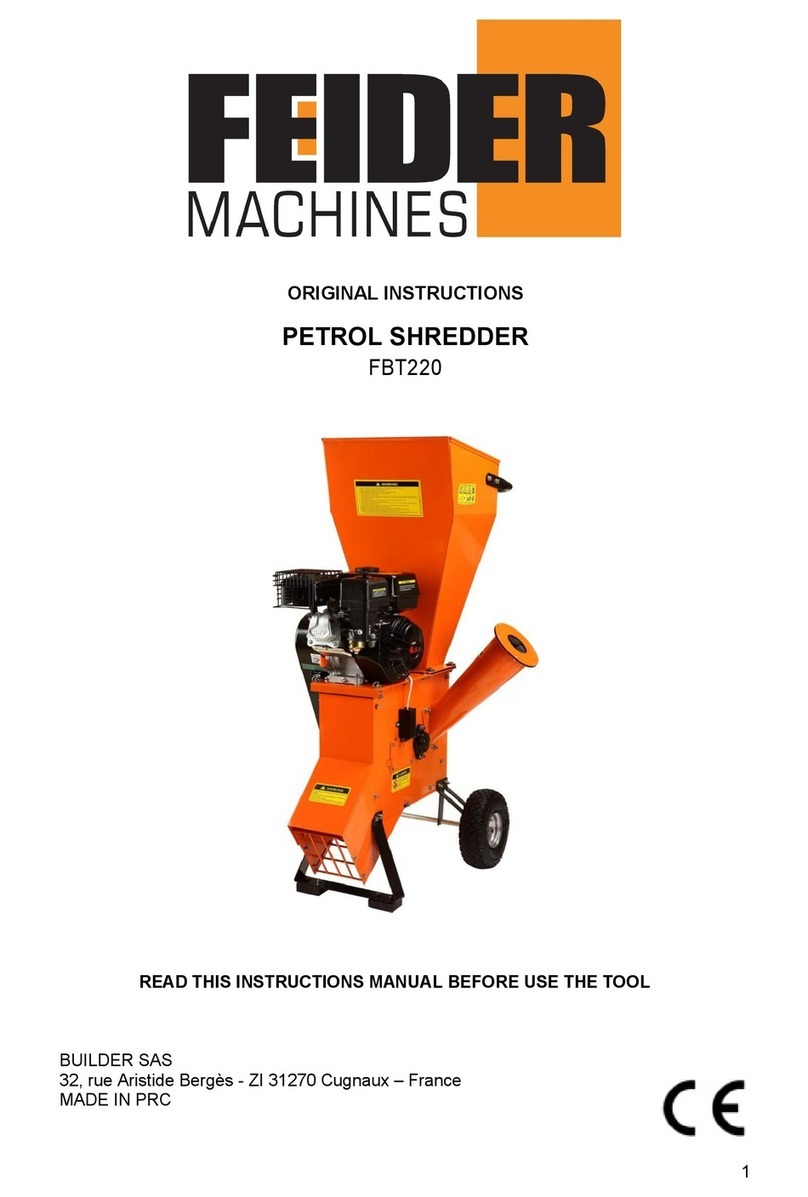

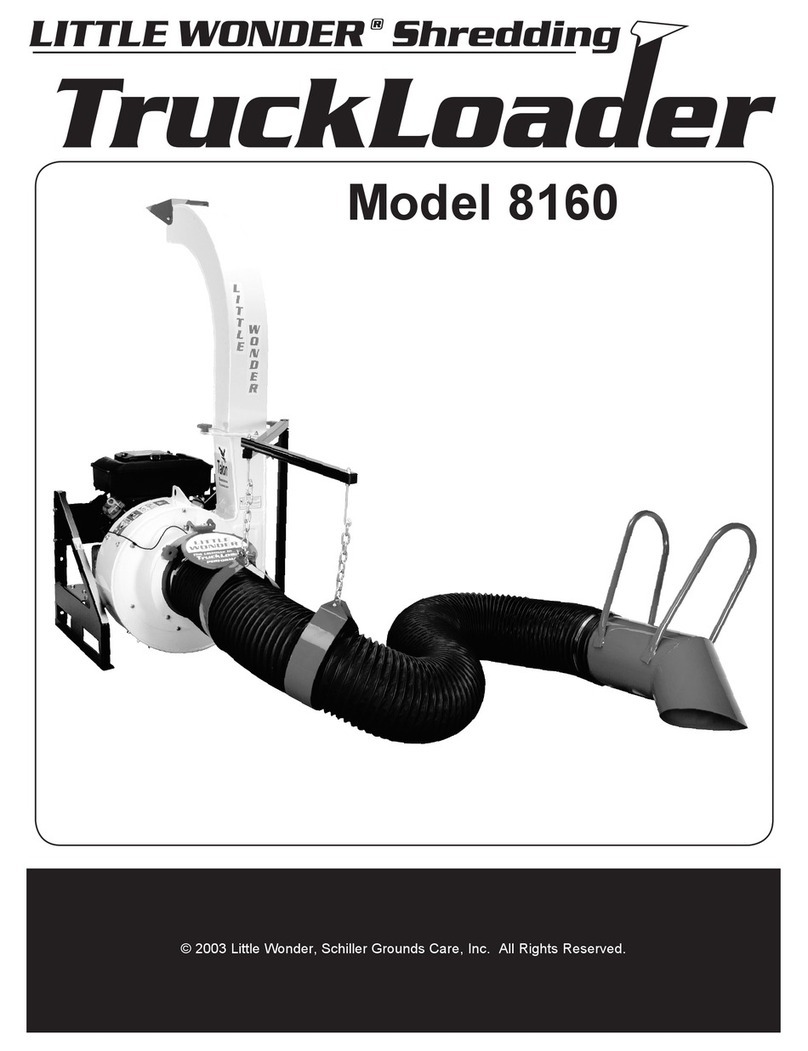

Feider Machines FBT70 User manual

ORIGINAL INSTRUCTIONS

INSTRUCTION MANUAL

PLANT SHREDDER

FBT70

READ THIS INSTRUCTIONS MANUAL BEFORE USE THE TOOL

FEIDER 32, rue Aristide Bergès - ZI 31270 Cugnaux –France

2/ 16

GENERAL SAFETY RULES

Warning symbol

Caution: Read carefully the manual before use.

Danger - Rotating blades. Keep hands and feet out of openings while

machine is running

Keep bystanders away

Wear eye and ear protection

Do not use as a step

3/ 16

Wear protective gloves

Wear safety footwear

Danger –risk of fire

Caution –hot surface

Warning –exhaust gas. Do not inhale them

Guarantee sound power level

4/ 16

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

Training

Become familiar with the owner's manual before attempting to operate this equipment.

Preparation

1) Do not allow children to operate this equipment;

2) Do not operate this equipment in the vicinity of bystanders;

3) Do not run engine powered machines in an enclosed area since the exhaust from an engine

contains carbon monoxide, which is colourless, odourless, and tasteless; carbon monoxide

can be extremely dangerous in enclosed areas;

4) Wear ear protection and safety glasses at all times while operating the machine;

5) Avoid wearing clothing that is loose fitting or that has hanging cords or ties;

6) Only operate the machine in open space (e.g. not close to a wall or other fixed object) and

on a firm, level surface;

7) Do not operate the machine on a paved or gravel surface where ejected material could

cause injury;

8) Before starting the machine, check that all screws, nuts, bolts, and other fasteners are

properly secured and that guards and screens are in place. Replace damaged or unreadable

labels;

9) Use extra care in handling fuels. They are flammable and the vapours are explosive. The

following points should be observed:

•use only an approved container;

•Never remove the fuel cap or add fuel with the power source running. Allow engine and

exhaust components to cool before refuelling;

•do not smoke;

•never refuel the machine indoors;

•never store the machine or fuel container inside where there is an open flame, such as a

water heater;

•if fuel is spilled, do not attempt to start the power source, but move the machine away from

the area of spillage before starting;

•always replace and securely tighten the fuel cap after refuelling;

•if the fuel tank is drained, this should be done outdoors.

Operation

1) Before starting the machine, look into the feeding chamber to make certain that it is empty;

2) Keep your face and body away from the feed intake opening;

3) Do not allow hands or any other part of the body or clothing inside the feeding chamber,

discharge chute, or near any moving part;

5/ 16

4) Keep proper balance and footing at all times. Do not overreach. Never stand at a higher

level than the base of the machine when feeding material into it;

5) Always stand clear of the discharge zone when operating this machine;

6) When feeding material into the machine be extremely careful that pieces of metal, rocks,

bottles, cans or other foreign objects are not included;

7) If the cutting mechanism strikes any foreign objects or if the machine should start making

any unusual noise or vibration, shut off the power source and allow the machine to stop.

Disconnect the spark plug wire from the spark plug (electric unit disconnect from supply) and

take the following steps:

•Inspect for damage;

•Check for and tighten any loose parts ;

•Have any damaged parts replaced or repaired with parts having equivalent specifications.

8) Do not allow processed material to build up in the discharge zone; this may prevent proper

discharge and can result in kickback of material through the feed intake opening;

9) If the machine becomes clogged at the inlet opening or discharge chute shut-off the power

source and disconnect the spark plug wire or remove the ignition key before clearing debris in

the inlet opening or discharge chute. Keep the power source clear of debris and other

accumulations to prevent damage to the power source or possible fire. Remember that

operating the starting mechanism on engine powered machines will still cause the cutting

means to move;

10) keep all guards and deflectors in place and in good working condition;

11) Do not tamper with the power source governor settings; the governor controls the safe

maximum operating speed and protects the power source and all moving parts from damage

caused by over-speed. Seek authorised service if a problem exists;

12) Do not transport this machine while the power source is running;

13) Shut off the power source and disconnect the spark plug lead (electric unit disconnect from

supply) whenever you leave the work area;

14) Do not tilt the machine while the power source is running.

Maintenance and storage

a) When the machine is stopped for servicing, inspection, or storage, or to change an

accessory, shut off the power source, disconnect the spark plug wire from the spark plug

(electric unit disconnect from supply), make sure that all moving parts have come to a

complete stop and, where a key is fitted remove the key. Allow the machine to cool before

making any inspections, adjustments, etc.

b) Store the machine where fuel vapour will not reach an open flame or spark. For extended

storage periods, run the unit dry of fuel. Always allow the machine to cool before storing;

c) When servicing the cutting means be aware that, even though the power source will not

start due to the interlock feature of the guard, the cutting means can still be moved by a

manual starting mechanism.

Additional safety instructions for units with bagging attachments

a) Shut-off the power unit before attaching or removing the bag.

6/ 16

INTENDED USE

This shredder is intended for mulching garden and pruning waste such as

green branches, twigs, brush, vines, and long grasses. DO NOT use this

shredder for chipping construction debris, plastic, paper products, rope or

twine, or any material that may contain metal.

GENERAL IDENTIFICATION

7/ 16

1. Hopper 2. Discharge chute 3. Hopper knob 4. Safe key

5. Dustbin 6. Wheel 7. Leg 8. Engine 9. Material push stick

ASSEMBLY INSTRUCTIONS

Hopper installation

1. Carefully insert the hopper into the hopper holder (Fig. A)

2. Locate the screws (total 4 screws) to correct position.

3. Fasten the screw completely.

Fig A

Dustbin installation

1. Insert the dustbin into body (Fig B), make sure the key well connected with

transverter. (Fig C)

2. Use the safe key to lock the dustbin well. ( Fig D)

Fig B Fig C

Fig E

8/ 16

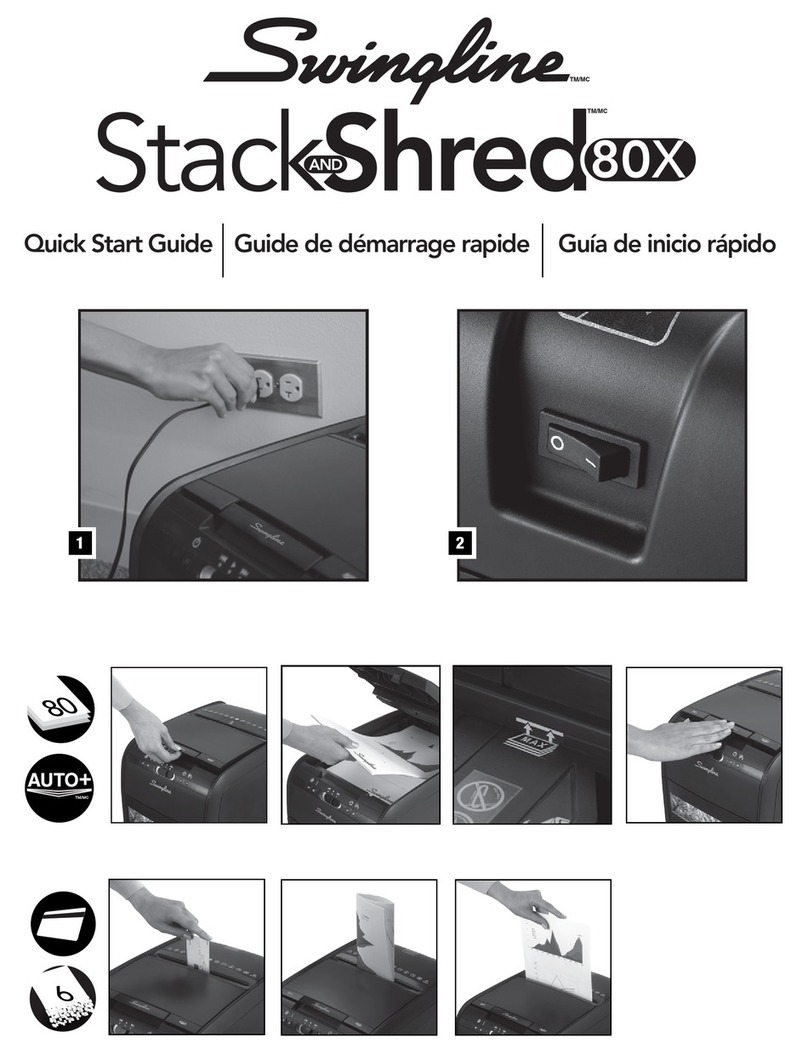

STARTING THE ENGINE

WARNING! Engine delivered without oil and fuel: Fill up with unleaded gasoline and

oil before staring the engine.

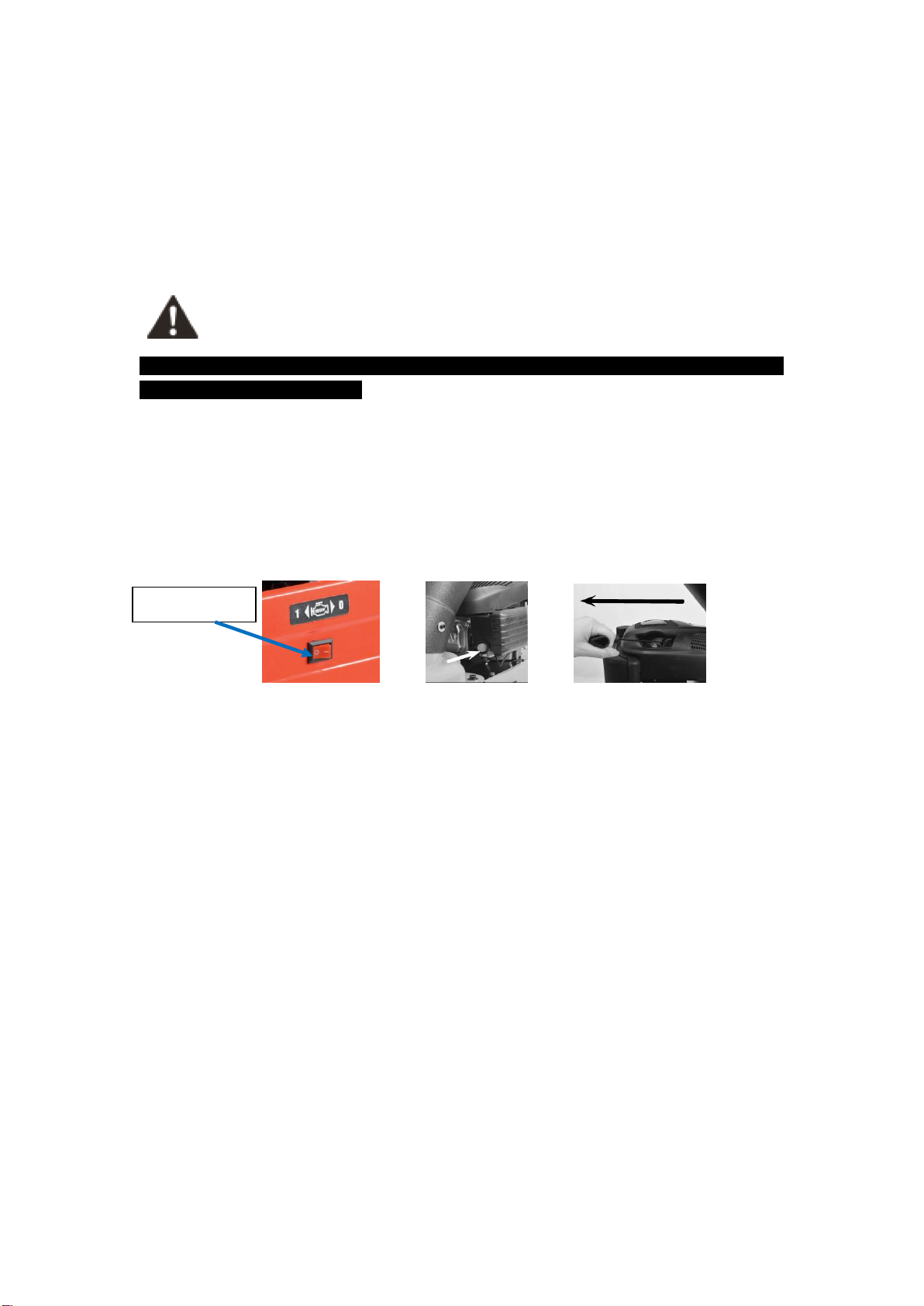

a) Turn engine switch to ON position.(Fig F)

b) Press the primer button 3 times. (Fig G)

c) Pull the recoil starter handle gently until it engages the give it a good strong

pull to start the engine. (Fig H)

Fig F Fig G Fig H

TURN THE ENGINE OFF

Turn the engine switch on OFF position, or take out the dustbin.

OPERATIONS

WARNING! Never operate without dustbin; it may be dangerous to your

body.

1. TOP HOPPER-FRONT CUT

The large slopping front chute of the top hopper is designed to accept

leaves and small garden clippings. Shredding and mulching is achieved by

natural suction of the debris through the blade chamber. Do not overfeed

and do not feed wet, soggy material into the shredder as this may clog the

blade chamber and the discharge chute. (Fig I)

Engine switch

9/ 16

Fig I

2. TOP HOPPER-BACK CHUTE

The smaller back chute of the top Hopper accepts medium to larger size

garden clippings. Shredding and mulching is achieved through the same

action as the front chute. If finer type mulch is required, re-feed the mulch

through again until the desired result is obtained. (Fig J)

Fig J

3. MATERIAL PUSH STICK

User supplied push stick to push remaining material into hopper opening.

DO NOT USE HANDS. (Fig K)

Fig K

MAINTENANCE

WARNING! Priors to any maintenance, to stop engine and switch if off

first.

WARNING! Disconnect spark plug wire from the spark plug to prevent

unintentional engine starting.

10 / 16

WARNING! Unintentional sparking can result in fire.

WARNING! Unintentional start-up can result in entanglement, traumatic

amputation, or laceration.

CAUTION: Use only genuine replacement engine parts. None compliant

parts may damage the engine, and may result in injury. In addition, use of

other parts may void your warranty rights.

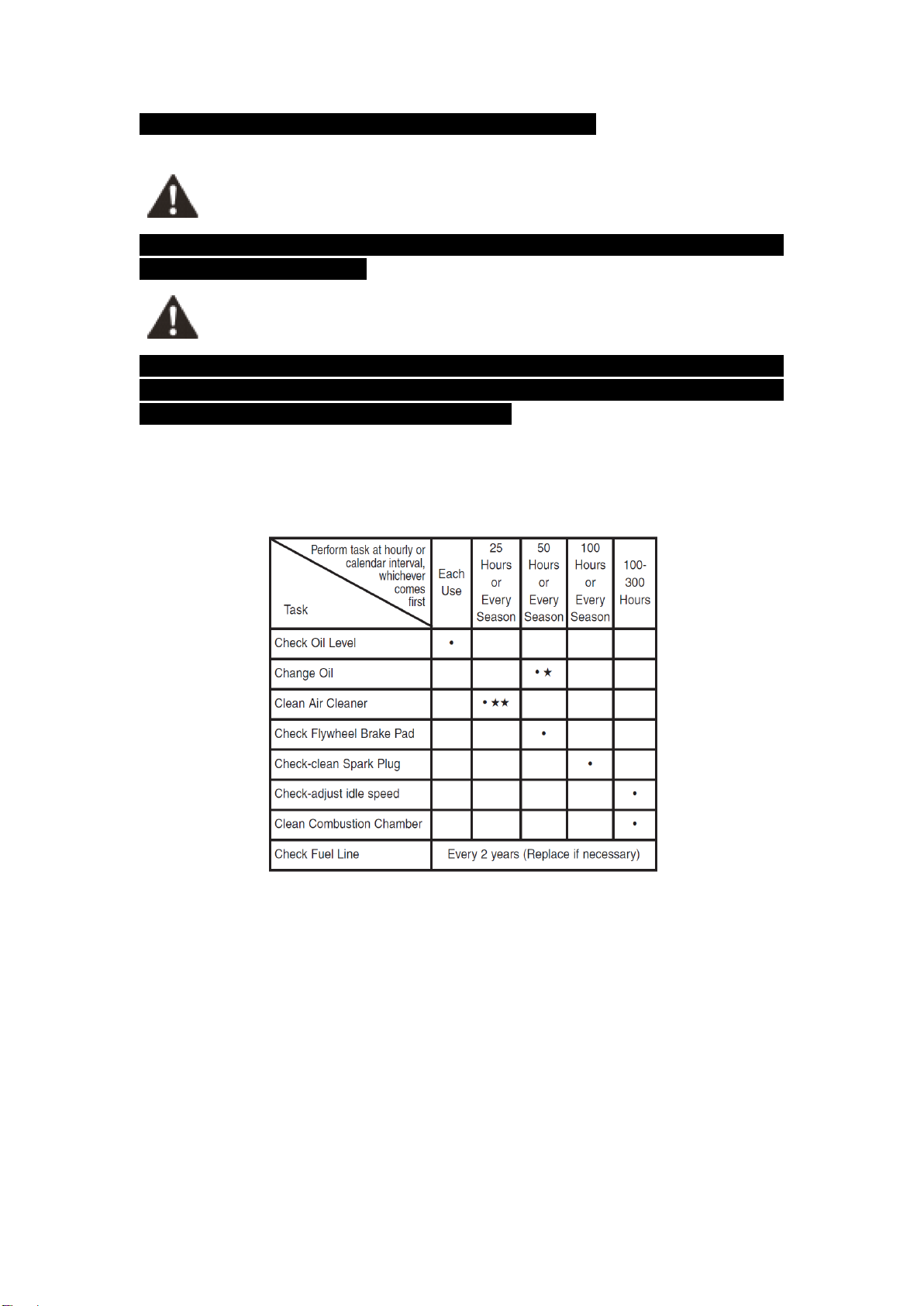

Regular maintenance will improve the performance and extend the life of

the engine. Please follow the instructions and schedules indicated

below:

Drain engine oil and change it after first 5-8 hours of operation and

every 50 hours or three months after that. It is also a highly

recommendation to change oil every 25 hours.

Clean air cleaner more frequently when working under dusty

conditions or when airborne debris is present. Replace of air cleaner

element if it is very dirty.

11 / 16

BLADE MAINTENANCE

WARNING! Before removing Top Hopper screw, ensure the machine is

switched off, and the machine is completely stopped.

WARNING! Take extreme care not to come in contact with cutting blades.

Danger!

WARNING! If ejection chute becomes clogged or cutting blades become

jammed, under no circumstances should you place your hands in

ejection chute to try to clear obstruction, as this will lead to serious

injury.

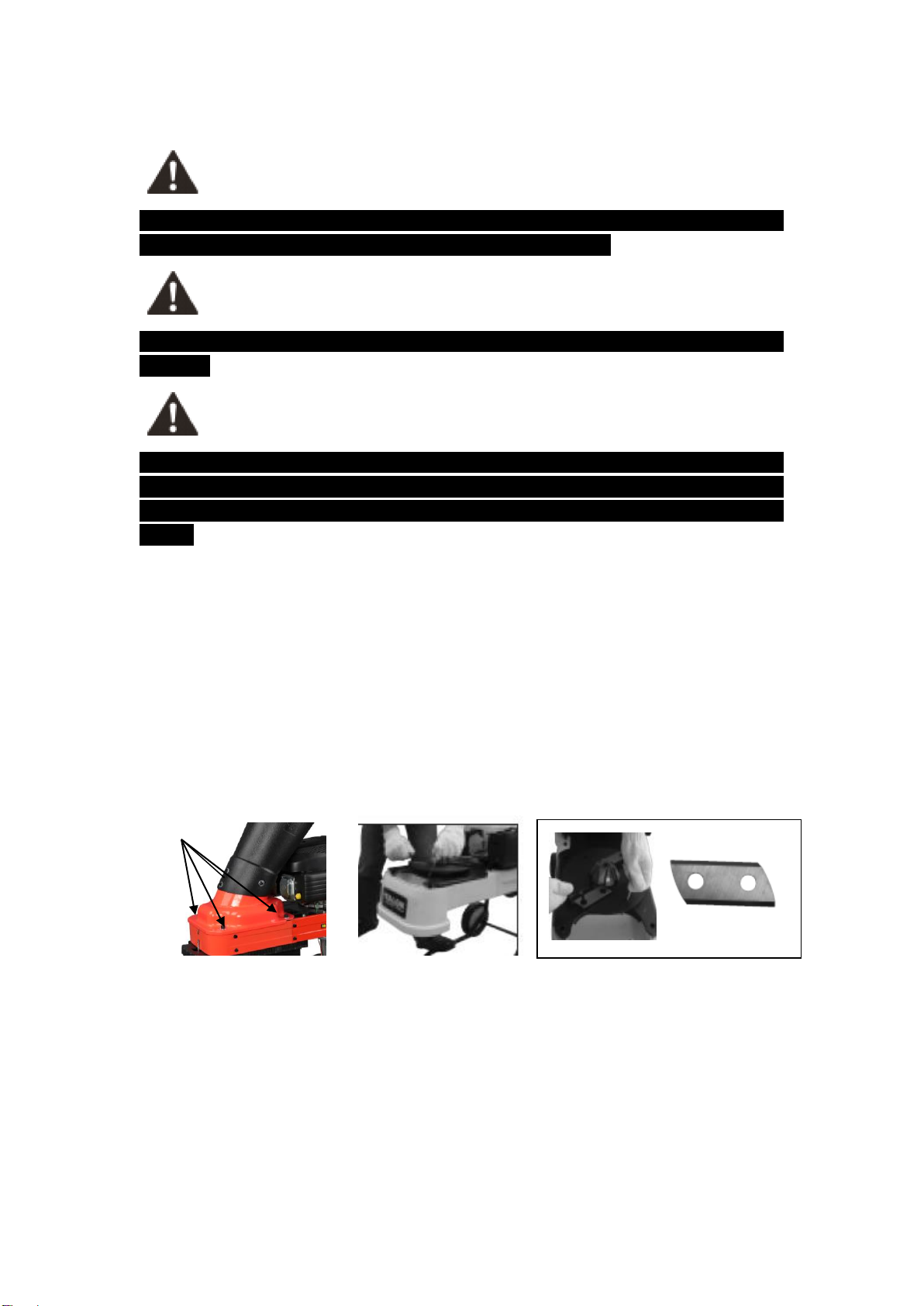

1. Switch the machine off, and make sure the machine is completely stopped.

2. Wear gloves when attempting any maintenance to the cutting blades.

3. Loose four safety 4 screws as shown on (Fig L), carefully lift up the hopper.

4. Steps on the hopper support with the foot, takes a tool to be fixed the blade

of plate. (Fig M)

5. Dismantles bit anchor screw (Fig N) with the suitable tool.

6. Close the hopper, tighten the screws.

NOTE: The blade is double edged. Should you have to change the blade,

rotate the blade 180 degree for sharper edge.

Fig L Fig M Fig N

CHANGE OIL

1. Let engine runs out of fuel, and wait until engine stopped and cooled slightly.

2. Disconnect spark plug wire and keep away from spark plug.

3. When engine is still warm, remove oil drain plug (A). Drain oil into a proper

container. (Fig O)

4. Clean the oil drain plug before restoring it back.

5. Remove dipstick. Add new recommended oil about 0.3L slowly to upper limit

12 / 16

on dipstick, don’t overfill.

6. Replace dipstick.

WARNING! Prevent skin contact with used engine oil. Wash your skin

with soap and water after oil change.

CAUTION: Used oil is a hazardous waste product. It is suggested to bring

used oil to your local recycling center with properly sealed container a

sealed container to your local recycling center. Don not discard with

household waste.

Fig O

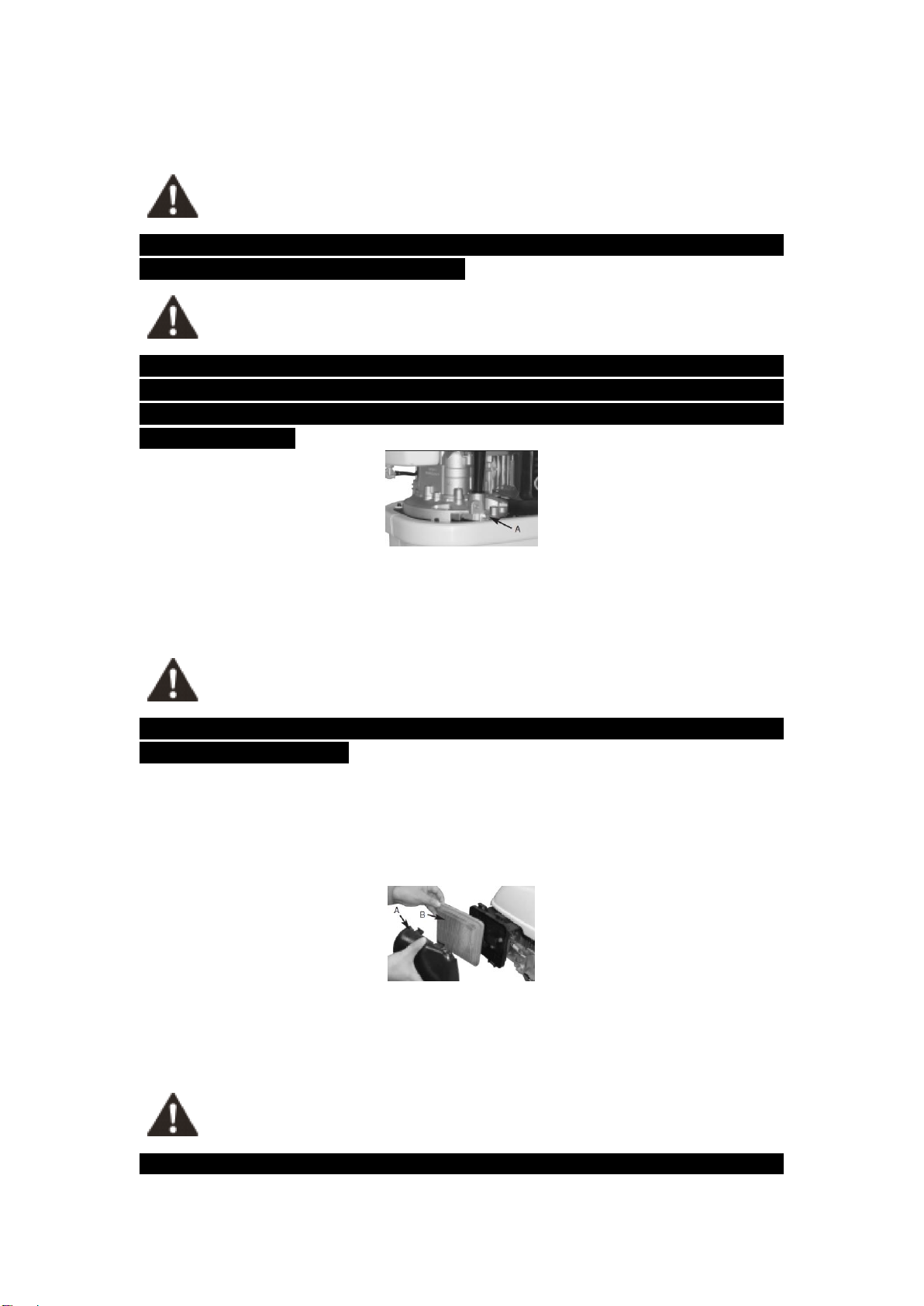

AIR CLEANER MAINTENANCE

A dirty air filter will increase air intake restriction. Periodical maintenance or air

filter will help to improve engine performance and reduce emissions.

WARNING! Never clean air filter with gasoline or an easy ignited solvent

it may cause explosion.

1. Remove the air cleaner cover (A), and carefully remove the filter element (B)

(Fig P)

2. Clean all parts.

3. Blow off dirt from filter element with pressure air.

4. Reinstall the filter element and air cleaner cover.

Fig P

SPARK PLUG

Recommended spark plug: F6RTC.

Stop the engine and allow it to cool

WARNING! DO NOT use an incorrectly rated plug. It is essential to keep

13 / 16

the spark plug in good condition-clean and properly adjusted.

WARNING! To keep engine at top performance spark plug gap should be

within specified and carbon built up free.

14 / 16

1. Removing spark plug with a spark plug wrench.

2. Inspect the spark plug visually. If spark plug is worn, dirty or has cracks,

replace with the recommended type and heat range.

3. The correct air gap is 0.70 to 0.80mm (Fig Q)

4. Tighten the spark plug.

5. After spark plug is tight; torque to 25-30N.m.

Fig Q

WARNING! An incorrectly tightened spark plug may result in poor engine

performance and permanent engine damage.

COMBUSTION DEPOSITS

We recommend that you should remove combustion deposits from the cylinder

head, top of piston, and around valves after every 100-300 hours of usage.

MUFFLER

WARNING! If engine just running down, do not touch muffler. Allow it to

cool before operation.

TRANSPORTING AND STORAGE

When storing engine for more than 30 days.

1. Store in a dry and clean area.

2. Run engine until fuel tank is empty and engine stops or add gasoline

preservative and running engine after adding for several minutes.

WARNING! Gasoline is flammable. Fuel or fuel vapors may explode. Keep

sparks and open flames from the working area.

3. Change engine lubrication oil.

4. Clean the exterior surfaces of the engine.

5. Remove spark plug, pour one teaspoon of fresh engine oil into cylinder.

Re-install spark plug without the spark plug wire attached. Pull starter rope

15 / 16

slowly several times to distribute the oil in the engine.

6. Slowly pull start handle (A) until the resistance is reached, then stop pulling.

At that point, valves are closed, that will prevent dust and rust from entering

cylinder. (Fig R)

7. Cover engine well to prevent dust.

Fig R

WARNING! When you service the engine, inspect the blade, or clean the

underside of the housing, make sure to always tip the engine with spark

plug up. Transporting or tipping the engine with the spark plug down will

cause:

1. Engine smoking

2. Hard starting

3. Spark plug fouling

4. Oil or petrol saturation of the air filter

Technical data

Sound pressure level: 95 dB(A) K=3dB(A)

Guarantee sound power level: 107 dB(A)

Power: 3,2 kW

Weight: 38,5 kg

The noise emission is measured according the requirements of the standards EN13683

Annex F.

16 / 16

CE DECLARATION

FEIDER

32, rue Aristide Bergès - ZI 31270 Cugnaux - France

Declare that the following tool:

Plant Shredder FBT70

Serial number:

Is in conformity with the requirements of the Directive Machine 2006/42/EC and to the

followings Europeans Directives: EMC Directive 2014/30/EU

This tool is also in conformity with the following these standards:

EN 13683:2003+A2:2011, EN ISO 14982:2009

Guaranteed sound power level:

LWA=107dB

Responsible of the technical file:Julia Zou

Cugnaux, 24/04/2019

Philippe MARIE / PDG

Table of contents

Other Feider Machines Paper Shredder manuals

Feider Machines

Feider Machines FBT420-1 User manual

Feider Machines

Feider Machines FBVES2800-UK User manual

Feider Machines

Feider Machines FBVE3000 User manual

Feider Machines

Feider Machines FBT420 User manual

Feider Machines

Feider Machines FBT400-1 User manual

Feider Machines

Feider Machines FBT70-2 User manual