Fenwal 35-65 Series User manual

#$!"

n

Safe start an full-time flame sensing

n

120/240 fiel selectable line voltage for use

with 120 VAC ignitor option

n

24/120/240 VAC hot surface ignitor mo els available

n

Blower control an airflow switch monitoring option

n

Diagnostic LED

n

Multiple trials for ignition

n

Automatic reset option

n

Local or remote flame sensing

n

Flame current test pins

n

Dual spee blower option for LoNox applications

n

Fail-safe gas valve control (35-66 only)

n

CE mo els available

#"

n

Pool an spa heaters

n

Gas furnaces

n

Water heaters

n

Any 24 VAC gas burner application un er 400K BTU

"!#

The Series 35-65 and 35-66 controls are designed to perform many

gas-fired 24 VAC appliance functions in a single control, resulting

in lower system cost. This series monitors the demand for heat,

controls the combustion blower, monitors proper airflow, ignites and

maintains the flame during heating, and provides diagnostic support.

The on-board diagnostics with LED output provide assistance with

troubleshooting and ensures safe and efficient burner operation.

The microprocessor circuit design provides precise, repeatable

timing sequences for ignition and purge times (pre-, inter-, and post-)

as well as multiple tries for ignition. The optional 120/240 VAC field

selectable line voltage capability provides additional field service

efficiency and lower inventory costs.

A ency Certifications

Design certified by CSA International to

CAN C22.2 #199-M89 and ANSI Z21.20

for Automatic Ignition Systems, including

UL1998 software review. M approval

and CE pending on selected models.

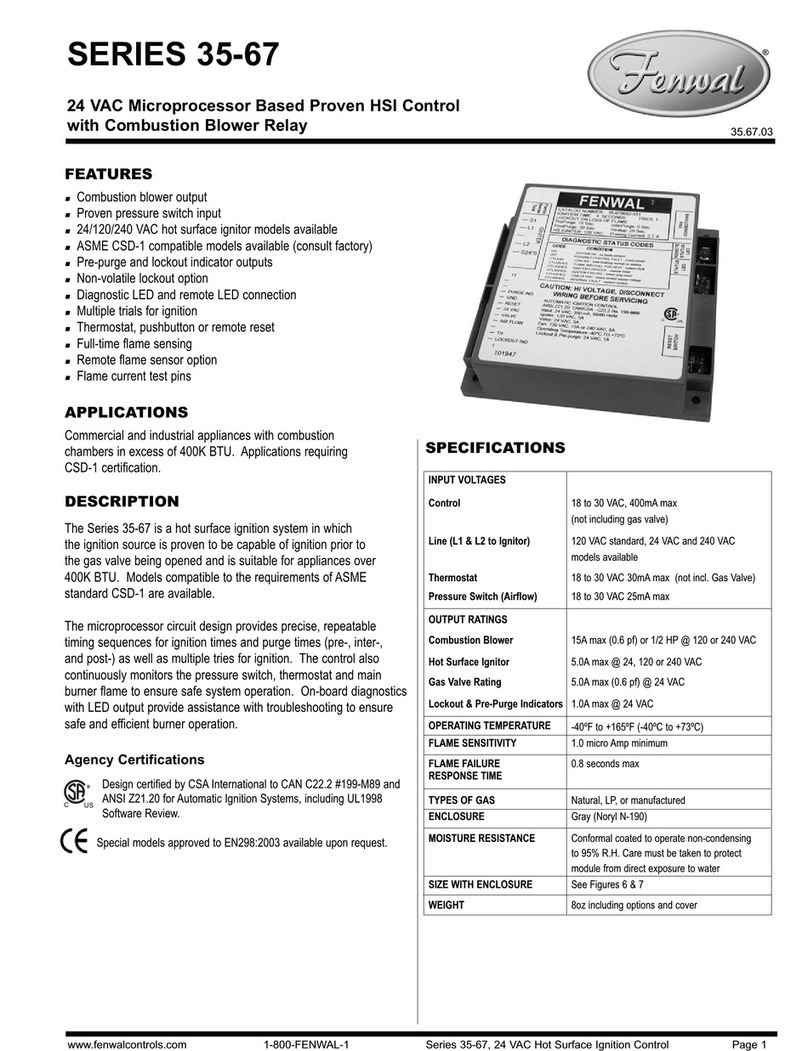

SERIES 35-65 & 35-66

24 VAC Microprocessor Based HSI Control

with 120/240 Field Selectable Line Volta e Capability

www.fenwalcontrols.com 1-800- ENWAL-1 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage Page 1

35-65,-66.02

"

!2/5%+)

633)15

%4!%/7)

20&645-21/28)3

2()/21/9

2563*%')/)0)15

!#

#

$"

"

Control: 18 to 30 VAC 50/60 Hz

(Class 2 Transformer)

Line: 24, 120 or 240 VAC

(L1 & L2 only)

300 mA max @ 24 VAC with blower and gas

valve relay energized (Control only)

2.0A max @ 24 VAC

3.0 LA max @ 120 VAC (1/4 hp)

1.5 LA max @ 240 VAC (1/4 hp)

5.0A max @ 120/240 VAC

-40º to +176º (-40ºC to +80ºC)

0.7 microamps minimum

Natural, LP, or manufactured

24 VAC, 120 VAC, or 240 VAC

mini-ignitors and silicon carbide ignitors

depending on model

Gray (Noryl N-190)

Conformal coated to operate non-condensing

to 95% R.H. Care must be taken to protect

module from direct exposure to water

See igures on Page 7

8 oz including cover

"#"

®

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 1

" #

8-5,6//-0)28)32()/421/9

Upon applying power (24 volts) to the R terminal, the control will

reset, perform a self-check routine, flash the diagnostic LED for a

second and enter the thermostat scan state.

8-5,2656//-0)28)3)30-1%/

When a call for heat is received from the thermostat supplying 24

volts to the W terminal, the control will perform a self-check routine,

flash the diagnostic LED for a second and begin the safety timing

sequence. After an optional "pre-purge" period, the hot

surface ignitor is energized for a heat-up period, followed by the

gas valve for the "trial for ignition" (T I) period.

%//*23)%52()/4

In addition to the self-check routine described above, when a call

for heat is received from the thermostat supplying 24 volts to the

W terminal, the control will check the pressure switch for normally

open contacts. The combustion blower is then energized and,

once the pressure switch contacts close, an optional "pre-purge"

period begins. After pre-purge, the hot surface ignitor is energized

for a heat-up period, followed by the gas valve for the "trial for

ignition" (T I) period.

+1-5-212()/4

When the flame is detected during the T I period, the ignitor is

de-activated and the gas valve remain energized. The thermostat

and main burner flame are constantly monitored to assure that the

system operates properly. When the thermostat is satisfied and the

demand for heat ends, the gas valve is immediately de-energized.

+1-5-212()/4

When the flame is detected during the T I period, the ignitor is

de-activated and the gas valve and combustion blower remains on.

The thermostat, pressure switch and main burner flame are

constantly monitored to assure that the system operates properly.

When the thermostat is satisfied and the demand for heat ends,

the gas valve is immediately de-energized, the control senses the

loss of flame signal and initiates an optional "post-purge" period

before de-energizing the combustion blower.

-1+/)392()/4

Should the main burner fail to light or the flame is not detected

during the T I period, the control will lockout. The gas valve

will be turned off immediately. or 35-66 models, the combustion

blower will be turned off following an optional "post-purge"

period. With the 1 hour reset option, if the thermostat is still

calling for heat, the control will automatically reset and attempt

a new T I sequence after one hour.

(continue ):

6/5-5392()/4

Should the main burner fail to light or the flame is not detected

during the first T I period, the gas valve is de-energized and

the control performs an optional "inter-purge" delay before

attempting another T I period. The control will attempt 2

additional T I's periods before locking out. In lockout, the

gas valve will be turned off immediately. or 35-66 models, the

combustion blower will be turned off following an optional

"post-purge" period. With the 1 hour reset option, if the

thermostat is still calling for heat, the control will automatically

reset and attempt a new T I sequence after one hour.

2'.265)'27)39

Recovery from lockout requires a manual reset by either

resetting the thermostat or by removing the 24 volts for a period

of 5 seconds.

2442*/%0))-+15-21

If the established flame signal is lost while the burner is operating,

the control will respond within 0.8 seconds. The gas valve is de-

energized immediately and a new T I sequence begins. If the

burner does not relight, the control will lockout as previously

described in the " ailure to Light - Lockout" section. Multi-try

models will make 2 more attempts to light the burner. If flame is

re-established, normal operation resumes.

"

2()/421/9

1. Combustion airflow is continually monitored during the ignition

sequence by the pressure switch (PSW terminal). If the pressure

switch contacts remain closed for 30 seconds at the start of the

ignition sequence without an output signal to the combustion blower,

an airflow fault is signaled and the control will remain in this fault

mode with the combustion blower off. If the pressure switch

contacts later open while there is still a call for heat, the control

begins the pre-purge period followed by a normal T I sequence.

2. If the pressure switch contacts remain open for more than 30

seconds after the combustion blower output ( 1 and 2 terminals)

is energized, an airflow fault is signaled and the control will remain

in this fault mode with the combustion blower on. If proper airflow

is later detected from the pressure switch input (PSW terminal),

the control begins the pre-purge period followed by a normal

T I sequence.

3. If the airflow signal is lost while the burner is firing, the control

will immediately de-energize the gas valve and an airflow fault is

signaled. The combustion blower will remain on for the post-purge

period and the control continues to monitor the PSW input waiting

for airflow to return. If proper airflow is detected during the

post-purge period, a normal T I sequence begins preceded by

any pre-purge period. If not, the control will enter a lockout

condition with the combustion blower off.

" $!#!%!("#($#

Page 2 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage www.fenwalcontrols.com 1-800- ENWAL-1

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 2

Internal Control ailure

Airflow ault (35-66 models)

Erroneous lame Signal

Lockout

$#&!

The 35-65 and 35-66 models are not position sensitive and can be

mounted vertically or horizontally. The control may be mounted on

any surface and fastened with #6 sheet metal screws. Secure the

control in an area that will experience a minimum of vibration and

remain below the maximum ambient temperature of 80°C (175º ).

All connections should be made with UL approved, 105°C (221° )

rated 18 gauge, stranded wire with .054" minimum insulation.

Refer to wiring diagram on Pages 5 or 6 when connecting the

control to other components in the system.

#

2)412545%35

,)30245%52112-+1-5-21

!%/7)2112-+1-523

+1-52321127%/7)

/%0)2.%9(63-1+

12*/%0)4)14)%*5)3

Steady On

1 lash

2 lashes

3 lashes

A. Miswired

B. 24 VAC Transformer bad

C. use/Circuit breaker bad

D. Bad control, check LED for steady

on or flashing codes

A. Miswired

B. Bad thermostat, no voltage

at thermostat terminal W

C. ailed ignitor

A. Defective ignitor

B. Miswired

C. Bad control, check voltage at ignitor

A. Valve coil open

B. Open valve wire

C. Bad control, check voltage at gas

valve terminal

A. Bad ignitor

B. Bad S1 wire

C. Poor ground at burner

D. Poor flame, check flame current

24 VAC supply to processor

(optional full time power)

Thermostat Input

120/240VAC Input (Hot)

Neutral

System Ground

Gas Valve

Remote lame Sense

120 VAC Ignitor

Ignitor

240 VAC Ignitor

lame Current Test Pins

2()/41/9

Blower Output

Blower Output

Pressure Switch Input

R

W

L1

L2

GND

GV

S

S1 - 120

S2

S1 - 240

C+ & C-

1

2

PSW

¼ in. Quick Connect

¼ in. Quick Connect

¼ in. Quick Connect

(or 5-pin Mate-N-Loc)

¼ in. Quick Connect

(or 5-pin Mate-N-Loc)

¼ in. Quick Connect

3/16 in. Quick Connect

¼ in. Quick Connect

¼ in. Quick Connect

(or 5-pin Mate-N-Loc)

¼ in. Quick Connect

(or 5-pin Mate-N-Loc)

¼ in. Quick Connect

¼ in. Quick Connect

(or 2-pin Mate-N-Loc)

¼ in. Quick Connect

(or 2-pin Mate-N-Loc)

¼ in. Quick Connect

#!$"#$

Terminal Desi nations

5

Label all wires prior to disconnection when servicing the control.

Wiring errors can cause improper and dangerous operation.

5

Operation outside specifications could result in failure of the

enwal product and other equipment with injury or death to people

and damage to property. Service to this product should only be

performed by a qualified technician.

/%0)%6/56//-0)28)32()/41/9

During normal sequence if an erroneous flame signal occurs,

due to the gas valve failing to close completely, the controller will

energize the combustion blower. Should the gas valve later close

completely and the flame signal be removed, the combustion

blower will power off following an optional post-purge period.

""!$!!#

lame current is the current that passes through the flame from

the sensor to ground. The minimum flame current necessary to

keep the system from lockout is 1 microamp. To measure flame

current, connect an analog DC microammeter to the C terminals

per diagram below. Meter should read 1 microamp or higher.

If meter reads below "0" on scale, meter leads are reversed.

Disconnect power and reconnect meter leads for proper polarity

www.fenwalcontrols.com 1-800- ENWAL-1 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage Page 3

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 3

#!&!!""

Select the proper harness based on the 35-65 and 35-66 control's termination connection on back page. Once the terminal configuration is

determined, complete the part number by replacing the last two digits ("XX") with the length in inches ("l" dimension). Standard wire lengths

are 12, 18, 24 30, 36 and 48 inches. Example 05-129845-018 = 18 inches. or other lengths, please contact enwal

Page 4 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage www.fenwalcontrols.com 1-800- ENWAL-1

)6892*,6''

)6892*,6'''

)6892*,6

)6892*,6

!#""!"

Custom configurations

are available

Custom configurations

are available

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 4

www.fenwalcontrols.com 1-800- ENWAL-1 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage Page 5

&!!""!"

35-65

35-65

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 5

&!!""!"

Page 6 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage www.fenwalcontrols.com 1-800- ENWAL-1

35-66

35-66

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 6

www.fenwalcontrols.com 1-800- ENWAL-1 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage Page 7

"""!"

!"

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 7

400 MAIN S REE , ASHLAND, MA 01721

EL: (508) 881-2000 FAX: (508) 881-6729

www.fenwalcontrols.com

© 2003 Kidde-Fenwal Printed in U.S.A. AG

hese instructions do not purport to cover all the details or variations in the equipment

described, nor do they provide for every possible contingency to be met in connection with

installation, operation and maintenance. All specifications are subject to change without notice.

Should further information be desired or should particular problems arise which are not covered

sufficiently for the purchaser’s purposes, the matter should be referred to KIDDE-FENWAL,

Inc., Ashland, Massachusetts.

P/N 35.65, 66.02 6/20/03

®

Page 8 Series 35-65, -66 HSI Control with 120/240 ield Selectable Line Voltage www.fenwalcontrols.com 1-800- ENWAL-1

#!$!#

- X X X

#60)146.308043

1 = 4 Seconds

3 = 7 Seconds

5 = 10 Seconds

7 = 15 Seconds

38,696.,

0 = None

1 = 15 Seconds

2 = 30 Seconds

6,96.,

0 = None

1 = 15 Seconds

2 = 30 Seconds

#60,746.308043

0 = Single Try without Automatic Reset

1 = Single Try with 1 Hour Automatic Reset

5 = Three Tries without Automatic Reset

6 = Three Tries with 1 Hour Automatic Reset

31;414:,6!,1);#,6203)8043464+,17

0 = ALL Q.C. Terminals Without ull Time Power (W Only)

1 = Mate-N-Loc (5 Pos.) with Q.C. Terminals without ull Time Power (W Only)

2 = Mate-N-Loc (2 Pos.) with Q.C. Terminals without ull Time Power (W Only)

5 = ALL Q.C. Terminals with ull Time Power (R Terminal)

6 = Mate-N-Loc (5 Pos.) with Q.C. Terminals with ull Time Power (R Terminal)

31;&08/14:,6!,1);#,6203)8043)3+47896.,-464+,17

0 = No Post-Purge All Q.C. Terminals without ull Time POWER (W Only)

1 = No Post-Purge All Q.C. Terminals with ull Time POWER (R Terminal)

2 = 30 Second Post-Purge All Q.C. Terminals *

3 = 60 Second Post-Purge All Q.C. Terminals *

5 = No Post-Purge Mate-N-Loc (5 Pos.) with Q.C. Terminals without ull Time Power (W Only)

6 = No Post-Purge Mate-N-Loc (5 Pos.) with Q.C. Terminals with ull Time Power (R Terminal)

7 = 30 Second Post-Purge Mate-N-Loc (5 Pos.) with Q.C. Terminals *

8 = 60 Second Post-Purge Mate-N-Loc (5 Pos.) with Q.C. Terminals *

* Post-Purge Requires ull Time Power (R)

.30846580437

0 = 120/240 VAC Mini-Ignitor (6 Second Heat-Up)

2 = 24 VAC Mini-Ignitor (4 Second Heat-Up) CE Approved

5 = 120/240 VAC Ignitor (20 Second Heat-Up)

6 = 120/240 VAC Ignitor (40 Second Heat-Up)

7 = 24 VAC Mini-Ignitor (4 Second Heat-Up)

97842,70.37"8)3+)6+)6892*,643-0.96)80434,748551;

3 = Customer Special eatures CE Approved (Refer To Drawing)

8 = Aftermarket Kit (Refer To Drawing)

9 = Customer Special eatures (Refer To Drawing)

58043)1,)896,7

1 = Dual Speed Blower (35-66 Model Only)

2 = 120/240 ield Selectable Line Voltage

3 = Dual Speed BLOWER AND 120/240 ield Selectable Line Voltage (35-66 Model Only)

5 = None

4+,1

5 = Without Combustion Blower Relay (Model 35-65)

6 = With Combustion Blower Relay (Model 35-66)

35 - 6X X XXX Description

DS 35 65 66:DS 35 65 66.qxd 9/27/2010 9:08 AM Page 8

This manual suits for next models

1

Table of contents

Other Fenwal Control Unit manuals

Popular Control Unit manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC FF128EP Series Installation, operation and maintenance manual

Advantech

Advantech WISE-1510 user manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1606-XLERED20Y Reference manual

FrSky

FrSky R9M 2019 LBT instruction manual

SonicWALL

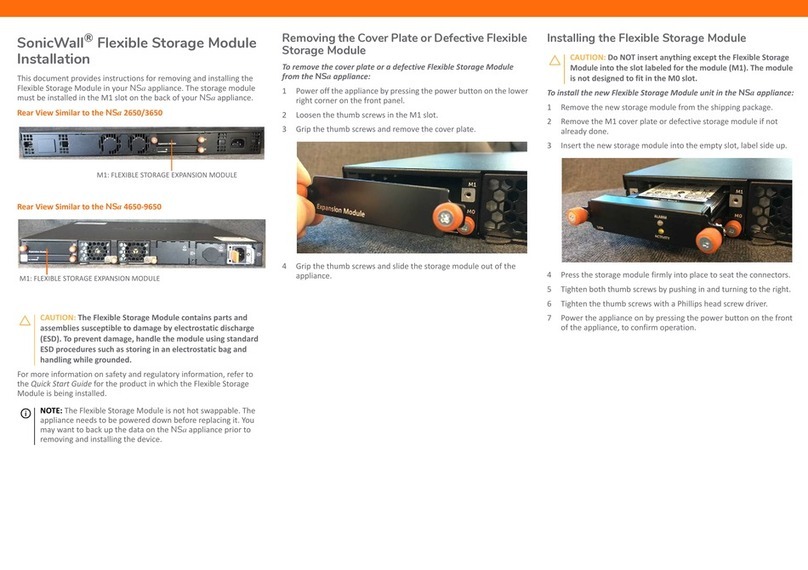

SonicWALL 01-SSC-0027 installation guide

DOEPFER

DOEPFER A-100 Series Assembly and Wiring Manual