Go to fetco.com for the latest version of all information P119 User Guide HWD-2102 REVISED MARCH 2020

Final Setup

1. Turn on the incoming water supply line and inspect both inside and outside of the equipment for leaks in all

fittings and tubes

2. Turn on the incoming power.

3. Turn on the power switch, located in the back of the unit.

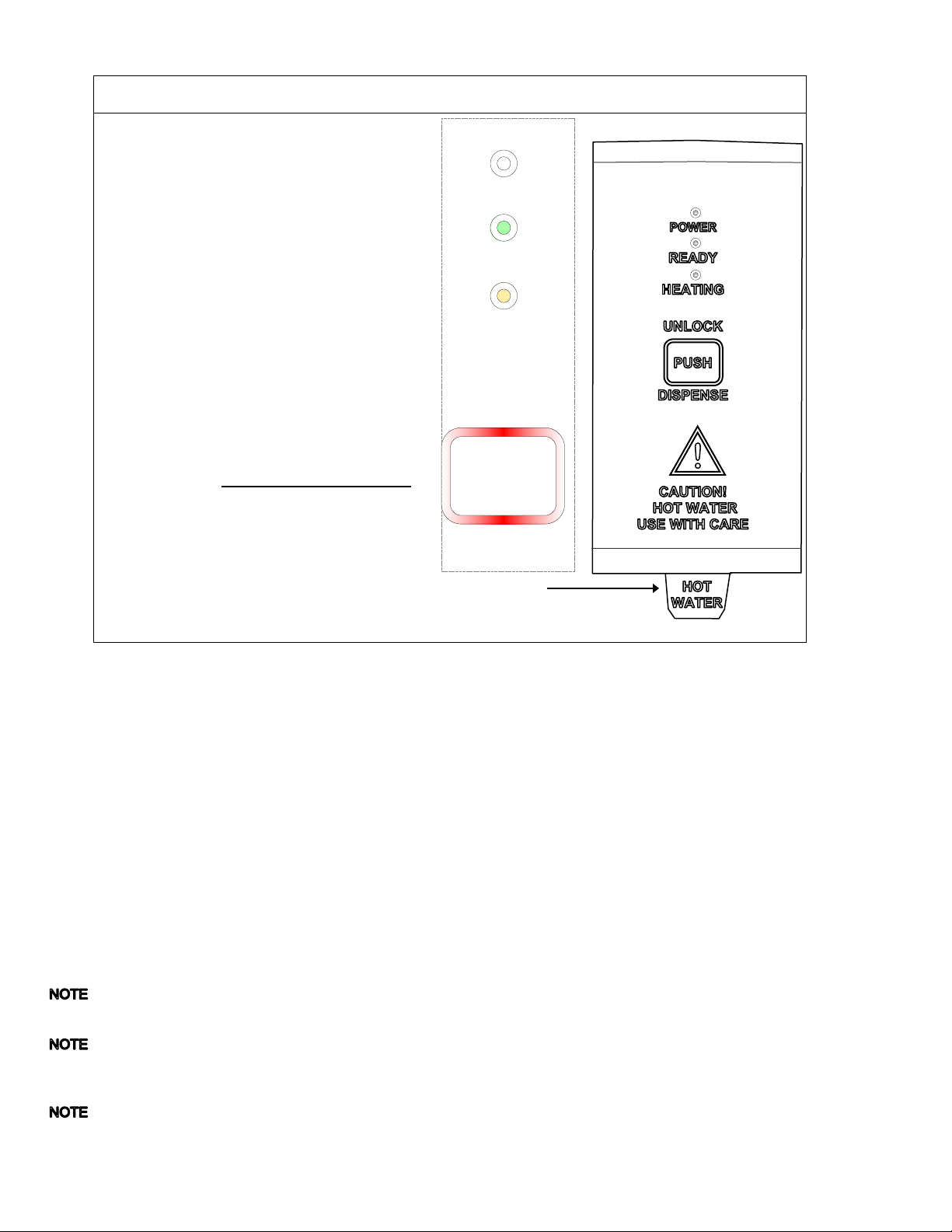

4. The LED indicator lights will show “Heating” (see illustration Page 4) on start-up

5. The hot water tank will begin filling and will stop when the water is sensed by the probe at the top of the tank.

The heaters are disabled by the control board until the tank is full. Unit may need to be restarted during first fill.

6. The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the control board until the tank is full of water. The

heating process will start automatically when the tank has filled.

7. Heaters will turn on when covered by water. Touch Panel displays status while the water is heating—there is no

“Filling” light. After the water has reached the set temperature, the “ready” icon will turn on.

8. Inspect for leaks. Look closely in the top and beneath the equipment and check all fittings during this inspection.

Operator Training

Review the operating procedures with the equipment operators. Pay attention to the following areas:

1. Show the location and operation of the water shut off valve as well as the circuit breaker for the unit.

2. We recommend leaving the power to the equipment on overnight. The water tank is well insulated and will use

very little electricity to keep the tank hot. Leaving the equipment in the “on” position will also avoid delays at the

beginning of shifts for the hot water dispenser to reach operating temperature.

Standby heat loss is ≤100 watts per hour.

Installation safety and hygiene directions-For International and CE equipment

1. Access to the service area is restricted to persons having safety/hygiene knowledge and practical experience of

the coffee brewer. This appliance must be installed in locations where it can be overseen by trained personnel.

2. For proper operation, this appliance must be installed indoors where the temperature is between 10°C/50°F to

35°C/95°F. Drain and remove al liquid from equipment and lines if exposed to freezing temperatures.

3. All commercial cooking equipment, including this unit, is not intended for use by children or persons with

reduced physical, sensory, or mental capabilities. Ensure proper supervision of children and keep them away

from the unit.

4. Children should be supervised to ensure that they do not play hot beverage equipment.

5. This unit must be installed and serviced by qualified personnel only.

6. Installation must conform to all local electrical and plumbing codes. Installation by unqualified personnel will void

the unit warranty and may lead to electric shock or burn, as well as damage to unit and/or its surroundings.

7. If the power cord requires repair or replacement-it must be performed by the manufacturer or authorized service

personnel with the specified cord only from the manufacturer in order to avoid a hazard.

8. Review the dimensions for the unit and verify that it will fit properly in the space intended for it. Verify that the

counter or table will support the total weight of the filled brewer and dispensers (See: Technical Data Page 2).

9. Place the brewer on the counter or stand. When the brewer is in position, level it front to back as well as side-to-

side by adjusting the legs.

10. Do not tilt appliance more than 10° to insure safe operation.

11. Unit is for protected indoor use only. Do not steam clean or use excessive water on unit.

12. This unit is not “jet-proof” construction. Do not pressure wash or use jet spray to clean this unit.

13. The unit is not waterproof-do not submerge or saturate with water.

Do not operate if unit has been submerged or saturated with water.

Equipment exposed to flood and contaminated must not be used due to electrical and food safety.

1401.000049.00

1101.000210.00

1104.000103.00