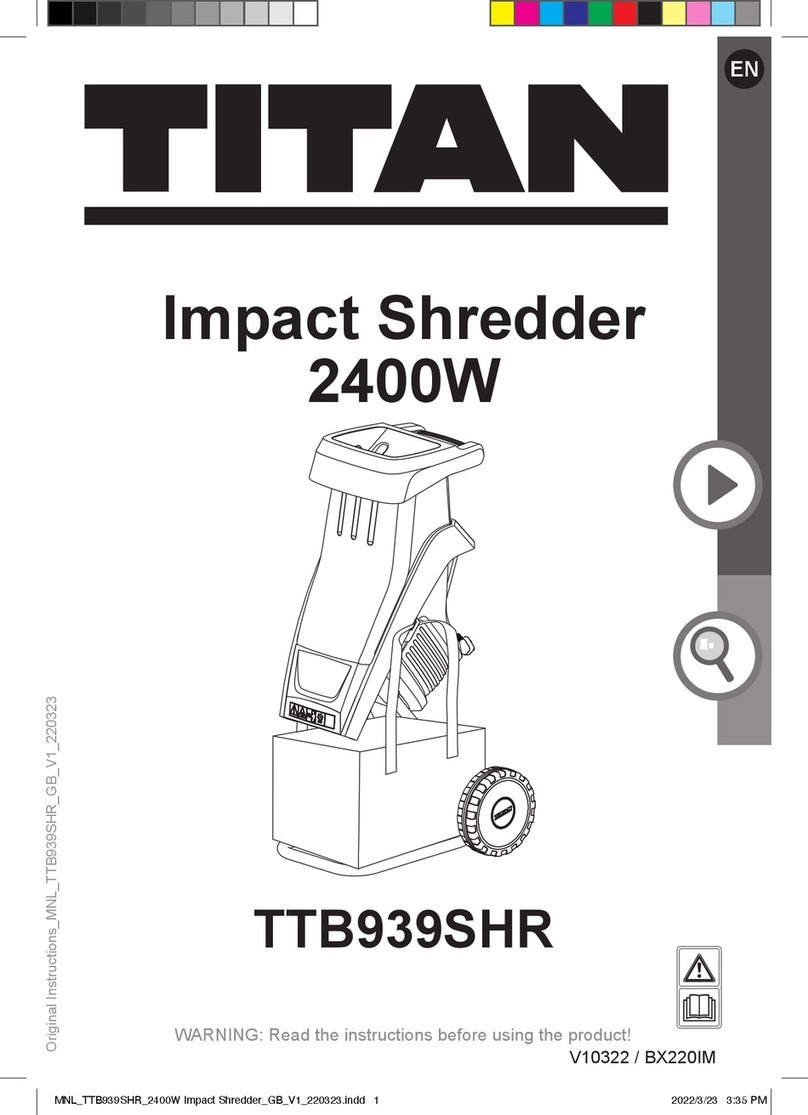

Feider Machines FBT420 User manual

1

ORIGINAL INSTRUCTIONS

PETROL SHREDDER

FBT420

READ THIS INSTRUCTIONS MANUAL BEFORE USE THE TOOL

BUILDER SAS

32, rue Aristide Bergès - ZI 31270 Cugnaux – France

MADE IN PRC

2

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

Safe operating practices

Training

Become familiar with the owner's manual before attempting to operate this equipment.

Preparation

1) Do not allow children to operate this equipment;

2) Do not operate this equipment in the vicinity of bystanders;

3) Do not run engine powered machines in an enclosed area since the exhaust from an engine

contains carbon monoxide, which is colourless, odourless, and tasteless; carbon monoxide can be

extremely dangerous in enclosed areas;

4) Wear ear protection and safety glasses at all times while operating the machine;

5) Avoid wearing clothing that is loose fitting or that has hanging cords or ties;

6) Only operate the machine in open space (e.g. not close to a wall or other fixed object) and on a

firm, level surface;

7) Do not operate the machine on a paved or gravel surface where ejected material could cause

injury;

8) Before starting the machine, check that all screws, nuts, bolts, and other fasteners are properly

secured and that guards and screens are in place. Replace damaged or unreadable labels;

9) Use extra care in handling fuels. They are flammable and the vapours are explosive. The following

points should be observed:

use only an approved container;

Never remove the fuel cap or add fuel with the power source running. Allow engine and exhaust

components to cool before refuelling;

do not smoke;

never refuel the machine indoors;

never store the machine or fuel container inside where there is an open flame, such as a water

heater;

if fuel is spilled, do not attempt to start the power source, but move the machine away from the

area of spillage before starting;

always replace and securely tighten the fuel cap after refuelling;

If the fuel tank is drained, this should be done outdoors.

Operation

1) Before starting the machine, look into the feeding chamber to make certain that it is empty;

2) Keep your face and body away from the feed intake opening;

3) Do not allow hands or any other part of the body or clothing inside the feeding chamber, discharge

chute, or near any moving part;

4) Keep proper balance and footing at all times. Do not overreach. Never stand at a higher level than

the base of the machine when feeding material into it;

5) Always stand clear of the discharge zone when operating this machine;

6) When feeding material into the machine be extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included;

7) If the cutting mechanism strikes any foreign objects or if the machine should start making any

unusual noise or vibration, shut off the power source and allow the machine to stop. Disconnect the

spark plug wire from the spark plug (electric unit disconnect from supply) and take the following

steps:

inspect for damage;

check for and tighten any loose parts ;

Have any damaged parts replaced or repaired with parts having equivalent specifications.

8) Do not allow processed material to build up in the discharge zone; this may prevent proper

discharge and can result in kickback of material through the feed intake opening;

9) If the machine becomes clogged at the inlet opening or discharge chute shut-off the power source

and disconnect the spark plug wire or remove the ignition key before clearing debris in the inlet

opening or discharge chute. Keep the power source clear of debris and other accumulations to

prevent damage to the power source or possible fire. Remember that operating the starting

mechanism on engine powered machines will still cause the cutting means to move;

10) keep all guards and deflectors in place and in good working condition;

11) Do not tamper with the power source governor settings; the governor controls the safe maximum

3

operating speed and protects the power source and all moving parts from damage caused by over-

speed. Seek authorised service if a problem exists;

12) Do not transport this machine while the power source is running;

13) Shut off the power source and disconnect the spark plug lead (electric unit disconnect from

supply) whenever you leave the work area;

14) Do not tilt the machine while the power source is running.

Mandedintenance and storage

a) When the machine is stopped for servicing, inspection, or storage, or to change an accessory,

shut off the power source, disconnect the spark plug wire from the spark plug, make sure that all

moving parts have come to a complete stop and, where a key is fitted remove the key. Allow the

machine to cool before making any inspections, adjustments, etc.

b) Store the machine where fuel vapour will not reach an open flame or spark. For extended storage

periods, run the unit dry of fuel. Always allow the machine to cool before storing;

c) When servicing the cutting means be aware that, even though the power source will not start due

to the interlock feature of the guard, the cutting means can still be moved by a manual starting

mechanism.

Additional safety instructions for units with bagging attachments

a) shut-off the power unit before attaching or removing the bag.

For Your Own Safety, Read Instruction Manual Before Operating this Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words which are intended to convey the level of

importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate

injury. It may also be used to alert against unsafe practices.

This symbol is used to alert the user to useful information about proper operation of the machine.

Safety Instructions for Machinery

1. READ THROUGH THE ENTIRE MANUAL BEFORE STARTING MACHINERY.

Machinery presents serious injury hazards to untrained users.

2. ALWAYS USE ANSI APPROVED SAFETY GLASSES WHEN OPERATING MACHINERY.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

3. ALWAYS WEAR AN ANSI APPROVED RESPIRATOR WHEN OPERATING MACHINERY THAT

PRODUCES DUST. Wood dust is a carcinogen and can cause cancer and severe respiratory

illnesses.

4. ALWAYS USE HEARING PROTECTION WHEN OPERATING MACHINERY.

Machinery noise can cause permanent hearing damage.

5. WEAR PROPER APPAREL. DO NOT wear loose clothing, gloves, neckties, rings, or jewelry

which may get caught in moving parts. Wear protective hair covering to contain long hair and wear

non-slip footwear.

6. NEVER OPERATE MACHINERY WHEN TIRED, OR UNDER THE INFLUENCE OF DRUGS OR

ALCOHOL. Be mentally alert at all times when running machinery.

7. ONLY ALLOW TRAINED AND PROPERLY SUPERVISED PERSONNEL TO OPERATE

MACHINERY. Make sure operation instructions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS AWAY. Keep all children and visitors a safe distance from the

work area.

9. MAKE WORKSHOP CHILD PROOF. Use padlocks, master switches, and remove start switch

keys.

10. NEVER LEAVE WHEN MACHINE IS RUNNING. Turn power OFF and allow all moving parts to

come to a complete stop before leaving machine unattended.

11. DO NOT USE IN DANGEROUS ENVIRONMENTS. DO NOT use machinery in damp, wet

locations, or where any flammable or noxious fumes may exist.

12. KEEP WORK AREA CLEAN AND WELL LIT. Clutter and dark shadows may cause accidents.

13. USE A GROUNDED EXTENSION CORD RATED FOR THE MACHINE AMPERAGE.

Undersized cords overheat and lose power. Replace extension cords if they become damaged. DO

4

NOT use extension cords for 220V machinery.

14. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING MACHINERY. Make

sure switch is in OFF position before reconnecting.

15. MAINTAIN MACHINERY WITH CARE. Keep blades sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN PLACE AND WORK CORRECTLY BEFORE USING

MACHINERY.

17. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking for keys and

adjusting wrenches before turning machinery ON.

18. CHECK FOR DAMAGED PARTS BEFORE USING MACHINERY. Check for binding and

alignment of parts, broken parts, part mounting, loose bolts, and any other conditions that may affect

machine operation. Repair or replace damaged parts.

19. USE RECOMMENDED ACCESSORIES. Refer to the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury.

20. DO NOT FORCE MACHINERY. Work at the speed for which the machine or accessory was

designed.

21. SECURE WORKPIECE. Use clamps or a vise to hold the workpiece when practical. A secured

workpiece protects your hands and frees both hands to operate the machine.

22. DO NOT OVERREACH. Keep proper footing and balance at all times.

23. MANY MACHINES WILL EJECT THE WORKPIECE TOWARD THE OPERATOR.

Know and avoid conditions that cause the workpiece to "kickback."

24. ALWAYS LOCK MOBILE BASES (IF USED) BEFORE OPERATING MACHINERY.

25. BE AWARE THAT CERTAIN WOODS MAY CAUSE AN ALLERGIC REACTION. in people and

animals, especially when exposed to fine dust. Make sure you know what type of wood dust you will

be exposed to and always wear an approved respirator.

Additional Safety Instructions for Chipper/Shredders

1. READ THIS ENTIRE MANUAL AND MOTOR MANUAL: These manuals contain proper operating

and safety instructions for this chipper/ shredder.

2. SAFETY EQUIPMENT: Wear safety glasses, hearing protection, and gloves when operating a

chipper/shredder. Make sure any bystanders are also wearing safety equipment.

3. ENGINE OPERATION: Refer to the motor manual for operating instructions and gasoline motor

safety warnings.

4. HAND SAFETY: DO NOT put hands or other body parts into hopper, funnel, or outlet while the

blades are turning. The chipper/shredder can drag you into the blade, causing amputation of fingers,

hands or other body parts. DO NOT touch the exhaust during or immediately after operation to

prevent burns.

5. CLOTHING: DO NOT wear loose clothing, neckties, scarves, or jewelry which may get caught in

moving parts. DO NOT wear clothing or gloves with pull ties or straps. This type of clothing could get

tangled with material that is being shredded, pulling you into the chipper/shredder.

6. OPERATING LOCATION: Set up the chipper/shredder on firm, level, grass or dirt. DO NOT set up

the chipper/shredder on gravel, asphalt, concrete, or stone. The chips are expelled from the machine

with enough force to ricochet off of hard surfaces and cause serious injury. DO NOT set up the

chipper/shredder in a location where sparks or heat from the motor could cause a fire.

7. SECURE FOOTING: Placing the chipper/shredder on a slope or slippery surface may cause the

operator to fall into the machine, causing burns from the motor, or an amputation if an arm

accidentally goes into the hopper. Wear non-slip, closed toed shoes or boots to maintain secure

footing.

8. JAMS AND CLOGGING: Turn the chipper/shredder OFF, allow all moving parts to come to a

complete stop, and disconnect the spark plug wire before attempting to free a jam or clog.

9. FEEDING MATERIAL: Hold branches and brush loosely, and allow the chipper/shredder to draw

the material in. The machine sometimes will draw material in very quickly and your hand may be

drawn in if you are holding tightly. If the blades hit a hard object, or if the machine begins to make an

unusual noise or vibration, immediately shut the chipper/shredder OFF.

10. TURN OFF CHIPPER/SHREDDER: Turn OFF the machine, allow all moving parts to come to a

complete stop, and disconnect the spark plug wire before moving the machine, emptying the bag,

unclogging the inlets or outlets, filling the gas tank, or performing maintenance and repairs.

11. STARTING THE CHIPPER/SHREDDER: Make sure the hopper and funnel are empty when

starting the machine. The pull start cord may stop suddenly causing the chipper/shredder to fall over

or injure your hand or arm.

12. CLEANING CHIPPER/SHREDDER: Allow the motor to cool off, then brush dust and chip build-

up off of the motor to prevent fire or motor overheating.

5

Explain symbols

Read operator's manual

Keep bystanders away

Danger - Rotating blades. Keep hands and feet out of openings while machine is

running

Wear eye and ear protection

Do not use as a step.

6

Configuration table

Model

FBT420

Power

8.6kw

Type

single cylinder four stroke air-cooled

gasoline engine

Engine Speed Max.

3600/min

Gasoline tank

6.5L

Oil tank

1.1L

Displacement

420cm3

Weight

103 kg

Chipping Capacity

100mm

Blade Speed

2800/min

Maximum cutting diameter

Fresh branches 10cm,dry branches7cm

Noise emission

Sound pressure level LpA:103dB(A);

Sound power level: LwA: 123dB(A)

Guarantee sound power level: 125 dB(A)

Packing list

1- Feeding hopper 2- Discharge chute 3-Tool Kits

4- Main body (see machine parts diagram)

7

Machine assembly

Machine parts diagram:

Feeding

hopper

Engine

Deflector

Main

body

Wheel

Discharge

chute

Installation of feeding hopper:

Note: It is recommended that this work

should be done by two people!

1, Insert the bolt of hopper into the

bracket of the main engine.

2, Put the hopper and tighten

the bolts.

Installation of discharge chute:

Refer to the picture on the right,

1, Confirm the direction of the discharge

2, insert the bolts into the bracket above

the main engine and tighten the

corresponding bolts

8

Instructions

1. Fuel confirmation

Please use No. 90 unleaded gasoline or above!

It is not recommended to use gasoline stored over 2 months!

Please replace or refill the fuel in the open air!

After the replacement, please remain the gasoline engine to be clean !

Make sure that the gasoline is filled to the machine when it is switch off.

Gasoline is harmful to health, please avoid direct contact.

For the first time, it is recommended that the amount of filling should be

550ml~600ml.. Oil standard is 4 stroke 20W-40.

Injection method (read maintenance for reference)

Warning

The cutter head is fixed by special bolts. Please check the tightness of the

cutter and the blade fixing bolts before using.

Check whether there is a foreign object inside the inlet. If there is a foreign

object, please take it out with a tool.

Do not put clothes, tools, etc. on the machine.

Please work in a flat and open area with good ventilation.

Stay away from the outlet direction.

If the machine has abnormal vibration during working, please stop the machine

and send it to the distributor for inspection. Please wear, goggles, ear

protection, labor protection gloves when working.

It is recommended that this machine be operated by professional persons. Do

not put hand into the inlet hopper.

2, Start-up instructions

Please refer to the quick use manual.

Warning

Please use this machine correctly. Please push the branches into the inlet

hopper and the automatic biting system will cut them into pieces.

9

If the feed is too thick or much, please mind the status of the machine and the

engine when slicing. Make sure the rotating speed of the gasoline engine all

the time. In order to ensure the working efficiency and experience, please feed

materials properly.

When chipping dry branches, please note that the maximum diameter should

not exceed 4cm.

If the branches are too thick, please chop or trim it and then shred it separately.

When chopping the branches approaching the limit diameter, please grasp the

material and push with your hands to avoid the danger of swinging back and

forth.

The emergency stop switch is only used for emergency situations, normal

shutdown should firstly reduce the engine to idle speed for a few

minutes,then switch off the engine.

Maintenance

Tip: Regular inspection and maintenance work can effectively ensure the

normal operation of the machine.

Warning

Please stop the machine before doing any maintenance, inspection and so on,

and wait until it stops rotating completely. Place the machine in a horizontal

position.

1, maintenance of gasoline engine

Routine inspection and maintenance can ensure

the perfect performance of the machine. Seasonal

maintenance is strongly recommended by professionals.

The adjustment of carburetor is required to be

operated by the specialized person of distributor.

The incorrect regulation of carburetor will directly

affect the performance of gasoline engine.

Clean the gasoline engine regularly, especially the location

of the oil injection, gasoline tank.

Regularly check if the oil is in normal level.

After the oil is wiped up,put the oil ruler back and

check the oil level. (see right picture),

if it’s below the minimum level, refill the oil, if

the oil is above the highest position,please release some oil appropriately.

10

When you clean the machine with a high pressure water jet , please do not

pour water into the bearings and inside of the gasoline engine, otherwise,

these parts will be damaged.

1.1 , How to change the oil

Please put the prepared oil container

to the bottom of the oil outlet.

Screw off the oil seal bolt and drain

the

oil. (see the right picture)

Quickly place the oil guide pipe to

collect the oil avoid

oil overflow .

Please follow the below table for routine inspection and maintenance

maintenance

Before

each

use

After

5 hours

using

After

25 hours

using

After

50 hours

using

After

100

hours

using

First use

after long

shelving

Last use

before a long

period

placement

Inspection

lubrication

and the bolt

fastening

states

×

×

Empty the oil

and gasoline

Check the oil

×

Change the

oil

×

×

×

×

Check the

blade edge

×

Cleaning or

replacing the

filter

×

×

Check or

replace the

spark plug

×

×

11

1.2 ,Maintenance of air filter

Timely cleaning and maintenance of air filter can effectively prolong the service

life of gasoline engines. Please replace the damaged air filters in time.

Remove the air filter cover, take out the filter element, wash the filter element

in soapy water, and rinse it clean. After drying, add two drops of oil to increase

the air filtration effect,and install it back in proper order.

Warning: Prohibit starting a gasoline engine without air filter!

1.3, Inspection of ignition system

Check the spark plug regularly.

Spark plug’s contact spacing is 0.6mm-0.7mm,

clean up the carbon deposition between contacts

In time.

1.4, Cleaning of cylinder cooling sink

The cylinder cooling sink is the

main way of cooling down the gasoline engine

in operation. Timely cleaning can effectively

prevent the cylinder from being damaged

due to overheating.

2, Belt maintenance

Please check the tightness of the belt

regularly and adjust the tightness of the

belt in time. (see the right picture)

--Loosen the fixed bolts(1)

--Loosen the nut, turn the screw stem (2),

adjust the tension by turning left and right.

--Ditto, release the tension pulley

and you can easily change the belt.

Remind, please tighten the belt properly, if the belt is too tight,it will shorten

the usage life.

Tips: Belt tightness can be measured on the double fingers press inward in a

range of 2cm or so.

2, Other maintenance

Before storing the machine for a long time, please lubricate the bearing and

clean the rotor and knife box, then make the anti-rust protection for the rotor

and knives.

12

Before cleaning and maintaining the rotor, firstly make sure that the rotor is

unable to self-rotate.

Regularly check if the emergency stop switch works properly.

Regularly check the tire pressure, the normal value is (1.5~1.9bar).

Movement & transportation

Please do not move the running machine

Note: after the machine is stopped, the surface of the muffler's cover is very

hot, and there is a high risk of scald .

Wait at least 5 minutes until the machine is completely cooled.

Due to the self weight of the machine 81kg, it is strongly recommended that

the transfer work to be completed by two people. In order to reduce the harm

caused by overweight, while transporting the machine with a vehicle, make

sure that the machine is fixed safely.

Storage

Store the machine after it ‘s completely cooled and cleaned thoroughly. Do not

leave the machine near the flammable and explosive materials.

If you will store your machine for a long time, follow below steps:

Completely cool down and clean up the machine.

Clean up all the fuel and oil.

Do not let children approach or play on the machine!

Please leave the machine in a dry and ventilated area.

.

13

Common problems and Solutions

Problem

Reason

Solution

Abnormal cutting and unable

to take in the materials

automatically

1.

The blade is

heavy wear .

2.

Feeding

material‘s diameter

exceeded the limit.

1.

Replace a blade.

2.

Take out the material

and make it smaller.

Uneven thickness of wood slices

Incorrect

cutting clearance

Adjust the space of the

knives. The correct value

should be 0.5-1.5mm.

The gasoline engine won't start

1.

Faulty Circuit of

gasoline engine

2.

Running out of

gasoline, engine stop

automatically.

3.

Lack of oil or too

much oil.

1.

Check the stop switch and

wire connection.

2.

Check oil level.

3.

Oil injection or oil release.

If the gasoline engine is running abnormally, please refer to the common

problem shooting in the gasoline engine manual. We strongly suggest that you

send the machine back to the agency for service.

14

CE DECLARATION

BUILDER SAS

32 rue Aristide Berges -Z1 31270 Cugnaux - France

Tel: +33 (0) 5.34.508.508 Fax: +33 (0) 5.34.508.509

Déclare que la machine désignée ci-dessous

PETROL SHREDDER

FBT420

Serial number: 20210455003-20210455022

20210641008-20210641027

Is in conformity with the requirements of the Directive Machine 2006/42/EC and to the followings

Europeans Directives: EMC Directive 2014/30/EU

Emission directive (EU) 2016/1628 & 2018/989/EU

Directive 2000/14/CE Annex VI, 2005/88/EC

This tool is also in conformity with the following these standards:

EN12100 :2010

EN14120 :2015

EN 14982:2009

Sound power level: LwA: 123dB(A)

Guarantee sound power level: 125 dB(A)

.

Responsable du dossier technique : Julia Zou

Cugnaux, 19/04/2021

Philippe MARIE / PDG

WARRANTY

The manufacturer guarantees the product against defects in material and workmanship for a period of 2

years from the date of the original purchase. The warranty only applies if the product is for household use.

The warranty does not cover breakdowns due to normal wear and tear.

The manufacturer agrees to replace parts identied as defective by the designated distributor. The

manufacturer does not accept responsibility for the replacement of the machine, in whole or in part , and/or

ensuing damage.

The warranty does not cover breakdowns due to:

• insucient maintenance.

• abnormal assembly, adjustment or operations of the product.

• parts subject to normal wear and tear.

The warranty does not extend to:

• shipping and packaging costs.

• using the tool for a purpose other than that for which it was designed.

• the use and maintenance of the machine done in a manner not described in the user manual.

Due to our policy of continuous product improvement, we reserve the right to alter or change specications

without notice. Consequently, the product may be dierent from the information contained therein, but a

modication will be undertaken without notice if it is recognized as an improvement of the preceding

characteristic.

READ THE MANUAL CAREFULLY BEFORE USING THE MACHINE.

When ordering spare parts, please indicate the part number or code, you can nd this in the spare parts list

in this manual. Keep the purchase receipt; without it, the warranty is invalid. To help you with your product,

we invite you to contact us by phone or via our website:

• +33 (0)9.70.75.30.30

• https://services.swap-europe.com/contact

You must create a "ticket" via the web platform.

• Register or create your account.

• Indicate the reference of the tool.

• Choose the subject of your request.

• Describe your problem.

• Attach these les: invoice or sales receipt, photo

of the identication plate (serial number), photo

of the part you need (for example: pins on the

transformer plug which are broken).

WARRANTY

15

WHAT TO DO IF MY MACHINE BREAKS DOWN?

the repairer will refuse the machine.

Go to the store with the complete machine and with the receipt or invoice.

the repairer will refuse the machine.

c) Create a SWAP-Europe service ticket on the site: https://services.swap-europe.com When making the

request on SWAP-Europe, you must attach the invoice and the photo of the nameplate (serial number).

d) Contact the repair station to make sure it is available before dropping o the machine.

Go to the repair station with the complete machine packed, accompanied by the purchase invoice and the

station support sheet downloadable after the service request is completed on the SWAP-Europe site

For machines with engine failure from manufacturers BRIGGS & STRATTON, HONDA and RATO, please

refer to the following instructions.

Repairs will be done by approved engine manufacturers of these manufacturers, see their site:

• http://www.briggsandstratton.com/eu/fr

• http://www.honda-engines-eu.com/fr/service-network-page;jsessionid=5EE8456CF39CD572AA2AEEDFD

290CDAE

• https://www.rato-europe.com/it/service-network

Please keep your original packaging to allow for after-sales service returns or pack your machine

with a similar cardboard box of the same dimensions.

For any question concerning our after-sales service you can make a request on our website https://

services.swap-europe.com

Our hotline remains available at +33 (9) 70 75 30 30.

If you bought your product in a store:

a) Empty the fuel tank if your product has one.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

If you bought your product on a website:

a) Empty the fuel tankif your product has one.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

PRODUCT FAILURE

16

THE WARRANTY DOES NOT COVER:

• Start-up and setting up of the product.

• Damage resulting from normal wear and tear of the product.

• Damage resulting from improper use of the product.

• Damage resulting from assembly or start-up not in accordance with the user manual.

• Breakdowns related to carburetion beyond 90 days and fouling of carburetors.

• Periodic and standard maintenance events.

• Actions of modication and dismantling that directly void the warranty.

• Products whose original authentication marking (brand, serial number) has been degraded, altered or

withdrawn.

• Replacement of consumables.

• The use of non-original parts.

• Breakage of parts following impacts or projections.

• Accessories breakdowns.

• Defects and their consequences linked to any external cause.

• Loss of components and loss due to insucient screwing.

• Cutting components and any damage related to the loosening of parts.

• Overload or overheating.

• Poor power supply quality: faulty voltage, voltage error, etc.

• Damages resulting from the deprivation of enjoyment of the product during the time necessary for repairs

and more generally the costs related to the immobilization of the product.

• The costs of a second opinion established by a third party following an estimate by a SWAP-Europe repair

station

• The use of a product which would show a defect or a breakage which was not the subject of an immediate

report and/or repair with the services of SWAP-Europe.

• Deterioration linked to transport and storage*.

• Launchers beyond 90 days.

• Oil, petrol, grease.

• Damages related to the use of non-compliant fuels or lubricants.

* In accordance with transport legislation, damage related to transport must be declared to carriers within 48

hours maximum after observation by registered letter with acknowledgement of receipt.

This document is a supplement to your notice, a non-exhaustive list.

Attention: all orders must be checked in the presence of the delivery person. In case of refusal by the

delivery person, it you must simply refuse the delivery and notify your refusal.

Reminder: the reserves do not exclude the notication by registered letter with acknowledgement within 72

hours.

Information:

Thermal devices must be wintered each season (service available on the SWAP-Europe site). Batteries must

be charged before being stored.

WARRANTY EXCLUSIONS

17

Table of contents

Other Feider Machines Paper Shredder manuals

Feider Machines

Feider Machines FBVE3000 User manual

Feider Machines

Feider Machines FBT70-2 User manual

Feider Machines

Feider Machines FBVES2800-UK User manual

Feider Machines

Feider Machines FBT70 User manual

Feider Machines

Feider Machines FBT420-1 User manual

Feider Machines

Feider Machines FBT400-1 User manual