All safety instructions are marked with this symbol and must be observed under all circumstances!

1.1 Prerequisites for the utilisation of the safety light curtains:

1Safety advice Please observe!

The unintentional repetition of a hazardous movement

must be prevented by the appropriate safety facilities.

-The safety category (Type 4) of the accident-prevention

light barrier should be at least the same as safety category

of the machine.

Approval:

Approval of the construction and the tests should be

carried out by competent personnel who are in possession

of all information provided by the supplier of the machine

and the BWS.

Annual inspection:

The operator must ensure that a competent person is

assigned with the task of inspecting the light barrier on a

yearly basis. This person may, for example, comprise an

employee of the light barrier manufacturer or of the

operator.

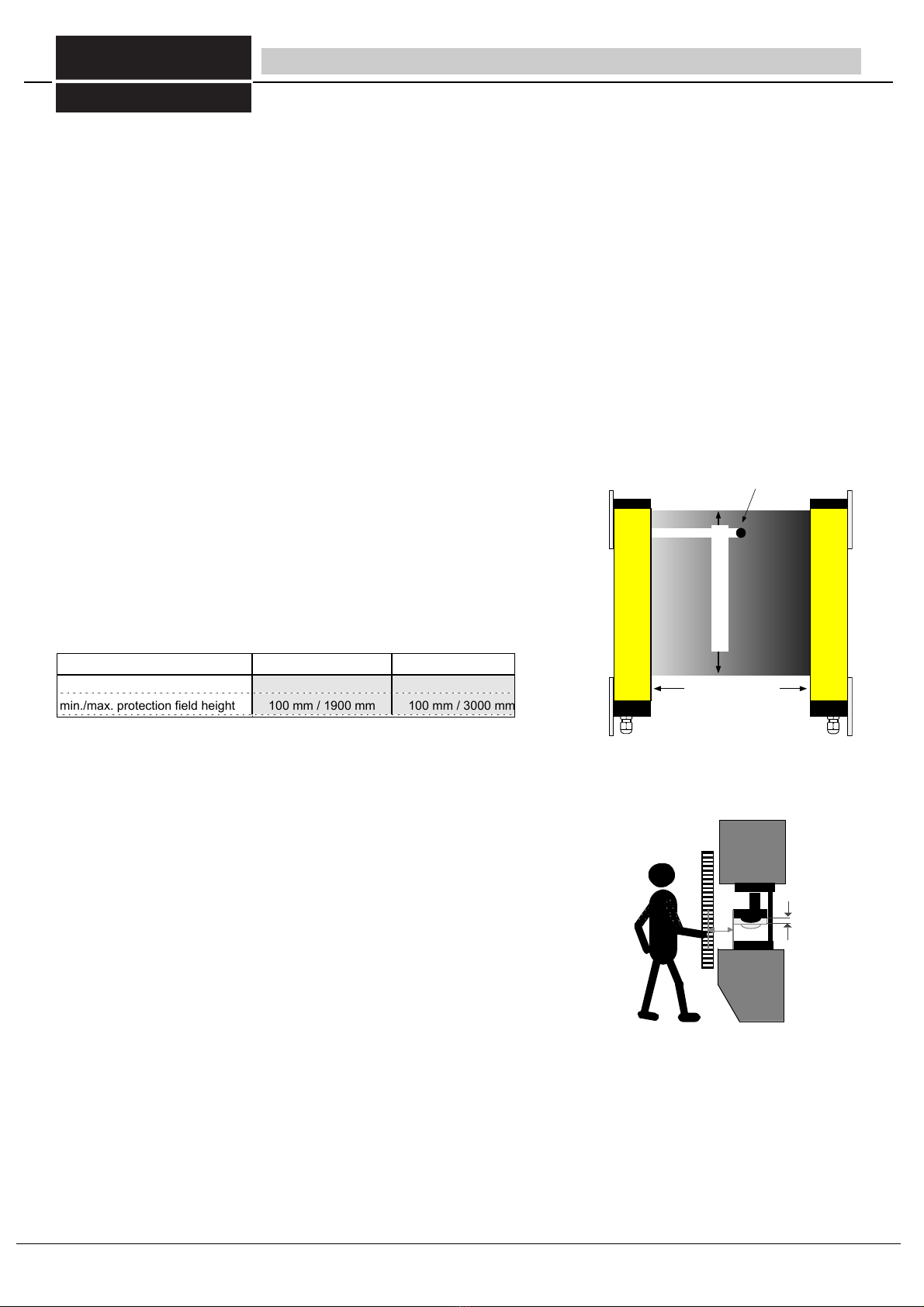

The safety distance between the protective field and the

hazardous area must be large enough to ensure that when

penetrating the protective field, the hazardous areas cannot

be reached before the hazardous movement is interrupted

or ended.

Access to the hazardous area must only be possible

through the protective field (reaching under, over or around

the field must not be possible).

Passing through the light barrier must only be possible if

the restart interlock is activated subsequent to the light

barrier being interrupted.

A new command to activate the next hazardous movement

must only be implemented via a dead-man switch. It must

not be possible for this start button to be actuated from

within the hazardous area: The switch must be located at a

point from which the accessible area can be viewed without

obstruction.

The hazardous state of a machine must be interrupted by

the sensory function of the ESPE.

The safe operation of the entire system can only be ensured through adherence to these operating

instructions and the corresponding accident prevention regulations.

These operating instructions comprise part of the light barrier and must be retained at the installation site.

All specifications of these operating instructions must be observed at all times. These operating instructions provide the

user with important information concerning the proper use of the ULVT/BLVT safety light barriers. .

When using safety light barriers, the effective standards and guidelines must be observed! The local authorities or

trade associations will provide you with the relevant information. Currently effective conditions and the regulations of the trade

associations must also be adhered to.

Qualified personnel. Installation, commissioning and maintenance must only be carried out by qualified personnel.

Danger sign When operating a machine with ULVT/BLVT ... safety light barriers, it must be ensured that nobody is located

within a hazardous area. A danger sign to this effect must be attached to the machine.

Light barriers do not provide protection from flying objects resulting from the operation of the machine.

When using the ULVT/ BLVT with an external switching unit or similar succeeding controls, it must be ensured by ap-

propriate, either contructional or organisatorial means, that at least once within 24 hours, a close-down of the light curtain by

intentional interruption ot testing of the protective field takes place in order to prevent any unnoticed accumulation of mal-

functions.

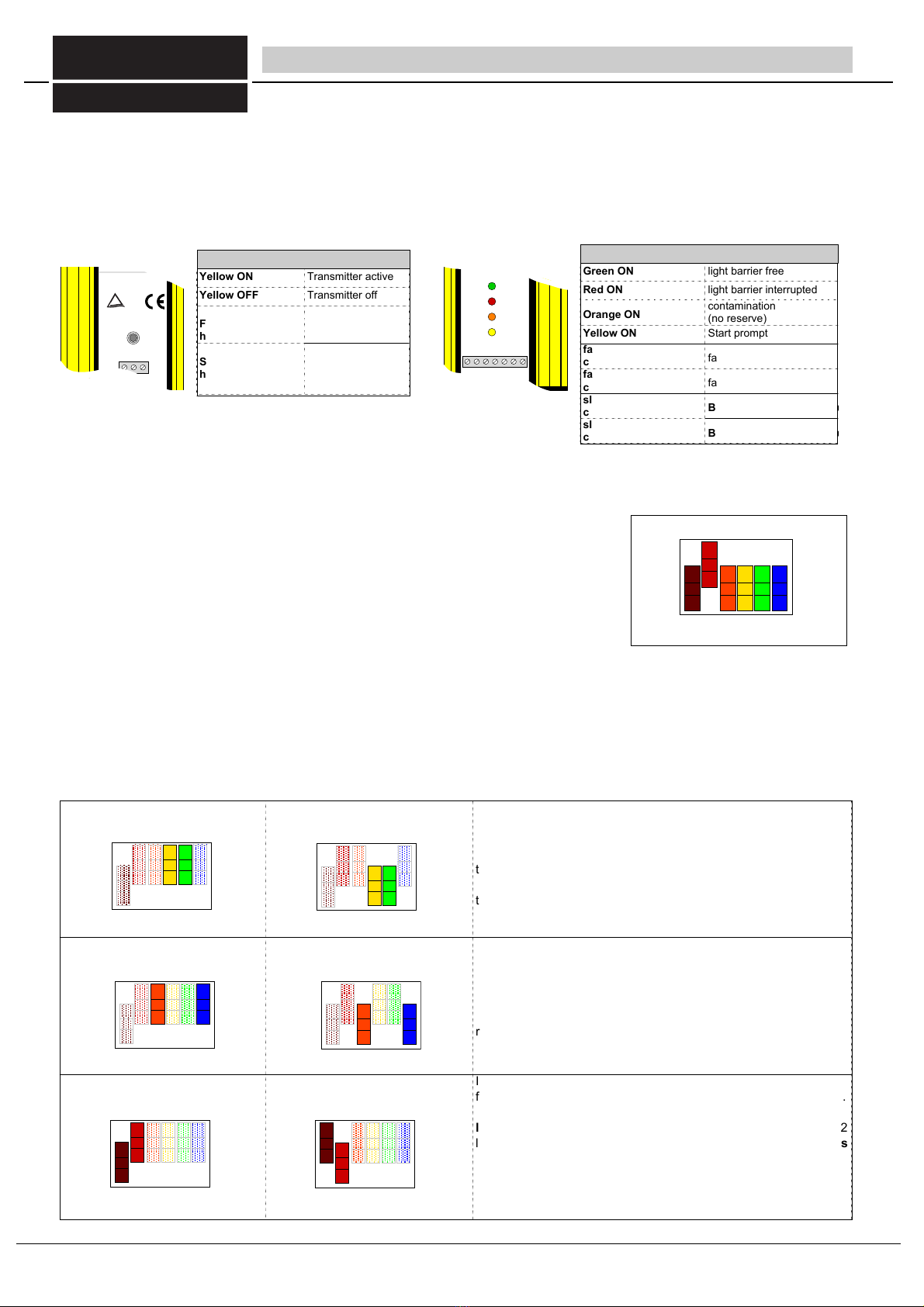

Caution, daily inspection (after 24 hours at the latest): Before the start of a shift, the light barrier must be checked as

follows: Using the test rod*, the light barrier is to be interrupted on the transmitting side from start to finish in such a way that

the light field is only covered by this part. The green LED (or the yellow LED in the operating mode with restart interlock) must

not light up from start to finish.

* The diameter of the test rod must correspond to the obstacle size specified on the nameplate of the receiving side.Acht

When using the BLVT Blanking features, the additional safety advices and all other instructions in chapter 7 must be

observed!

When using the Cascading features, the additional safety advices and all other instructions in chapter 8 must be

observed!

FIESSLER

E L E K T R O N I K

Maintenance information: The ULVT/BLVT... system is maintenance-free depending on the construction. (This does not,

however, release the obligation to carry out the prescribed annual inspection pursuant to EN 61496, ZH 1/281 and/or ZH 1/

597.) On request by the customer, the Fiessler Elektronik company will carry out the initial approval and annual

inspection. In addition, customer-training seminars concerning the implementation of the annual inspection are held at

regular intervals.

The protective panels in front of the transmitter and receiver should simply be cleaned at regular intervals with a solvent-free

detergent. Solvents can damage the plexiglass panels of the transmitter and receiver. As an alternative, light barriers with

silicate glass are available.

5

Fiessler Elektronik GmbH & Co. KG Doku Nr. 958 Stand 22.01.2018 RK Phone: +49 (0) 711 / 91 96 97-0 Internet: http://www.fiessler.de