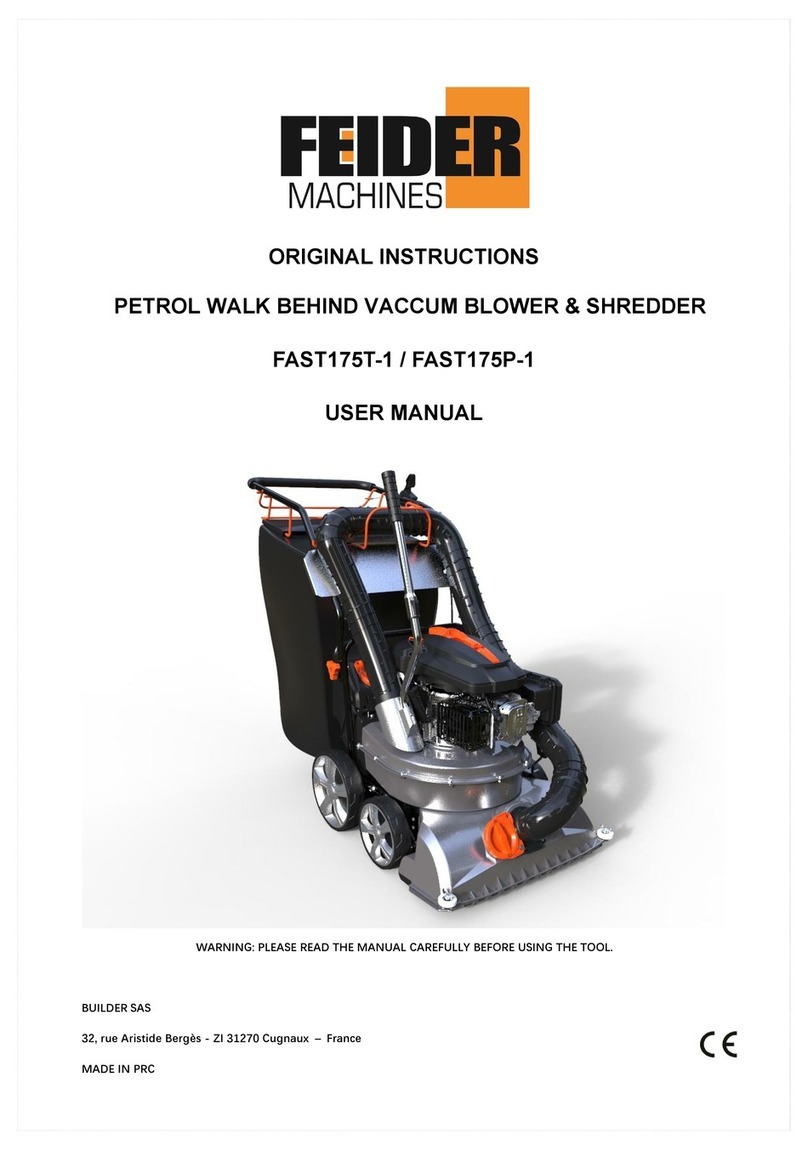

Feider Machines FBAE200-2 User manual

ORIGINAL INSTRUCTIONS >EN

PETROL SWEEPER

FBAE200-2/FBAE200ES-2

USER GUIDE

CAUTION: Read this manual before using this machine!

CONTENTS

1. SAFETY INSTRUCTIONS....................................................................................................................3

2. MAIN COMPONENTS...........................................................................................................................8

3. PACKAGE CONTENTS........................................................................................................................9

4. ASSEMBLY.............................................................................................................................................9

5. OPERATION.........................................................................................................................................11

6. CHANGE ATTACHMENTS................................................................................................................15

7. SERVICE & REPAIR - GENERAL....................................................................................................16

8. STORAGE.............................................................................................................................................17

9. TROUBLESHOOTING........................................................................................................................17

10. MAINTENANCE.................................................................................................................................17

11. TECHNICAL DATA...........................................................................................................................22

12. DECLARATION OF CONFORMITY...............................................................................................23

13. WARRANTY....................................................................................................................................... 24

14. PRODUCT FAILURE........................................................................................................................ 25

15. WARRANTY EXCLUSIONS............................................................................................................26

02

1. SAFETY INSTRUCTIONS

Please read this entire manual prior to operating the equipment. It instructs you how to

safely and easily set up, operate and maintain your machine. Please be sure that you, and

any other persons who will operate the machine, carefully follow the recommended safety

practices at all times. Failure to do so could result in personal injury or property damage.

Function of Sweeper

This sweeper is designed solely for the use in clean up, maintenance and similar. And please pay

more attention that NOT for small stone cleaning, to avoid the injury.

Use in any other way is considered contrary to the intended use. Compliance with and strict

adherence to operation, service and repair conditions, as specified by the manufacturer, are also

essential elements of the intended use.

Terms used in Manual

Right-hand, left-hand, front and rear are determined from actual operating position.

SAFETY STATEMENTS

DANGER

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

WARNING

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH COULD RESULT IF THE

INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

CAUTION

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF THE INSTRUCTIONS

ARE NOT FOLLOWED PROPERLY.

NOTICE

THIS STATEMENT IS USED WHERE EQUIPMENT OR PROPERTY DAMAGE COULD RESULT

IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SYMBOL BY ITSELF OR USED WITH A SAFETY SIGNAL WORD THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR

PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

GENERAL SAFETY PRECAUTIONS

WARNING

READ MANUAL PRIOR TO INSTALL

Improper installation, operation, or maintenance of this equipment could result in serious injury or

death. Operators and maintenance personnel should read this manual as well as all manuals

related to this equipment and the prime mover thoroughly before beginning installation, operation,

or maintenance. Follow all Safety instructions in this manual.

WARNING

READ AND UNDERSTAND ALL SAFETY STATEMENTS

03

Read all safety decals and safety statements in all manuals prior to operating or working on this

equipment. Know and obey all regulations, local laws and other professional guidelines for your

operation. Know and follow good work practices when assembling, maintaining, repairing,

mounting, removing or operating this equipment.

WARNING

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before operating. Visually inspect

your equipment before you start, and never operate equipment that is not in proper working order

with all safety devices intact. Check all hardware to assure it is tight. Make certain that all locking

pins, latches, and connection devices are properly installed and secured. Remove and replace any

damaged, fatigued or excessively worn parts. Make certain all safety decals are in place and are

legible. Keep decals clean, and replace them if they become worn and hard to read.

WARNING

PROTECT AGAINST FLYING DEBRIS

Always wear proper safety glasses, goggles or a face shield when driving pins in or out or when

operation causes dust, flying debris, or any other hazardous material.

WARNING

LOWER OR SUPPORT RAISED EQUIPMENT

Do not work under raised booms without supporting them. Do not use support material made of

concrete blocks, logs, buckets, barrels or any other material that could suddenly collapse or shift

positions. Make sure support material is solid, not decayed, warped, twisted, or tapered. Lower

booms to ground level or onto blocks. Lower booms and attachments to the ground before leaving

the cab or operator’s station.

WARNING

DO NOT MODIFY MACHINE OR ATTACHMENTS

Modifications may weaken the integrity of the attachment and may impair the function, safety, life

and performance of the attachment. When making repairs, use only the manufacturer’s genuine

parts, following authorized instructions. Other parts may be substandard in fit and quality. Never

modify any RoPS (Roll over Protection System) equipment or device. Any modifications must be

authorized in writing by the manufacturer.

WARNING

SAFELY MAINTAIN AND REPAIR EQUIPMENT

• Do not wear loose clothing, or any accessories that can catch in moving parts. If you have long

hair, cover or secure it so that it does not become entangled in the equipment.

• Work on a level surface in a well-lit area.

• Use properly grounded electrical outlets and tools.

• Use the correct tool for the job at hand. Make sure they are in good condition for the task required.

• Wear the protective clothing equipment specified by the tool manufacturer.

WARNING

SAFELY OPERATE EQUIPMENT

Do not operate equipment until you are completely trained by a qualified operator in how to use the

controls, know its capabilities, dimensions, and all safety requirements.

04

• Keep all step plates; grab bars, pedals, and controls free of dirt, grease, debris, and oil.

• Never allow anyone to be around the equipment when it is operating.

• Do not allow riders on the attachment or the prime mover.

• Do not operate the equipment from anywhere other than the correct operators position.

• Never leave equipment unattended with the engine running or with this attachment in a raise

position.

• Do not alter or remove any safety feature from the prime mover or this attachment.

• Know your work site safety rules as well as traffic rules and flow. When in doubt on any safety

issue, contact your supervisor or safety coordinator for an explanation.

WARNING

FALL HAZARD - DO NOT OPERATE NEAR UNGUARDED EDGES.

• This sweeper is NOT intended for roof top use.

• When operating sweeper, adhere to all government rules, local laws and other professional

guidelines for your sweeping application.

- Road surface cleaning shall only be operated by specially trained personnel. The user must

know how to assemble, handle, operate and maintain this machine. People not trained must

have a formation given by a professional.

- Always transport the tool by the handles. Do not lift the tool and do not use any device to

transport it.

- Always wear protective equipment, which shall include at least eye protection, hearing

protection, helmet, trousers, and protective shoes.

- If blockage is likely to occur, stop the machine; let the machine cool down. Inspect the

machine and remove the blockage. If machine is damaged do not use it and bring it to

specially trained personnel. for inspection and reparation.

- Maintenance work in hydraulic system is only to be carried out by specially trained

personnel.

Safe operation practices for pedestrian-controlled snow throwers

General

This machine is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury.

Training

a) Read, understand and follow all instructions on the machine and in the manual(s) before

operating this unit. Be thoroughly familiar with the controls and the proper use of the machine.

Know how to stop the unit and disengage the controls quickly.

b) Never allow children to operate the machine. Never allow adults to operate the machine without

proper instruction.

c) Keep the area of operation clear of all persons, particularly small children.

d) Exercise caution to avoid slipping or falling, especially when operating the machine in reverse.

Preparation

a) Thoroughly inspect the area where the machine is to be used and remove all doormats, sleds,

boards, wires and other foreign objects.

b) Disengage all clutches and shift into neutral before starting the engine (motor).

05

c) Do not operate the machine without wearing adequate winter garments. Avoid loose fitting

clothing that can get caught in moving parts. Wear footwear that will improve footing on slippery

surfaces.

d) Always wear safety glasses or eye shields during operation or while performing an adjustment

or repair to protect eyes from foreign objects that may be thrown from the machine.

e) Handle fuel with care; it is highly flammable:

1) Use an approved fuel container.

2) Never add fuel to a running engine or hot engine.

3) Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.

4) Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always

place containers on the ground, away from your vehicle, before filling.

5) When practical, remove gas-powered equipment from the truck or trailer and refuel it on the

ground. If this is not possible, then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

6) Keep the nozzle in contact with the rim of the fuel tank or container opening at all times, until

refueling is complete. Do not use a nozzle lock-open device.

7) Replace gasoline cap securely and wipe up spilled fuel.

8) If fuel is spilled on clothing, change clothing immediately.

f) Use extension cords and receptacles as specified by the manufacturer for all units with electric

starting motors.

g) Adjust the collector housing height to clear gravel or crushed rock surface.

h) Never attempt to make any adjustments while the engine (motor) is running (except when

specifically recommended by manufacturer).

Operation

a) Do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all

times.

b) Exercise extreme caution when operating on or crossing gravel drives or walks. Stay alert for

hidden hazards or operating near public roads.

c) After striking a foreign object, stop the engine (motor), remove the wire from the spark plug,

disconnect the cord on electric motors, thoroughly inspect the snow thrower for any damage,

and repair the damage before restarting and operating the snow thrower.

d) If the machine should start to vibrate abnormally, stop the engine (motor) and check

immediately for the cause. Vibration is generally a warning of trouble.

e) Stop the engine (motor) whenever you leave the operating position, before unclogging the

collector/ impeller housing or discharge chute, and when making any repairs, adjustments or

inspections.

f) Do not run the engine indoors, except when starting the engine and for transporting the snow

thrower in or out of the building. Open the outside doors; exhaust fumes are dangerous.

g) Exercise extreme caution when operating on slopes.

h) Never operate the machine without proper guards and other safety protective devices in place

and working.

i) Never direct the discharge toward people or areas where property damage can occur. Keep

children and others away.

j) Do not overload the machine capacity by attempting to clear snow at too fast a rate.

06

k) Never operate the machine at high transport speeds on slippery surfaces. Look behind and use

care when operating in reverse.

l) Disengage power to the collector/impeller when the machine is transported or not in use.

m) Use only attachments and accessories approved by the manufacturer of the machine (such as

wheel weights, counterweights or cabs).

n) Never operate the machine without good visibility or light. Always be sure of your footing, and

keep a firm hold on the handles. Walk; never run.

o) Never touch a hot engine or muffler.

Clearing a clogged discharge chute

a) Hand contact with the rotating impeller inside the discharge chute is the most common cause of

injury associated with snow throwers. Never use your hand to clean out the discharge chute.

b) To clear the chute:

1) SHUT THE ENGINE OFF!

2) Wait 10 s to be sure the impeller blades have stopped rotating.

3) Always use a clean-out tool, not your hands.

Maintenance and storage

a) Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the

equipment is in safe working condition.

b) Never store the machine with fuel in the fuel tank inside a building where ignition sources are

present such as hot water heaters, space heaters or clothes dryers. Allow the engine to cool

before storing in any enclosure.

c) Always refer to instruction handbook for important details if the snow thrower is to be stored for

an extended period.

d) Maintain or replace safety labels, as necessary.

e) Run the machine a few minutes after throwing snow to prevent freeze-up of the

collector/impeller.

SYMBOLS

WARNING!

WARNING! Read the instructions before operating the machine.

DANGER! Ejected objects. Do not turn the brush towards onlookers or

animals.

DANGER! Keep people, children and animals away from the work area.

Toxic fumes; do not operate inside house.

07

Wear protective foot wear.

Wear protective gloves.

Unplug the spark plug before maintenance and repair. Read the instruction

manual.

DANGER! Always use hearing protectors. Wear ear protection against

noise! Always use eye protectors. Wear eye protections.

Guarantee sound power level.

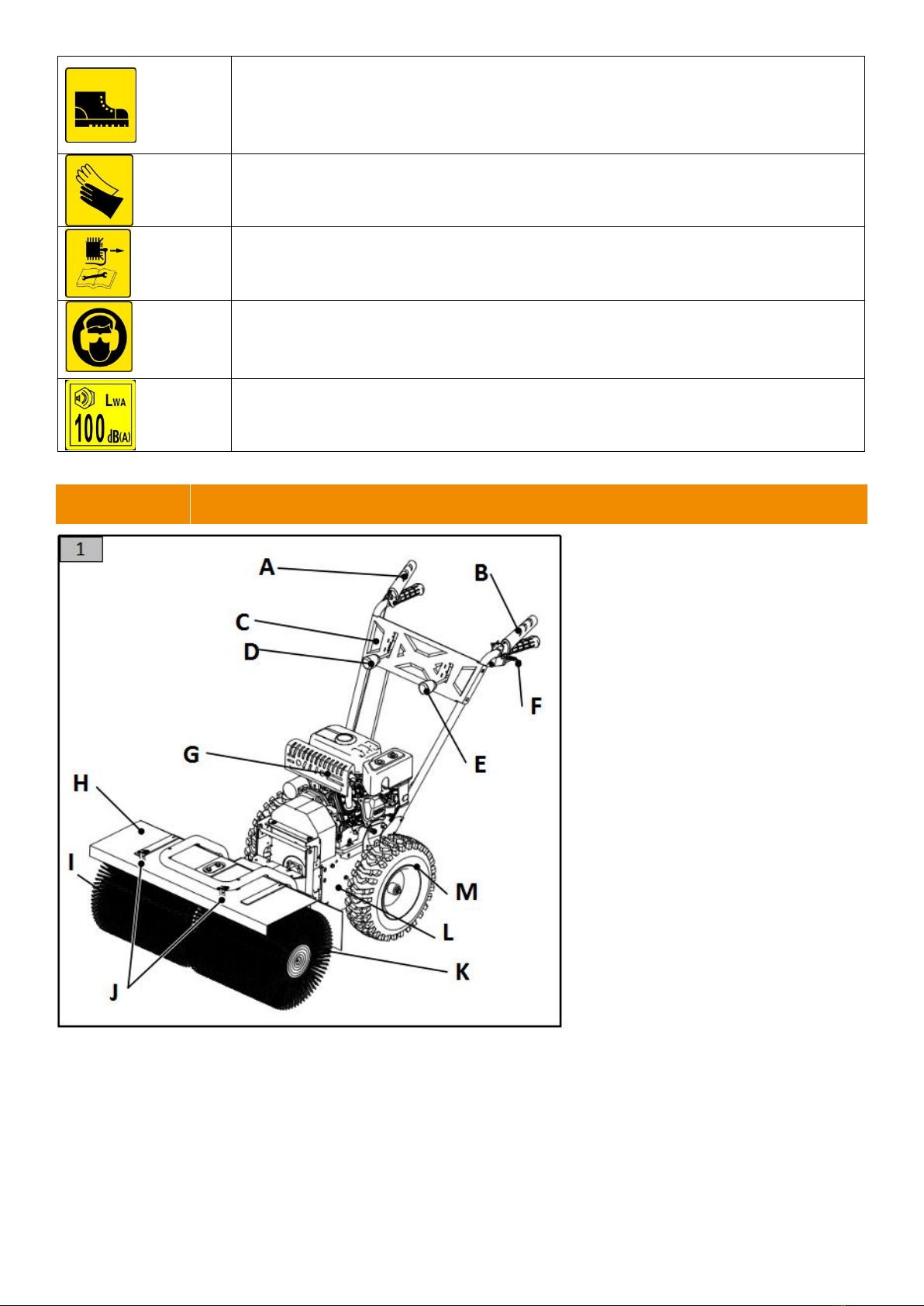

2. MAIN COMPONENTS

A. Brush control lever

B. Drive control lever

C. Dashboard

D. Gear position

E. Brush direction

F. Unlock control lever

G. Fuel tank

H. Brush safety guard

I. Brush

J. Fixing accessories equipment

K. Caster wheels

L. Transmission box

M. Wheel

08

3. PACKAGE CONTENTS

Pos.

Description

Qty

A1

Handle with pre-installed rods and wires

1

A2

Separate handle with bolts

1

B

Handle fastening screws

4

C

Handle fastening bolts

4

D

Spark plug removal key

1

E

Nuts and bolts

4

NOTES:

1. Cautiously open the packaging, paying attention not to lose components.

2. Consult the documentation in the box, including these instructions.

3. Remove all the unassembled parts from the box.

4. Remove the machine from the box.

5. Dispose of the box and packaging in compliance with local regulations.

4. ASSEMBLY

Please note that during assembly, maybe you’ll need a helper!

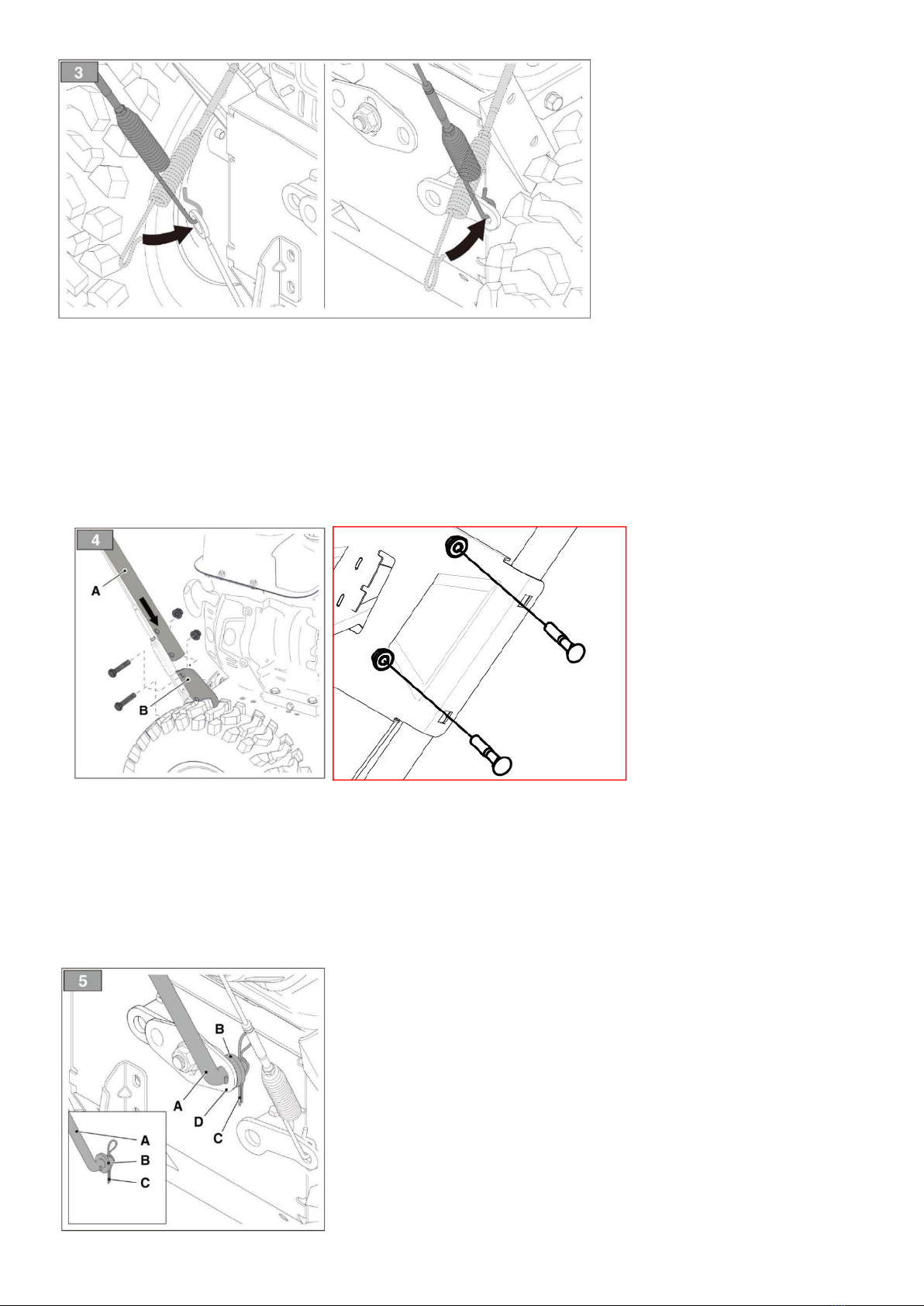

1. Forward and brush control cable assembly

Couple the cable eyelet to the specific opening (fig. 3).

NOTE: The cables are already pre-assembled on the dashboard.

09

2. Handle assembly

The dashboard is delivered with one handle disassembled. The machine handle assembly screws,

gear control fastening screws and nuts and bolts to secure the brush directional control are

delivered in a separate package found in the machine packaging. Install as follows:

a) Install the separate handle to dashboard by fixing two bolts.

b) Bring the two tubes at the ends of the handle (fig. 4.A) up to the support (fig. 4.B).

c) Insert the screws in the holes and secure in place with the nuts.

3. Installation of the gear control

a) Remove the previously assembled articulated joint (fig. 5.A) on the washer gear control (fig. 5.B)

and nut (fig. 5.C).

b) Insert the articulated joint (fig. 5.A) of the gear control in the hole on the lever (fig. 5.D) to

connect it to the transmission.

c) Secure the washer (fig. 5.B) and nut (fig. 5.C).

10

4. Brush directional control assembly

a) Remove the previously assembled articulated joint (fig. 6.A) on the brush directional control nut

(fig. 6.B).

b) Insert the articulated joint (fig. 6.A) on the brush directional control in the lever hole (fig. 6.C) to

connect it to the drive.

c) Secure the nut (fig. 6.B).

5. OPERATION

ENGINE OPERATION

NOTICE: THE MOTOR IS DELIVERED WITHOUT OIL AND GASOLINE.

Oil Filling

Place the motor in a horizontal position. Remove the plug and fill with oil right to the edge. (Fig.7)

Fuel

Use lowest available octane unleaded fuel. When filling, place the machine in a horizontal position.

Always replace old fuel. Always stop the motor when fueling. Never fill up with fuel on a hot motor.

Never use gasoline mixed with oil.

Operation - Start and Stop

Cold Motor

Activate the motor choke. Set the throttle control on full speed. (Figure 8) first, pull the starting rope

a couple of times, shortly, until if feels tight. Pull the starting rope slowly to the point where it feels

tight, place your left hand on the motor in order to hold back, and pull the starting rope hard once.

For electric start, Plug the extension cord into the outlet located on the engine’s surface. Plug the

other end of extension cord into a 230-volt, grounded, AC outlet in a well-ventilated area. Set the

throttle control on full speed (Figure 8). then push start button to start engine.

When the motor runs, deactivate the choke.

NOTICE: NEVER LET THE STARTING ROPE WIND AGAIN BY ITSELF.

Follow it all the way back with your hand. If the motor will not run in spite of several attempts this

may be caused by the fact that there is too much fuel in the cylinder/carburetor, and that the spark

plug has become moist. Remove the plug and wipe it off.

Stop the Motor

Set the throttle control in position “Stop”. Set the throttle lever to idle and let the motor run for 12-20

seconds before the lever is moved to stop. Never leave the sweeper without stopping the motor.

11

NOTICE: Do not turn off the motor by switching on the choke, as this may result in damage to the

motor.

MACHINE OPERATION

CAUTION

A SWEEPER IS A DEMANDING MACHINE.

Only fully trained operators or trainee operators under supervision of a fully trained person should

use this machine.

Before operating sweeper:

Operate sweeper controls in an off-road location.

Be sure that you are in a safe area, away from traffic or other hazards.

Check all hardware making sure it is tight.

Replace any damaged or fatigued hardware with properly rated fasteners.

Check tire pressure before sweeping.

Remove from the sweeping area all property that could be damaged by flying debris.

Be sure all persons not operating the sweeper are clear of the sweeper discharge area

protection; and a dust mask.

Always wear proper apparel such as a long sleeved shirt buttoned at the cuffs; safety glasses

goggles or a face shield; ear protection; and a dust mask.

While operating sweeper

DANGER

FALL HAZARD - DO NOT OPERATE NEAR UNGUARDED EDGES.

This sweeper is not intended for roof top use.

When operating sweeper, adhere to all government rules, local laws and other professional

guidelines for your sweeping application.

Minimize flying debris - use the slowest rotating speed that will do the job.

Keep hands, feet, hair and other loose clothing away from all moving parts.

Before leaving the operator’s position for any reason stop engine.

NOTICE: AVOID TRANSMISSION DAMAGE. Do not shift while in motion.

WARNING

Leave the brush hood (shield) and all other shields and safety equipment in place when operating

12

the sweeper.

When sweeping on rough terrain, reduce speed to avoid “bouncing” the sweeper. Loss of

control can result.

Never sweep toward people, buildings, vehicles or other objects that can be damaged by flying

debris.

Only operate the controls while the engine is running.

While you operate the sweeper slowly in an open area, check for proper operation of all

controls and all protective devices. Note any repairs needed during operation of the sweeper.

Report any needed repairs.

Before each use

Perform daily maintenance as indicated in Maintenance Schedule.

Run the sweeper at a low idle, check for proper brush rotation and drive engagement.

WARNING

AVOID SERIOUS INJURY.

Check for large objects that could harm the operator or others if thrown by the sweeper. Remove

these items before operating.

During use

Directing Debris

Avoid excessive downward pressure on the brush sections to prevent excessive wear. A two to

four inch wide pattern is sufficient for most applications.

Direct debris by angling the brush head in that direction.

Observe wind direction. Sweeping with the wind makes sweeping more effective and helps

keep debris off the operator.

The terms swing and angle are used interchangeably.

Brush Direction

The brush direction is regulated by a lever (fig. 9B) that tilts it in the required direction. Move the

lever forward or rear in one of the 3 available positions to tilt the brush.

· Lever forward = 15oto the right.

· Lever central = 0ono tilt.

· Lever rear = 15oto the left.

Sweeping

To sweep:

1. Turn the handle(fig.9A) to control Forward and Rear.

2. Turn the brush directional control (fig. 9 B) to the required

position. (See Brush Direction)

3. Set the gear depending on the route and the amount of

material to be swept.

4. Engage the brush drive. (fig. 9C)

5. Engage the traction drive. (fig. 9D)

NOTICE: AVOID SWEEPER DAMAGE. Reduce travel speed to

avoid hitting immovable objects.

The sweeper is equipped with an instant shutoff, when you release the levers, the brush and

machine stop.

Operating Tips

NOTICE: AVOID SWEEPER DAMAGE. Do not ram into piles.

13

Large areas

For uneven or dirt surfaces, reduce speed to avoid jogging the brush and damaging it.

Sweep creating a central passage dividing the area in 2 parts and then sweeping the remaining

areas. This reduces the load on the brush.

Snow

Snow is removed more easily when it is still fresh. Pass back over the already cleared zones to

remove snow residue.

If possible, clear the snow in the direction of the wind. Check the distance and the direction of

the removed snow.

Reduce the engine rotations before stopping it.

Dirt & Gravel

To reduce the amount of duct lifted when sweeping, work at low brush speed. If possible, also

work on damp or cloudy days or after it rains.

For gravel, adjust the height of the brush to avoid throwing them and causing potential

damages.

Heavy Debris

Reduce forward speed and work without using the entire machine working width.

WARNING

SAFELY OPERATE EQUIPMENT

Do not operate equipment until you are completely trained by a qualified operator in how to use the

controls, know its capabilities, dimensions, and all safety requirements.

Keep all step plates; grab bars, pedals, and controls free of dirt, grease, debris, and oil.

Never allow anyone to be around the equipment when it is operating.

Do not allow riders on the attachment or the prime mover.

Do not operate the equipment from anywhere other than the correct operators position.

Never leave equipment unattended with the engine running or with this attachment in a raise

position.

Do not alter or remove any safety feature from the prime mover or this attachment.

Know your work site safety rules as well as traffic rules and flow. When in doubt on any safety

issue, contact your supervisor or safety coordinator for an explanation.

WARNING

IN AN EMERGENCY, RELEASE LEVERS AS QUICKLY AS POSSIBLE AND STOP THE ENGINE.

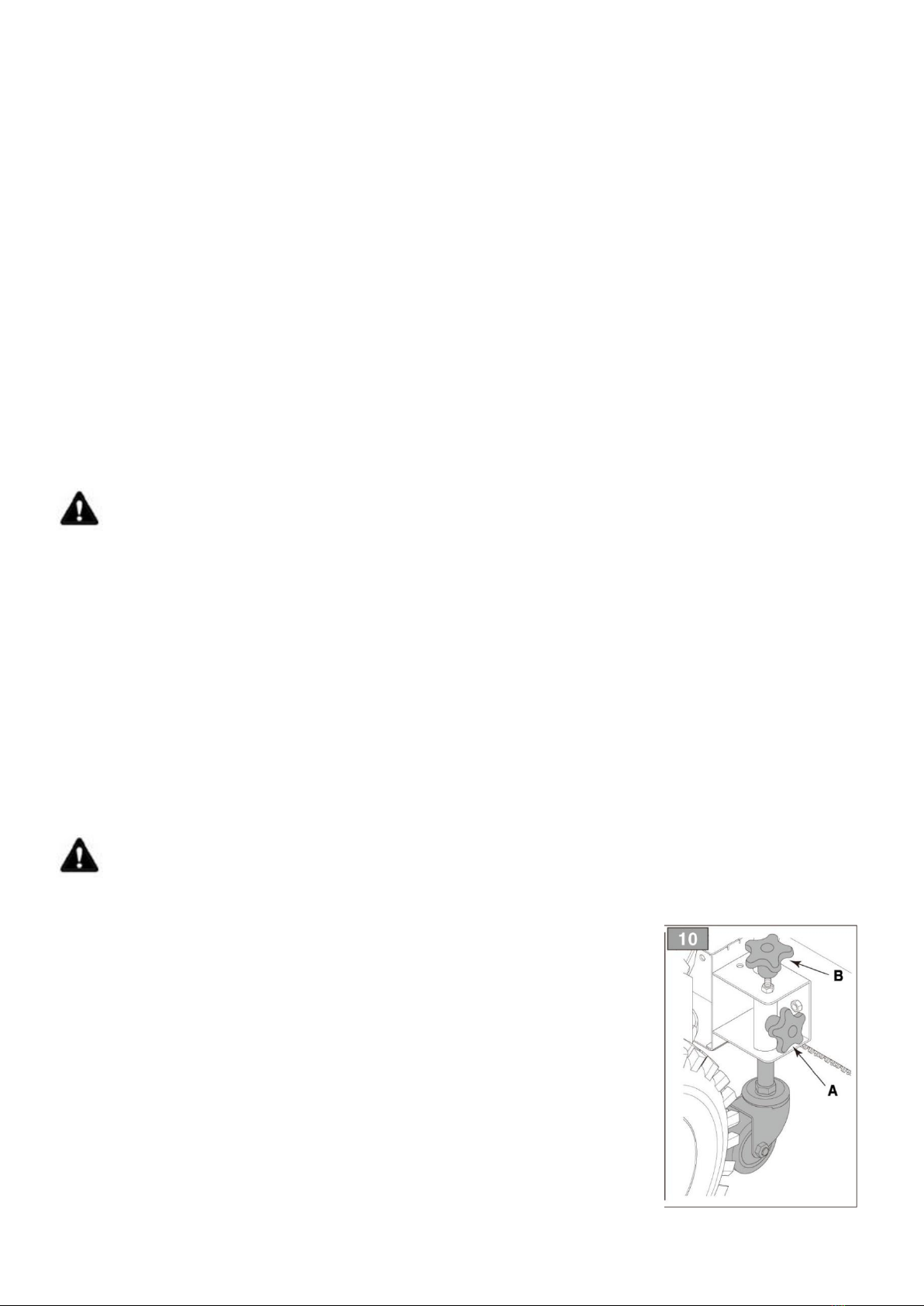

Height adjustment of Caster Wheels & Brushes

Once the brushes get worn it is necessary to adjust the height of the

brushes, i.e. how close they are to the surface to sweep. This adjustment

takes place by moving the plastic rings of the brush caster wheels. See

as follows:

1. Loosen the side knob (fig. 10.A);

2. Rotate the upper knob (fig. 10.B) in clockwise / anticlockwise to lift /

lower the small wheels;

3. Fix the side knob (fig. 10.A);

14

6. CHANGE ATTACHMENTS

If what you bought is multi-function sweeper & snow thrower, you should change the

function by yourself. Please check below steps for success assembly work.

To Separate Engine part and Attachments (Sweeper / Snow thrower head)

1. If the attachment on the machine is sweeper, please do following first:

a) Pull the hook (fig.11 A) upward to release the direction bar;

b) Pull the direction bar (fig.11 C) out from the hole.

c) Click the direction bar (fig.11 C) into hook (fig.11 B) to avoid its moving.

If the attachment on the machine is snow thrower, please skip this step.

2. Grasp the red lock control lever under left handle. Raise up the engine part to release

attachment (fig.12).

To Connect Engine part with Attachments (Sweeper / Snow thrower head)

1. Put the sweeper / snow thrower head on an open area.

2. If you are going to connect sweeper head, please make sure that both caster wheels (fig.13A)

are in fifth groove.

15

3. Hold the handle of the engine part, and move it towards the attachment.

4. Lower the engine part to make the bar (fig.14A) go into the two hooks (fig.14B) to interlock gears

of two parts (fig.14C) as shown in fig.15. Please note that during this period, do not grasp the red

lock control lever as shown in fig. 12.

5. If you are connecting snow thrower head, it’s OK for working now.

6. If you are connecting sweeper head, you have to continue the following steps:

a) Remove the direction bar (fig.11 C) from the hook (fig.11 B).

b) Press the direction bar (fig.11 C) to the hole on the sweeper head.

c) Press down the hook (fig.11 A) to fix the direction bar (fig.11 C).

Then your sweeper is workable now.

7. SERVICE & REPAIR - GENERAL

Repair or adjust the sweeper in a safe area, away from traffic and other hazards.

Before adjusting or servicing remove spark plug wire from spark plug.

16

8. STORAGE

NOTICE:

Do not store the sweeper with weight on the brush. Weight will deform the bristles, destroying

the sweeping effectiveness.

Do not store polypropylene brushes in direct sunlight. The material can deteriorate and crumble

before the bristles are worn out.

Keep polypropylene brush material away from intense heat or flame.

9. TROUBLESHOOTING

The engine does not

start

Check whether oil has entered into the carburetor.

Plug out the spark plug cap and check whether it ignites.

Check whether the oil level is too low.

Check whether the cylinder pressure is normal.

The engine burns

engine oil

Check the oil volume to make sure that the oil level is not above the

calibration of the dipstick.

Check whether the reed valve works normally (whether the reeds fit

properly and can reset freely).

Check whether the piston ring is worn.

The engine stalled

suddenly.

Check whether the igniter is damaged or the flameout wire is grounded.

Check that the fuel inlet is not smooth or there is no fuel.

Insufficient power of

the engine

Check whether the engine fuel if normal or not.

Check whether the rotating speed of the engine is too low.

Check whether the air valve clearance is correct (the inlet air valve

clearance is 0.1-0.15mm. The outlet air valve clearance is 0.15-0.2mm).

Check the air intake system is for air leakage or air filter blockage.

Check the piston rings for wear.

The brushes will not

rotate

Check whether the belt coupling is adjusted correctly.

Check whether the v-belt is defective

The machine will not

run

Make sure that the belt coupling is adjusted correctly

The machine does

not sweep effectively

Check whether the v-belt is defective

Check whether the brush distance to the surface is set correctly

10. MAINTENANCE

MAINTENANCE SCHEDULE

PROCEDURES

BEFORE

EACH USE

25 HOURS

100 HOURS

AFTER EACH

USE

Hardware - Inspect & tighten

Engine & Air Filter - check & clean

if necessary

Oil, engine - check level

Wash Unit - Remove Grease &

Debris

17

Maintenance

If you need to change the belts, please contact the distributor or local agent. Do not change them

by yourself.

Residual risks

Even when the machine is used as prescribed it is not possible to eliminate all residual risk factors.

The following hazards may arise in connection with the power tool’s construction and design:

1. Damage to lungs if an effective dust mask is not worn.

2. Damage to hearing if effective hearing protection is not worn.

3. Damages to health resulting from vibration emission if the power tool is being used over longer

period of time or not adequately managed and properly maintained.

WARNING

This machine produces an electromagnetic field during operation. This field may under some

circumstances interfere with active or passive medical implants. To reduce the risk of serious or

fatal injury, we recommend persons with medical implants to consult their physician and the

medical implant manufacturer before operating this machine.

Replace Engine Oil in Crankcase

To avoid engine damage, it is important to:

●Check oil level before each use and every five operating hours.

●Change oil after first two operating hours and every 25 operating hours thereafter.

1. Be sure the gas cap is on and is tighten securely.

2. Clean area around oil drain plug.

3. Place approved recyclable oil container under oil drain plug.

Note: Used oil must be disposed of at a proper collection center.

4. Take off the oil filler cap and remove the oil drain bolt and washer.

5. After draining the engine oil, fit on the oil drain bolt and washer and tighten them.

6. Place the engine in level position, refill recommended oil to the upper level (Oil capacities: 0.5L).

7. Reinstall the oil dipstick and tighten.

8. Wipe away any spilled oil.

Maintain Air Cleaner

NOTICE: In the case of no element or element damaged, the dust will be sucked into the engine

and result in rapid wear of the engine.

1. Remove the air cleaner cover.

2. Remove element.

3. Check the filter element, clean the filter element and replace the filter element if it’s damaged.

4. Clean the air filter base and the air filter cover. Dust should be prevented from entering the intake

port leading to the carburetor.

18

5. Install the foam filter element, and then cover the filter cover over the top.

Checking Spark Plug

Check spark plug yearly or every 100 operating hours

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Replace spark plug if porcelain is cracked or if

electrodes are pitted, burned or fouled with deposits.

4. Check electrode gap with a feeler gauge and set gap

to 0.030(0.76mm)if necessary. see Fig 16.

5. Re-install spark plug and tighten securely

NOTE: A resistor spark plug must be used for replacement. Contact the distributor or local agent for

a replacement spark plug.

Carburetor

If you suspect your carburetor needs adjusted, contact the distributor or local agent, engine

performance should not be affected at altitudes up to 7000 feet (2134 meters). For operation at

higher elevations, contact the distributor or local agent.

Engine Speed

WARNING: Avoid serious injury or death, DO NOT modify engine in any way, Tampering with the

governor setting can cause the engine and equipment to operate at unsafe speeds. NEVER tamper

with factory setting of engine governor. Running the engine faster than the speed set at the factory

is dangerous.

Lubrication

WARNING:Before lubricating, repairing, or inspecting, disengage all controls and

stop engine. Wait until all moving parts have come to a complete stop.

Gear Shaft

The gear (hex) shaft should be lubricated at least once a

season or after every 25 hours of operation.

1. Remove the lower frame cover by removing the two

screws which secure it.

2. Apply a light coating of an all-weather multi-purpose

grease to the hex shaft. See Fig 17.

IMPORTANT: Avoid oil spillage on rubber friction

Wheels

At least once a season, remove both wheels. Clean and coat the axles with a multipurpose

automotive grease before re-installing wheels.

Gear Case

The auger gear case has been filled with grease and sealed at the factory. If disassembled from

any reason, lubricate with two ounces of new grease.

NOTE: Do not over fill the gear case. Damage to the seals could result. Be sure the vent plug is

free of grease in order to relieve pressure

Fig 16

Fig.17

19

Brush Belt Replacement

To remove and replace your snow sweeper’s brush belt,

proceed as follows:

1. Remove the belt cover on the front of the engine by removing the two self-tapping screws. See

Fig.18.

NOTE: Drain the gasoline from the snow sweeper, or place of plastic under the gas cap.

2. Carefully pivot the snow sweeper up and forward so that it rests on the auger housing. Remove

the frame cover from the underside of the snow sweeper by removing four self-tapping screws

which secure it. See Fig.19.

3. Loosen and remove the shoulder screw which acts as a belt keeper. See Fig.20.

4. a. Roll the brush belt off the engine pulley. See Fig.21.

b. Unhook the support bracket spring from the frame. See Fig.22.

5. Remove the belt from around the auger pulley, and slip the belt between the support bracket

and the auger pulley. Reassemble brush belt by following instructions in reverse order.

NOTE: Do NOT forget to re-install the shoulder screw and reconnect the spring to the frame

after installing a replacement brush belt.

Drive Belt Replacement

To remove and replace your snow sweeper’s brush belt, proceed as follows:

1. Remove the belt cover in the front of the engine by removing the two self-tapping screws. See

Fig. 23.

Fig.18

Fig.19

Fig.20

Fig.21

Fig.22

20

This manual suits for next models

1

Table of contents

Other Feider Machines Blower manuals

Popular Blower manuals by other brands

Ryobi

Ryobi RY40407VNM Operator's manual

DeWalt

DeWalt DCBL590 instruction manual

Poulan Pro

Poulan Pro 452 MVB Operator's manual

STEWART-AMOS

STEWART-AMOS Starfire S-4XL Operation and maintenance manual

Echo

Echo SHRED 'N' VAC ES-250 Operator's manual

Wolf Garten

Wolf Garten LI-ION POWER BA 700 operating instructions