Fike SHP 10-051 User manual

Product Manual

Conventional

Fire Alarm/Suppression

System

Manual P/N: 06-130

Rev. No: 3, 04/02

P/N: 10-051

firealarmresources.com

firealarmresources.com

FIKE CORPORATION

UL S2203 SHP Product Manual Page i

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No. 3, 04/02

Fike Corporation - Offices

Copyright Information

This document may not be reproduced, in whole or in part, by any means without the prior express written

permission of Fike Corporation.

Fike

is a registered trademark of Fike Corporation.

Disclaimers

The information contained in this manual is as accurate as currently possible. This manual is intended to

be an aid to Fike authorized sales outlets, who have been trained in an approved manner by Fike, and

the user who is a customer of the Fike authorized sales outlet. Fike does not warrant that this manual is

technically correct, complete, or free from writing problems or that the Fike products referenced therein

are free from minor flaws.

In accordance with our policy of continuing product and system improvement, Fike reserves the right to

change designs or specifications without obligation and without further notice.

Reader Responses

Fike encourages input from our sales outlets and end users on how we can improve this manual and the

products themselves. Please direct all calls of this nature to Fike’s Product Support Department

at (816) 229-3405.

Any communication received becomes the property of Fike Corporation.

Warranties

Fike provides a one-year limited manufacturer's warranty on this product. The standard warranty is printed

in each Marketing Price List. All warranty returns must be returned from an authorized Fike Sales outlet.

Contact Fike's Marketing Department for further warranty information. Fike maintains a repair department

that is available to repair and return existing electronic components or exchange/purchase previously

repaired inventory component (advance replacement). All returns must be approved prior to return. A

Material Return Authorization (MRA) number should be indicated on the box of the item being returned.

Contact the appropriate Regional Sales Manager for further information regarding Material Return

Procedures.

Fike Corporation

World Headquarters

704 South 10th Street

P.O. Box 610

Blue Springs, Missouri 64013

U.S.A.

Ph: (816) 229-3405

Fax: (816) 229-5082

Fike Canada

4140 Morris Drive

Burlington, Ontario L7L 5L6

Canada

Ph: (905) 681-3100

Fax: (905) 681-3107

Fike Europe

Toekomstlaan 52

B-2200 Herentals

Belguim

Ph: 011-32-14-210031

Fax: 011-32-14-210743

Fike Latina

Avenida Paulista 2202, 3°, cj34

Cerqueira Cesar, Sao Paulo

Brazil, CEP 01310-300

Ph: 011-55-11-251-5244

Fax: 011-55-11-284-8479

Fike United Kingdom

10-11 Enterprise Estate

Moorfield Road

P.O. Box 540

Guildford, Surrey GU1 1RB

United Kingdom

Ph: 011-44-8700-777-540

Fax: 011-44-7000-777-540

Fike Singapore PTE. LTD.

30, Loyang Way #01-09

Loyand Industrial Estate

Singapore, 509769

Singapore

Ph: 011-65-545-7989

Fax: 011-65-545-6689

firealarmresources.com

firealarmresources.com

FIKE CORPORATION

UL S2203 SHP Product Manual Page ii

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No. 3, 04/02

TABLE OF CONTENTS

Section Page

1.0 Preface................................................................................................................................................... 1

1.1 About This Manual .............................................................................................................. 1

1.2 Product Support .................................................................................................................. 1

1.3 Revision History .................................................................................................................. 1

1.4 Terms Used in this Manual .............................................................................................. 1-3

1.5 Symbols Used in this Manual.............................................................................................. 4

1.6 Safety Notices ..................................................................................................................... 4

2.0 Product Overview ................................................................................................................................ 5

2.1 Product Description............................................................................................................. 5

2.2 Listings and Approvals ........................................................................................................ 5

2.3 Agency Standards and Compliance................................................................................. 5-6

2.4 Related Documentation.......................................................................................................6

2.5 SHP Features...................................................................................................................... 7

3.0 Equipment/Products............................................................................................................................. 9

3.1 Main Panel Hardware..................................................................................................... 9-10

3.2 Input Devices ...............................................................................................................11-12

3.3 Output Devices.................................................................................................................. 12

3.4 Ancillary Devices............................................................................................................... 13

3.5 Spare Parts ....................................................................................................................... 14

3.6 Specifications ............................................................................................................... 15-18

3.7 Enclosure Specifications ................................................................................................... 19

4.0 Installation........................................................................................................................................... 21

4.1 Enclosure Installation ........................................................................................................ 21

4.2 Power and Field Wiring..................................................................................................... 22

4.3 Wiring Verification ............................................................................................................. 23

4.4 System Module Installation ............................................................................................... 23

4.5 System Configuration........................................................................................................ 23

4.6 Wiring Diagrams........................................................................................................... 24-25

4.7 Circuit Configuration..................................................................................................... 26-27

4.8 Initial Power-Up................................................................................................................. 28

4.9 Complete Field Wiring....................................................................................................... 28

4.10 Checkout System .............................................................................................................. 28

4.11 Releasing Hardware..........................................................................................................28

5.0 Operations ........................................................................................................................................... 29

5.1 User Switch Interaction ..................................................................................................... 29

5.2 Diagnostic LED Code Designators ................................................................................... 29

5.3 Silencing Rules ................................................................................................................. 29

5.4 Outputs Disabled Mode..................................................................................................... 30

5.5 Supervisory and Trouble Status LED’s ............................................................................. 30

5.6 Latching versus Non-Latching Troubles ........................................................................... 30

5.7 Waterflow Alarm Operations ............................................................................................. 30

5.8 Supervision Response Times ........................................................................................... 30

5.9 Low Power Conditions ...................................................................................................... 30

5.10 Alarm Operation (Suppression Mode) .............................................................................. 31

5.11 Alarm Operation (Sprinkler Mode) .................................................................................... 32

5.12 Supervisory Operation ...................................................................................................... 32

5.13 Trouble Operation ............................................................................................................. 32

firealarmresources.com

FIKE CORPORATION

Page iii SHP Conventional Fire Suppression Panel UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

6.0 Servicing .............................................................................................................................................. 33

6.1 Checkout ........................................................................................................................... 33

6.2 Maintenance...................................................................................................................... 33

6.3 Troubleshooting ........................................................................................................... 33-36

Appendix 1 ................................................................................................................................................. 37

Battery Calculations .................................................................................................................. 37-38

Appendix 2 ................................................................................................................................................. 39

ULC Operation ............................................................................................................................... 39

Appendix 3 ................................................................................................................................................. 41

System Operation Posting ............................................................................................................. 41

Index ........................................................................................................................................................... 43

firealarmresources.com

FIKE CORPORATION PREFACE

UL S2203 SHP Product Manual Page 1 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No. 3, 04/02

1.0 PREFACE

1.1 ABOUT THIS MANUAL

This manual is intended to be a complete reference for the installation, operation, and service of the Fike

Single Hazard Panel (SHP) Fire Alarm/Suppression Control System. The information contained in this

manual must be utilized by the factory trained Fike sales outlet in order to properly install, test and service

the SHP. This manual can also be used by the end user as an Operations Manual for the SHP.

Before you refer to any section in this manual, and before you attempt to install or use the SHP, be sure

to read the important safety notices in section 1.6.

This manual is divided into sections for easy reference. The first-time installer and/or user should

thoroughly read and understand the instructions contained within this manual before using this device.

These instructions must be followed to avoid possible damage to the SHP itself or adverse operating

conditions caused by improper installation and programming.

1.2 PRODUCT SUPPORT

If you have a question or encounter a problem not covered in this manual, you should first try to contact

the sales outlet that installed the protection system. Fike has a worldwide distribution network. Each

sales outlet sells, installs, and services Fike equipment. Look on the inside door, left side, there should

be a sticker with an indication of the sales outlet who sold the system. If you can not locate the sales

outlet, please call Fike Customer Service for locating your nearest sales outlet, or go to our web-site at

www.fike.com. If you are unable to contact your installing sales outlet or you simply do not know who

installed the system you can contact Fike Product Support at (816) 229-3405, Monday through Friday,

8:00 a.m. to 5:00 p.m. CST.

1.3 REVISION HISTORY

Document Title: SHP Conventional Fire Alarm/Suppression System Product Manual

Document Reorder Number: 06-130

Revision Section Date Reason for Change

0 All Sections 06/12/96 Initial Release

1 All Sections 11/02/99 ULC Additions

2 All Sections 12/01/01 Product Update

3 Section 4.6, 6.3.1 04/02 Added wiring and correct

1.4 TERMS USED IN THIS MANUAL

The following are various terms used in this manual with a brief description of each:

Term Description

Ω

ΩΩ

ΩSymbol for “ohm”. Unit of resistance.

AC Normal State (“AC Normal” Green LED ON) The system is in the AC Normal state when

appropriate AC power is being applied to the system.

Abort An input to a suppression system to prevent an unwanted discharge of fire

suppressant agent. The SHP has several different abort types.

Alarm State (“Alarm” Red LED ON, Piezo pulsing) The alarm occurs when an input circuit

configured for alarm operation has been activated. Activation typically

initiated by a detector or contact device. The system leaves the alarm state

upon entry into the pre-discharge or release state.

firealarmresources.com

PREFACE FIKE CORPORATION

Page 2 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

Class A wiring Input circuits capable of transmitting an alarm signal during a single open or a

non-simultaneous single ground fault on a circuit conductor shall be

designated as Style D or Class A. Similarly, output circuits capable of

activating during a single open or a non-simultaneous ground fault on a circuit

conductor shall be designated as Style Z or Class A. Commonly referred to

as redundant or 4-wire connection; this manual refers to 4-wire connections

as Class A wiring.

Class B wiring Input circuits incapable of transmitting and alarm signal beyond the location of

the fault condition (listed for Class A wiring above) shall be designated as

Style B or Class B. Similarly, output circuits incapable of operating beyond

the location of the fault condition shall be designated as Style Y or Class B.

This manual refers to 2-wire connections as Class B wiring

Cross-zone Detection A detection scheme where two detectors must activate before the system

enters into the pre-discharge state; at least one detector from each detection

initiating circuit must be active.

Initiating Device A system component that originates transmission of a change-of-state

condition, such as in a smoke detector, manual fire alarm box, or supervisory

switch. This manual interchanges the terms initiating device and input device.

Initiating Device Circuit A circuit to which automatic or manual initiating devices are connected where

the signal received does not identify the individual device operated. This

manual interchanges the terms initiating device circuit and input circuit.

Normal State (“Trouble” Yellow LED OFF) The system is in the normal state when the

power supply and all circuits are configured properly, connected, and

responding properly. The system remains in normal state until a trouble

condition occurs.

Notification Appliance A fire alarm system component such as a bell, horn, speaker, light, or textual

display that provides audible, tactile, or visible output, or any combination

thereof. The device notifies building occupants of system status. This

manual interchanges the terms notification and audible appliance.

Notification Appliance

Circuit

A circuit or path directly connected to a notification appliance(s). This manual

interchanges the terms notification appliance circuit and audible circuit.

Non Power-Limited A circuit designation given for wiring purposes. The amount of current flowing

through the circuit is unlimited vs. being limited, or power-limited. AC power

and Battery wiring is Non Power-limited.

Power-Limited A circuit designation given for wiring purposes. The amount of current flowing

through the circuit is limited (typically by fuse) vs. being unlimited, or non-

power limited. The SHP input and output circuits are power limited. The

circuit has a maximum power that flows through it or it current limits and

opens.

Pre-discharge Delay The time (in seconds) that the system will delay entering the release state

after the zone’s detection type has been satisfied. Activation of an abort

switch will have an effect on this value, depending upon the abort type

selected.

Pre-discharge State (“Alarm” Red LED ON, Piezo chirping) The pre-discharge state occurs when

the zone’s detection type input conditions are satisfied (Cross Zone

Detection, Sequential Alarm Detection, or Single Detector Release). Upon

time delay countdown completion (unless delayed by a pertinent activated

abort input), the system leaves the pre-discharge state and enters the release

state.

Release State (“Alarm” Red LED ON, Piezo chirping) The release state occurs upon

completion of the pre-discharge state or upon activation of a manual release

input. At the start of the release state, output circuits configured for releasing

shall operate.

firealarmresources.com

FIKE CORPORATION PREFACE

UL S2203 SHP Product Manual Page 3 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No: 3, 04/02

Sequential Detection A detection scheme where the sum total of active detectors on the initiating

circuits must be two or more before the system will enter the pre-discharge

state.

Single Detector Release

Detection

A detection scheme where activation of one detector causes the system to

enter the pre-discharge state. SDR (Single Detector Release) detector(s) are

installed on initiating circuits setup for sequential detection.

Solenoid On Time The time (in minutes) that the solenoid is activated upon entering the release

state. Reset of the system overrides this value.

Supervisory State (“Supervisory” Yellow LED ON, Piezo Warble) The supervisory state occurs

upon activation of a supervisory input circuit. The supervisory state is non-

latching and will follow the status of the supervisory input contact.

Trouble State (“Trouble” Yellow LED ON, Piezo Constant) The trouble state occurs upon

any detectable condition which could impair system operation including

connection problems, ground faults, hardware problems, power problems,

configuration problems, or prematurely activated abort inputs. Certain trouble

conditions are latching; others allow the system to reset upon trouble

condition removal. Depending upon the type of trouble condition, the system

may or may not remain operational. When the system is in trouble state, it is

not in the normal state.

firealarmresources.com

PREFACE FIKE CORPORATION

Page 4 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

1.5 SYMBOLS USED IN THIS MANUAL

The following symbols are used throughout this manual.

NOTE: Used to call your attention to an important procedure, function or operational

procedure.

CAUTION: Used to identify functions or procedures of utmost importance.

WARNING: Used to identify functions and/or procedures that could cause property damage

or personal injury if the procedures identified in this manual are not followed.

1.6 SAFETY NOTICES

Be certain to read all the following warnings and cautions before installing or using this device.

Accidental damage to the device could result if these warnings and cautions are not heeded!

CAUTION: The SHP contains static sensitive components. Handle the electronics by

the edges only and avoid touching the integrated components. Keep the

electronics in the protective static bags it was shipped in until time for

installation. Always ground yourself with a proper wrist strap before handling

the module(s). If the installer is grounded at all times, damage due to static

discharge will not occur. If the module requires repair or return to Fike, it

must be shipped in an anti-static bag.

CAUTION: To ensure proper system operation after installation of the SHP, this device

must be tested in accordance with NFPA 72 - 1999 edition. Re-acceptance

testing is required after any change, addition or deletion of system

components, or after any modification, repair or adjustment to system

hardware or wiring.

WARNING: Failure to disconnect power to the releasing circuit(s) and disarm the

solenoid(s) or any other "critical operation" contacts prior to system testing

may cause accidental activation of the system.

firealarmresources.com

OVERVIEW FIKE CORPORATION

UL S2203 SHP Product Manual Page 5 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No. 3, 04/02

2.0 PRODUCT OVERVIEW

2.1 PRODUCT DESCRIPTION

The Fike SHP (P/N 10-051) is a compact, cost-effective, conventional fire alarm and suppression

releasing panel. The SHP is designed for use with Fike Clean Agent Fire Suppressant, CO2, or sprinkler

(pre-action/deluge) suppression systems. The SHP controller is shipped from the factory pre-configured

for Clean Agent suppression operation.

The main controller contains all electronics required for a complete detection and control system suitable

for most applications. Optional modules, which plug into the main circuit board, are available to add

increased functionality to the system.

2.2 LISTINGS AND APPROVALS

Approval Agency File Number

Underwriters Laboratories S2203

Type: Local, Remote Station, Central Station PPU

Service Type: A-Automatic Fire Alarm, M-Manual Fire Alarm

WF-Water-flow alarm, SS-Sprinkler Supervisory Service,

Releasing, DACT

Type Signaling: Non-coded

Underwriters Laboratories of Canada (ULC) CS401/CS770-25168, 25169

Factory Mutual (FM) OZ8A0.AY

California State Fire Marshall (CSFM) 7165-0900:114

City of New York (MEA) 126-96-E

2.3 AGENCY COMPLIANCE AND STANDARDS

This Fire Alarm Control Panel complies with the following NFPA, UL, and ULC standards:

NFPA 72 – National Fire Alarm Code

UL 864 – Standard for Control Units for Fire Protective Signaling Systems

CAN/ULC S527 – Standard for Control Systems for Fire Alarm Systems

Smoke and Thermal

Detectors

Waterflow and Sprinkler

Supervisory

Manual Fire Alarm

or

Manual Releasing

and Abort

Stations

Audible and Visual

Alarm Signals

HVAC and Equipment

Shutdown

Sprinkler

Preaction

Clean Agent

Release

firealarmresources.com

OVERVIEW FIKE CORPORATION

Page 6 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

The installer should also be familiar with the following documents and standards:

National Fire Protection Association (NFPA) Codes:

NFPA 12 – Carbon Dioxide Extinguishing Systems (High Pressure Only)

NFPA 12A – Halon 1301 Extinguishing Systems

NFPA 13 – Sprinkler Systems

NFPA 15 – Water Spray Fixed Systems

NFPA 16 – Deluge, Foam-water and Foam-water Spray Systems

NFPA 70 – National Electrical Code (NEC)

NFPA 70, Article 300 – Wiring Methods

NFPA 70, Article 760 – Fire Protective Signaling Systems

NFPA 72 – National Fire Alarm Code

NFPA 101 – Life Safety Code

NFPA 110 – Emergency Standby Power Systems

NFPA 2001 – Clean Agent Fire Extinguishing Systems

Underwriters Laboratories (UL) Standards:

UL 38 – Manually Actuated Signaling Boxes

UL 217 – Smoke Detectors, Single and Multiple Station

UL 228 – Door Closers – Holders for Fire Protective Signaling Systems

UL 268 – Smoke Detectors for Fire Protective Signaling Systems

UL 268A – Smoke Detectors for Duct Applications

UL 346 – Waterflow Indicators for Fire Protective Signaling Systems

UL 464 – Audible Signaling Appliances

UL 521 – Heat Detectors for Fire Protective Signaling Systems

UL 1481 – Power Supplies for Fire Protective Signaling Systems

UL 1638 – Visual Signaling Appliances

UL 1971 – Visual Signaling Appliances

Factory Mutual (FM) Standards:

FMRC 1011 and 1012 – Deluge and Pre-action Sprinkler Systems

FMRC 3820 – Electrical Utilization Equipment

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction

2.4 RELATED DOCUMENTATION

To obtain a complete understanding of the specific features of the SHP or to become familiar with related

functions in general, refer to the documentation listed below. Please reference the most current version

or the version noted on the label located on the product.

Document Title Part Number Revision No, Date

Agent Release Module (ARM III) Manual 06-106 0, 06/94

Compatible Notification Appliances and Releasing Devices 06-186 0, 03/01

The DACT/Fire Communicator Addendum 06-159 1, 04/01

The DACT/Fire Communicator Manual 06-160 1, 04/01

firealarmresources.com

FIKE CORPORATION OVERVIEW

UL S2203 SHP Product Manual Page 7 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No: 3, 04/02

2.5 SHP FEATURES

•General

Microprocessor-controlled

Power-limited on all circuits except

power connections (P1)

Field selection of either sprinkler

(solenoid) or suppression (ARM-III)

operation

Eight system status LEDs to provide

positive indication of system status

Seven segment diagnostic LED for

trouble and event occurrences

System configuration via dip-switches

Local piezo with distinct event tones

Reset switch

Audible silence switch

Disable Mode for audible and release

circuits

Disable switch for release circuits

Alarm and trouble resound

•Power

Integral 2.6 amp power supply at

24VDC nominal

Selection of 120, or 240/208 VAC power

input at 50 or 60 hertz

Supplemental power input capability up

to 8 amps at 24 VDC

Resettable and non-resettable regulated

power output

Battery/Earth fault supervision

7 AH to 18 AH battery options, up to 90

hours standby

•Enclosure

Steel enclosure 21” high by 14.35” wide

by 4” deep (Back-box dimensions)

Enclosure is equipped with a .50” wide

lip to facilitate flush mounting

Removable door for easy installation

Enclosure is available in Red or Gray

•Initiating Device Circuits

Up to two Style B initiating device

circuits capable of sequential alarm,

cross-zone, or single detector release

operation with an overall system

capacity of 50 detectors maximum

Up to three Style B initiating device

circuits capable of monitoring closed

contact devices

Optional Class A module that converts

all four initiating device circuits to Style

D wiring and operation

•Notification Appliance Circuits

Three Style Y notification appliance

circuits rated at 2.0 amps each

•Releasing Circuits

One Agent Release circuit with

maximum of 6 ARM III’s

or

One Solenoid release circuit which can

activate one 24V or two 12V solenoids

•Relays

General Alarm and Trouble relays

Optional SRM4 module to add four

DPDT dry relay contact outputs

•Sprinkler Monitoring Points

Waterflow input

Supervisory input

firealarmresources.com

OVERVIEW FIKE CORPORATION

Page 8 of 43 SHP Product Manual UL S2203

Rev. No. 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

This page intentionally left blank

firealarmresources.com

FIKE CORPORATION EQUIPMENT

UL S2203 SHP Product Manual Page 9 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No. 3, 04/02

3.0 EQUIPMENT/PRODUCTS

3.1 MAIN PANEL HARDWARE

The 10-051 SHP control panel consists of a red (or gray) metal enclosure with removable door for ease of

mounting flush or surface. The back-box is 21” high x 14.35 “ wide x 4 “ deep. It also includes a 0.5” lip

around the back box to facilitate flush mounting. Refer to Section 3.7 for a complete detail of the back-

box dimensions.

The basic part numbers for the components covered in further detail in this section are as follows:

Part Number Description

10-051-c-p SHP Control System

c: (R = red, G = gray)

p: (1 = 120VAC, 2 = 208 or 240VAC)

10-2171 SHP Controller Printed Circuit Board

10-2172 Class A Input Module

10-2176 SRM4 Relay Module

10-2190-b Battery Assembly AH selection

b: (1 = 7 AH, 2 = 18 AH)

•10-051 SHP Control System

Includes the main controller with transformer and AC terminal

block inside steel enclosure (red or gray). The enclosure

door is equipped with a standard Fike keylock and a viewing

window covered with clear lexan. The enclosure includes

space for installing batteries (up to 18 AH – ordered

separately).

•10-2171 SHP Controller

The controller is the heart of the SHP control panel. It contains

the system’s central processing unit, power supply, and other

primary components. It also includes the electronics required to

support the optional Class A module and SRM4 Relay module.

firealarmresources.com

EQUIPMENT FIKE CORPORATION

Page 10 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

•10-2172 CLASS A INPUT MODULE

The optional Class A Input Module allows any of the four initiating

device circuits to be wired Class A (Style D) versus the standard

Class B (Style B) method. The Class A module mounts directly

onto the SHP Controller utilizing four stand-offs supplied with the

module. If used, any of the four circuits wired as Class B rather

than Class A, shall have the pertinent resistor (R1-R4) removed

from that circuit.

•10-2176 SRM4 RELAY MODULE

The optional SRM4 Relay Module provides

four DPDT dry contact relays, which activate

upon selected events per the configuration

switches. The SRM4 Relay module mounts

directly onto the SHP Controller at RM4

utilizing four nylon stand-offs supplied with

the module.

•10-2190-B Battery Assembly

Batteries are required for alarm systems for maintaining

emergency back-up power. Two each 12V batteries are

required and are to be wired in series for maintaining a 24VDC

back-up. Most systems require at least a 24 hour standby

current with 5 minutes alarm current for determining minimum

battery size. Refer to Appendix 1 for Battery Calculation form

for determining required battery size for system. The 10-

2190-1 consists of 2 each 7A-H, 12VDC batteries with a wiring

harness. The 10-2190-2 consists of 2 each 18 A-H, 12VDC

batteries with the same wiring harness.

firealarmresources.com

FIKE CORPORATION EQUIPMENT

UL S2203 SHP Product Manual Page 11 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No: 3, 04/02

3.2 INPUT DEVICES

The SHP is required to list compatibility with specific conventional detectors. The following items have

been approved for use with the SHP. Refer to the Detection Input Compatibility portion of Section 3.6,

Specifications, for selecting the appropriate detector base and head. Other devices such as contact

closure input devices, contact closure detectors, notification appliances, and Solenoids are all listed in the

Fike Compatibility Document, P/N 06-186.

Old Part Number Part Number Description

63-1024 Photoelectric Detector

67-1033 Ionization Detector

63-1025 Photo/Thermal Detector

60-1020 135°F Fixed Temperature Heat Detector*

60-1022 190°F Fixed Temperature Heat Detector*

60-1029 135°F Fixed, Rate of Rise Heat Detector

60-1030 190°F Fixed, Rate of Rise Heat Detector

67-1027 67-1034 430 Ω, 6” Base

67-1028 67-1036 430 Ω, 4” Base

67-1010 67-1035 220 Ω, 6” Base (SDR or Cross Zone Only)

67-1017 67-1037 220 Ω, 4” Base (SDR or Cross Zone Only)

63-1012 430 ΩRelay Base

NOTE: If using LED graphic, it is required to use the older type bases. Please note on the order,

“Using conventional graphic with panel, do not substitute bases”.

•63-1024 Photoelectric Detector

The photoelectric smoke detector is well suited for fires ranging from smoldering to

flaming. It utilizes two bi-colored LED’s for indication of status. In a normal standby

condition the LED’s flash Green every 3 seconds. When the detector senses that it’s

sensitivity has drifted outside the UL listed sensitivity window the LED’s will flash Red

every 3 seconds. When the detector senses smoke and goes into alarm the status

LED’s will latch ON Red.

•67-1033 Ionization Detector

The Ion Detector can be used in areas where early warning of superheated or flaming

combustibles is expected. It utilizes two bi-colored LED’s for status indication

purposes. In a normal standby condition the LED’s flash Green approximately once

each second. When the detector senses smoke and goes into alarm the status LED’s

will latch ON Red.

firealarmresources.com

EQUIPMENT FIKE CORPORATION

Page 12 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

•60-1020 Heat Detector 135°

°°

°F / Fixed Temperature

•60-1022 Heat Detector 190°

°°

°F / Fixed Temperature

The heat detector is suited for installation where high heat output fires are expected

or in areas where ambient conditions would not allow use of other detection

methods. Each detector is fixed temperature rated for 135°F (60-1020) where

ambient temperatures do not exceed 120°F or 190°F (60-1022) where ambient

temperatures exceed 120°F but not 160°F. Features mechanically operated contact

closures. Contact is not latching.

•60-1029 Heat Detector 135°

°°

°F / Rate-of-Rise

•60-1030 Heat Detector 190°

°°

°F / Rate-of-Rise

The fixed temperature / rate-of-rise heat detector features electronic circuitry to

close normally open contacts when the fixed temperature is reached or when the

rate-of-rise is greater than 12°F / minute.

Warning: Heat detectors are for property protection only, not life safety!

•67-1034 6” Base

Electronics-free 6” base with plastic tamper-lock lug. Contains a 430Ωresistor. Can

be used for Sequential or Cross Zone detection.

•67-1036 4” Base

4” version of the 67-1034

•67-1035 6” Base

Electronics-free base with plastic tamper-lock lug. Contains a 220Ωresistor. Can

be used with Cross Zone or Single Detector Release detection.

•67-1037 4” Base

4” version of the 67-1035

•63-1012 Relay Base

This 6” base is equipped with a 430Ωresistor and two sets of Form “C” relay

contacts.

3.3 OUTPUT DEVICE

Refer to FIKE Notification Appliance and Releasing Compatibility Document (06-186).

firealarmresources.com

FIKE CORPORATION EQUIPMENT

UL S2203 SHP Product Manual Page 13 of 43

FM 0Z8A0.AY Manual P/N: 06-130 Rev. No: 3, 04/02

3.4 ANCILLARY DEVICES

The following table lists several ancillary devices that can be used in conjunction with the SHP panel to

provide increased system flexibility and performance. For detailed wiring instructions for each of these

devices refer to the appropriate product manual.

P/N Manual P/N Description Function

10-2256 06-159 Digital Alarm Communicator Complies with NFPA 72-Supervising Station

Fire Alarm System

10-1832 06-106 ARM-III (Agent Release Module) Provides primary means for Fike’s Clean

Agent suppression systems

10-107 –

10-110

06-019 Conventional Graphic Annunciator Provides graphic point annunciation for

detectors

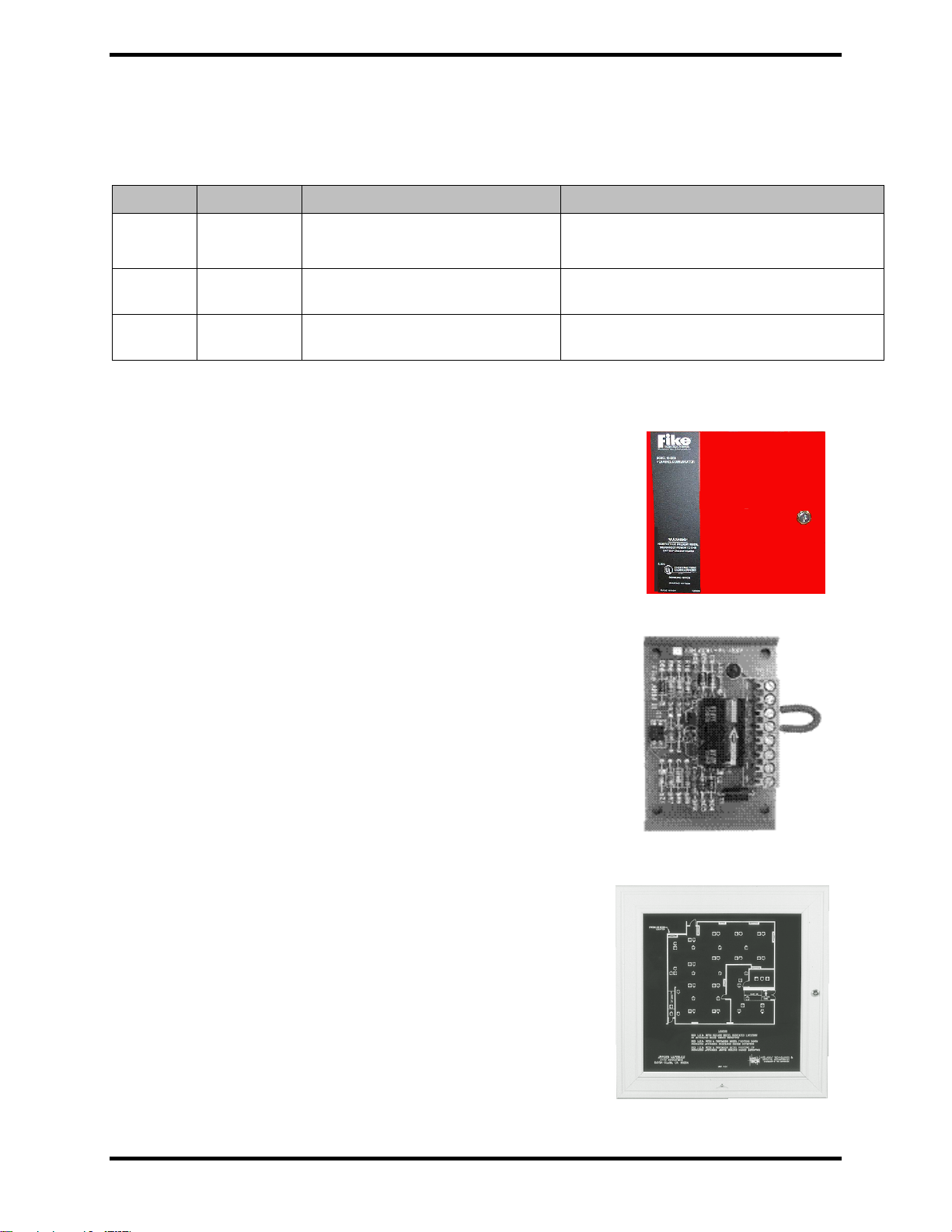

•10-2256 Digital Alarm Communicator/Transmitter (DACT)

The SHP panel is capable of communicating to a Central Station via

the DACT (optional). The DACT monitors the relay outputs of the

SHP. It is necessary to program the DACT with the 10-2257

programmer and 10-2258 cable or 10-2259 modem and 06-151

software.

•10-1832 Agent Release Module (ARM III)

The SHP panel is capable of supporting up to 6 ARM’s on the single

Agent Release Output Circuit. The ARM is required for each Clean

Agent Suppressant Container. Refer to the ARM manual, 06-106 for

detailed instructions on the ARM.

•10-107 – 10-110 Conventional Graphic Annunciator

Fike Graphic Annunciators provide a graphic display of the

protected area using LED’s to indicate the location of smoke

detectors.

firealarmresources.com

EQUIPMENT FIKE CORPORATION

Page 14 of 43 SHP Product Manual UL S2203

Rev. No: 3, 04/02 Manual P/N: 06-130 FM 0Z8A0.AY

3.5 SPARE PARTS

Description Part Number

SHP Enclosure with Transformer 10-2175-c-p

Enclosure Back-box 10-2206-c

Enclosure Door 10-2209-c

Keylock with cam 02-1606

Panel Key Only (without cam) 02-4983

Battery, 7 Amp-Hour 02-2018

Battery, 18 Amp-Hour 02-2820

Battery Cables 10-2192

Standoff and lock washer/hex nut kit (30 each) 02-4035

Transformer, 110VAC 02-3936

Transformer, 208/240 VAC 02-3938

120 VAC Varistor 02-1532

208/240VAC Varistor 02-2275

Mounting hardware for SRM4 or Class A Module

(each uses 4 ea. 3/8” nylon spacer) 02-4008

250V, 12 Amp Fuse (F1) 02-3945

Releasing circuit end-of-line (EOL) assembly, 2.7K 10-2316

Input circuit EOL assembly, 4.3K 10-2318

Output circuit EOL assembly, 2.0K 10-2319

Capacitor, 100uF, 50V (for testing battery circuit) 02-3774

Power terminal (P1) yellow cover 02-4007

Flashbulb (for testing ARM III release) 12/box 02-3799

Touch-Up Paint (Not available from Fike)

Red-Sherwin Williams - #F63VXR9951-4343 Polane

2.8T Plus Polyurethane Enamel

Gray-Sherwin Williams - #F63VXA9975 Polane T

Plus Polyurethane Enamel

firealarmresources.com

Table of contents

Other Fike Security System manuals