Filabot Reclaimer User manual

REV.A11‐25‐2019

Filabot

Vermont, USA, Earth

1-802-505-6772

Filabot Reclaimer

Operation Manual

This manual applies to the Filabot Reclaimer.

Triex LLC, Barre, VT 05641, USA

1

CAUTION! Read Carefully

HEAVY Fully assembled Reclaimer weighs 125lbs. DO NOT attempt

to lift or assemble the Reclaimer alone.

SHARP ROTATING BLADES Never operate the Reclaimer with out

all hoppers closed and secured. Never operate the Reclaimer if any

parts appear missing or damaged. NEVER ATTEMPT TO MODIFY

OR BYPASS SAFETY SWITCHES OR CIRCUITRY.

SHARP PLASTIC SHRAPNEL Crushing, cutting, or otherwise

breaking down plastics such as PLA and others will create high

speed projectiles and sharp edges. Always wear proper eyewear and

gloves when working with the Reclaimer and processing plastic.

In Case of Emergency hit the EMERGENCY STOP button or pull

the power cord out of the machine.

Only use the Reclaimer to process thermoplastic polymers. No other

use has been tested or approved by Filabot.

Always STOP the Reclaimer before opening the hoppers.

The Reclaimer is designed for indoor use only. Operate in a clean,

dry area.

Check the AC input voltage specified on the S/N Label near the

power inlet. Only use the specified input voltages to operate the

Reclaimer or damage to the components will occur.

Do not use this device if any parts appear missing or damaged.

Do not modify this device without authorization from Filabot.

Contact Filabot with any questions

1-802-505-6772

2

General Specifications

Power Input: 115VAC-10A or 230VAC-6.5A 50/60Hz 1-phase

1550W MAX - varies with settings

Input Connector Type: IEC 320-C14

Weight: 57kg (125 lbs)

Overall Dimensions:

Drive Control: 230V 3-phase Variable Frequency Drive

4.2A Motor Current Limit

Jam Detection and Automatic Reversing

Drive Motor: 1HP 230V 3.2A 3-phase

62Hz 1780 RPM

Inverter duty

Final Drive: 20:1 Worm gearbox into

2.5:1 #50 roller chain

Final Drive Output: 35 RPM

216 ft-lbs (Calculated)

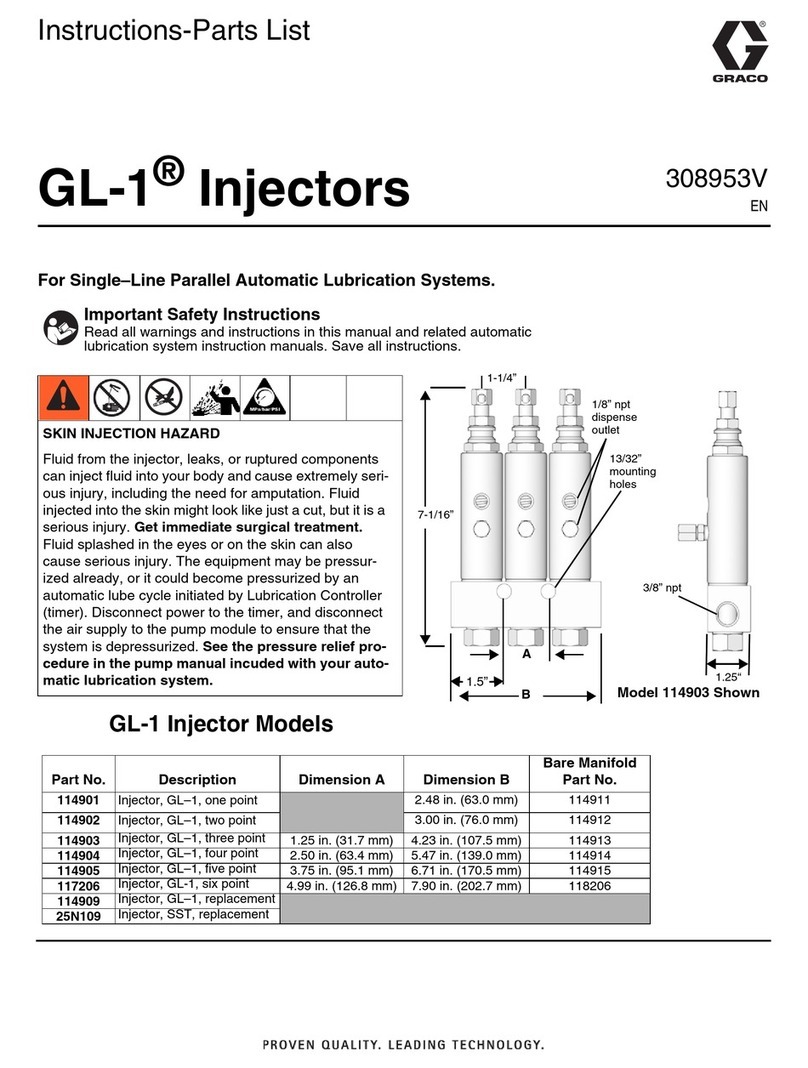

Shredder: Rotating Blades: 0.25” Wide A2 Hardened Steel

Fixed Blades: Reversible 0.50” 4140 Steel Plate

Granulator: Rotating Drum: 0.20” x 0.20” Cutting Teeth

17-4 SS Hardened

Fixed Blades: Reversible 0.50” 4140 Steel Plate

3

Parts Included

1. Reclaimer Main Body

2. Motor Base Assembly

3. Shredder Hopper

4. Granulator Hopper

5. Shredder Hopper Gas Spring Assembly

6. Granulator Hopper Gas Spring Assembly

7. (2) 5/16”-18 x 7/8” Hex Head Bolts

8. (2) 5/16” Washers

9. (4) 3/8”-16 x 1” Hex Head Bolts

10. (4) 3/8” Split Lock Washers

11. (20) Plastic Drawstring Bags 10" Wide, 14" High

12. Main Bearing Tool

Tools Required:

9/16” Wrench

1/2” Wrench

#2 Philips Screw Driver

Rigid table capable of supporting at least 200lbs

Call 1-802-505-6772 or visit Filabot.com for additional/replacement parts

4

Assembly

WARNING: Fully assembled Reclaimer weighs 125lbs. DO NOT attempt

to lift or assemble the Reclaimer alone.

Two people are required to assemble the Reclaimer.

Assemble the Reclaimer on a rigid table capable of supporting at least

200lbs. If such a table is not available, assemble and operate the

Reclaimer on the floor.

WARNING: The Reclaimer Main Body tips easily when not attached to

the Motor Base Assembly. Someone must steady the Reclaimer Main

Body while assembling it to the Motor Base Assembly.

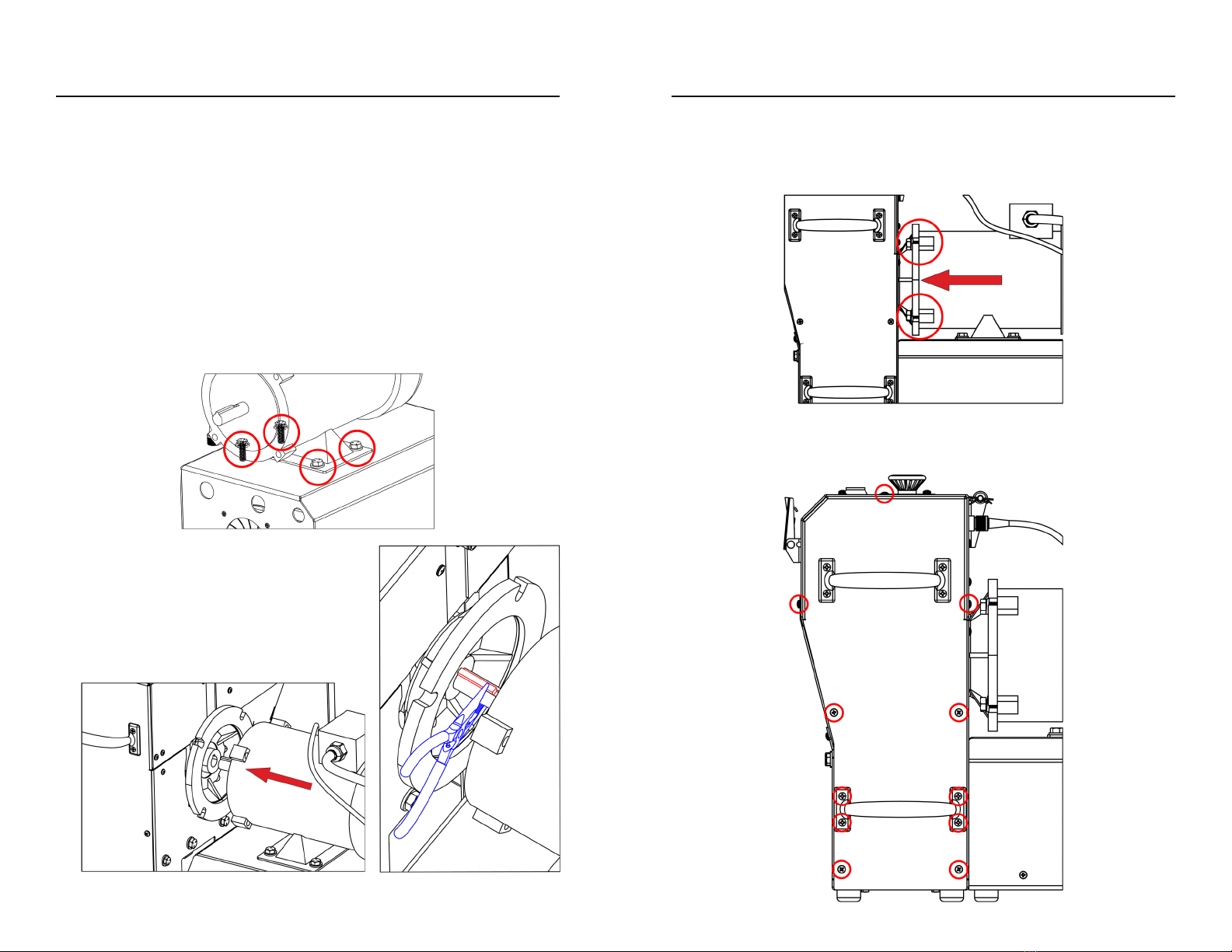

1. Loosen the 4 motor base bolts using a 1/2” wrench. Do not remove

the bolts.

2. Line up the motor shaft with the gearbox

input on the Reclaimer. Use a pair of

pliers to hold the shaft key from sliding

back while inserting the shaft. Caution!

Reclaimer can tip over easily. Have

someone support the Reclaimer while

attaching the motor.

5

Assembly

3. Push the motor face flat against the gearbox face. Make sure there is

not gap between the motor face and gearbox face. Install the (4)

3/8”-16 x 1” motor bolts with lock washers and tighten them using a

9/16” wrench.

4. Remove the (7) highlighted panel screws and (4) handle screws with

a #2 Philips screwdriver and remove the Reclaimer right side panel.

6

Assembly

5. Behind the Reclaimer side panel and below the gearbox, install the

(2) 5/16”-18 x 7/8” lower drive enclosure bolts with washers and

tighten using a 1/2” wrench. The motor base enclosure may need to

be shifted under the motor to allign the holes.

6. Reinstall the panel and (7) highlighted panel screws and (4) handle

screws and handle which were removed in step 4.

7. Using a 1/2” wrench, tighten the (4) base bolts which were loosened

in step 1.

8. Remove the inner cotter pin from the hopper hinge and slide out the

rode while removing the aluminum spacers and plastic washers.

7

Assembly

9. Remove the (4) top panel screws using a #2 Philips screw driver.

Line up the two gas spring assembly brackets with the holes in the

top panel as shown and reinstall the screws. Be sure the square

cutouts in the gas spring assembly brackets match with the sensor

cutouts on the top panel.

10. Set the hoppers on top of the Reclaimer in the orientation shown.

8

Assembly

11. Reinstall the hopper hinge rod, spacers, plastic washers and cotter

pin in the order shown.

12. Remove the nuts from the end of the gas springs not attached to the

bracket on the top panel. One at a time, tip each hopper back and

insert the threaded stud on the end of the gas spring the nut was

removed from into the hole midway up the back of the hopper.

9

Assembly

13. Reinstall the nuts on the gas spring studs on the inside of the hopper

and tighten using a 1/2” wrench.

14. Plug the grey control cable from the back of the drive enclosure into

the bulkhead located on the back of the Reclaimer above the motor

and tighten the thumbnut to secure the connector. Make sure to

allign the notch in the connector with the bump on the inside of the

bulkhead.

10

Controls & Inputs

1. Stage 1 Shredder Hopper – Max part size 3 inches in any dimension

(must fit in 3” sphere).

2. Stage 2 Granulator Hopper – Max material size 1/2 inch.

3. Output hopper.

4. Emergency stop button – Press for emergency stopping only, use

Start/Stop button for normal stopping.

5. Start and Stop button – Press to start the machine, press while

running to stop the machine.

6. Safety Reset button – Press at initial power on or after the E-stop or

hopper saftey switches are tripped to reset the safety circuit.

11

Controls & Inputs cont.

7. DrivestatusindicatorLED.Outputcode:

Solidgreen–Drivepoweron,readytostart

Flashinggreen–Driveoperatingnormally,motorisrunning

Solidred–Safetytrip(SafetyswitchesorEmergencyStop)

Off–Nodrivepower(IfMainPowerisilluminatedandindicatoris

offthensafetycircuitmustbereset.

Flashingred(code8)–(8flashesfollowedbypause)Overcurrent

detection,checkReclaimerforjam.Toresetovercurrentdetection,

powerofforhitEmergencystopandwaituntilindicatorLEDturns

offbeforepushingtheSafetyResetbutton.

8. Main power switch and main power indicator.

9. Serial Number & Voltage Input Label

10. Power inlet – IEC C14 110VAC

12

Operation

1. Make sure all 3 hoppers are fully closed and latched.

2. Secure the drawstring collection bags to the flanges on the bottom of the ouput

hopper as shown:

3. Plug the power cable into the power inlet on the machine and into a 110VAC

outlet.

4. Turn on the main power switch. It should illuminate if the machine has power.

5. Make sure the E-stop button is pulled up and push the Safety Reset button to

power up the drive. The status indicator should illuminate green if the drive has

powered on.

6. Press the Start/Stop button to start the machine.

7. To begin shredding, place parts with a maximum dimension of 3 inches in the

top of the Shredder hopper. Do not fill the hopper past the bottom of the view

13

window to avoid feed issues in the hopper. During operation you may need to

adjust the bags so they fill completely.

8. At anytime during shredding, or when the collection bag for the Shredder is

full, the Shredder output can be loaded into the Granulator hopper. Press the

Start/Stop button to stop the machine and transfer the output of the Shredder

into the Granulator hopper.

NOTE: It is recommended to screen the output of the Shredder to remove

material smaller than 1/4 inch before transfering it to the Granulator. This

reduces over granulating of smaller material to help make sure final granule

size is as consistent as possible.

9. Replace the drawstring bag on the Shredder output and press the Start/Stop

button to begin granulating. If granulated material consistency is not

satifactory, it can be screened and run through the Granulator again.

NOTE: Material can be loaded into both hoppers while running allowing for

simultainious Shredding and Granulating.

14

2019,TriexLLC,BarreVT,USA.Nopartofthismanualmaybecopied,stored,transmitted,or

otherwisereleasedwithouttheexpresswrittenconsentofTriexLLC.Thismanualappliesonlyto

theFilabotEX6.WhileTriexLLChasappliedallpossiblecautioninproducingthismanual,weurge

thecustomeroruserofthisdevicetocontactTriexLLCwithanyquestionsorconcernsabout

operation,beforeoperatingthedeviceormakinganyadjustments.TriexLLCprovidesno

assuranceofapplicabilityoftheproducttocustomers'requirements.

Table of contents

Other Filabot Industrial Equipment manuals