6.2 DIL switch 2

Switching position Function

DIL 2.1: Off

(factory setting)

Reserved

DIL 2.1: On è 10 Reset to factory setting ("FactoryReset")

Tab. 12 DIL switch 2.1

Switching position Function

DIL 2.2: Off

(factory setting)

Reserved

DIL 2.2: On è 10 Reset to factory setting ("FactoryReset")

Tab. 13 DIL switch 2.2

6.3 Rotary switch operating mode

Switching position Operating mode/function

0: Off – Network connection "Cloud" deactivated (switch-off of inter-

face)

– No communication with the cloud

1: Onboarding – Network connection "Cloud" activated

– Gateway for integration into the cloud ("Onboarding") ready

2: Readonly – Gateway sends process data of the configured field devices to

the cloud

– Manual adding of field devices enabled

– Automatic adding of field devices via the Auto-Scan function

blocked

– Removal of field devices and removal of the gateway from the

cloud ("Offboarding") blocked

– Receipt of data, e.g. parameters, from the cloud disabled

– Parameters of connected devices cannot be changed

3: Read/Write – Gateway sends process data of the configured field devices to

the cloud

– Manual adding of field devices enabled

– Automatic adding of field devices via the Auto-Scan function

enabled

– Removal of field devices and removal of the gateway from the

cloud ("Offboarding") enabled

– Receipt of data, e.g. parameters, from the cloud enabled

– Parameters of connected devices can be changed

Tab. 14 Rotary switch operating mode

7 Ensuring the degree of protection

NOTICE!

Short circuit as a result of ingress of liquids or foreign matter.

Malfunction or damage to the electronics.

• Use connection devices (connecting cables, plugs, adapters) with the

required degree of protection.

• Use cover caps to seal unused connections.

• Mount the DIL switch cover:

– Check the seal.

– Place cover and press it on.

– Tighten screws.

Tightening torque: maximum0.4Nm.

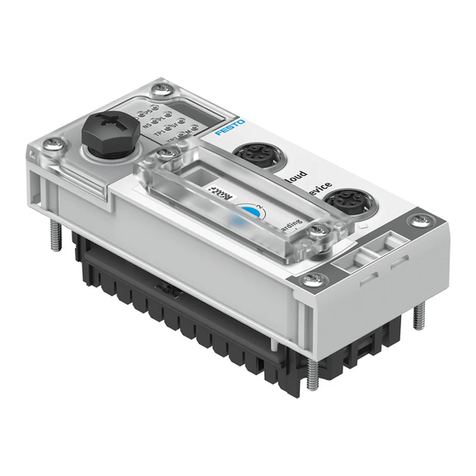

8 Connection technology

Using the M12 socket 6 (è Fig.1), a terminal CPX can be directly connected with

the gateway without a network connection, i.e. without an industrial Ethernet

connection.

Connection Connecting hardware Cover cap

Network connection "Cloud"1)

Network connection "Device"1)

Plug NECU-M-S-D12G4-C2-ET

Interface to terminal CPX

without a network connection2)

Connecting cable

NEBC-M12G5-S-1,5-N-M12G5

ISK-M12

1) socket, M12, D-coded, 4-pin, SPEEDCON-compatible

2) socket, M12, A-coded, 5-pin

Tab. 15 Connection technology

9 Parameterisation

The gateway can be parameterised via the FestoField Device Tool (FFT).

Alternatively, the integrated web server of the gateway can be used via the net-

work connection "Device" for the parameterisation, e.g. for setting the IP

addresses of the network connections:

Connect the gateway via the network connection "Device" with a PC or Notebook.

Calling up the web server:

èhttp://<IP-Adresse_des_Netzwerkanschlusses_"Device"> (see IP configuration

(factory settings) è 13 Technical data)

Logging in:

èUser name: admin

èPassword (factory setting): CPX-IoT Product Key on the type plate, e.g.

3S7PMM2M93V

10 Reset to factory setting ("FactoryReset")

1. Set rotary switch to "Off".

2. Switch off the power supply.

3. Set DIL switch 2.1 and 2.2 to "On".

4. Switch on the power supply.

ÄLEDM flashes quickly for a few seconds.

– Do not switch off the power supply

– Do not actuate the DIL switch

5. If the LEDM has stopped flashing:

Set DIL switch 2.1 and 2.2 to "Off".

ÄThe gateway has returned to the factory setting.

11 Firmware update

A firmware update is possible via the Festo Field Device Tool (FFT)

èwww.festo.com/sp.

12 Module replacement

After replacing a gateway, integration into the cloud („Onboarding“) must be car-

ried out again èFesto App World, www.festo.com/appworld.

13 Technical data

Property Specification/value

General technical data èSystem description of the

terminal CPX (CPX-SYS)

Power supply

Operating power supply UEL/SEN [VDC] 24 ±25%

Intrinsic current consumption at nominal operat-

ing voltage 24V from operating voltage supply

UEL/SEN

[mA] Typically 80

(internal electronics)

Mains buffering time [ms] 10

Separation of network interface from operating

voltage supply UEL/SEN

Galvanic

Protection against electric shock1) Through the use of PELV circuits

Degree of protection by housing2)3),

With power supply connection

– Via interlinking block IP65/IP67

– Via end plate IP20

Connection technology

Network connections 2 × sockets, M12, D-coded, 4-pin,

SPEEDCON-compatible

Interface to terminal CPX

without a network connection

1 × socket, M12, A-coded, 5-pin

Network-specific characteristics

Cloud DHCP IP configuration (factory settings)

Device IP address: 192.168.0.1

Subnet mask: 255.255.255.0

Encryption of data transmission to the Cloud HTTPS

Transmission technology Industrial Ethernet,

Switched Fast Ethernet

Specification IEEE 802.3u (100Base-TX)

Transmission rate [Mbit/s] 10/100 (full duplex/half duplex)

Crossover detection Auto-MDI/MDI-X

Number of devices (network connection

"Device")

Maximum 104)

Cable specification

Cable type Ethernet twisted pair cable, shiel-

ded (Shielded Twisted Pair, STP)

Transmission class (Link Class) Category Cat 5

Cable diameter5) [mm] 6…8

Wire cross section6) [mm2] 0.14…0.75

Cable length [m] Maximum 100

1) protection against direct and indirect contact in accordance with IEC60204-1/EN60204-1

2) Degree of protection in accordance with IEC60529, module completely assembled, plug connector in the

plugged-in status or provided with cover cap

3) Connected products may only fulfil a lower degree of protection.

4) More devices can be operated depending on the application.

5) when using the plug NECU-M-S-D12G4-C2-ET

6) 22AWG required for max. connection length between network participants (end-to-end link)

Tab. 16 Technical data

14 Specified standards

Version

IEC 60529:2001-02 IEEE 802.3:2014-00

Tab. 17 Specified standards