Fike 10-11 Series User manual

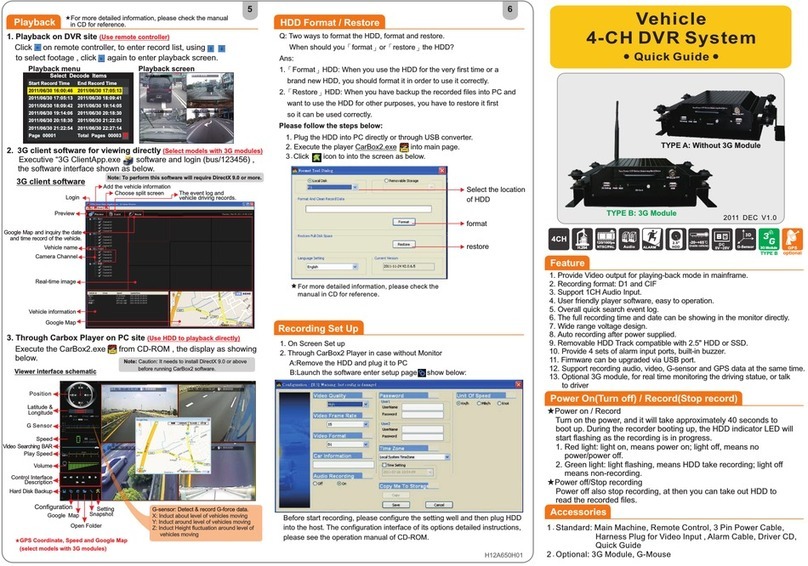

INTELLA-SCAN

GRAPHIC ANNUNCIATOR

Installation and

Operating Instructions

Manual P/N 06-131

Date: 2/1/98

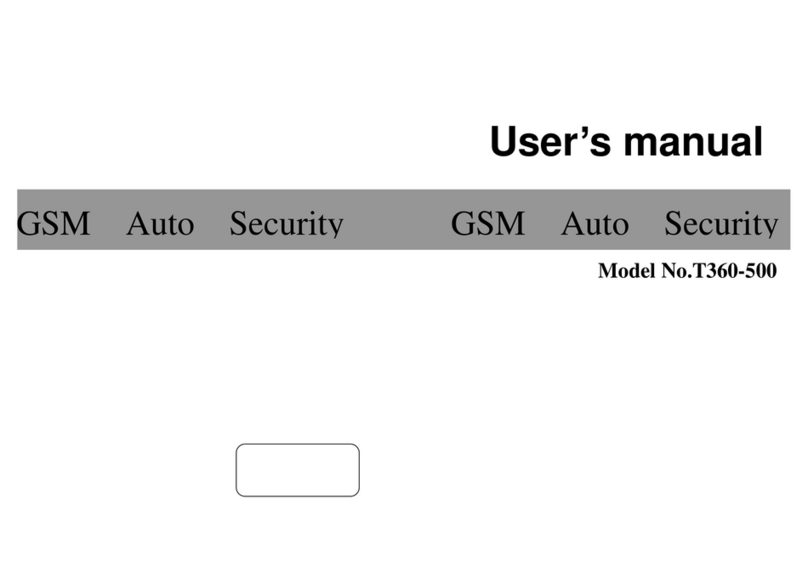

18"

C

GA

LEGEND

DETECTO

GG

GG

YY

R

R

R

R

COMMUNICATIONS

MI CROCOMPUTER

STE

REVIE

TEST

SILENC

CO. LOCATION

R

R

10

R

R

R

R

R

R

10

EQUIPMENT

RR

CONFERENCE

10

108

STORAGE

RR

GA

HE

YOU

GG

YY

C

GG

RAMP

RR

OFFIC

10

GG

10

A

A

POWER

R

R

ELECTRIC

ROOM

ROO

11

RR

COP

GG

RR

GG

RECEPTION

10

YY

OFFIC

10

R

R

Pr ot ect i on

R

ELEVATORS

LOBB

PRE-ACTION

LEASE SPACE

TAMPE

AA

LOWAIR

AA

WATERFLOW

AA

RISER

LOBBY

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 2

Table of Contents

Overview 3

Possible Systems / Wiring Diagram 4

Module Part Numbers & Definition

Graphics Micro Board 5

Graphic Switch Card 6

LED Driver Boards 7

Ordering Information 8

Spare Parts / Door Connection to Back Box 9

Programming 10

Checkout 15

Troubleshooting 16

Specifications/Power Calculations 21

Appendix A 22

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 3

Overview

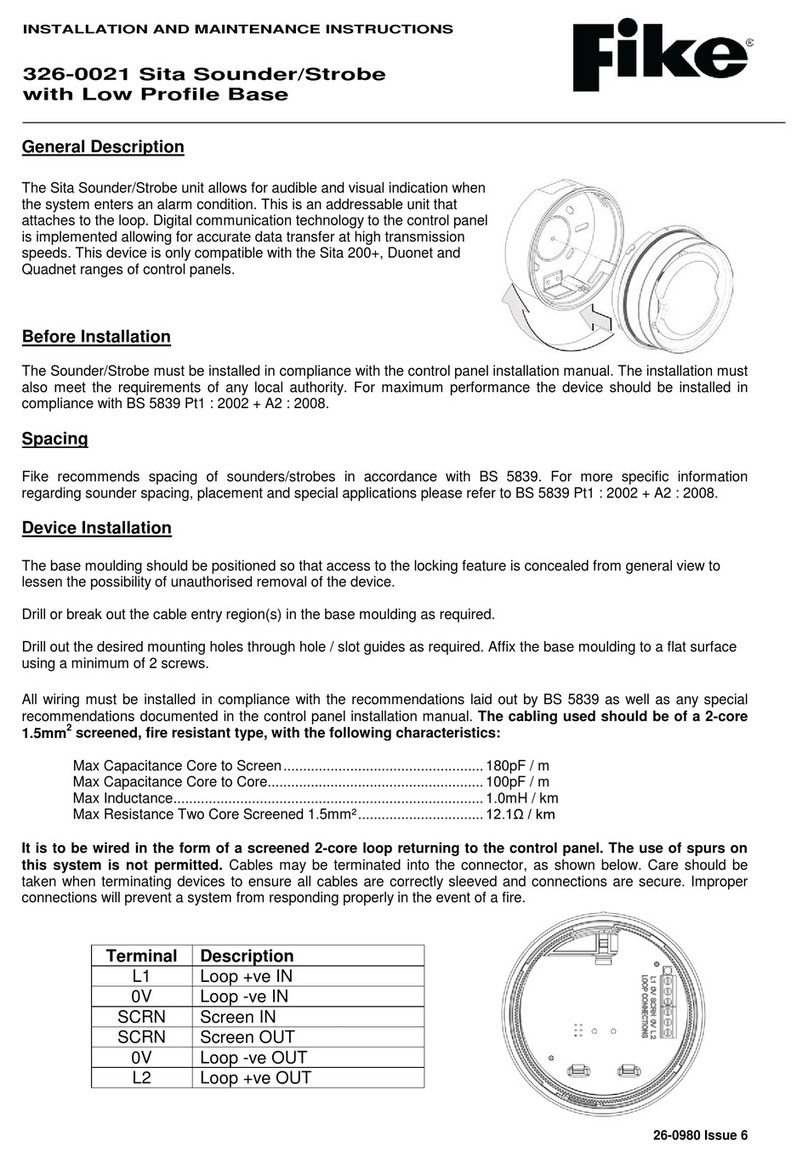

The Fike 10-11XX Graphic Annunciator is an ancillary system designed for use with the Fike Intella-

ScanFire Alarm Control Panel. It is designed to provide remote status of an individual device, zone,

and system by illumination of a color LED(s). Each Graphic Annunciator is a customized design

(typically a building floor layout) defined by the customer. The LED indicators are available in four

individual colors to distinguish event type (Red, Yellow, Green, Orange). A typical Graphic viewing

window will illustrate building or zone detectors. When the Intella-Scan panel receives an alarm or

trouble, the Graphic Annunciator will illuminate the appropriate LED and sound the local piezo. The

illuminated LED will give the operator an instant locator to the appropriate alarm/trouble location. Two

diagnostic LED’s (‘MICRO COMPUTER OK and COMMUNICATION OK”) verify the system is

operating. All LED’s will blink OFF each time data is received from the Intella-Scan system. The blink

rate will vary depending on the size of the system and the other types of ancillary devices that are

connected. Four operator switches are located on the front of the panel door:

SILENCE - Press to silence the local piezo, when ON. The local piezo will sound each time an

event occurs.

TEST - Press to verify that each LED can illuminate. ALL LED’s will illuminate when

pressed.

REVIEW - Press and hold to review sequence of events, when used in conjunction with the

STEP switch. Review is used for detector address and system type LED’s only, it

will not review zone type LED’S.

STEP - While the REVIEW switch is pressed, press to chronologically step through

events. First press will illuminate first LED; second press will add the second

LED, etc. Systems with only one Micro board will step through LEDsin

chronological order. Systems with multiple Micro boards (JP6 should be installed

on each Micro board) will step through EVENTs in chronological order, whether

an LED was programmed for the event or not. Therefore, on a multiple Micro

board system, it is possible that the status of the LED display will not change if no

LED was programmed for the given event.

The Graphic Annunciator will turn ON only 1 LED at a time. The flash rate between each ON/OFF time

is so short, it appears to be constantly ON. This design allows many LED’s to appear ON at the same

time, with minimal current being drawn from the system. The Intella-Scan communicates to the Graphic

through a fiber optic connection. The Graphic is field programmable by using the Fike PGRAPHIC or

EGRAPHIC Software Program.

.

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 4

Wiring Diagrams/Installation

LED DRIVER

LED DRIVER

LED DRIVER #1

ANODE

CATHODE

RED

BLK

LED

34 PIN

RIBBON CABLE

RIBBON CABLE

34 PIN

RIBBON CABLE

34 PIN

RIBBON CABLE

6 PIN

RIBBON CABLE

6 PIN

18-31VDC @ 120MA

NON-SUPERVISED

+-

FIBER OPTIC CABLE, 200 FT. MAX. , O.D. OF 2.25 mm

SIMPLEX PLASTIC, 1mm DIA., O.D. OF 2.25 mm,

NON-SUPERVISED

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 5

Module Part Numbers and Definition

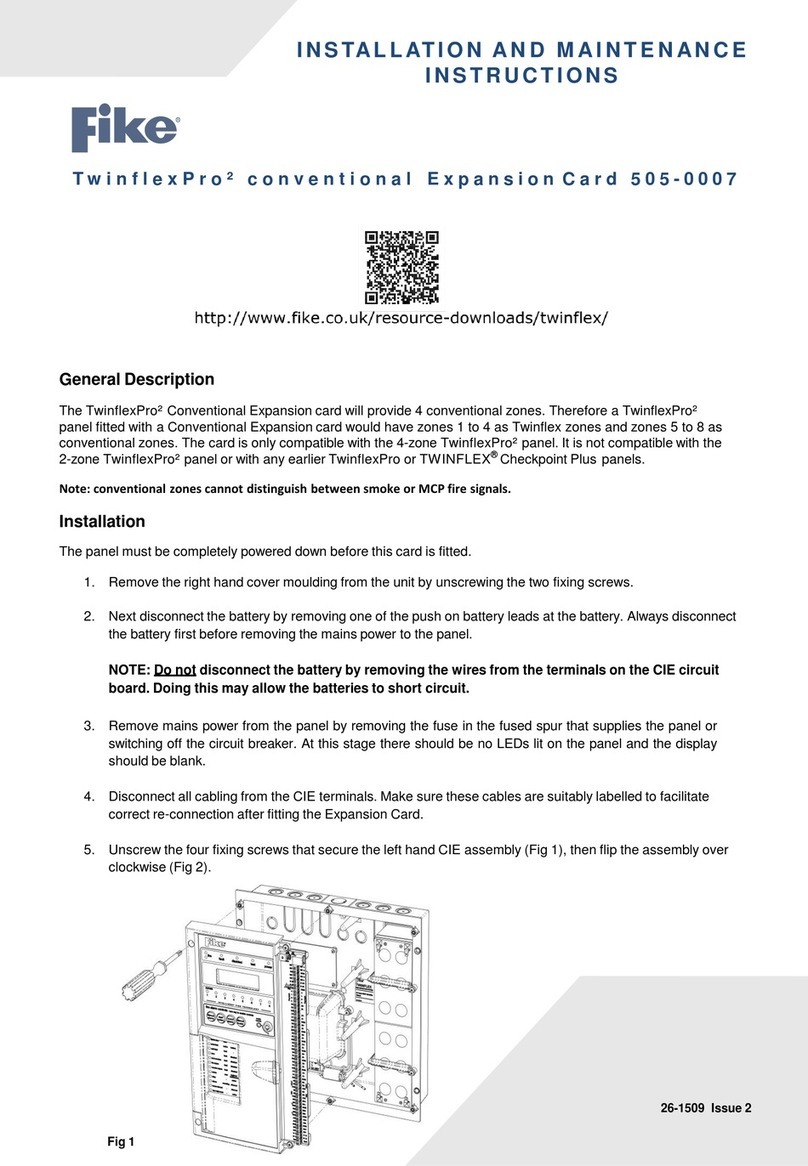

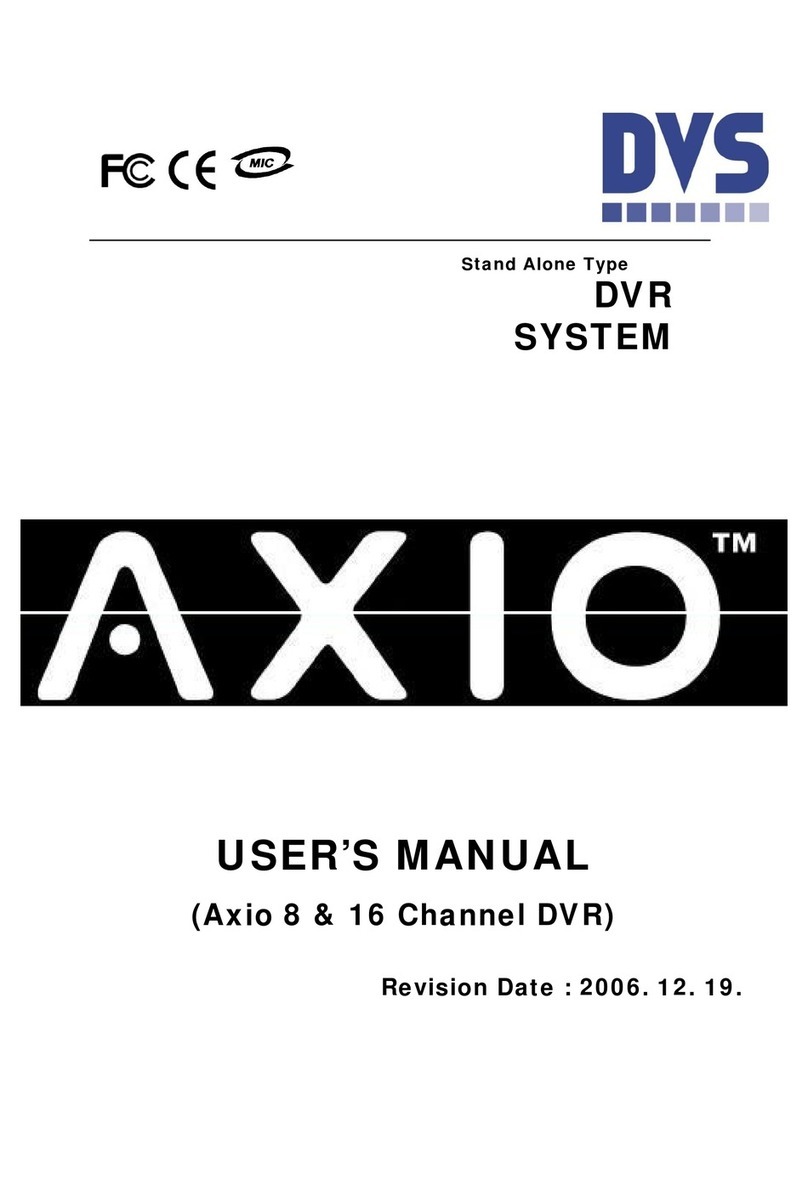

10-2085 Graphics MicroController Board

Each

Each Graphic Annunciator Door Assembly includes one micro board, which is the ‘brains’ of the

system. The following are features of the micro board:

Each can support up to 256 LED’s

Powered by 24 volt (P2 positions 1&2) DC source

Allows power to pass thru board, 24 volt (P2 positions 5&6)

RS232 communication serial port, P4, for programming the LED assignments

Fiber optic receiver (P6) for receiving data; transmitter (P7) connector to act as a repeater.

Connects to the LED Driver Board #1 via P1 ribbon cable connector

Connects to the door switch card via P5

Local piezo to annunciate new event

Fused power with on/off switch

Jumpers, J1 &J3, for configuration purposes

Jumper J2 for fiber optic transmitting distance

The Graphics MicroController board is programmed using a Personal Computer and software program

EGRAPHIC. The software program communicates to the Graphics Micro using Fike Communications

cable, P/N 10-1874. When programming the LED, the LED’s are illuminated in the order that they are

hard-wired to the LED Driver board. Each LED shall have detector address, zone, or system

assignments made.

The Micro board controls the LED’s by using a 16 x 16 array (16 Anode lines and 16 Cathode lines).

Each LED Driver board has 8 rows (anodes) of 16 each (cathodes) LED’s. When it needs to turn ON an

LED it pulls the appropriate cathode line low and anode line high.

The Micro Board is mountable in graphic back box via standoffs.

S

2

-

+

PIEZO-ALERT

PAL 328

U1 C3

+

F1

C2

+

S1

C24

C21

C19

C1

8

C6

C

5

C15

C1

4

C1

3

C12

C1

0

POWE

R

5VIN

24VIN

OFF

ON

L1

A

Fike 10- 2085

R3

U9

U4

R6

MADE I N USA

R7R8 NC

JP5

JP4

JP3

JP2

JP1

NC

NC

JP9

JP8

JP7

JP6

NC

100

FT

150

FT 200

FT

P1

P4

92915- R- HS-

J2

+

C1

P2

U2

P7 P6

X1

P5

C4

C7

U11

U6

R4

J1

U5

C9

U7

U13

R2

24VIN

COM

5VIN

COM

24VOUT

COM

5VOUT

COM

C8

A

ss

y

No . RE

V

U12

C20

U8

C23 U17 C1

6

U16

R5

U18

C22

U14

U3

R1

D1

C17

1

6

C11

J3

D2 D3

D4

D5

U15

+

+

PCB No

02- 3516 REV 0

COMPONENT SI DE

+

+-

1234

8.00"

6.00"

RCVR

XMIT

J1 JUMPER FUNCTIONS

JP6 - MULTIPLE MICRO BD'S

JP7 - TWO LED'S FOR ONE SENSOR (4 ACM'S OR LESS)

JP8 - LED #3 = SYSTEM ALARM, LED #4 = SYSTEM TROUBLE

JP9 - INTELLA-SCAN FIRMWARE VERSION PREVIOUS TO V3.3

NC

NC

J3 JUMPER FUNCTIONS

JP1 - CONFIGURATION TRANSMIT DATA THROUGH RS232

JP2 - NORMAL OPERATION, DATA FROM FIBER OPTIC RCVR

JP3 - FIBER OPTIC SERIAL LOOPBACK DIAGNOSTIC TEST

JP4 - NORMAL OP. AND CONFIG., SEND DATA OUT FIBER XMIT

JP5 - WRITE ENABLE

NC

FIBER XMIT (P7)

MAX DISTANCE

NC

NC

NC

100 FT

150 FT

200 FT

J2

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 6

10-2086 Intella-Scan Graphics Switch Card

C

C

N

O

N

C

C

C

N

C

N

O

C

C

N

C

N

O

C

C

N

C

N

O

SW1SILENCE LAMP TEST SW4 REVIEW SW3 STEP

SW

2

4.00"

1.45"

FRONT

BACK

T1 T2 T4 T3

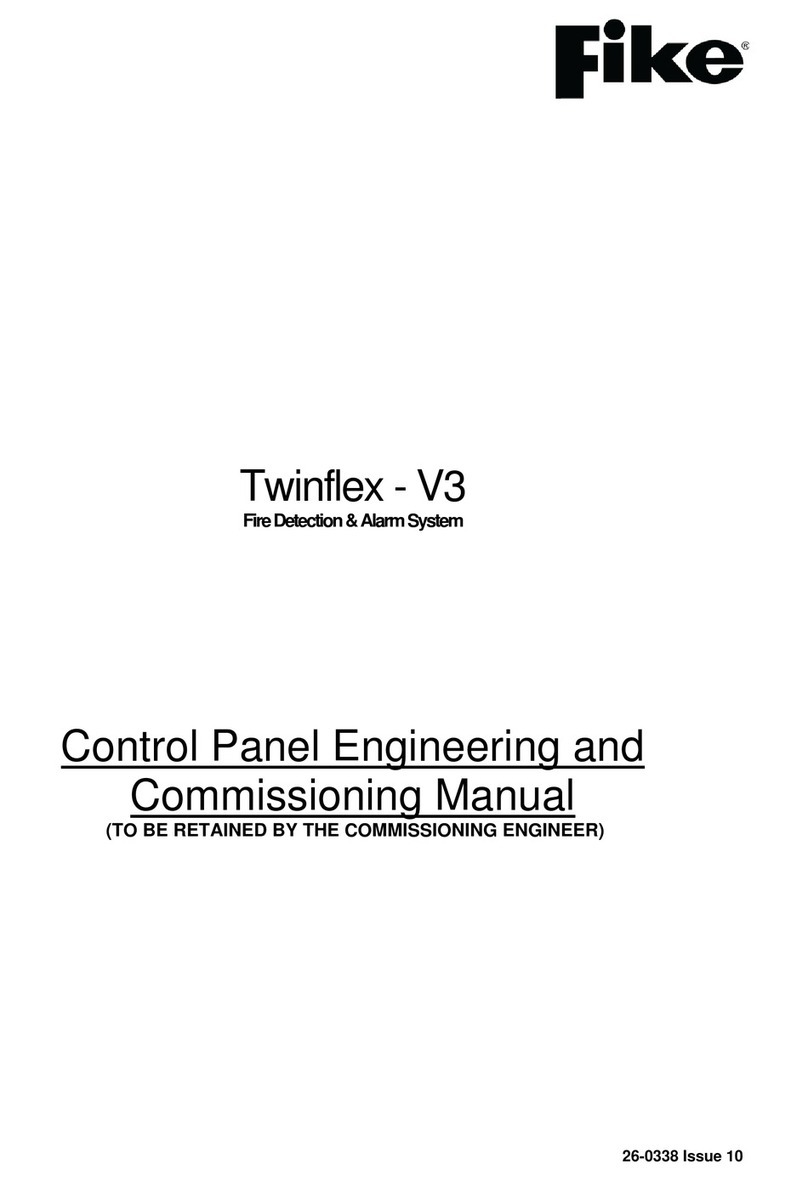

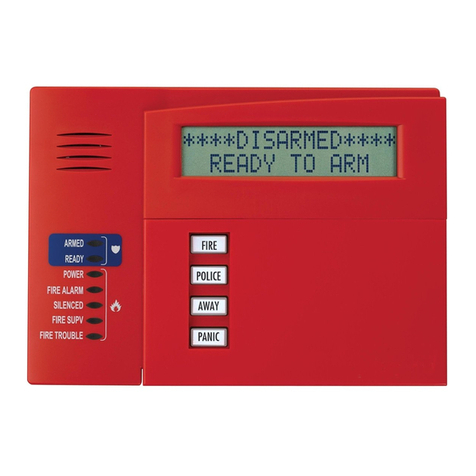

Each Graphic Annunciator Door Assembly contains one graphics switch card. The switch card is

mounted in a manner that the switches are accessible on the front of the panel door. The switch card

contains four push button switches: Silence, Lamp Test, Review, and Step. Note: When using multiple

Micro boards on the same graphic panel, tie all switch connections together. Each Micro board switch

card connector (P5) has headers on both sides of the board. Connect the Switch to the first Micro board,

top side P5; Connect bottom side of P5 on the first Micro board to the second Micro board P5, top side,

etc.

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 7

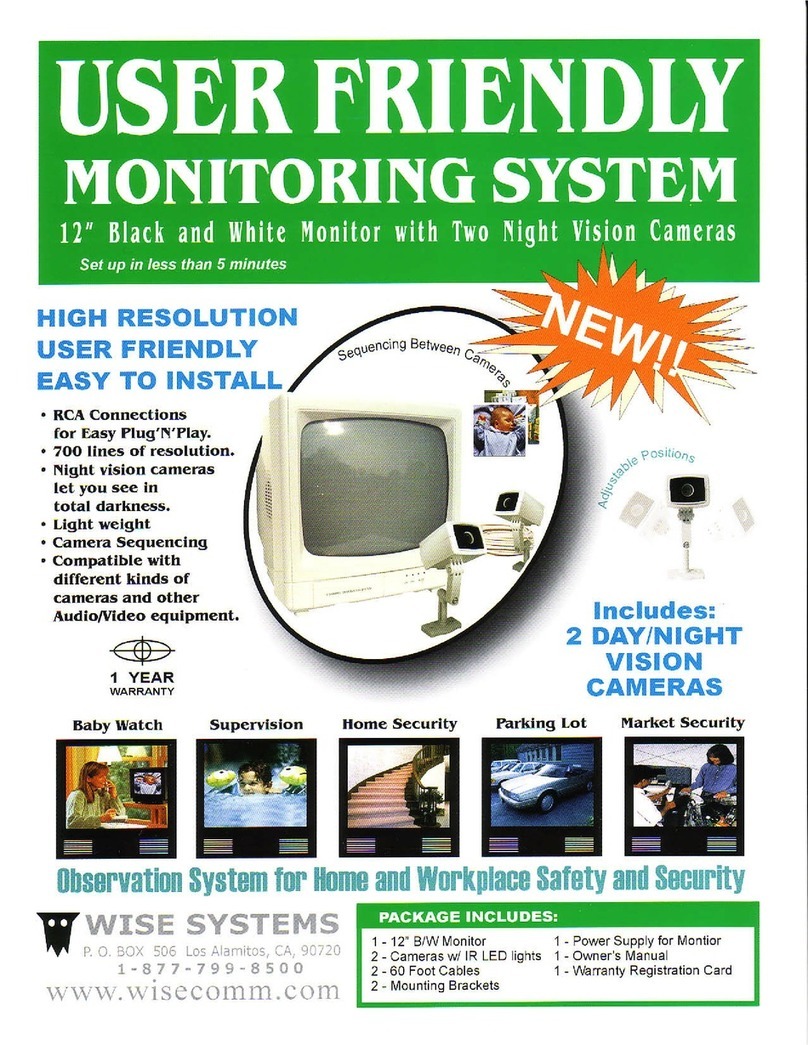

10-1858 LED Driver Board #1

64

56

484032241681

256 248 240 232 224 216 208 200 193

POSI TIVE LEADS

CONNECT TO

INSIDE POINTS OUTSI DE POINTS

CONNECT TO

NEGATI VE LEADS

-32

-64 -64

-32

-64

-64

-32-32

-64 -64 -64

-64

-32

-64

-64

-32 -64 -64

-64

-32

-32

-64 -64 -64

REV

3.3125"

8.0938"

10-1859 LED Driver Board #2

128

120

1121049688807265

192 184 176 168 160 152 144 136 129

POSI TIVE LEADS

CONNECT TO

INSIDE POINTS OUTSI DE POINTS

CONNECT TO

NEGATI VE LEADS

REV

3.3125"

8.0938"

Each Graphic Annunciator Door Assembly includes an LED Driver Board #1 which is mounted inside

the graphic annunciator door. The LED Driver Board is an interface board between the micro and

LED’s. It includes terminal blocks which provide connection for the LED leads. When ordering more

than 128 LED’s, LED Driver Board #1 has two 34 pin ribbon cable connectors to allow series

connection from the Micro board to the 10-1859 (LED Driver Board #2). LED Driver Board #2 has one

34 pin ribbon cable connector to connect from the 10-1858 LED Driver Board #1 and is likewise

mounted inside the graphic annunciator door.

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 8

Ordering Information

To order a complete Graphic Annunciator assembly a minimum of two parts are required, a door

assembly and a back box. The door assemblies are typically shipped with all electronics necessary to

support up to 128 LED’s. The back box is typically shipped with minimal hardware. Additional

components may be required (fiber optic cable, connectors, and power supply), especially if ordering

more than 128 LED’s. Refer to the power calculation table in the Specification section of this manual to

determine maximum system current.

The Graphic Annunciator may be surface or flush mounted and is available in six different sizes. Below

is a chart describing the door assembly P/N, viewing window size (l x h), maximum number of LED’s

placeable, back box P/N, and back box dimensions (l x h).

MAX DOOR ASSEMBLY BACK BOX

LED’s P/N DISPLAY

LENGTH

DISPLAY

HEIGHT P/N LENGTH HEIGHT

128 10-111H 18" 11" 10-1879 23.5" 16.5"

128 10-111V 11" 18" 10-1878 16.5" 23.5"

256 10-112 18" 18" 10-1880 23.5" 23.5"

512 10-113H 31" 18" 10-1882 36" 23.5"

512 10-113V 18" 31" 10-1881 23.5" 36"

640 10-114 31" 31" 10-1883 36" 36"

When ordering a graphic annunciator with more than 128 LED’s it is necessary to order additional parts. The

chart below provides a list of additional parts requirement for the number of LED’s on the door assembly.

ADDITIONAL PARTS REQUIRED FOR PANELS WITH MORE THAN 128 LED’S

Number of LED’s 129-256 257-384 385-512 513-640 641-768 769-896 897-1024

P/N NAME Qty. Qty. Qty. Qty. Qty. Qty. Qty.

10-1858 LED Driver #1 1 1 2 2 3 3

10-1859 LED Driver #2 1 1 2 2 3 3 4

10-2085 Micro Board 1 1 2 2 3 3

10-1903 34 Cond. , 2 ft. 1 2 3 4 5 6 7

02-3029 6 Cond. micro-sw 1 1 2 2 3 3

10-1950* 34 Cond., 4 ft. 1

02-2959 Fiber Optic cable,

500 ft. roll 1 1 1 1 1 1 1

02-2958 Fiber Connector

Rcvr, Black 1 2 2 3 3 4 4

02-2957 Fiber Connector

Xmit, Red 1 2 2 3 3 4 4

* The 10-1950 4 ft. long 34 conductor ribbon cable is required on the 10-113H and 10-114 Door

Assemblies, use it in place of 10-1903 (2 ft. long cable).

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 9

Spare Parts

02-2999 Tool for Annunciator LED Disconnect (not required on new 10-1858/9’s)

02-3038 LED Orange

02-3013 LED, Green

02-3009 LED, Red

02-3247 LED, Yellow

02-3002 PCB Mount Support, Plastic (For mounting LED Driver Board)

02-3001 PCB Mount, Plastic (For mounting LED Driver Board)

02-2957 Connector, Fiber Optic Transmitting, Red

02-2958 Connector, Fiber Optic Receiving, Black

10-1874 Communication Cable Assembly

02-3390 Software key (To operate PGraphic/EGraphic software)

06-096 Basic Intella-Scan II software (ESCAN, ECOM, EGRAPHIC)

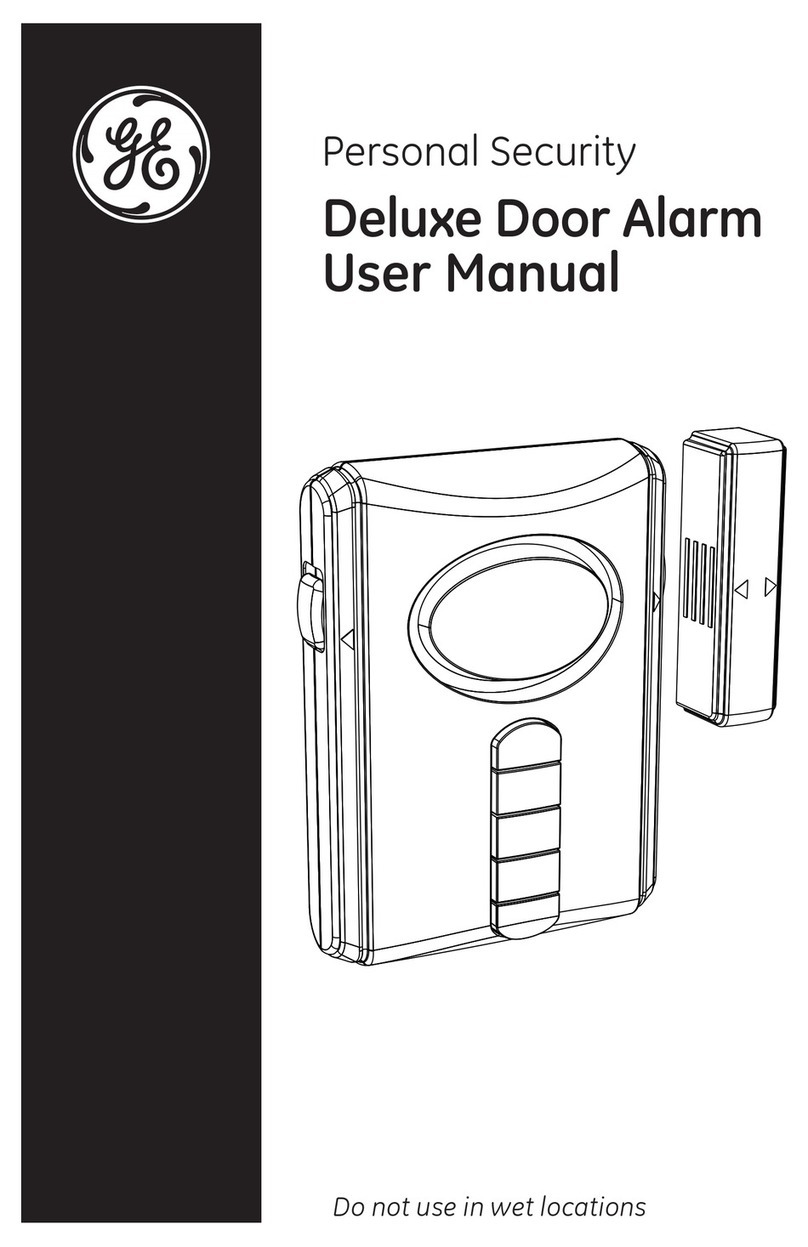

Door Connection to Back Box

The Graphic Annunciator is typically a left sided hinged door, unless specified differently when

ordered. The back box is typically installed prior to receiving the door assembly and electronics. It

is best to have two people when attaching the door to the back box (one to hold the door aligned in

place, and one to insert the screws through the hinge and door assembly). The following steps

should be followed to connect the door to the back box, while referring to the picture below:

1. Open the hinge that is attached to the back box to approximately 135°.

2. Place the door assembly up next to the hinge (the door will be open at 90°).

3. Align the hinge openings with the groove on the door assembly.

4. Install self-tapping screws (supplied with the door assembly) through hinge and into door

groove. Start with outer-most screws first, then center screw, then remaining screws.

R

A

SS

EMBLY

SC

REW

G

R

OO

VE

BA

C

K B

O

X

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 10

Programming

The LED’s are field programmed and configured for their proper illumination with a portable

Personal Computer using the Fike DOS compatible PGRAPHIC or EGRAPHIC program. The

program communicates to the Micro board RS232 connector via COM1 or COM2 Serial Port using

Fike communication cable, P/N 10-1874 (DB25 to RJ11) or 10-1874A (DB9 to RJ11).

Basic Requirements

IBM-PC compatible computer

DOS 3.0 or greater

EGRPAHIC (or PGRAPHIC) software program

10-1874 Fike serial communication cable (or 10-1874A)

Software key installed on LPT1 of computer (keyed to software above)

Starting the Program

Apply power to the Graphics Micro and install the communication cable between the computer and

the Graphics Micro P3. Start the program by typing “EGRAPHIC” from the directory where the file

is located and then press <Enter>. If COM1 on the computer is being used by another application, it

is possible to use COM2 with this software. To use COM2 instead of the default COM1, simply

type “EGRAPHIC /COM2” followed by <Enter>.

When the program starts, the first display screen is the license screen, press space bar to begin the

program. The second screen displayed is the Main Menu:

Select:

(1) Run Diagnostics

(2) Configure the Graphic Annunciator

(3) Jumper Settings for normal operation

(4) Quit Program (Return to DOS)

To Configure the Graphic Annunciator for the installation, press 2 (Configure the Graphic

Annunciator). The next screen will appear:

1) Turn the Graphic Annunciator OFF.

2) REMOVE the FIBER OPTIC CABLE from connector P6 on the Graphic Annunciator.

3) Make sure P6 is not facing direct sunlight or florescent lighting.

4) Position the Annunciator JUMPERS: JP1-IN, JP2-OUT, JP3-OUT, JP4-IN, JP5-IN.

5) Connect the COM1 SERIAL PORT to Graphic Annunciator using Fike Cable 10-1874.

6) Turn the Graphic Annunciator ON to establish communication.

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 11

Remember: 1) An LED can be assigned to multiple Sensors. A Sensor cannot be assigned to

multiple LED’s. The only EXCEPTION is: If four or fewer ACM’s are used then JP7

may be installed to allow a maximum of 2 LEDs to be assigned to a Sensor. Assign

the second LED by adding 4 to the ACM number.

2) An LED assigned to a zone condition remains on until the panel is reset.

Example: An LED assigned to ALARM remains on during PRE DISCHARGE

and RELEASE.

3) Install JP8 to turn on LED #3 when ANY zone is in ALARM and turn on LED #4

when ANY zone is in TROUBLE.

4) Install JP9 when using Graphic Annunciator firmware version 3.3 (or newer) with

Intella-Scan firmware previous to version 3.3.

Waiting for Graphic Annunciator to accept security code ........

(Press ESC to abort)

Note: LED Hardware Assignments

The following LED assignments must be located at these addresses on the 10-1858 LED Driver

board:

LED address #1 Micro Computer OK

LED address #2 Communications OK

LED address #3 Any alarm (if JP8 is installed)

LED address #4 Any trouble (if JP8 is installed)

All other LED addresses are programmable (LED 3 & 4 are also programmable if JP8 is NOT

installed).

Once communication is established, EGRAPHIC will step the user through programming the graphic

annunciator. It will first ask for system information, enter the number of ACM’s or ASM’s in the

Intella-Scan system:

How many Analog Sensor Modules are present?

The second configure screen will be the LED selection screen. As described on the computer, use

the arrow keys to find the LED Address of the LED to program. The LED will illuminate when its

address is selected.

F1-SUMMARY F5-CLEAR ALL F9-CLEAR CURRENT LED ADDRESS ESC-QUIT

LED Address = 1

Use ←and →KEYS to select LED, press <ENTER> to assign purpose

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 12

Once <Enter> is pressed, the computer will ‘beep’ and the third configure screen will appear. It is

for selecting the Intella-Scan ACM number in which the device is connected and the LED purpose:

LED Address = 1

Enter ACM Number: 1

For individual address response enter ACM number or for Zone Response enter ‘T’ for Trouble, ‘A’

for Alarm, ‘P’ for Pre Discharge or ‘R’ for Release.

(or just press <ENTER> to accept)

For individual address response, the fourth and final configuration screen is for selecting the

addressable loop address number in which the device is set to. After <ENTER> is pressed on this

screen, the screen will go back to the second configure screen. The fourth screen (individual

address):

LED Address = 1

Enter ACM Number: 1

Enter Sensor Number:

Enter a number between 1 and 127. (just press <ENTER> to abort)

For Zone Response in Trouble, Alarm, Pre Discharge, or Release, the fourth and final configuration

screen is for selecting the zone number for the response type. After <ENTER> is pressed on this

screen, the screen will go back to the second configure screen. The fourth screen (Zone Response ):

Note: The screen below shows Zone Trouble Response. Substitute ‘A’ and ‘Alarm’ in place

of ‘T’ and ‘Trouble’ for Zone Alarm Response; ‘P’ and ‘Pre Discharge’ for Zone Pre

Discharge Response; ‘R’ and ‘Release’ for Zone Release Response.

LED Address = 1

Enter ACM Number: T

Enter Zone Trouble Number:

Enter a number between 1 and 127. (just press <ENTER> to abort)

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 13

If several LED’s are programmmed incorrectly or it is necessary to change several LED assignments,

the “Clear All” selection is useful. The “CLEAR ALL” selection is located in the second

configuration screen (F5 - CLEAR ALL). If F5 is selected, the screen will display a verification:

F1-SUMMARY F5-CLEAR ALL F9-CLEAR CURRENT LED ADDRESS ESC-QUIT

You have selected CLEAR ANNUNCIATOR!Do you wish to do this?(YorN);

If ‘Y’ is pressed, the screen will display:

ANNUNCIATOR CLEARED, press SPACE BAR to continue ...

When configuration of the LED’s is complete, a summary of the LED programming can be obtained

from configuration screen 2 (F1-Summary). If F1 is pressed, the computer will display:

Getting Annunciator Data ........

Followed by:

Send Results to Printer? (Y or N)

The programmed LED information is not capable of being saved to a file, therefore it is

recommended that this information is printed and kept with Intella-Scan configuration information,

or other pertinent records. This document would allow for quick reprogramming of the Graphic

Micro if the configuration was ever lost or damaged. Below is a sample of a summary screen:

DATE: 08-08-1995 TIME: 15:09:52 PAGE: 1

-----------------------------------------------------------------

LED Address:3 Analog Sensor Module:1 Sensor Number:76 Type:Both

LED Address:6 Analog Sensor Module:1 Sensor Number:2 Type:Trouble

LED Address:7 Analog Sensor Module:7 Sensor Number:80 Type:Alarm

LED Address:20 -------------- Zone: 1 ALARM --------------

LED Address:46 -------------- Zone: 2 TROUBLE ------------

LED Address:50 -------------- Zone: 1 PRE DISCHARGE ------

LED Address:68 -------------- Zone: 2 RELEASE ------------

LED Address:256Analog Sensor Module:2 Sensor Number:1 Type:Both

If <ESC> is pressed from the second Configuration screen, the program will go back to the main

menu. The Main Menu contains a selection for ‘Jumper settings for normal operation’, selection 3.

This screen is useful to verify the correct jumper settings:

Jumper Settings for normal operation

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 14

Jumper JP2 and JP4 should be IN.

Jumper JP6 must be IN for Annunciators with ONE computer board.

Jumper JP6 must be OUT for Annunciators with MORE THAN ONE computer board.

Remember: 1) An LED can be assigned to multiple Sensors. A Sensor cannot be assigned

to multiple LED’s. The only EXCEPTION is: If four or fewer ACM’s are used then JP7

may be installed to allow a maximum of 2 LEDs to be assigned to a Sensor. Assign

the second LED by adding 4 to the ACM number.

2) An LED assigned to a zone condition remains on until the panel is reset.

Example: An LED assigned to ALARM remains on during PRE DISCHARGE

and RELEASE.

3) Install JP8 to turn on LED #3 when ANY zone is in ALARM and turn on LED #4

when ANY zone is in TROUBLE.

4) Install JP9 when using Graphic Annunciator firmware version 3.3 (or newer)

with Intella-Scan firmware previous to version 3.3.

Press SPACE BAR to continue.....

The Selection ‘Run Diagnostics’ from the main menu is covered in the Troubleshooting section of this

manual.

Checkout

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 15

1. Verify wiring is correct and free from opens and shorts.

2. Apply power to the Graphic system.

3. Verify “Micro Computer OK” LED is ON.

4. Verify “Communication OK” LED illuminates within one minute of power up.

5. If both LED’s are ON, begin verifying LED programming by creating events on the Intella-Scan

to turn ON each LED. The “Walk Test” mode in Intella-Scan II provides an alternate method

of testing the graphic annunciator programming. The graphic annunciator will function the

same during “Walk Test” as it does in normal operation.

6. Press Silence to silence local piezo when an event occurs.

7. After several LED’s have been turned ON, review the events in order by pressing and holding

the REVIEW button. Press the step button once to see the first alarm. Press the step

button again to see the second LED, etc. Note: Review is used for detector address and

system type LED’s only, it will not review zone type LED’s.

8. Once the system has been verified for operation, reset the Intella-Scan to a system Normal.

Verify the Graphic Annunciator returns with only “Micro Computer OK” and

“Communication OK” LED’s ON.

Note: Under normal operation, All LED’s will blink OFF each time data is received from the Intella-

Scan system. The blink rate will vary depending on the size of the system and the other types of

ancillary devices that are connected.

Troubleshooting

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 16

The IntellaScan II system was design to maximize system timing. If ancillary devices are used on an

Intella-Scan II system it is necessary to ‘turn ON’ the pertinent data. To tell the ECU to send the

pertinent data, start ESCAN with “ESCAN /serial”. The system variables screen will then display

options for sending each data type out its appropriate port. If your configuration was created without

Graphic data being sent out the fiber port, bring up the configuration in ESCAN as described; turn

ON the graphic data; re-save the configuration; re-load the configuration into the ECU. A simple

quick check, to see if the ECU is sending data is to look at the fiber optic transmitter connector. If it

is flashing, some type of data is being transmitted.

Verify distances are not being exceeded. If repeaters are being used, check the signal light strength

at each transmitter and receiver connector and verify jumpers are set correctly for distances required.

If a problem is encountered with a single LED not illuminating, press TEST to see if ALL LED’s

turn ON. If it does not illuminate, check the LED wiring to the LED Driver Board terminal block. If

it illuminates for TEST, but not when device is activated, check the programming summary printed

from the configuration.

EGRAPHIC has “built-in” troubleshooting software. When the program starts, the first display

screen is the license screen, press space bar to begin the program. The second screen displayed is the

Main Menu:

Select:

(1) Run Diagnostics

(2) Configure the Graphic Annunciator

(3) Jumper Settings for normal operation

(4) Quit Program (Return to DOS)

Diagnostics will test communication paths, switches, RAM, and LED’s. If any problems are

encountered during configuration or check-out, perform diagnostics on the Graphic system. If

Selection “1”, Run Diagnostics is selected the following screen is displayed:

Perform in the following order:

1) Turn the Graphic Annunciator OFF.

2) REMOVE the FIBER OPTIC CABLE from connector P6 on the Graphic Annunciator.

3) Make sure P6 is not facing direct sunlight or florescent lighting.

4) Position the Annunciator JUMPERS : JP1-IN, JP2-OUT, JP3-OUT, JP4-IN.

5) Connect the COM1 SERIAL PORT to Graphic Annunciator using Fike Cable 10-1874.

6) Turn the Graphic Annunciator ON to establish communication.

Waiting for Graphic Annunciator to accept security code .........

(Press ESC to abort)

Once communication is established from performing the previous screen steps, the Diagnostics

Menu will be displayed:

SELECT ONE:

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 17

(1) ECHO Test

(2) SWITCH Test

(3) RAM Test

(4) LED Test

(5) SERIAL LOOPBACK test

(6) Quit Diagnostics

The ECHO Test will test the connections from the computer to the graphic micro serial port. The

software program sends a “HELLO” to the micro board, and the micro board returns a “HELLO” to

the computer. If ECHO Test, selection 1, is pressed the screen will change as follows:

SELECT ONE:

(1) ECHO Test

(2) SWITCH Test

(3) RAM Test

(4) LED Test

(5) SERIAL LOOPBACK test

(6) Quit Diagnostics

YOU HAVE SELECTED ECHO TEST.

Press SPACE BAR to continue or ESC to abort test.....

ECHO TEST IN PROGRESS.....

ECHO OKAY

Press any key to continue.....

The switch test will test electrical connection of the Silence, Lamp Test, Review, and Step switches

on the Graphic Annunciator door. If SWITCH Test, selection 2, is pressed the piezo will enunciate

(Press Silence Switch to silence piezo) and the display will change as follows, each switch depress

will show up on the screen:

SELECT ONE:

(1) ECHO Test

(2) SWITCH Test

(3) RAM Test

(4) LED Test

(5) SERIAL LOOPBACK test

PRESS THE SILENCE SWITCH ONCE TO SILENCE THE BEEPER, THEN.....PRESS THE TREE

KEYS: REVIEW, STEP AND LAMP TEST OF GRAPHIC ANNUNCIATOR

TURN ANNUNCIATOR OFF AND THEN ON TO QUIT TEST

-----------------------------------------------------------------

REVIEW switch

STEP switch

LAMP TEST switch

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 18

The RAM test will verify that the RAM on the Graphic Micro Board is capable of being written to

and read from. This test will write over any configuration currently located in RAM and the

configuration will be lost. If RAM test, selection 3, is selected the display will change as follows:

SELECT ONE:

(1) ECHO Test

(2) SWITCH Test

(3) RAM Test

(4) LED Test

(5) SERIAL LOOPBACK test

(6) Quit Diagnostics

YOU HAVE SELECTED RAM TEST.

CAUTION: RAM test erases configuration data, annunciator must be reprogrammed!

Write Enable jumper JP5 must be installed to pass RAM test

Press SPACE BAR to continue or ESC to abort test.....

The LED test will test each LED by illuminating, then extinguishing each LED, one at a time. The

micro steps through each address that is accessible, therefore if there are few LED’s there will be a

time period between cycles. As indicated on the screen, press “F1” to slow down the cycling, press

“F2” to speed up the cycling of the LED’s. If LED test, selection 4, is pressed, the display will

change as follows:

SELECT ONE:

(1) ECHO Test

(2) SWITCH Test

(3) RAM Test

(4) LED Test

(5) SERIAL LOOPBACK test

(6) Quit Diagnostics

LED TEST IN PROGRESS.....

PRESSING ‘F1’ SLOWS DOWN PROCESSION, ‘F2’SPEEDS UP PROCESSION

Press ESC to end test.

The Serial Loopback test will test the communication loop. It will send a command out the

computer to the Graphic Micro board serial port. The Graphic Micro board will transmit out the

fiber optic transmitter. Through fiber optic cable, the receiver will receive the data and the message

will be sent back to the computer through the serial port connection. Each Micro board transmitter

should be tested. If Serial Loopback test, selection 5, is pressed the screen will change as follows:

You have selected SERIAL LOOPBACK TEST.

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 19

Set the Jumpers to: JP1-OUT JP2-IN JP3-IN JP4-OUT

Install the test fiber optic cable between P6 AND P8

(For 10-2085 install between P6 and P7)

Press SPACE BAR when ready or ESC to abort test.....

SERIAL LOOPBACK TEST ! IN PROGRESS.....SERIAL LOOPBACK OKAY

Press SPACE BAR to continue.....

YOU have selected SERIAL LOOPBACK TEST.

TEST TWO:

Install the test fiber optic cable between P6 and P7.

(For 10-2085 leave cable installed between P6 and P7)

Press SPACE BAR when ready or ESC to abort test.....

SERIAL LOOPBACK TEST 2 IN PROGRESS.....SERIAL LOOPBACK OKAY

Press SPACE BAR to continue.....

Set the jumpers as they were before this test: JP1-IN, JP2-OUT,

JP3-OUT, JP4-IN

Remove the test fiber optic cable between P6 and P7.

Press SPACE BAR when ready .....

When quit diagnostics, selection 6, is selected the computer will prompt the user to set the jumpers

on the graphic micro back for normal operation as shown below:

Do the following to put the Graphic Annunciator into normal service:

OBSOLETE

Graphic Annunciator Manual P/N 06-131 2/98

Page 20

Jumpers JP2 and JP4 should be IN.

Jumpers JP1, JP3, JP5, JP7, JP8 and JP9 should be OUT.

Jumper JP6 must be IN for Annunciators with only ONE computer board.

Jumper JP6 must be OUT for Annunciators with MORE THAN ONE computer board.

Remember: 1) An LED can be assigned to multiple Sensors. A Sensor cannot be assigned to

multiple LED’s. The only EXCEPTION is: If four or fewer ACM’s are used then JP7

may be installed to allow a maximum of 2 LEDs to be assigned to a Sensor. Assign

the second LED by adding 4 to the ACM number.

2) An LED assigned to a zone condition remains on until the panel is reset.

Example: An LED assigned to ALARM remains on during PRE DISCHARGE

and RELEASE.

3) Install JP8 to turn on LED #3 when ANY zone is in ALARM and turn on LED #4

when ANY zone is in TROUBLE.

4) Install JP9 when using Graphic Annunciator firmware version 3.3 (or newer) with

Intella-Scan firmware previous to version 3.3.

Press SPACE BAR to continue.....

Specifications

OBSOLETE

This manual suits for next models

6

Table of contents

Other Fike Security System manuals

Popular Security System manuals by other brands

Honeywell Home

Honeywell Home Ademco Vista Series Programming guide

HOME8

HOME8 H13012US quick start guide

Response

Response RE5000AD Installation and operating instructions

Swann

Swann ADW-340 instruction manual

ADEMCO

ADEMCO Security System VISTA-10SE Installation and setup guide

Nice

Nice HSMO - HSA1 Operation instructions