Fike Twinflex V3 User manual

26-0338 Issue 10

Twinflex - V3

FireDetection&AlarmSystem

Control Panel Engineering and

Commissioning Manual

(TO BE RETAINED BY THE COMMISSIONING ENGINEER)

Twinflex V3 Control Panel Engineering and Commissioning Manual

2

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every care

has been taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability whatsoever in

respect of such contents.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential and commissioning should only

be carried out by competent persons.

Fike cannot guarantee the operation of any equipment unless all documented instructions are complied with, without variation.

E&OE.

Fike equipment is protected by one or more of the following patent numbers: GB2426367, GB2370670, EP1158472, PT1035528T, GB2346758,

EP0917121, GB2329056, EP0980056, GB2325018, GB2305284, EP1174835, EP0856828, GB2327752, GB2313690

© 2009 Fike Safety Technology Ltd. All rights reserved. Document revised January 2013.

Twinflex V3 Control Panel Engineering and Commissioning Manual

3

Contents

Introduction.......................................................................................................................5

System Design.......................................................................................................5

Equipment Guarantee............................................................................................5

Antistatic Handling Guidelines...............................................................................5

Warning..................................................................................................................5

The Twinflex System .............................................................................................6

Twinflex Control Panel.....................................................................................................7

Mounting the Control Panel...................................................................................7

Physical Dimensions..............................................................................................7

Power Supply Unit.................................................................................................8

General Assembly .................................................................................................9

Topology and Cabling............................................................................................9

System Wiring Schematic......................................................................................10

Control Panel Connections....................................................................................11

Twinflex Repeater Panel ..................................................................................................18

Installation 1st Stage .............................................................................................18

Installation 2nd Stage............................................................................................18

Connections...........................................................................................................18

Operation...............................................................................................................19

Testing...................................................................................................................19

General Operation ............................................................................................................20

Introduction............................................................................................................20

Access Levels........................................................................................................20

Access Level 2 (User) Operating Diagram: 2&4 Zone Panels..............................21

Access Level 2 (User) Operating Diagram: 8 Zone Panels...................................22

LED Indication .......................................................................................................23

Access Level 1 (Normal)........................................................................................25

Access Level 2 (User)............................................................................................25

Access Level 3 (Engineer).....................................................................................25

Programming Summary.........................................................................................31

Check Point Plus ..............................................................................................................32

Introduction............................................................................................................32

Zone Modes...........................................................................................................32

Instant Zones: Normal Operation in Communal Areas..........................................32

Delayed Zones: Confirmation Delay in Dwelling Areas.........................................33

Delayed Zones: Local or Zonal Confirmation?......................................................33

Confirmation Delay Time.......................................................................................34

Checkpoint Plus Setup at Access Level 3 (Engineer)...........................................34

Installation and Commissioning .....................................................................................36

Installation 1st Stage .............................................................................................36

Installation 2nd Stage............................................................................................36

Commissioning......................................................................................................36

End User Training..................................................................................................37

Twinflex V3 Control Panel Engineering and Commissioning Manual

4

Fault Finding .....................................................................................................................38

Summary of Faults.................................................................................................38

Finding Zone Faults...............................................................................................40

Advanced Connections....................................................................................................41

Monitored Relays on the ‘Remote Fire Output’ .....................................................41

Remote Indication LEDs........................................................................................41

Connecting Two Panels Together.........................................................................42

Connecting More than Two Twinflex Panels Together..........................................43

Magnetic Door Hold Units......................................................................................44

Technical Data ..................................................................................................................45

Control Panel Specification ...................................................................................45

Resistor Colour Codes...........................................................................................46

Battery Calculations...............................................................................................47

Installation Checklist..............................................................................................48

Commissioning Checklist.......................................................................................49

Cable Continuity and Insulation Test Results........................................................50

Control Panel Instruction Notice............................................................................51

Apartment Notice for Checkpoint Plus Systems....................................................52

Important Points ...............................................................................................................56 – BACK PAGE

Twinflex V3 Control Panel Engineering and Commissioning Manual

5

Introduction

This Manual is intended as a guide to the engineering and commissioning principles of the Twinflex 2-wire

Fire Detection and Alarm system, and covers the system hardware information only.

Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on this

equipment is essential, and commissioning should only be carried out by competent and approved

persons. For further details of the availability of commissioning services contact your supplier.

System Design

This document does not cover Fire Alarm system design, and a basic understanding is

assumed.

A knowledge of BS5839: Pt 1: 2002 +A2: 2008 : Fire Detection and Alarm Systems for

Buildings is essential.

It is strongly recommended that a suitably qualified and competent person is consulted in

connection with the Fire Alarm System design and that the entire system is commissioned in

accordance with the current national standards and specifications.

Equipment Guarantee

The equipment carries no warranty unless the system is installed, commissioned and serviced

in accordance with this manual and the relevant standards by a suitably qualified and

competent person or organisation

Anti Static Handling Guidelines

Immediately prior to handling any PCBs or other static sensitive devices, it is essential to

ensure that a personal connection to earth is made with an anti-static wrist-strap or similar

apparatus.

Always handle PCBs by their sides and avoid touching any components. PCBs should also be

stored in a clean dry place, which is free from vibration, dust and excessive heat, and protected

from mechanical damage.

Warning

Do not attempt to install this equipment until you have fully read and understood this

manual.

Failure to do so may result in damage to the equipment and could invalidate the warranty.

Technical support will not be available if the instruction manual has not been read and

understood. Please have this instruction manual available whenever you call for technical

support.

For further technical support please contact your distributor. Do not call the Fike Safety

Technology support department unless your distributor has first given their advice and

attempted to rectify the issue.

EMC This equipment when installed is subject to the EMC directive 2004/108/EC. It is also subject

to UK Statutory Instrument 2006 No. 3418.

To maintain EMC compliance this system must be installed as defined within this manual. Any

deviation from this renders the installer liable for any EMC problems that may occur either to

the equipment or to any other equipment affected by the installation.

!

!

!

!

!

Twinflex V3 Control Panel Engineering and Commissioning Manual

6

The Twinflex System

This system is an intelligent ‘2-wire’ system with conventional type cabling format, and is classed as an

‘Analogue non-addressable’ system due to the architecture used within the system design. All field devices

including sounders on a zone are connected via a common 2-core and screen fire rated cable, and

communicate with the control panel using the ‘Twinflex’ data protocol.

The Twinflex panel is able to recognise and separately indicate a detector alarm and a manual call point

alarm. The panel also monitors each zone for detector head removal, device fault, ‘End of line’ fault and

open or short circuit fault.

Every device has an inbuilt ‘End of line’ signal, which may be activated as required.

Do not use a resistor or capacitor or any other 3rd party ‘End of line’

module for ‘End of line’.

The Twinflex control panel also provides a single conventional 24V sounder circuit, a monitored

conventional 24V relay circuit, a volt free common fire relay and a volt free common fault relay. There is

also a multifunction non-latching input, programmable with options such as ‘Class-Change’ and ‘Remote

fire input’.

The Twinflex control panel also incorporates an integral power supply unit and requires the following

standby batteries to provide up to 72 hour standby times (refer to Technical Data for further information).

2 or 4 zone panel 2 x 12v 2.1 Ah batteries

8 zone panel 2 x 12v 3.2 (or 3.3) Ah or 7.2 Ah batteries

Please note that the earlier version 1 of the control panel requires only one battery, so check the battery

labels in the control panel for clarification, as all the current version 3 control panels are labelled clearly

with ‘Battery 1’ and ‘Battery 2’.

Unlike most conventional fire alarm systems, which require separate pairs of cables for detector zones and

sounder circuits, the Twinflex system requires one 2-core and screen fire rated cable for each zone to

accommodate both detection devices and sounders. Furthermore sounders are incorporated within the

detector to reduce system components and simplify installation.

Twinflex V3 Control Panel Engineering and Commissioning Manual

7

Control Panel

Mounting the Control Panel

Firstly identify the proposed location for the control panel. Ensure that the control panel will be easily

accessible, and that account is taken of any subsequent work that may affect access. It should be located

at the most likely point of access for the fire services.

The control panel should be mounted on a flat, vertical wall at a height where the indicators may be seen

without difficulty.

Do not locate the control panel at high level where stepladders or other access equipment

may be required, in spaces with restricted access, or in a position that may require access

panels to be removed.

Do not locate the control panel where extremes of temperature or humidity may occur, or

where there is any possibility of condensation or water ingress.

Like all electronic equipment, the control panel may be affected by extreme environmental conditions. The

position selected for its installation should therefore be clean and dry, not subjected to high levels of

vibration or shock and at least 2 metres away from any pager or radio transmitting equipment. Ambient

temperatures should be within the range given within the Technical Data section, i.e., not directly over a

radiator or heater.

In common with all microprocessor-controlled panels, the control panel may operate erratically or may be

damaged if subjected to lightening induced transients. Proper earth/ground connections will greatly reduce

susceptibility to this problem.

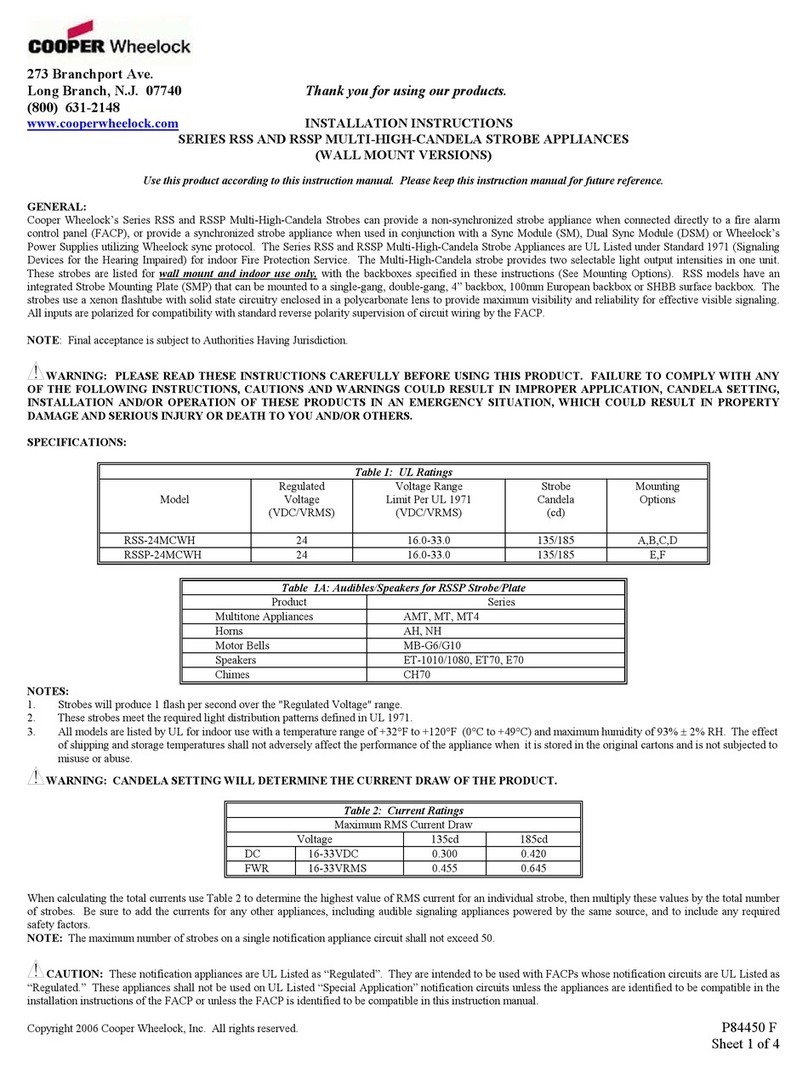

Physical Dimensions

2 & 4 Zone Panels 8 Zone Panels

The 2 & 4 zone control panel back box is designed as a dual-purpose surface or flush unit. The

14mm flange facilitates flush mounting. To allow installation of the main front moulding, this flange

must be flush with the mounting surface and not recessed into it.

The 8 zone panel is designed for surface mounting only and will require the use of the optional

flush mount bezel if the control panel needs to be flush mounted.

Twinflex V3 Control Panel Engineering and Commissioning Manual

8

Power Supply Unit

The Fire Alarm Panel 230V AC supply requires fixed wiring between 0.75 mm2and 1.5 mm2, a 3 amp

fused un-switched spur with local isolation, to be terminated into the fused terminals provided in the back

box. On the 8 zone panel a metal cover, held in place with a locking nut, protects these terminals. The

mains supply should be dedicated to the Fire Alarm Panel and should be clearly labelled ‘FIRE ALARM:

DO NOT SWITCH OFF’ at all isolation points.

Note: The output of the power supply to zones, sounder outputs and auxiliary supply can vary between

21V and 32V.

The control panel requires standby sealed lead acid batteries to be installed according to the following

table. These are to be sited in the control panel back box in the provided enclosure. The batteries should

be connected in series using the connection leads supplied. See the section entitled Control Panel

Connections for panel connections.

Control Panel Standby Requirements Batteries required

All 2 or 4 zone panels 24 hours & 30 minutes in

alarm 2 x 12v 2.1 Ah

All 2 or 4 zone panels 72 hours & 30 minutes in

alarm 2 x 12v 2.1 Ah

All 8 zone panels 24 hours & 30 minutes in

alarm 2 x 12v 3.2 (or 3.3) Ah

All 8 zone panels 72 hours & 30 minutes in

alarm 2 x 12v 7.2 Ah

Note that the charging circuit will be in its high impedance state (approximately 3V DC) if no batteries,

faulty batteries or only one battery is connected. The full 27V DC charging voltage should be present if the

correct batteries are connected.

If the system shows a charger or battery fault on first power up, leave the system to charge its batteries for

5-6 hours.

In order to test for correct operation of the batteries, remove the mains 230V AC fuse and allow the

batteries to settle from their charging voltage for approximately 5 minutes. The battery voltage should then

be measured using an electronic test meter and a voltage greater than 24V DC should be seen.

Note that batteries are electrically live at all times and great care should be taken to ensure that the

terminals are never presented with a short circuit. Care should be taken at all times, especially during

transit, installation and normal use.

Batteries no longer required should be disposed of in a safe and environmentally friendly manner by the

manufacturer or a suitable recycling service. They should never be incinerated or placed in normal rubbish

collection facilities.

Twinflex V3 Control Panel Engineering and Commissioning Manual

9

General Assembly

2 & 4 Zone Panels

8 Zone Panels

Topology & Cabling

All system wiring should be installed to comply with BS 5839 : Pt 1 : 2002 and BS 7671 (wiring regulations)

and any other standards relevant to the area or type of installation. A cable complying with the BS 5839 : Pt

1 : 2002 Category 1 (cables required to operate for prolonged periods during fire conditions) is required.

This must be a 2-core 1.5mm2screened fire resistant cable (ie. MICC, FP200, Firetuff, Firecell, Lifeline or

equivalent).

Each zone requires a separate 2-core radial circuit from the control panel to the furthest point of the zone,

to a maximum of 500 metres.

In order to protect against possible data corruption it is important ensure the following points are adhered

to:

1. The cable screen must be connected to earth/ground at the control panel only.

2. The cable screen must not be connected to earth/ground at any point other than the control

panel, ie. do not connect the screen to a device back box.

3. The cable screen continuity must be maintained at every point of the circuit, using the

terminals provided or a suitable connection block.

Refer to the following System Wiring Schematic for further details.

Twinflex V3 Control Panel Engineering and Commissioning Manual

10

System Wiring Schematic

The following schematic may prove useful as an aid to understanding the cable requirements for the system;

Twinflex V3 Control Panel Engineering and Commissioning Manual

11

Control Panel Connections

2 & 4 Zone Panels

Battery Connections: BAT+, BAT-

The battery terminals require 24V from 2 x 2.1Ah sealed lead acid batteries, connected in series, in

order to provide secondary backup power when the primary power fails. This input is protected by

the 3A fuse connected inline with the positive battery lead.

AC Input: AC – A, AC – B, EARTH

The AC input is connected to the yellow leads coming from the transformer mounted within the

back box, and is the primary power supply for the system.

Twinflex V3 Control Panel Engineering and Commissioning Manual

12

Auxiliary Power: Aux 24V (Nominal) O/P +, Aux 24V (Nominal) O/P -

250mA of auxiliary, nominal 24V DC power (between 21 & 32 volts) is available here. It is

recommended that additional Power Supply Units be installed to provide power for additional

loads.

Remote Alarm Output: Remote Alarm O/P +/-

The remote alarm output may be used to connect a standard 24V DC conventional relay. This is

monitored for short circuit and open circuit with a 4K7 ohm ‘End Of Line’ resistor and is rated at

24V DC 250mA. The relay operates when the control panels enters the fire state and deactivates

when the system is reset. Any relays must be dioded. See the section on relays for further

information.

Remote Alarm input: Alarm I/P

The Remote alarm input is a non-latching input suitable for interfacing to other fire panels. Simply

apply auxiliary –ve (0V) to this terminal and its chosen function will operate as follows;

Mode 1 – Timed Class Change

On application of a 0V trigger, the sounders will operate for 10 seconds, but the control panel will

show no indication, and neither the ‘Fire Relay’ nor the ‘Remote Alarm Output’ will operate.

Mode 2 – Remote Alarm excluding ‘Remote Alarm Output’

On application of a 0V trigger, the sounders will operate, the control panel will show ‘Common Fire’

and ‘Remote Alarm Input’ indication, the ‘Fire Relay’ will change state, but the ‘Remote Alarm

Output’ will not operate. This will reset when the trigger condition is removed.

Mode 3 – Class Change

On application of a 0V trigger, the sounders will operate until the trigger condition is removed, but

the control panel will show no indication, and neither the ‘Fire Relay’ nor the ‘Remote Alarm

Output’ will operate.

Mode 4 – Remote Alarm

On application of a 0V trigger, the sounders will operate, the control panel will show ‘Common

Fire’, ‘Remote Alarm Input’ and ‘Remote Alarm Output’ indication, and the ‘Fire Relay’ and the

‘Remote Alarm Output’ will change state. This will reset when the trigger condition is removed.

Repeater Outputs: Z1, Z2, Z3, Z4, Flt

The repeater output will change to 0v when the relevant state is present, ie, the ‘Z1’ terminal will

become 0v when zone one is in the fire state. An Led or low current relay may be operated if

connected between this terminal and auxiliary 24V positive. Any relays must be dioded. See the

section on relays for further information.

Twinflex V3 Control Panel Engineering and Commissioning Manual

13

Repeater Inputs: EVAC, SIL, RST

These inputs require that a switched 0V trigger is applied in order for the relevant action to take

place as follows;

EVAC- Evacuate Input

On application of the 0V trigger input the sounders will operate, the control panel will show

‘Common Fire’ and ‘Remote Alarm Output’ indication, and the ‘Fire Relay’ and the ‘Remote Alarm

Output’ will change state. This will latch in place and the control panel must be reset to clear the

event.

SIL – Silence Input

On application of the 0V trigger input the alarm sounders will stop if they were operating.

RST - Reset Input

On application of the 0V trigger input the system will reset.

Fire Relay: NO, COM, NC

The fire relay provides a set of volt free single pole changeover contacts rated at 30V DC 1A. This

contact will change state when the control panel enters the fire state, and remain so until the

system is reset. All inductive loads should be diode protected (eg. using a 1N4004 diode) to

prevent back EMF. However, if this is not done, the load should be limited to 200mA to reduce the

likelihood of back EMF causing damage to the relay contacts.

Fault Relay: NO, COM, NC

The fault relay provides a set of volt free single pole changeover contacts rated at 30V DC 1A. This

contact will change state when the control panel enters the fault state, and remain so until the fault

condition is cleared. All inductive loads should be diode protected (eg. using a 1N4004 diode) to

prevent back EMF. However, if this is not done, the load should be limited to 200mA to reduce the

likelihood of back EMF causing damage to the relay contacts.

Conventional Sounder Circuit: BELL OUTPUT +/-

The conventional sounder circuit may be used to connect a standard sounders or strobe circuit.

This is monitored for short circuit and open circuit with a 4K7 ohm ‘End Of Line’ resistor and is

rated at 24V DC 500mA (Note: loads must be kept below 500mA to avoid blowing the fuse).

The alarm sounders operate when the control panel enters the fire state and deactivates when the

system is silenced. Nominal output voltage 21 – 32V.

Device circuits: ZONE 1/2/3/4 +/-

The Twinflex devices may be connected in radial circuits utilising the in built ‘End Of Line’ signal

within the last device. NB. Do not use a resistor or capacitor or any other 3rd party ‘End of line’

module for ‘End Of Line’ on the zones. Unused zones must be programmed off. See the

programming section for further details.

Fuses

Bell Fuse - Located on PCB adjacent Bell Output terminals......................F500mA (Quick Blow)

Battery Fuse – Located in line in the positive battery lead..........................F3A (Quick Blow)

Mains Fuse – Located in the back box adjacent to the transformer............T315mA (Anti Surge)

Twinflex V3 Control Panel Engineering and Commissioning Manual

14

8 Zone Panels

POWER SUPPLY:

24V DC SWITCH

MODE PSU

LOCATED IN

CONTROL PANEL

BACK BOX

POWER

SUPPLY DC

E

RED

BLACK

Twinflex V3 Control Panel Engineering and Commissioning Manual

15

Device circuits: ZONE 1/2/3/4/5/6/7/8 +/-

The Twinflex devices may be connected in radial circuits utilising the in built ‘End Of Line’ signal

within the last device. NB. Do not use a resistor or capacitor or any other 3rd party ‘End of line’

module for ‘End Of Line’ on the zones. Unused zones must be programmed off. See the

programming section for further details.

Remote Alarm Output: Remote Fire O/P +/-

The remote alarm output may be used to connect a standard 24V DC conventional relay. This is

monitored for short circuit and open circuit with a 4K7 ohm ‘End Of Line’ resistor and is rated at

24V DC 800mA. The relay operates when the control panels enters the fire state and deactivates

when the system is reset. Any relays must be dioded. See the section on relays for further

information.

Conventional Sounder Circuit: SOUNDER +/-

The conventional sounder circuit may be used to connect a standard sounder or strobe circuit. This

is monitored for short circuit and open circuit with a 4K7 ohm ‘End Of Line’ resistor and is rated at

24V DC 800mA. The alarm sounders operate when the control panel enters the fire state and

deactivates when the system is silenced

Fire Relay: NO, COM, NC

The fire relay provides a set of volt free single pole changeover contacts rated at 30V DC 1A. This

contact will change state when the control panel enters the fire state, and remain so until the

system is reset. All inductive loads should be diode protected (eg. using a 1N4004 diode) to

prevent back EMF. However, if this is not done, the load should be limited to 200mA to reduce the

likelihood of back EMF causing damage to the relay contacts.

Fault Relay: NO, COM, NC

The fault relay provides a set of volt free single pole changeover contacts rated at 30V DC 1A. This

contact will change state when the control panel enters the fault state, and remain so until the fault

condition is cleared. All inductive loads should be diode protected (eg. using a 1N4004 diode) to

prevent back EMF. However, if this is not done, the load should be limited to 200mA to reduce the

likelihood of back EMF causing damage to the relay contacts.

Remote Alarm input: Alarm I/P / Class Change

The Remote alarm input is a non-latching input suitable for interfacing to other fire panels. Simply

apply auxiliary 0V to this terminal and its chosen function will operate as follows;

Mode 1 – Timed Class Change

On application of a 0V trigger, the sounders will operate for 10 seconds, but the control panel will

show no indication, and neither the ‘Fire Relay’ nor the ‘Remote Alarm Output’ will operate.

Mode 2 – Remote Alarm excluding ‘Remote Alarm Output’

On application of a 0V trigger, the sounders will operate, the control panel will show ‘Common Fire’

and ‘Remote Alarm Input’ indication, the ‘Fire Relay’ will change state, but the ‘Remote Alarm

Output’ will not operate. This will reset when the trigger condition is removed.

Twinflex V3 Control Panel Engineering and Commissioning Manual

16

Mode 3 – Class Change

On application of a 0V trigger, the sounders will operate until the trigger condition is removed, but

the control panel will show no indication, and neither the ‘Fire Relay’ nor the ‘Remote Alarm

Output’ will operate.

Mode 4 – Remote Alarm

On application of a 0V trigger, the sounders will operate, the control panel will show ‘Common

Fire’, ‘Remote Alarm Input’ and ‘Remote Alarm Output’ indication, and the ‘Fire Relay’ and the

‘Remote Alarm Output’ will change state. This will reset when the trigger condition is removed.

Internal Speaker: INT SPEAKER +/-

This feature is not currently in use.

Auxiliary Power: Aux 24V O/P +, Aux 24V O/P

Nominal between 21 and 27V

800mA of auxiliary 24V DC power is available here. It is recommended that additional Power

Supply Units be installed to provide power for additional loads.

Power Supply: DC, DC, EARTH

The DC input is connected to the red and black leads coming from the switch mode power supply

mounted within the back box, and is the primary power supply for the system.

Note: Previously the control panel used a 24V AC input, connected to a transformer mounted

within the back box. Ensure that the correct type of power supply is utilised.

Repeater Outputs: Z1, Z2, Z3, Z4, A = FLT O/P, B = RESET O/P

The repeater output will change to 0V when the relevant state is present, ie, the ‘Z1’ terminal will

become 0V when zone one is in the fire state. An Led or low current relay may be operated if

connected between this terminal and auxiliary 24V positive. Any relays must be dioded. See the

section on relays for further information.

Repeater Inputs: D = SILENCE, E = RESET, F = EVAUATE

These inputs require that a switched 0V trigger is applied in order for the relevant action to take

place as follows;

F = EVAC - Evacuate Input

On application of the 0V trigger input the sounders will operate, the control panel will show

‘Common Fire’ and ‘Remote Alarm Output’ indication, and the ‘Fire Relay’ and the ‘Remote Alarm

Output’ will change state. This will latch in place and the control panel must be reset to clear the

event.

D = SIL – Silence Input

On application of the 0V trigger input the alarm sounders will stop if they were operating.

E = RST - Reset Input

On application of the 0V trigger input the system will reset.

Twinflex V3 Control Panel Engineering and Commissioning Manual

17

Battery Connections: BAT+, BAT-

The battery terminals require 24V from 2 x 3.2 (or 3.3) Ah or 2 x 7.2 Ah sealed lead acid batteries,

connected in series, in order to provide secondary backup power when the primary power fails.

This input is protected by the 3A fuse located on the PCB.

Note that earlier versions of the 8 zone control panel had two sets of battery connections and

required a 12V battery on each. With the current versions a link wire is provided to allow the

batteries to be connected in series to the single set of connectors.

Fuses

Sounder Fuse - Located on PCB near centre. ...........................................F1A (Quick Blow)

Remote Fire Fuse - Located on PCB adjacent Fire relay...........................F1A (Quick Blow)

Battery Fuse – Located on PCB adjacent to battery terminals....................F3A (Quick Blow)

Mains Fuse – Located in the back box adjacent to the transformer............T3A (Anti Surge)

Twinflex V3 Control Panel Engineering and Commissioning Manual

18

Twinflex Repeater Panel

Installation 1st Stage

This unit is classed as ‘secondary indicating equipment’ (as stipulated in the British Standards). It is

available in 8 or 16 zone formats and has the optional functionality to provide system controls (silence,

reset and evacuate). The main control panel controls and indication will not be affected or hidden.

Fix the back box in a suitable position using the three screw holes provided remembering to allow enough

space for the correct termination of the appropriate cables.

The repeater panel requires a multi-core cable from the main control panel, and must consist of the

following:

Number of Cores Function Example 8 zone

repeater

2 24V DC power supply 2

5 Silence, reset, evacuate, fire and fault 5

1 Per zone indication required 8

Example Total 15

Please remember that all high voltage testing must be carried out before the installation of any electronic

devices as this may cause damage. The installer needs to provide proof of zone continuity readings etc., to

enable commissioning to proceed.

Installation 2nd Stage

Once all testing has been carried out on the cabling and ‘continuity & integrity’ has been proven, then the

repeater panel may be assembled.

Connections

Twinflex V3 Control Panel Engineering and Commissioning Manual

19

Operation

In the event of a fire state being active on one of the main control panel zones, the common fire LEDs and

the relevant zone led will light up, and the buzzer will sound.

Turning the key switch to the on position enables the controls buttons for ‘Silence Alarms’, ‘Reset System’

and ‘Sound Alarms’. If these controls are not required then do not connect the terminals labelled ‘EVAC’,

‘SIL’ and ‘RESET’.

Testing

Simply ensure that the relevant zone indications occur by activating each zone in turn at the main control

panel and by creating a fault. The controls may be tested at the same time by silencing and resetting from

the repeater panel.

Twinflex V3 Control Panel Engineering and Commissioning Manual

20

General Operation

Introduction

This section describes the operation of the panel in response to fire and fault conditions, operator actions

required to process alarms and restore the panel to the normal state, and engineering functions such as

testing and system configuration.

The panel controls and indicators are largely the same for the 2/4 and the 8 zone panels, but there are a

few differences. Eg, the 8 zone panel uses a key switch for Access Level 2 (User) entry, whereas the 2/4

zone panels use a code entry.

Access Levels

The system access levels are set into three access levels as follows. For simple indication the status of the

‘Controls Enabled’ LED will show the level selected as follows;

Access

Level Description Controls Enabled LED 2/4z Panel

Codes 8z Panel Codes

1 Normal OFF - -

2 User ON ACCESS 514 Key Switch

3 Engineer FLASHING ACCESS 5244 ACCESS 5244

Table of contents

Other Fike Security System manuals