FIAMA SM85.ATEX User manual

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 1 of 6

USE AND MAINTENANCE MANUAL

MEMBRANE LEVEL SWITCH

“SM85.ATEX”

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 2 of 6

Manual Purpose

This manual has been designed by the manufacturer to provide the necessary information regarding the

instrument to those who are authorized to carry out safely its installation, maintenance, dismantling and disposal.

All necessary information for buyers and planners can be found in the sales documentation.

In addition to adopting good technical construction methods, this information should be read carefully and strictly

applied. Inobservance of this information could cause risks for the health and safety of people and damage to

equipment.

This information provided by the manufacturer in the original language (Italian) is also available in other languages

to satisfy legislative and/or commercial needs.

This manual must be kept in a good condition by a responsible person in a safe place so that it is always available

for consultation. In case this manual is lost or damaged, a replacement should be requested directly from the

manufacturer quoting the manual code.

This manual reflects the state of the instrument at the time of input on the market: however the manufacturer

reserves the right to make changes, add or improve the manual without giving any reason to hold the present

manual inadequate.

Identification of the equipment

The identification label is applied on the cover of the instrument:

It contains all the necessary data which is required for safe operation.

Environmental conditions

Process temperature from -10°C to 80°C (inside the tank or silo, zone 20).

Storage

Avoid areas with excessive moisture and exposed to the elements (excluding outdoor areas). Avoid direct contact

of the unit with the ground. Stack the unit being careful not to load with excessive weights. It is leading you to the

proper functioning of the instruments and for the maintenance of mechanical protection, care in handling. Do not

strike the instrument with tools like hammers or similar items.

Conformity declaration and CE marking

The unit complies with the following Community Directives:

2014/34/UE: Equipment and protective system intended for use in potentially explosive atmospheres (ATEX).

2460 II 1/2 D Ex ia IIIC T85°C Da IP65 -10°C < Tamb < +80°. Use in zone 20, intrinsic safety protection

mode “ia”, max superficial temperature 85°C, environmental temperature from -10°C to 80°C.

Certificate n. EUM1 13 ATEX 0930 X – Notification: Presafe 15 ATEX 187658Q.

2014/30/UE Electromagnetic compatibility.

Control, maintenance, technical servicing

The instrument does not need a periodic setting but needs a check of correct functioning at least once a year:

Verify the integrity of the case, mobility of the spring, and general functioning.

Avoid layers of dust higher than 50mm on the instrument.

The instrument does not need a particular maintenance except cleaning, which has to be carried out by using a

soft, damp, cloth with ethyl alcohol or water. Do not use hydrocarbon solvents (trichloroethylene, petrol, diluents,

etc.). Repairs should be done exclusively by the FIAMA technical assistance center. For any type of technical

assistance please contact the manufacturer indicating the data on the identification plate, the approximate working

hours, and the type of fault.

Manufacturer’s responsibility

The manufacturer declines any responsibility in case of:

•Using the instrument contrary to the national safety and accident-prevention laws;

•Incorrect installation, inobservance or wrong procedures of the instructions provided in the present

manual;

•Defective electrical power supply;

•Modifications or tampering;

•Operations carried out by untrained or unqualified personnel.

The safety of the instrument also depends on the strict observance of the instructions contained in the manual:

always operate the instrument in its functioning capacity and carry out a careful routine maintenance.

•All phases of inspection and maintenance must be done by qualified personnel only.

•The configurations provided in the manual are the only ones permitted.

•Do not try to use the product in anyway which is contrary to the provided indications.

The instructions in this manual do not substitute but accomplish the obligations of the current law.

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 3 of 6

Description

The SM85-ATEX is a simple and economical level switch that

checks the minimum or maximum level in silos and tanks

containing material which is non-sticky in the form of granules or

dust such as rice, cereals, plastic, coffee, sand, cement, etc.

The working principle is simple: the pressure exerted by the

product on the membrane activates the signal micro switch.

Switching sensitivity is adjusted using a screw on the cover.

The unit is installed externally on the wall of the container through

the three holes of the fixing flange. The body of the unit remains

outside of the container, on the side or on the bottom, while the

membrane is in contact with the product.

The product is classified Group II, category 1/2, and installation

zone 20.

The protection mode which is considered is Intrinsic Safety “ia”

which is based on the use of a barrier with intrinsic safety, external

to the unit, which is normally not supplied by FIAMA and is

normally selected and provided by the end user.

The maximum allowed ambient temperature is 80°C.

Installation

The unit can be installed in environments where a potentially explosive

atmosphere, in the form of a cloud of flammable dust, is present

permanently or for long periods within tanks or silos (zone 20).

Installation of the unit must occur in combination with an intrinsic safety

barrier which is able to provide adequate separation between the safe zone and the danger zone.

Analysis of the intrinsic safety risk EN 60079-11

The safety of the unit which is part of this risk analysis is based on the basic principles of the intrinsic safety

protection mode.

This protection consists of a limitation, in the conditions of normal operation or of preventable faults or of rare

faults, the amount of electrical energy of the circuits which are installed in the danger zone and of the connected

instrumentation which is installed in the safe zone so that arcs or sparks or high surface temperatures cannot

ignite the explosive atmosphere.

The unit in the danger zone and the associated electrical plant (intrinsic safety barrier) must be designed to reduce

the open circuit tension (Voc) and the short circuit current (Isc) down to such values which cannot ignite the

explosive atmosphere by opening, short-circuiting, grounding, or heating any part of the circuit.

The implementation of this protection mode is the only accepted method to protect electrical installations which

operate in the danger zones (zone 20).

During implementation of intrinsic safety, it is necessary to consider the following three parts:

•Unit in the danger zone: membrane sensor with micro switch

•Safety interface: intrinsic safety barrier

•Interconnecting cables

An apparatus with switches can be considered a simple apparatus if it does not generate or accumulate more than

1.5V, 100mA, 25mW. Such an apparatus, if powered by a safety interface, which guarantees respect of the

electrical parameters for power supply, is not able to generate sparks that can ignite the gases which have a MIE

value (Minimum Ignition Energy) higher than the energy released during commutation of the contact.

Associated apparatuses

The interfaces between the field and the control room instrumentation are usually called “Barriers”; these protect

the circuits in the danger zone, by limiting the voltage and current, in normal use and fault conditions.

There are two types of intrinsic safety interfaces:

•Zener barriers

•Galvanic separation barriers

The fundamental difference is the way that potentially dangerous energy, coming from the control room, is diverted

to prevent entry into the circuits located in the danger zone.

The barriers must by designed and certified according to the requirements of Directive 2014/34/UE and must have

the following marking:

II (1) D [Ex ia]

ZONA 20

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 4 of 6

Interconnecting cables

The low values of voltage and tension which are present in the instrinsic safety circuit allow the use of cables

which are normally used for field instrumentation, as long as the capacity and inductance of these is correctly

taken into account in the calcultations regarding system safety. The cable parameters are rarely a problem for the

distance of the field devices, especially when galvanic separation barriers are used.

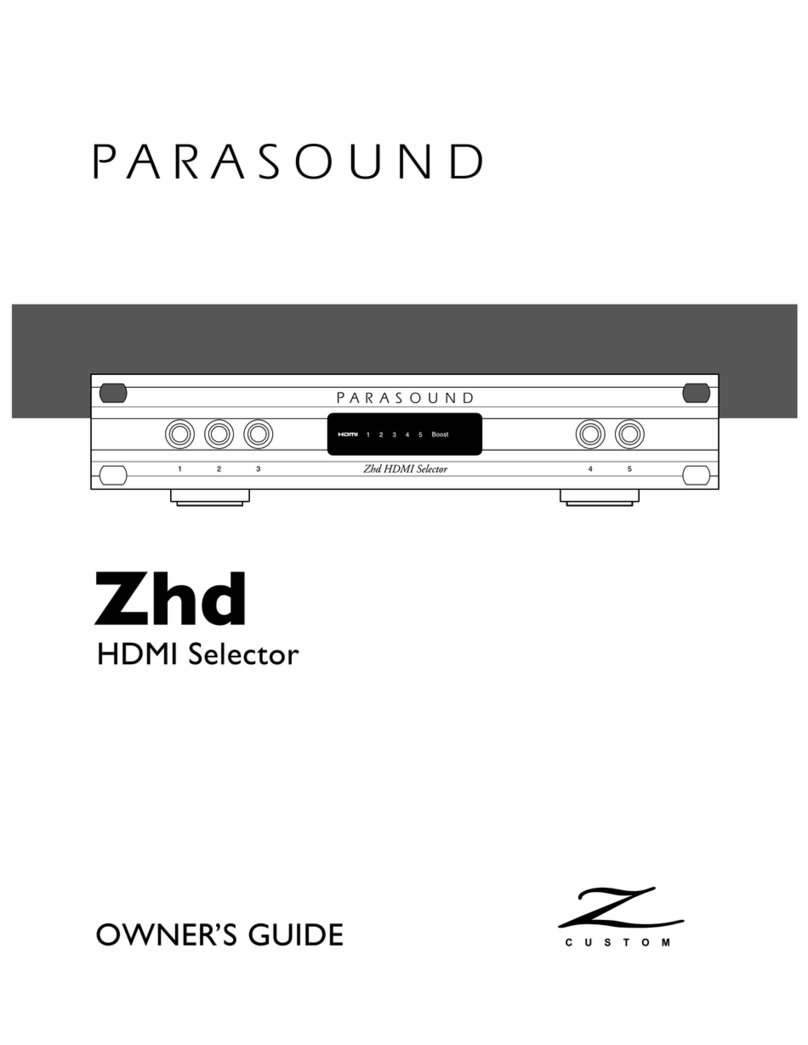

Resistive circuits

A circuit is considered resistive when the reactive parts,

inductance and capacity, are null or negligible, as is the case of

this analysis.

The energy which can be released by a circuit of this type

depends essentially upon the voltage V that powers it and by the

current limitation which is due to the presence of the resistor R.

In this case it is not easy to correlate the value of the minimum

ignition energy MIE (Minimum Ignition Energy), with the circuit

characteristics which generate the spark.

The ignition curves for resistive circuits are indicated in the side

graph.

The graph shows the ignition curves of the gas groups which are

considered in the various norms. Observing the curves, the lower

the open circuit voltage Voc, the higher the power that can be

used in safety. This characteristic allows the process

instrumentation, which operates at voltages in the 20-30V range,

to be used in applications of intrinsic safety.

Intrinsic safety loop coordination

In the coordination, the following relations must be verified:

Uo ≤Ui

Io ≤Ii

Po ≤Pi

Ci+Cc ≤Co

Li+Lc ≤Lo

where:

•Uo: maximum output voltage (peak AC or DC) which can

be supplied by an intrinsic safety barrier which is in open

circuit and powered by the primary voltage Um

•Io: maximum current (peak AC or DC) which can be

supplied by an intrinsic safety barrier which is in short-

circuit

•Po: maximum electrical power which can be supplied by an intrinsic safety barrier

•Co: maximum capacity which can be connected to the intrinsic safety barrier

•Lo: maximum inductance which can be connected to the intrinsic safety

•Ui: maximum voltage (peak AC or DC) which can be applied to the intrinsic safety sensor in the danger

zone

•Ii: maximum current (peak AC or DC) which can be applied to the intrinsic safety sensor in the danger

zone

•Pi: maximum input power which can be applied to the intrinsic safety sensor in the danger zone

•Ci: total equivalent internal capacitance of the intrinsic safety apparatus

•Li: total equivalent internal inductance of the intrinsic safety apparatus

•Cc: cable capacitance [F/m]

•Li: cable inductance [H/m].

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 5 of 6

Marking:

2460 II 1/2 D Ex ia IIIC T85°C Da IP65 -10°C < Tamb < +80°

Ui = 30V

Ii = 100mA

Pi = 3W

Ci = negligible

Li = negligible

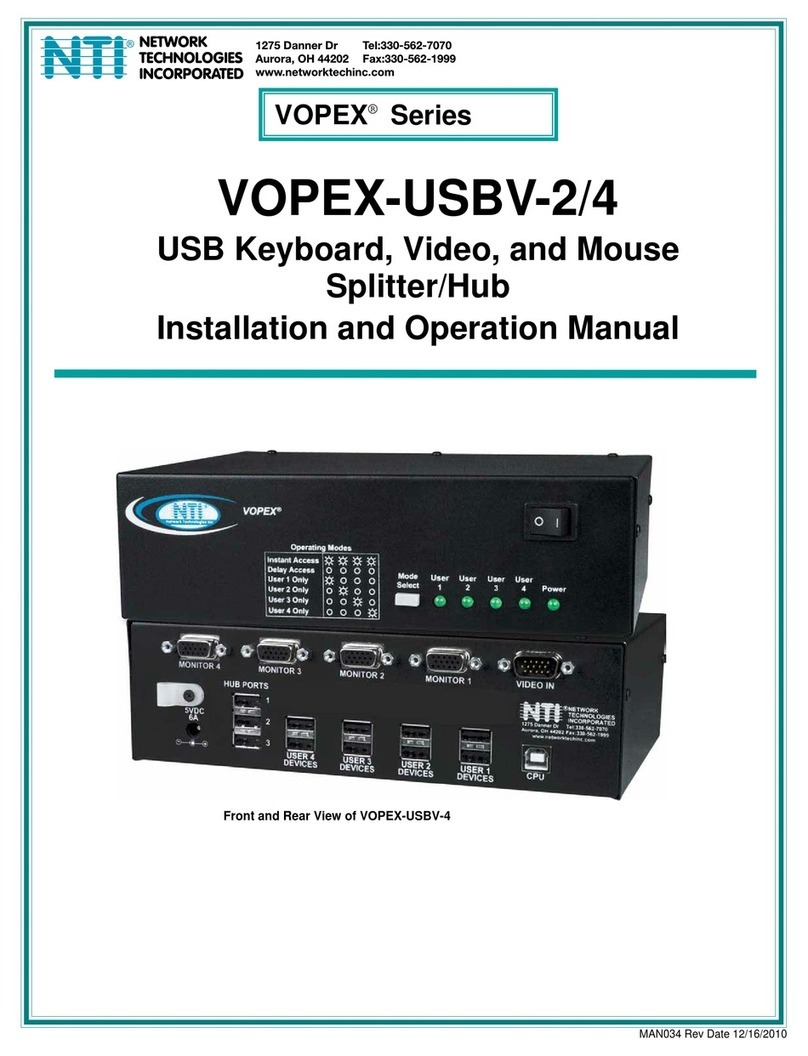

Dimensions

Flangia di fissaggio

Fixing flange

Befestingungsflansch

Pressacavo

Cablepress

Kabelverschraubung

Membrana in gomma siliconica

Rubber silicone membrane

Gummi Membrane Silikon

Vite regolazione sensibilità

Sensibility regulation screw

Schraubezur Sensibilitätsregulierung

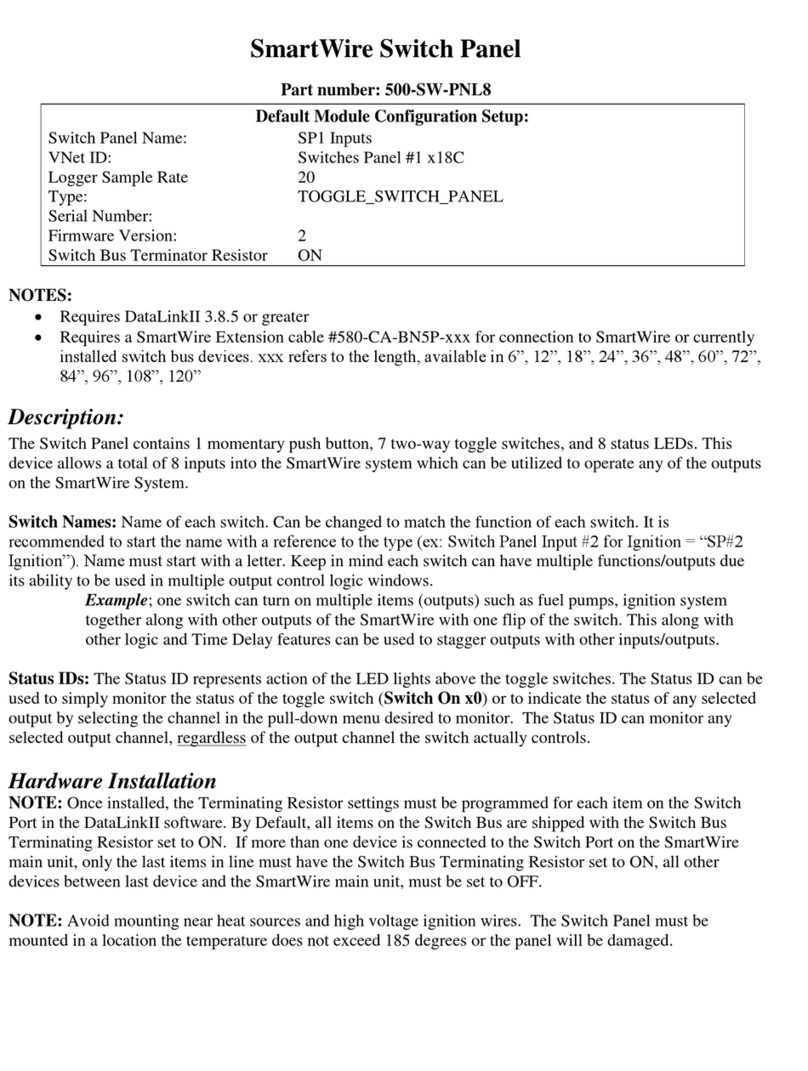

Electrical schematic

NC

COM

NO

ATEX level switch SM85.ATEX

Date: 07/2018 SM85.ATEX_ing_rev05.doc page 6 of 6

Technical characteristics

Case Flange: aluminum alloy

Body: antistatic polyamide

Membrane: antistatic silicone

Protection rating IP65

Electrical contacts 30V - 100mA (values imposed by the intrinsic safety circuit)

Temperature range -10° + 80°C

Cable entrance PG7 cable gland

Relative humidity 10-90%

Working pressure Atmospheric pressure

Reference ATEX 2014/34/UE

Electromagnetic compatibility 2014/30/UE

Certificate number EUM1 13 ATEX 0930 X Notification: Presafe 15 ATEX 187658Q

Marking 2460 II 1/2 D Ex ia IIIC T85°C Da IP65 -10°C < Ta < +80°

Manufacturer

Any communication with the manufacturer must be addressed to:

FIAMA S.R.L.

Via G. Di Vittorio, 5/A

43016 San Pancrazio (Parma) - Italy

tel: (+39) 0521-672341

fax: (+39) 0521-672537

email: [email protected]

web: www.fiama.it

FIAMA SRL is not responsible for damage to persons or equipment deriving from any tampering or

incorrect use or use which is not conforming with the characteristics of the unit.

MOD mdt03_00

F.I.A.M.A. s.r.l.

Via G. di Vittorio, 5/a

43016 San Pancrazio PR, ITALY

Tel. + 39 0521 67 23 41 - Fax + 39 0521 67 25 37

Cod. Fisc. e Part. IVA 02046950347

E-mail : info@fiama.it

Internet: www.fiama.it

mdt03_07-dich-conf-ce-SM85-atex.doc

DICHIARAZIONE DI CONFORMITÀ EU

EU Declaration of Conformity

FABBRICANTE / Manufacturer : F.I.A.M.A. s.r.l.

DESCRIZIONE PRODOTTO / Description of the equipment :

SEGNALATORE DI LIVELLO A MEMBRANA MODELLO SM85-ATEX

Membrane Level Switch model SM85-ATEX

DIRETTIVA 2014/34/EU ATEX

2014/34/EU “Atex” Directive”

Organismo Notificato : Num. identificazione: 2460

Notified Body : Identification number :

Certificato Sistema Qualità Produzione n°: PRESAFE 15 ATEX 187658Q

Certificate Production Quality System n°

Certificato Mod. B n°: EUM1 13 ATEX 0930 X

Certificate MOD B n°:

Marcatura: 2460 II 1/2 D Ex ia IIIC T85°C Da IP65 -10°C < Tamb < +80°

Marking

Norme Armonizzate EN 1127-1:2011, EN 60079-0:2018, EN 60079-11:2012

Harmonized Standards

DIRETTIVA 2014/30/EU “Compatibilità elettromagnetica”

2014/30/EU “Electromagnetic Compatibility” Directive

Norme Armonizzate EN 61000-6-2:2005, EN 61000-6-3:2007, EN61326-1:2013

Harmonized Standards

La presente dichiarazione di conformità è rilasciata sotto la responsabilità esclusiva del fabbricante. L’oggetto della dichiarazione di

cui sopra è conforme alla pertinente normativa di armonizzazione dell’Unione.

This declaration of conformity is issued under the sole responsibility of the manufacturer. The object of the declaration described is in conformity

with the relevant Union harmonisation legislation

Data / Date :

07/2021

Posizione /Qualification :

Amministratore Delegato

Nome /Name :

Barbieri Maria Carla

Firma / Signature :

DNV Nemko Presafe AS,

Gaustadalléen 30,

0373 Oslo, Norway

Table of contents

Popular Switch manuals by other brands

GarrettCom

GarrettCom Hardened Ethernet Switches P62F Installation and user guide

mindtouch

mindtouch Biamp Tesira quick start guide

Choetech

Choetech HUB-M43 user manual

Encore

Encore ENHGS-800 datasheet

SMC Networks

SMC Networks 6724L2 Management guide

Enerwave

Enerwave ZW500DM-PLUS installation instructions