1 User manual

Fei Bao

Fei Bao L-39 User manual

Fei Bao

Fei Bao hawker hunter User manual

Fei Bao

Fei Bao Velox User manual

Fei Bao

Fei Bao F-4 Phantom II User manual

Popular Toy manuals by other brands

Carl Goldberg Products

Carl Goldberg Products ULTIMATE BIPLANE instruction manual

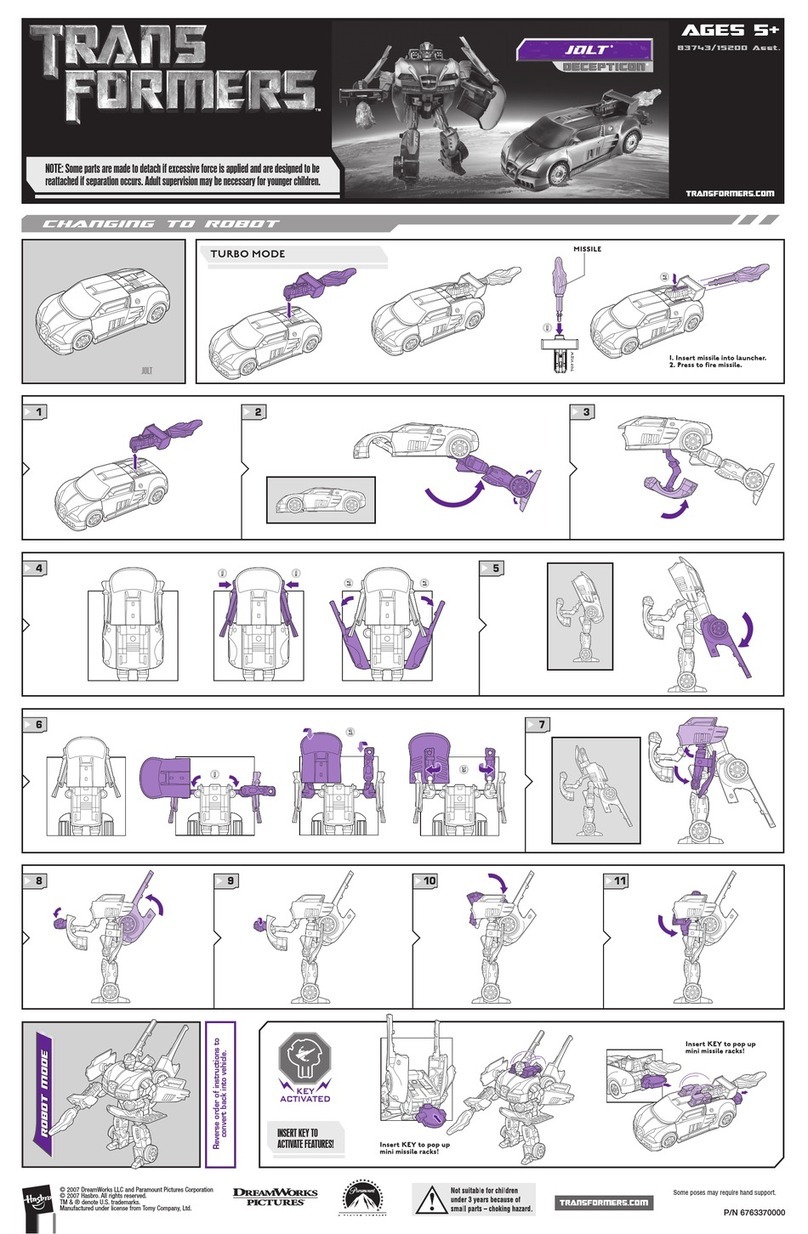

Hasbro

Hasbro Transformers 83743 instruction manual

Viessmann

Viessmann 4709 H0 user manual

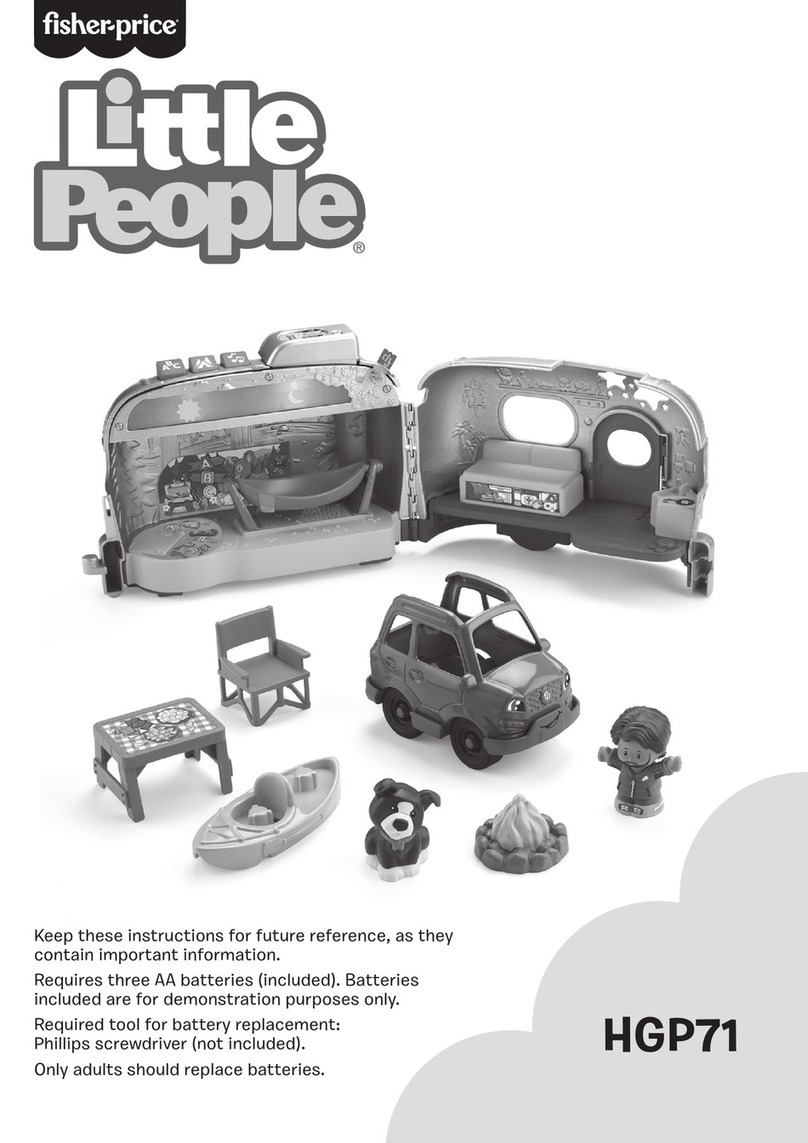

Fisher-Price

Fisher-Price Little People HGP71 manual

NATURE & DECOUVERTES

NATURE & DECOUVERTES MON ATELIER TRANSFORMABLE quick start guide

krakpol

krakpol 102/243005 Assembly instructions