FERPINTA HGR User manual

INTRODUCTION

// OPERATOR’S MANUAL

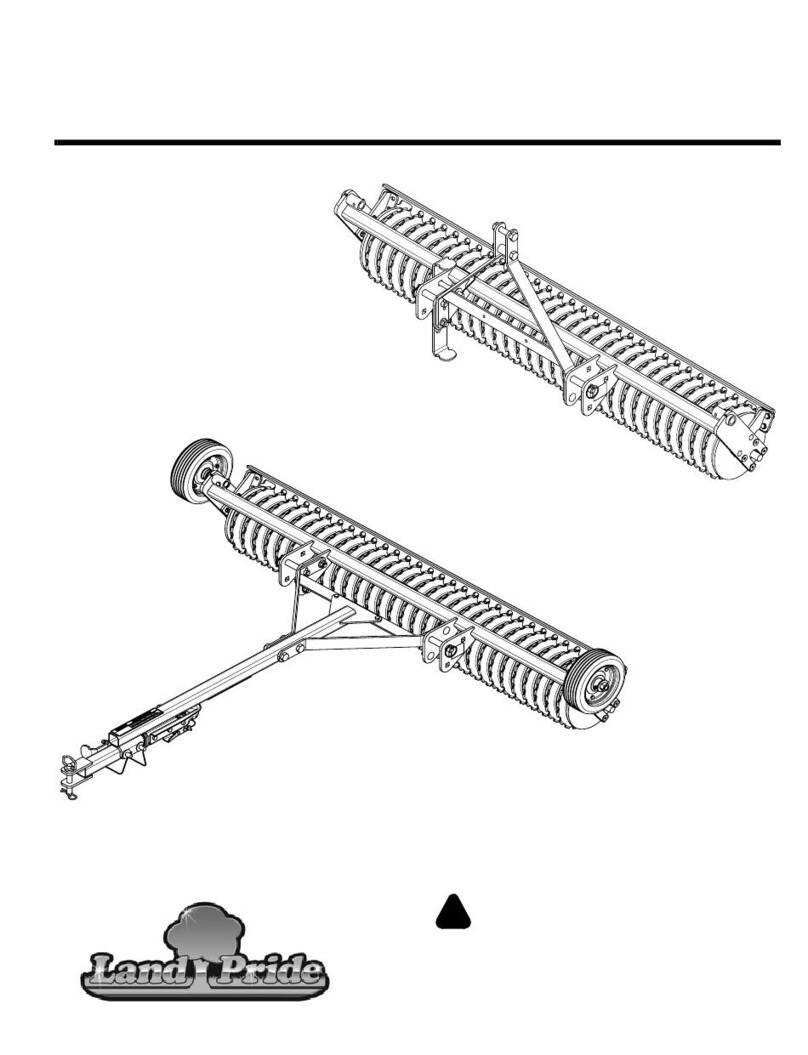

DISC ARROWS •HGR | HGR - H

EN

INTRODUCTION

ÍNDEX

INTRODUCTION__________________________________________

DECLARAÇÃO DE CONFORMIDADE_______________________

SIMBOLOGY_____________________________________________

WARNING LABELS________________________________________

WARNING LABELS POSITION______________________________

TECHNICAL SPECIFICATIONS _____________________________

GENERAL SAFETY RULES __________________________________

TRACTOS’S PREPARATION ________________________________

3 POINT LINLAGE (TUZ) __________________________

DISC HARROW SET’S STABILITY ___________________

COUPLING TO TRACTOR_________________________

STARTING WORK ________________________________________

UPPER ATTACHMENT POINT______________________

DEPTH ADJUSTMENT_____________________________

DISCS SECTIONS________________________________

SIDE SCREENS__________________________________

SCRAPER_______________________________________

OPTIONALS_____________________________________________

LIGHTNING SYSTEM CONNECTION________________________

PREPARE THE MACHINE FOR WORK________________________

UNFOLDING THE MACHINE ______________________

INSTRUCTIONS FOR USE__________________________

TRANSPORTATION ON PUBLIC ROADS____________

MAINTENANCE AND SERVICE_____________________________

TIMETABLE-MAINTENANCE AND SERVICE __________________

MALFUNTIONS OR PROBLEMS / POSSIBLE SOLUTION________

PARTS REPLACEMENT____________________________________

2

3

3

4

5

8

9

11

11

11

12

14

14

14

15

16

18

19

20

21

21

22

23

25

26

29

30

PROLONGED IMMOBLIZATION____________________

WARRANTY CONDITIONS_________________________

HOW TO ORDER PARTS ___________________________

32

33

34

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

2

INTRODUCTION

Dear Customer,

Congratulations on your choice, as you have just purchased equipment built with high technology and

strict quality standards.

All our efforts are put into research, innovation, development and improvement of this product, so that you

can take advantage of the quality, performance, and work in safety.

This manual was created to help you and to advise about safety, maintenance and how to use the

equipment. Thereby, you will be able to use it with confidence to ensure a good performance. Please start

by reading it carefully to become familiar with all the equipment and the most important aspects of safety,

its usage as well as other useful information.

Anyone operating, maintaining, or transporting this equipment must read and thoroughly understand the

instructions outlined in this manual before starting to work.

Please take note of all issues related to safety and instructions included in this manual, complying with them

in order to guarantee your safety and others safety.

Please keep the manual in an accessible and safe place, so that you can refer to it whenever necessary.

It is essential that this equipment is inspected periodically, that it is maintained and fitted with suitable spare

parts.

HERCULANO will provide you with any necessary support, solving problems or clarifying questions that you

may have when using the equipment.

HERCULANO –ALFAIAS AGRÍCOLAS S.A.

3720-051 Oliveira de Azeméis

PORTUGAL

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

3

SIMBOLOGY

DANGER!

Failure to comply with this signal may cause damage

to the equipment and cause serious injuries to people,

endangering your own life.

•All "Danger" instructions must be followed and

respected!

CAUTION!

The special caution signals go next this symbol!

•Please take the necessary precautions and follow

the recommended operating instructions to avoid

problems or accidents.

WARNING!

If you do not respect this signal, you will be subject to

severe injuries and possible damage to the

equipment.

•All "Warning" instructions must be followed and

respected!

MAINTENANCE!

Iconography used for Maintenance and/ or Cleaning!

•Carefully carry out the recommended

maintenance and cleaning procedures in order to

extend the equipment's service life and keeping

the safety conditions.

INFORMATION

Additional useful information goes next these symbols!

•Please read all the points with additional

information carefully since they are useful to

become familiar with your equipment.

“EC” DECLARATION OF CONFORMITY

SAFETY ALERTS

This equipment complies with the requirements of the European Parliament and

Council Directive, 2006/42/EC, of 17 May 2006, transposed into Portuguese law

by Decree-Law No. 103/2008 of 24 June 2008.

The EC Declaration of Conformity is attached to the Trailer User Manual.

This Operator’s manual includes the following symbols:

LUBRICATION!

The Lubrication and Oil Level Replacement

Instructions go next to this symbol!

•Please pay attention to the lubrication points and

periodicity, or the replacement of grease or oil

level. Failure to follow this instruction may

jeopardize the proper performance of the

equipment.

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

4

SAFETY

PERSONAL PROTECTIVE EQUIPMENT

It is very important that the operator wears personal

protective equipment daily to minimize the risks of

an accident.

The instructions in this manual are essential, please

always use PPE's - Personal Protective Equipment

PLEASE WEAR –PROTECTION FOOTWEAR

PLEASE WEAR –PROTECTION GLOVES

PLEASE WEAR–PROTECTION HELMET

PLEASE WEAR –PROTECTION VEST/ CLOTHING

0

READ THE OPERATOR’S USER MANUAL!

Before first usage familiarize yourself with the

instruction manual and safety regulations it

provides.

EW00060

STOP THE ENGINE BEFORE ANY MAINTNANCE

SERVICE!

Turn the engine off and take the key out of ignition

before starting maintenance or service!

EW00061

RISK OF CRUSHING OF THE LIMBS BY WORKING

ELEMENTS OF THE MACHINE OR CUTTING BY SHARP

EDGES!

Keep the distance from the machine! Take special

precautions when replacing sharp elements!

EW00063

RISK OF CRUSHING OF THE BODY WITHIN THE THREE-

POINT LINKAGE OPERATING AREA!

People are not allowed between the harrow and

the tractor when mounting the machine and using

the hydraulic draw- bar!

EW00068

DANGER OF A PALM OR FINGER SQUEEZE BY

MOVING PARTS OF THE MACHINE!

Do not reach the area of moving elements (working

depth regulating actuators, side screens regulation,

outermost discs assembling) during operation or

when the tractor`s engine is on, or when the

hydraulic installation is working!!

EW00062

DANGER OF WHOLE-BODY SQUEEZE WHEN THE

MACHINE SWINGS DURING TURNING!

Do not stay around machine`s range during work or

transportation! Keep safe distance when reversing!

EW00067

MARKS PLACES FOR LIFTING SLING FIXING!

Marks spots suggested for machine`s safe loading

and unloading from the means of transport,

including ensuring its stability when hanging on

ropes, belts, or chains. Always take the lifted

machine`s weight into consideration EW00066

RISK DUE TO UNEXPECTED MOVEMENT OF THE

MACHINE!

This risk can result in serious bodily injuries, potentially

fatal injuries.

Before the machine is detached from the tractor

protect transport wheels with a wedge!

RISK OF CRUSHING OF THE WHOLE BODY OR ITS PART

DUE TO FALLING OF AN UNPROTECTED SUB-ASSEMBLY!

Failure to use a support foot may result in major

injuries. Before the machine is detached, protect the

drawbar against falling by means of a support foot!

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

5

SAFETY

WARNING LABELS POSITION

•PLEASE KEEP THE LABELS LEGIBLE AND IN GOOD CONDITION.

•IF THEY DETERIORATE OR ARE LOST, REPLACE THEM WITH NEW ONES.

(PLEASE ASK THEM FROM YOUR AGENT, OR CONTACT THE MANUFACTURER DIRECTLY)

EW00060

EW00061

EW00068

EW00063

EW00067

EW00066

EW00062

HGR 15 | HGR 17 | HGR 20

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

6

SAFETY

WARNING LABELS POSITION

HGR 25| HGR 27 | HGR 30 | HGR 40

•PLEASE KEEP THE LABELS LEGIBLE AND IN GOOD CONDITION.

•IF THEY DETERIORATE OR ARE LOST, REPLACE THEM WITH NEW ONES.

(PLEASE ASK THEM FROM YOUR AGENT, OR CONTACT THE MANUFACTURER DIRECTLY)

EW00066

EW00062

EW00066

EW00067

EW00068

EW00067

EW00063

EW00061

EW00060

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

7

SAFETY

WARNING LABELS POSITION

EW00060

EW00061

EW00063

EW00068

EW00067

EW00063

EW00062

EW00063

EW00062

EW00062

EW000

HGR 40 H| HGR 50 H | HGR 60 H

•PLEASE KEEP THE LABELS LEGIBLE AND IN GOOD CONDITION.

•IF THEY DETERIORATE OR ARE LOST, REPLACE THEM WITH NEW ONES.

(PLEASE ASK THEM FROM YOUR AGENT, OR CONTACT THE MANUFACTURER DIRECTLY)

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

8

TECHNICAL SPECIFICATIONS

HGR 40 H

HGR 50 H

HGR 60 H

CHARACTERISTICS

WORKING WIDTH (M)

4,0

5,0

6,0

INDICATIVE EMPTY

WEIGHT (KG)

2250

2600

3100

DISCS DIAMETER (“/MM)

22/560

22/560

22/560

DISCS THICKNESS (MM)

6

6

6

NUMBER OF DISCKS

32

40

48

WORKING DEPTH (CM)

14

14

14

RECOMMENDED POWER

(CV)

120-150

140-180

160-200

HGR 15

HGR 17

HGR 20

HGR 25

HGR 27

HGR 30

HGR 40

CHARACTERISTICS

WORKING WIDTH

(M)

1,5

1,7

2,0

2,5

2,7

3,0

4.0

INDICATIVE EMPTY

WEIGHT (KG)

700

780

825

1100

1180

1320

1750

DISCS DIAMETER

(“/MM)

22/560

22/560

22/560

22/560

22/560

22/560

22/560

DISCS THICKNESS

(MM)

6

6

6

6

6

6

6

NUMBER OF

DISCKS

12

14

16

20

22

24

22

WORKING DEPTH

(CM)

14

14

14

14

14

14

14

RECOMMENDED

POWER (CV)

50

60

70

85-115

90-120

100-130

11-150

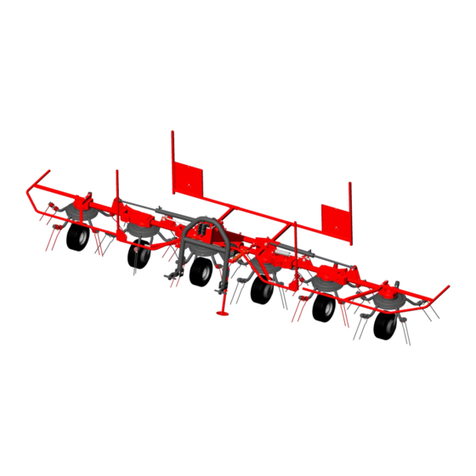

The Disc Harrow is designed for cultivation of the soil after ploughing and before sowing. The Disc Harrow may

also be used on stubbles on condition that crop residue is crumbled and the stubble is short. The main working

element is a set of disks used for cutting the soil and mixing it intensively afterwards.

The Disc Harrow is designer for cultivation of slightly rocky light and medium soils providing the humidity proper

for agricultural processes, on flat or slightly corrugated terrain. (Maximum slope 8,50).

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

9

GENERAL SAFETY RULES

The below-mentioned safety regulations refer to the disk

harrow mounted on the tractor. Notwithstanding, always

observe general occupational health and safety rules

and road traffic regulations.

•In addition to the recommendations included in this

instruction manual, follow general occupational health and

safety rules as well.

•Observe the warning symbols placed on the machine. Their

observance is for your own safety!

•Stay of any personnel on the machine during work and

transport is forbidden. Before operation, make sure that

nearby the machine there are no bystanders. Pay special

attention to children.

•Lever for the tractor's hydraulic sections should be operated

only from the driver’s seat.

•When the machine is coupled with the tractor, raised or

lowered on the tractor’s hydraulic lift and on the headlands,

check whether there are no bystanders, children in

particular, nearby the the tractor + disk harrow assembly.

•It is forbidden to approach the disk harrow while it is being

lifted and lowered.

•Do not stand between the tractor and the harrow while the

engine is working.

•It is forbidden to reverse the tractor and make turns with the

harrow lowered to the working position.

•While making turns, take the far protruding elements into

account, do not use the brakes independent of the tractor.

•Connect the machine to the tractor as described herein.

•The machine can be connected only to tractors of

adequate power and equipped with category 3 rear three-

point linkage (in accordance with PN-ISO 730-1:1996). Also

remember to choose the tractor's class properly to ensure

its manoeuvrability.

•To maintain proper tractor's manoeuvrability, the machine

should be connected to the tractor equipped with a set of

front axle ballast weights. Pressure of the tractor's front axle

with the mounted harrow must be at least 20% of the

tractor's weight

•Use special, dedicated pins and cotter pins to secure

connections between the machine and the tractor. It is

forbidden to use the substitute means, such as bolts, rods,

wires etc., as these can be sheared or fall out during work or

transport, and thus cause an accident or damage to the

machine. Diameter of the pins must be compliant with the

machine's three-point linkage category.

•It is forbidden to leave the tractor with the machine

mounted on slopes or other sloping areas without protecting

it against uncontrolled rolling. Take special care while

working on the slopes.

•Never leave the tractor with the engine operating. Before

leaving the driver’s seat, lower the machine, turn the

tractor's engine off, remove the ignition key, and engage

the hand brake.

•Because of natural materials wearing out, flexible hydraulic

wires should be replaced every four years. Date of

manufacture (year and number of the week) is placed on

the hydraulic wires.

•Speed must be adjusted to the road conditions.

•When transporting the machine drive your tractor as near

the right side of the road as possible.

•Exercise particular care when driving on public roads,

observe the relevant road traffic rules and regulations. For

the time of transport on the public roads, install the following

on the disk harrow: warning signs painted in white and red

stripes, with lamps: front –white position, rear –red position

and red round reflective (warning signs can be ordered at

the machine's manufacturer on additional charge or

purchased at a point of sale of agricultural machinery) and

a warning triangle for slow moving vehicles.

GENERAL SAFETY RULES

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

10

GENERAL SAFETY RULES

•During transport and work it is forbidden to stand on the

harrow or load it with additional ballast weights.

•During breaks in operation, the harrow should be stored on

a firm and level surface, with all working units lowered in a

place that is inaccessible to unauthorised personnel and

animals.

•Pay particular attention when dismantling and use drawings

provided in the spare parts catalogue.

•When loading, the lifting devices (e.g. forklift truck,

overhead crane) can be operated only by the personnel

with proper qualifications. Elements of the frame (marked on

the machine) should be used as fixing points.

BE CAREFUL! PREVENT ACCIDENTS!

BEFORE START WORKING

•The machine can be used only by adults who hold

adequate qualifications to drive tractors, are familiar with

instruction manuals of both the machine mounted, and the

tractor.

•Antes de começar, verifique se a condição da grade de

disco e do trator garante a segurança rodoviária e do

trabalho.

•The tractor cooperating with the harrow must be equipped

with ballast weights of the front axle. Balance of the tractor

with the machine mounted its manoeuvrability and braking

capacity must be kept. Observe the maximum permissible

load per axle and transport dimensions.

•Exercise particular caution when the machine is being

connected to and disconnected from the tractor. Turn the

tractor's engine off, remove the ignition key, and engage

the hand brake.

•When connecting hoses to tractor's hydraulic system make

sure the hydraulic system is depressurized. Check position of

control levers for the tractor's hydraulic system.

•Appliances controlled by the hydraulic sections can be

activated only when there are no personnel within the

operation area of the machine. There are crushing and

cutting places on the parts activated with the use of the

other force than their own (e.g. hydraulic system).

•Check air pressure in tractor's tyres.

•Balance of the tractor with the machine mounted its

manoeuvrability and braking capacity must be maintained.

Observe the maximum permissible load per axle and

transport dimensions. Balance of the tractor with the

machine mounted its manoeuvrability and braking

capacity must be maintained. Observe the maximum

permissible load per axle and transport dimensions.

•If working units are clogged during operation, clean the

machine by lifting / lowering it few times on the tractor's

linkage.

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

11

PREPARATION OF THE TRACTOR

- Tractor’s overall weight (Kg).

- Front axle load of unloaded tractor (Kg).

- Rear axle load of unloaded tractor (Kg).

- Weight of front ballast weights (Kg).

- Weight of the machine mounted at rear (Kg).

- Distance between centre of gravity of front ballast

weights and centre of the front axle (m).

- Distance between tractor axles (m).

- Distance between the centre of rear axle and

centre of back suspension system couplings (m).

- Distance between the centre of ball joint of rear

suspension system and the centre of gravity of the

mounted machine (m).

The tractor must be equipped with front weights

to ensure the optimum driving properties, proper

mass distribution and equal working depth.

The calculation procedure of the counterweight

mass for the mounted machine as the ballast

weights mounted in front of the tractor are the

following:

−Calculating the increase of the tractor`s rear

axle`s weighting:

11

222222222

3-POINT LINKAGE (TUZ)

Construction of the suspension system assumes that

the tractor and the machine are meant to work

together as set. Functionality of the set is influenced

by the way the upper and lower links on

hangers are regulated.

To make optimal regulation of the BT harrow easier,

in case the tractor has three linking points, the upper

link should be linked to the highest point.

Lower links should be regulated to be set on the

same height

Regulation of the hangers must allow lifting the

machine to the proper height, so that it could be

transported safely.

Regardless of whether the lower links have the

chains attached or not,

the telescopic stretcher bar or other stabilization

system used should be regulated in a way enabling

the BT harrow mounted to the tractor to move

slightly from side to side, without swaying too much

during transportation.

FRONT AXLE LOAD

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

12

PREPARATION OF THE TRACTOR

To verify the total stability so that the minimum weight of front weights can be calculated, what leads to

making sure that the front axle load is at least 20% of the mass of the tractor alone, the formula presented

below can be used:

−Calculating the real load of front axle formula:

−Calculating real total mass formula:

−Calculating real rear axle load formula:

MOUNTING THE HARROW ON TRACTOR

HGR 15 | HGR 17 | HGR 20 | HGR 25| HGR 27 | HGR 30 | HGR 40

Note: For a correct and safe assembly of the harrow,

the tractor must be on firm and level ground.

Proceed as follows:

•Switching the hydraulic system to standing position.

•Putting the ball couplings on harrow catch ball (put

the bolts attached to the harrow through the ball

couplings of tractor`s lower links and secure them

with pins).

•Backing the tractor to the distance enabling linking

the coupling bolts of the harrow to the lower links of

the tractor, as well as connecting the upper link to

the harrow`s hanger

•Connecting the tractor`s upper link and securing its

bolt.

•Regulating tractor`s lower links stabilizators.

•Connecting harrow`s hydraulic wires to the tractor`s

external hydraulic system (if applicable).

•Checking lifting and lowering the harrow, working

section`s folding and unfolding, rear shaft positioning

regulation that are steered hydraulically, (if

applicable).

•Connecting the lighting installation wires (if provided)

by putting the seven-polar plug into the tractor`s

electrical installation slot and check the machine`s

lighting.

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

13

PREPARATION OF THE TRACTOR

MOUNTING THE HARROW ON TRACTOR

HGR 40H | HGR 50H | HGR 60H

Note: For a correct and safe assembly of the harrow,

the tractor must be on firm and level ground. Proceed

as follows:

•Switch the tractor's hydraulic system into position

adjustment;

•Reverse the tractor for a distance enabling

connection of tractor lower links (DC) to latch bar (B)

on the harrow.

•mount ball-and-socket joints of the tractor's lower

links onto latches on the harrow (pass pins provided

with the harrow through ball-and-socket joints and

secure with cotters).

•Adjust the anti-roll bars of the tractor's lower links.

•Connect hydraulic hoses (P) of the harrow to

sockets of external hydraulic sections on the tractor

(H)

•Check lifting and lowering of the whole harrow,

folding of working sections and function of

hydraulically controlled rear roller position

adjustments.

•Connect cable of lighting system of the harrow (if

provided) by plugging the seven-pole plug to the

socket of the tractor's wiring system and check for

proper function of the mounted machine's lighting

system.

BE CAREFUL! PREVENT ACCIDENTS!

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

14

STARTING WORK

UPPER SUSPENTION POINTS

The machine can be connected with the tractor`s

upper link by the permanent slots (OS) or movable

slots (OP) that allow the harrow to lift up slightly when

stumbling upon large disturbing items during working

on rocky fields.

Using movable slots can help eliminating unwanted

machine`s vibrations and swaying.

Movable slots are also recommended for mounting

wide (4m) disk harrows.

When the upper link is connected to the movable slot

of the hanger, the link must be untightened so that

the bolt is unloaded when the harrow is lowered

down.

Note: Movable slots are available on all machines

except HGR 15, HGR 17 and HGR 20 which have 3

slots (OS).

When regulating the tractor`s couplers and changing the geometry of

harrow`s fastening stay cautious! There is a risk of body squeeze!

There is a risk of body squeeze or body parts being cut off by unwanted

and accidental machine and tractor disconnecting! Make sure that no

outsiders are present in the machine`s area during its regulation.

DEPTH REGULATION

Correctly mounted, levelled and adjusted harrow

during cultivation should move evenly behind the

tractor and maintain such position so that the area is

cultivated onto the same depth.

To keep uniform working depth of the harrow, level

the harrow:

•In transverse direction by shortening or

lengthening of the right hanger.

•In lengthwise direction by shortening or

lengthening of the upper connector.

Adjustment of working depth of disks assembly is

done using adjustment located at the coupler

between main frame and rear roller, as the harrow is

lifted by the roller.

To set working depth of the machine by changing

adjustment setting on the frame:

•Lift the machine on the tractor's three-point

linkage lift.

•Remove pins (P) secured with cotters which limit

movements of rear roller arms and the frame of

the machine against each other on the

adjustment gauge (R).

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

15

STARTING WORK

•Turn the actuators (S) on using the tractor`s hydraulic

system (the actuators are placed on each arm- there

are two or three of them, depending on the machine`s

width). Lower or lift the rear shaft towards the main

frame of the disk harrow. If the machine is not

equipped with actuators, it should be lowered or lifted

using TUZ suspension system to change the working

depth settings.

•Secure the shaft`s arms again by putting the pins in the

slots. Make sure that you are using slots placed most

closely to the arms position. Remember! Perform the

described action on both sides of the machine,

making sure that pins are placed equally on both left

and right regulation scales

•Regulate the coupler between the tractor and the disk

harrow so that the harrow is positioned in parallel to the

ground (in working position).

•In case of working resistance exceeding tractor`s

traction output, the working depth should be lowered.

NOTE: It is explicitly important to remember about setting the

regulating pins equally on both sides of the machine.

Disobeying hereby provision will lead to machine`s fast

damage.

If there are problems with pulling the pins out or putting them

back in, the harrow should be unloaded by lifting it up and

letting it fall freely.

DISKS SECTIONS

Both disc sections are mounted to the main frame

using holders allowing for horizontal adjustment of the

discs' working position (three or four holders at each

disc’s section according to working width of the

machine). Thanks to such solution it is also possible to

position the sections against each other in a way

other than factory-set, if the operator finds it is

required by specific soil conditions on a particular lot

(soil type, moisture or amount of harvest residues) to

achieve soil mixture as thorough as possible or to

cover harvest residues.

The horizontal adjustment causes no change in disc

spacing in relation to each other within one section,

or no change in angle of their operation.

ATTENTION! Switching of both disc sections to side

positions (outermost) will cause a slight increase in the

machine's working width and may cause the

machine to leave strips of inaccurate cultivated soil

between rows of discs, operation of which is not

followed by the other section (as a rule each strip of

the soil under cultivation should be “mixed” by two

rows of discs at the same time within a single

passage).

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

16

STARTING WORK

DISK SECTIONS

Para alterar a posição da secção de discos:

•Secure the tractor against rolling and lower the

harrow onto the ground.

•Remove locking screws (R1) on holders of a given

section.

•Loosen nuts of adjustment screws (R2) on holders

of a given section.

•Slightly lift the harrow on the tractor's hydraulic

system and slide the disks section into a desired

position.

•Re-tighten screws R2 and install screws R1.

NOTE: It is recommended that the above procedure related to

change in position of disks section is carried out by a

specialized service.

NOTE: When adjusting disks and whole sections there is a risk

of crushing, cutting, truncation caused by failure to follow

safety regulations!

Never remove adjustment screws as this may cause falling of

the whole machine sub-assembly and thus result in crushing of

the operator's body or it part, including potentially lethal

injuries!

!

SIDE SCREENS

HGR 15 | HGR 17 | HGR 20

Side screens, located at both sections, are intended

to prevent formation of any unevenness at the edge

of the field under cultivation. Properly set screens

disable pouring of the soil onto the strip near the strip

under cultivation and thus provide protection

against formation of undesired unevenness as

bumps or holes on the line between strips of soil

under cultivation.

Each screen can be adjusted for the distance from

the last one on a given disk section.

To change horizontal position of the screen:

•Remove fastening bolt (S).

•Slide screen holder (U) out of the aggregate

frame to fix it in its optimal position.

•Remount the screen holder (U) using bolt (S).

ATTENTION! The above procedure should be carried

out for both screens, from the left and the right side

of the machine

OPERATOR’S MANUAL: DISC ARROWS HGR | HGR - H

17

STARTING WORK

NOTE: When performing horizontal adjustment of the side

screen remember to secure it against falling and sliding from

the disks section frame after adjustment screws are loosened!

If caution is not exercised there is a risk of crushing a part of

the operator's body!

The screen also has vertical position adjustment as

including soil conditions, working depth and driving

speed, the soil thrown by the last disk before the

screen can be released onto a variable height.

To adjust the height of the side screen, proceed as

follows:

•Unscrew (S1, S2 eS3) bolts and adjust the screen

(E) using the existing holes in the support (U).

•Once this is done, retighten the screws.

ATTENTION: The above procedure should be carried out for

both screens, from the left and the right side of the machine.

SIDE SCREENS

HGR 25| HGR 27 | HGR 30 | HGR 40 | HGR 40H | HGR 50H | HGR 60H

In a similar way here too, it is possible to adjust the

horizontal position and the vertical position of the side

screens.

To change horizontal position of the screen:

•Loosen nuts (N) and screws (S).

•Move holder (RP) of the side screen to a desired

position.

•Tighten screws (S) and nuts (N).

To adjust the screen height:

•Unlock and remove pin (P) and insert it in a

desired hole on the gauge (R)

•Secure the pin (P).

This manual suits for next models

1

Table of contents

Other FERPINTA Farm Equipment manuals

Popular Farm Equipment manuals by other brands

SIP

SIP SPIDER 615 PRO Instruction for work

aivituvin

aivituvin XZ7001 instruction manual

Hardi

Hardi COMMANDER DELTA FORCE Instruction book

paladin

paladin HARLEY POWER BOX RAKE T6 Operator's & parts manual

AGRI EASE

AGRI EASE BE-P3FK Operations & parts manual

AIRTUG

AIRTUG TT-M-EM-3 Assembly & operating instructions